Manufacturing method of array substrate, array substrate and display panel

A technology of an array substrate and a manufacturing method, applied in the display field, can solve the problems of affecting the electrical properties of the active layer, insufficient hydrogenation of the active layer, etc., and achieve the effects of improving the electrical properties and improving the hydrogenation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

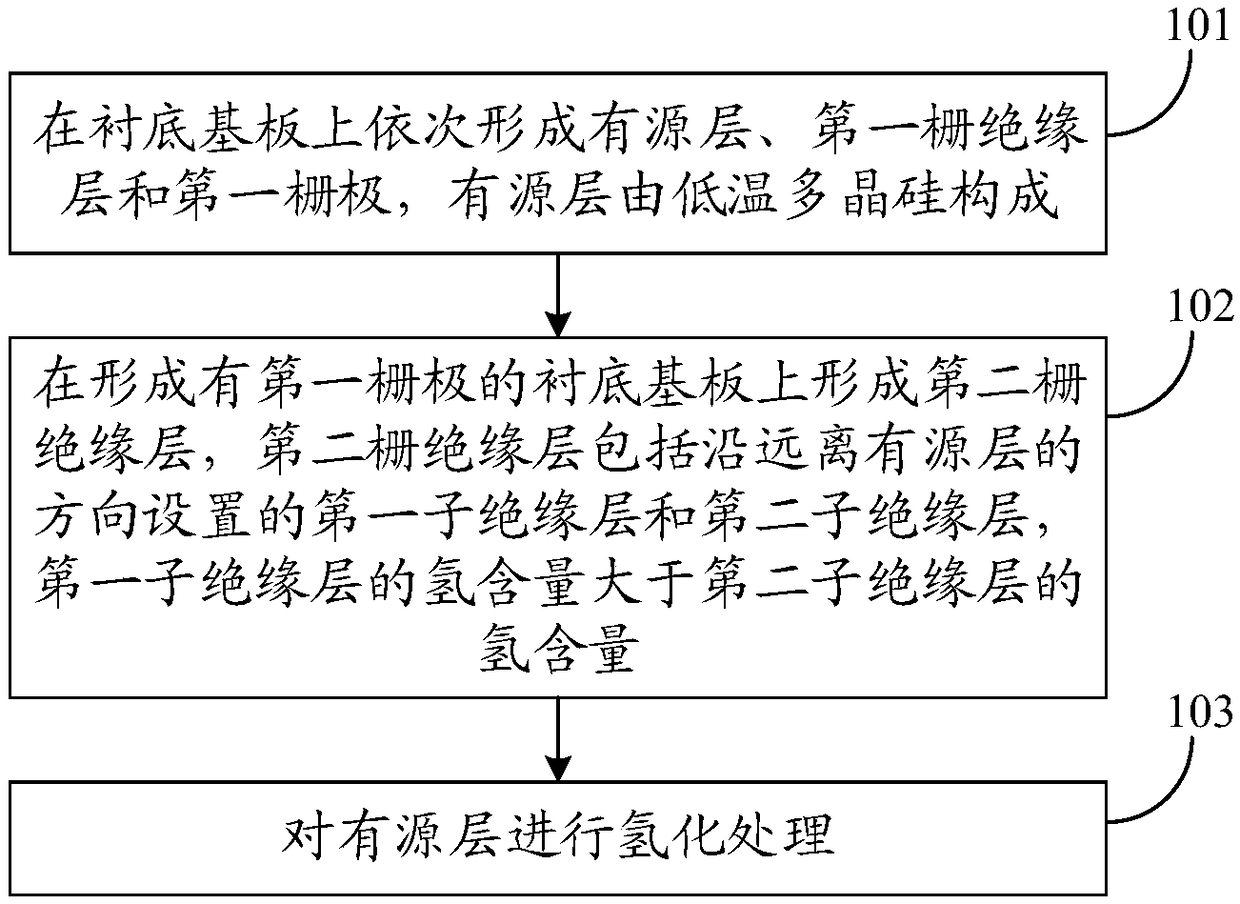

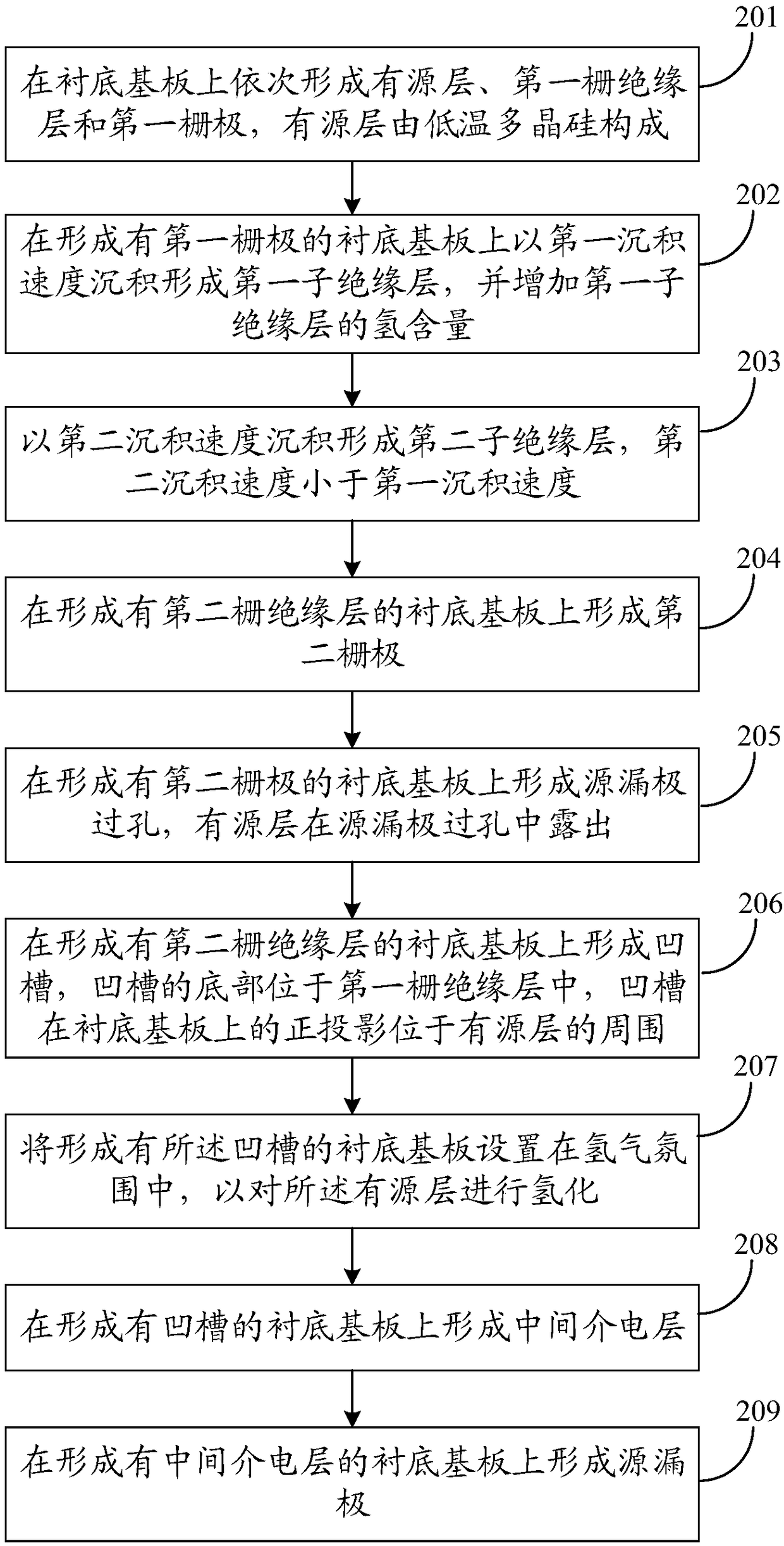

Method used

Image

Examples

Embodiment Construction

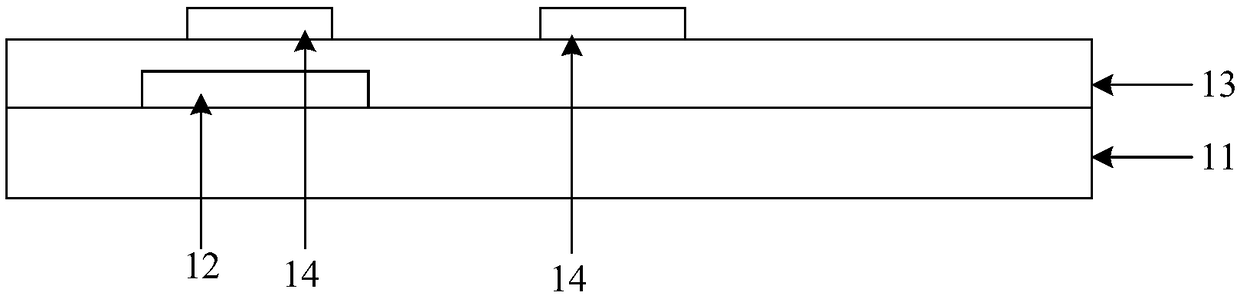

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0052] With the development of flexible display panels, the requirements for display panels gradually transition from bending (English: Bendable), bending (English: Foldable), to elastic flexibility (English: Stretchable). There are multiple layers of inorganic films in the array substrate of the current flexible display panel. When the display panel undergoes relatively severe deformation, the inorganic films in the array substrate are more likely to collide and separate. Micro-damages may occur in the display, and the micro-damages can expand into larger cracks and affect the normal operation of the display panel. Therefore, replacing the existing inorganic film layers with organic films has become the current mainstream development ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com