An automatic control method for zinc layer thickness in a continuous hot galvanizing zinc line

A layer thickness, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as uncontrollable effect, time-varying, and accurate control of impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

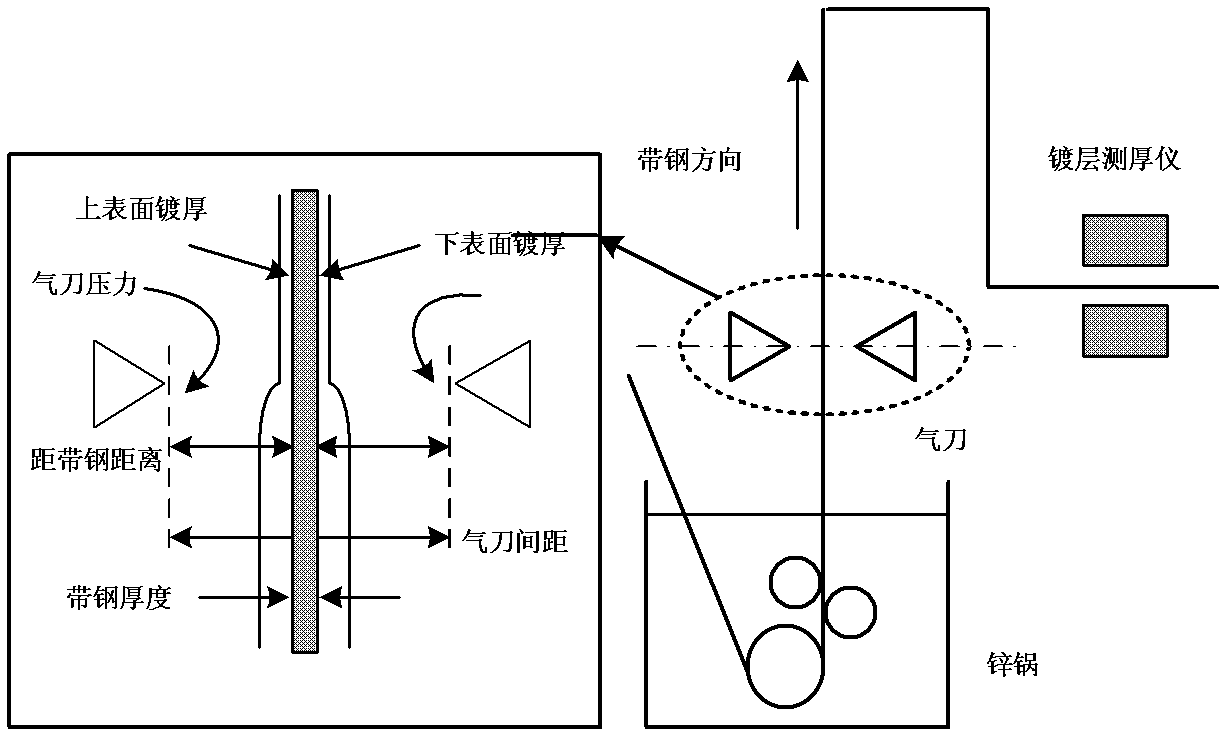

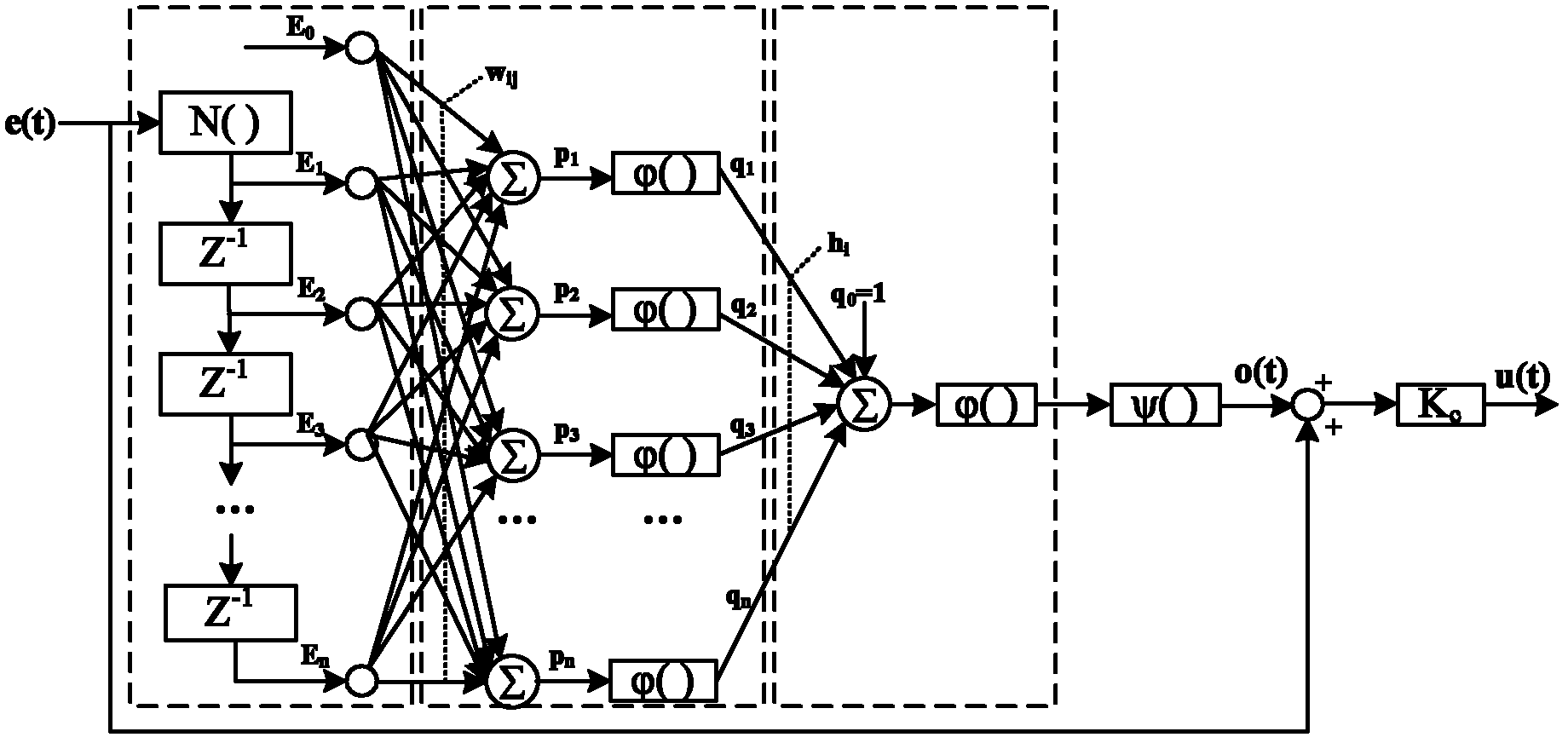

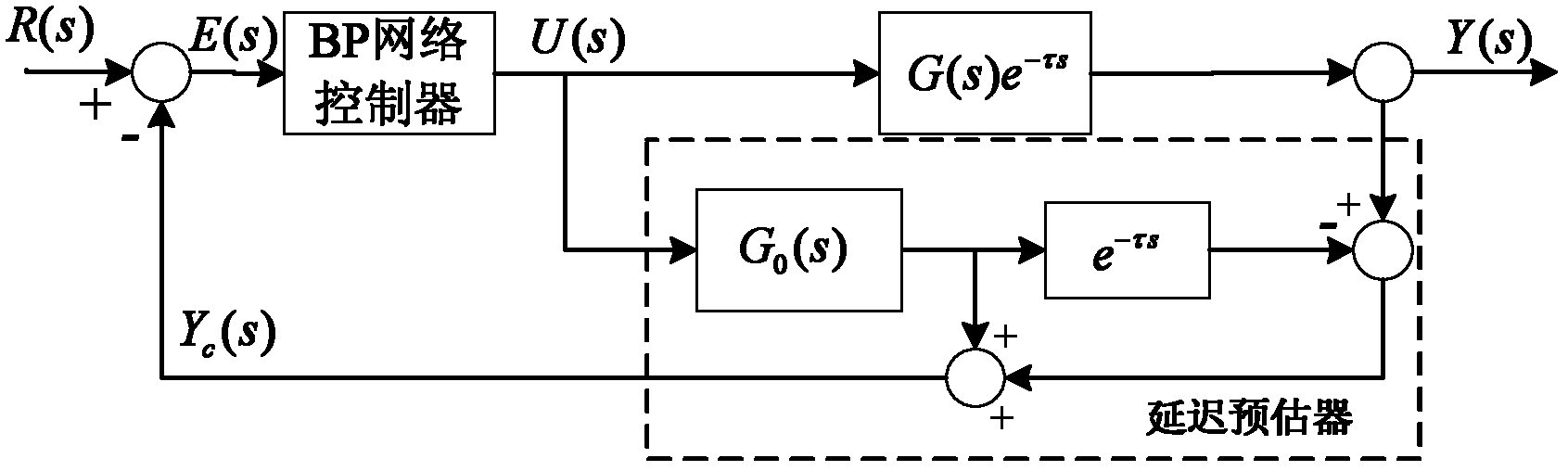

[0044] A continuous hot-dip galvanizing line zinc layer thickness automatic control method, the method uses BP neural network structure adaptive controller and delay prediction strategy to achieve precise control of the coating closed loop, such as figure 2 , image 3 , Figure 5 As shown, by sampling the thickness deviation of the coating as the input value of the adaptive control model of the BP neural network structure, through the two sets of weighting factors Δw in the adaptive control model ij (n), Δh j The data processing of (n) finally produces a reasonable output, adjusts the air knife pressure in real time, and finally makes the deviation between the set value of the coating thickness and the actual sampled value become smaller and smaller; the weighting factor Δw ij (n), Δh j (n) It can be updated online at each sampling interval through the following formula. The learning algorithm keeps refreshing the above weighting factors based on the principle of the minimum devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com