Neopentyl glycol condensation hydrogenation production process and its equipment

A technology for neopentyl glycol and production process, which is applied in the field of neopentyl glycol condensation and hydrogenation production process and its devices, can solve the problems of incomplete separation of high molecular weight impurities, large catalyst activity affected by the outside world, and high reaction temperature and pressure. , to achieve the effect of mild pressure, excellent hydrogenation effect and improved product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0056] 1. Condensation reaction section

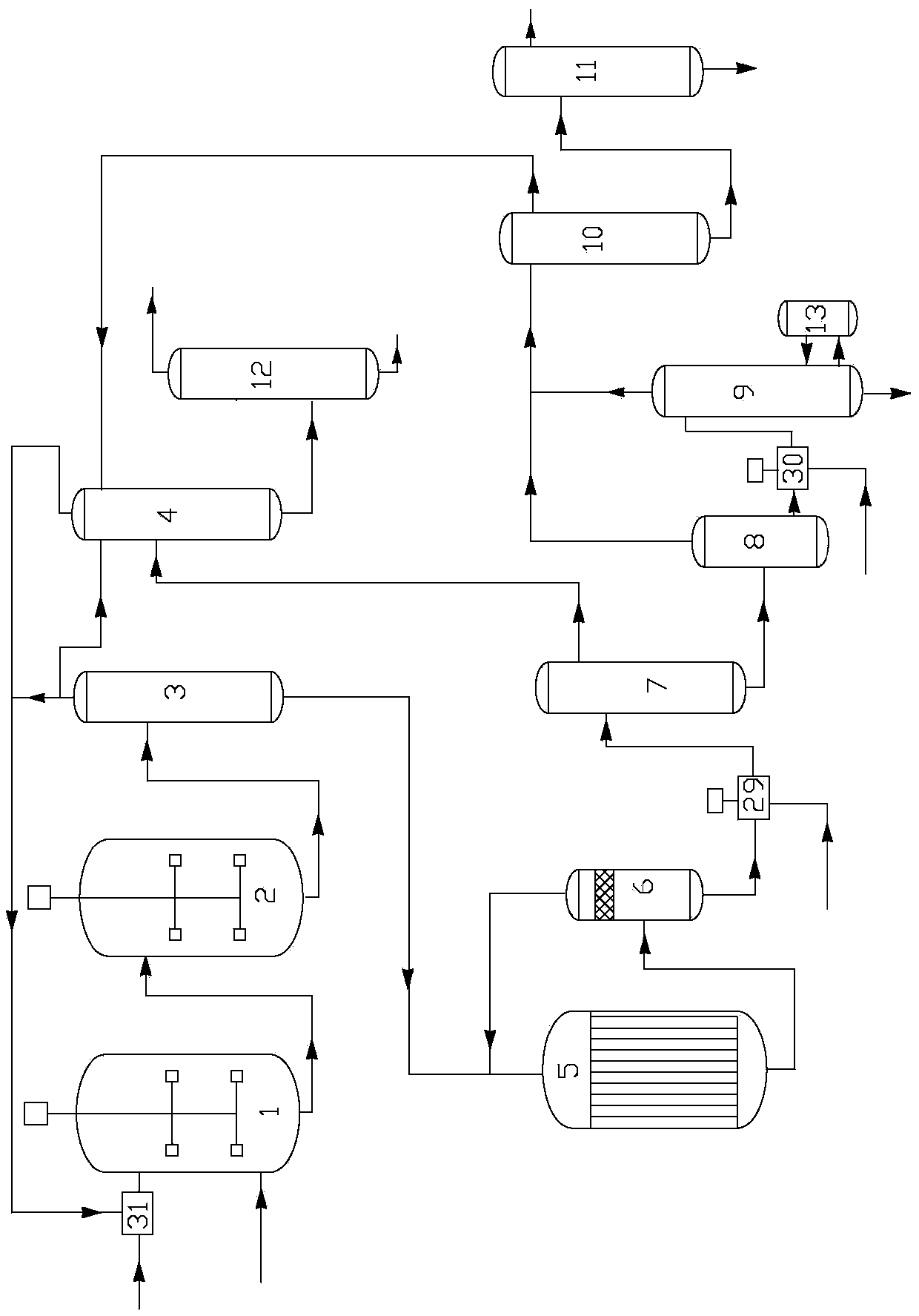

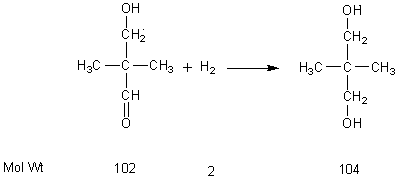

[0057] Such as figure 1 As shown, the molar ratio of isobutyraldehyde, formaldehyde, methanol and water is 1:1.2:0.1:2.8, and the amount of catalyst triethylamine is 0.02 mole per mole of formaldehyde. Put it into the condensation reactor with stirrer, in the first condensation reactor 1, the temperature is 85°C, the pressure is 0.5MPa, in the second condensation reactor 2, the temperature is 90°C, the pressure is 0.5MPa, after the reaction of two condensation reactors A mixed aldol condensation mixture containing hydroxypivalaldehyde is obtained at the bottom of the reaction, and the heat of reaction is removed by a cooler located on the circulation line.

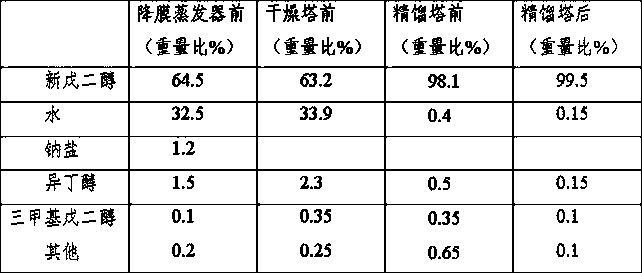

[0058] Table 1 Comparison of components before and after condensation reaction

[0059]

[0060] The aldol condensation mixed mixture is separated from the unreacted isobutyraldehyde, formaldehyde and triethylamine in the condensation circulation tower 3, and the gas phase com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com