Hydrocracking catalyst as well as preparation method and application thereof

A hydrocracking and catalyst technology, applied in the field of catalysis, can solve the problems of low yield of light aromatics BTX, low yield of gasoline fractions, low RON, etc., and achieve the effects of low chemical hydrogen consumption, less light products, and increased proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

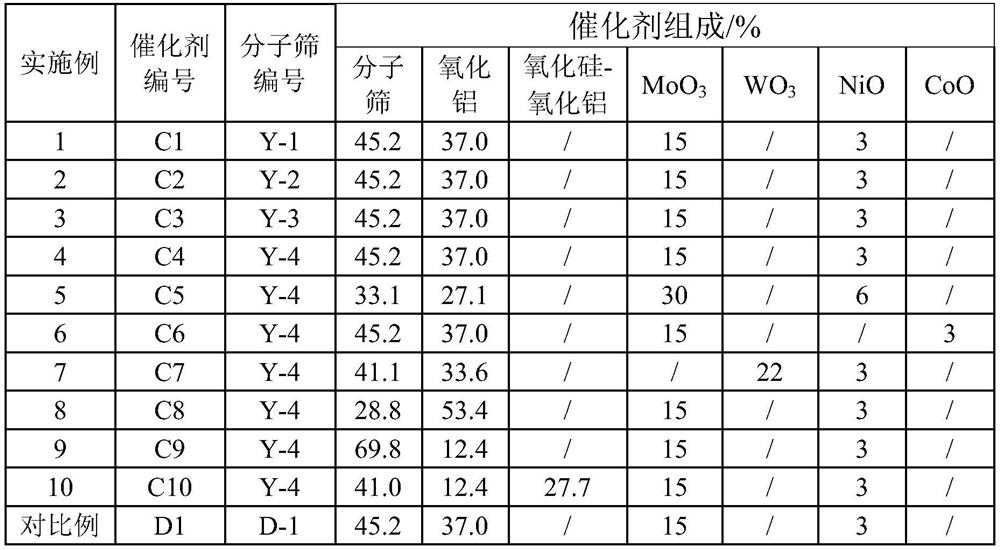

Examples

preparation example Construction

[0060] Specifically, the preparation method of Y molecular sieve of the present invention may comprise the following steps:

[0061] Mix NaY molecular sieve with ammonium salt and water for the first ammonium exchange treatment to obtain the first ammonium exchange molecular sieve;

[0062] The first ammonium-exchanged molecular sieve is subjected to the first hydrothermal roasting treatment in a water vapor atmosphere to obtain the first water-baked molecular sieve;

[0063] mixing the first water-baked molecular sieve with water and adding the first dealumination agent to carry out the first dealumination treatment to obtain the first dealumination molecular sieve;

[0064] The first dealuminated molecular sieve is subjected to a second hydrothermal roasting treatment in a water vapor atmosphere to obtain a second hydrobaked molecular sieve;

[0065] mixing the second water-baked molecular sieve with water and adding a second dealumination agent for second dealumination tre...

Embodiment

[0093] Reagents, Instruments and Tests

[0094] In the following examples, preparation examples and comparative examples, the raw material specifications used are as follows:

[0095] NaY molecular sieve, industrial product, silicon-aluminum ratio > 4.7, crystallinity > 85%

[0096] Sulfuric acid, chemically pure

[0097] Hydrochloric acid, chemically pure

[0098] Nitric acid, chemically pure

[0099] Oxalic acid, solid, chemically pure

[0100] Fluorosilicate, technical grade

[0101] Ammonium nitrate, chemically pure

[0102] Ammonium chloride, chemically pure

[0103] Ammonium oxalate, chemically pure

[0104] Ammonium sulfate, chemically pure

[0105] In the following examples, preparation examples and comparative examples, involved instruments and test methods are as follows:

[0106] The unit cell constant is determined by X-ray diffraction (XRD) using RIPP145-90 standard method (see "Petrochemical Analysis Method (RIPP Test Method)", Yang Cuiding, etc., Scienc...

preparation example 1

[0113] The preparation of preparation example 1 molecular sieve Y-1

[0114] (1) Use NaY zeolite as raw material to exchange with ammonium sulfate solution. The treatment conditions are: according to the ratio of NaY molecular sieve (dry basis): ammonium sulfate: water = 1:1.0:10, exchange at 90°C for 2h, filter and pass through Wash with deionized water and dry at 120°C for 4 hours.

[0115] (2) The molecular sieve obtained in the step (1) is subjected to the first hydrothermal calcination treatment, the calcination temperature is 520° C., and the calcination is carried out under 100% water vapor atmosphere for 2 hours.

[0116] (3) Molecular sieve obtained in step (2) is according to the ratio of molecular sieve (dry basis): sulfuric acid: ammonium chloride: water = 1: 0.06: 0.40: 9, first add water to beating the molecular sieve and slowly add concentration of 20% Sulfuric acid, control the dropping time for 30min, raise the temperature, treat at 70°C for 40min, filter, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com