Ni@MoC/NMC catalyst for reducing biological plasticizer neopentyl glycol dibenzoate and preparation method

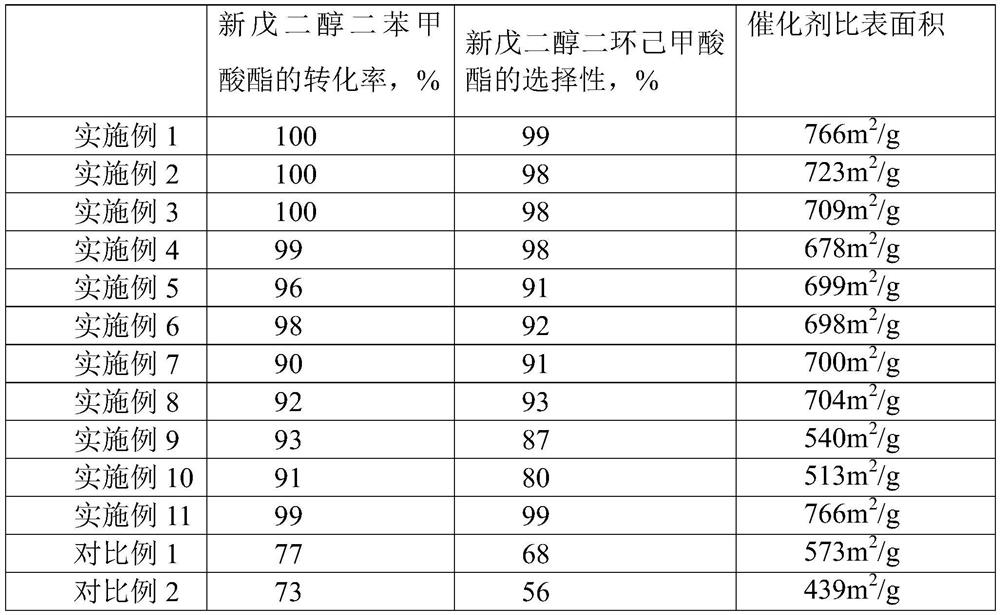

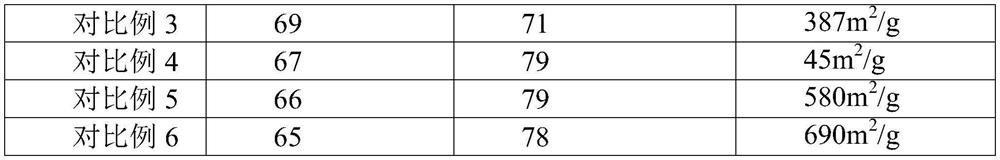

A technology of neopentyl glycol dibenzoate and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, carboxylate preparation, etc., and can solve the problems of low product selectivity and low conversion rate of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the Ni@MoC / NMC catalyst of the present embodiment comprises the following steps:

[0028] 1) Measure 200mL of absolute ethanol and 200mL of deionized water, and mix to obtain an ethanol solution. Weigh 5g of P123 and dissolve it in ethanol solution, stir at room temperature (temperature is 25°C, rotating speed is 500 rpm) for two hours, then weigh 2g of dopamine, continue to stir for 3 hours, take 1.0g of ammonium molybdate tetrahydrate Put it in a beaker and stir for 2 hours, then weigh 0.5g of nickel nitrate and put it in the beaker, continue to stir at room temperature for 3 hours, take 5ml of TMB (mesitylene) and slowly drop into the above solution, continue to stir for 4 hours, and then dissolve the above solution Move it into a constant temperature water bath at 30°C (rotating at 500 rpm), take 25ml of ammonia water and slowly drop it into the solution, and stir for 3-4h. Then the above reacted solution was centrifuged and washed three t...

Embodiment 2

[0034] In Example 1, 1.0 g of ammonium molybdate tetrahydrate and 0.5 g of nickel nitrate hexahydrate were weighed instead of 0.5 g of ammonium molybdate tetrahydrate and 1 g of nickel nitrate hexahydrate were weighed.

Embodiment 3

[0036] In Example 1, 1.0 g of ammonium molybdate tetrahydrate and 0.5 g of nickel nitrate hexahydrate were weighed instead of 1.5 g of ammonium molybdate tetrahydrate and 1 g of nickel nitrate hexahydrate were weighed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com