Saturated alkane dehydrogenation catalyst and preparation method thereof

A technology for alkane dehydrogenation and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Interaction, Pt particle aggregation and growth, etc., to avoid the loss of alkali metal, improve activity and stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

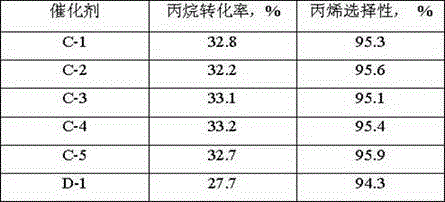

Examples

Embodiment 1

[0017] Weigh an appropriate amount of pseudohydroboehmite containing 14g of alumina, and disperse it in 100mL of distilled water with stirring. Take the prepared tin nitrate solution containing 1g of Sn and the magnesium nitrate solution containing 3g of magnesium oxide, mix them, add to the dispersion liquid, and heat to 70°C. Add 1M ammonium carbonate solution dropwise to the system until the pH value of the solution is 8. Stirring was stopped and aged at constant temperature for 12 hours. After solid-liquid separation, it was dried at 120°C for 4 hours and calcined at 800°C for 16 hours. The obtained solid is weighed and mixed with pseudoboehmite in a ratio of 1:1 to form it. Dry at 120°C for 4h and calcined at 600°C for 4h to prepare the carrier. Weigh an appropriate amount of chloroplatinic acid and dissolve it in deionized water, add it to the above carrier, age for 2 hours, dry at 80°C for 8 hours, bake at 600°C for 4 hours, and then dechlorinate in nitrogen containi...

Embodiment 2

[0020] Weigh an appropriate amount of pseudohydroboehmite containing 14g of alumina, and disperse it in 100mL of distilled water with stirring. Take the prepared tin nitrate solution containing 1.5g of Sn and the magnesium nitrate solution containing 4g of magnesium oxide, mix them, add to the dispersion liquid, and heat to 70°C. Add 1M ammonium carbonate solution dropwise to the system until the pH value of the solution is 9. Stirring was stopped and aged at constant temperature for 24 hours. After solid-liquid separation, it was dried at 100°C for 6h and calcined at 900°C for 8h. The obtained solid is weighed and mixed with pseudoboehmite in a ratio of 1:1 to form it. Dry at 120°C for 4h and calcined at 600°C for 4h to prepare the carrier. Weigh an appropriate amount of chloroplatinic acid and dissolve it in deionized water, add it to the above carrier, age for 2 hours, dry at 80°C for 8 hours, roast at 600°C for 4 hours, and then dechlorinate in nitrogen containing 20V% ...

Embodiment 3

[0022]Weigh an appropriate amount of pseudohydroboehmite containing 14g of alumina, and disperse it in 100mL of distilled water with stirring. Take the prepared tin nitrate solution containing 0.5g of Sn and the magnesium nitrate solution containing 5g of magnesium oxide, mix them, add to the dispersion liquid, and heat to 80°C. Add 1M ammonium carbonate solution dropwise to the system until the pH value of the solution is 8. Stirring was stopped and aged at constant temperature for 24 hours. After solid-liquid separation, it was dried at 100°C for 6h and calcined at 900°C for 8h. The obtained solid is weighed and mixed with pseudoboehmite in a ratio of 1:1 to form it. Dry at 120°C for 4h and calcined at 600°C for 4h to prepare the carrier. Weigh an appropriate amount of chloroplatinic acid and dissolve it in deionized water, add it to the above carrier, age for 2 hours, dry at 80°C for 8 hours, roast at 600°C for 4 hours, and then dechlorinate in nitrogen containing 20V% w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com