Energy-saving washing device for washing machine part processing

A technology for cleaning devices and parts, applied to heating devices, cleaning methods using liquids, dryers, etc. Ensure cleaning quality and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

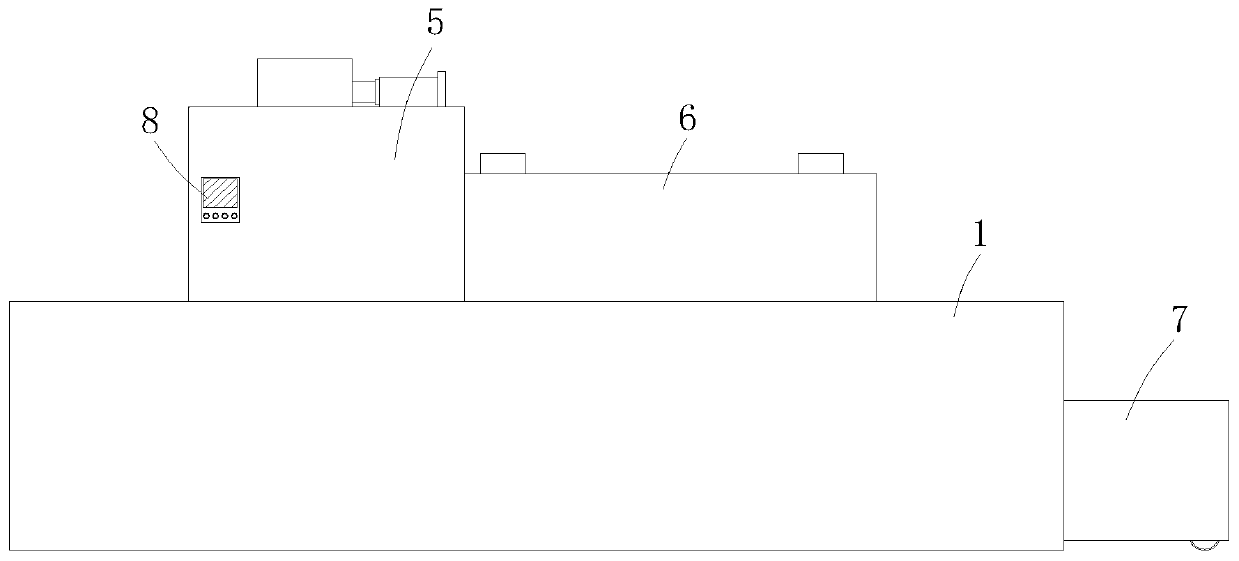

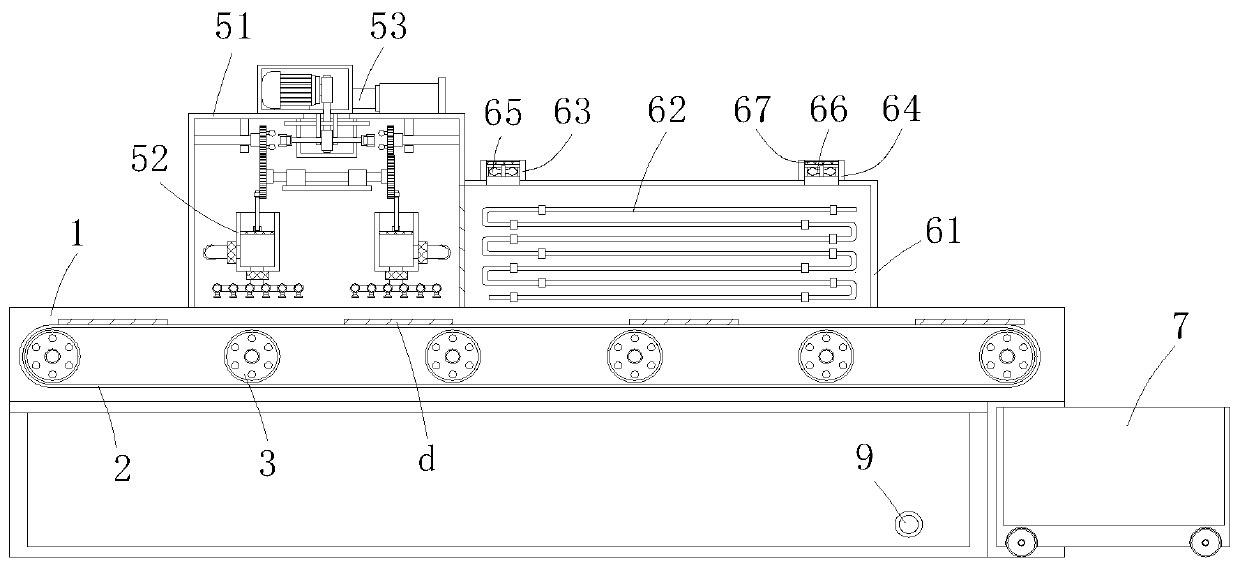

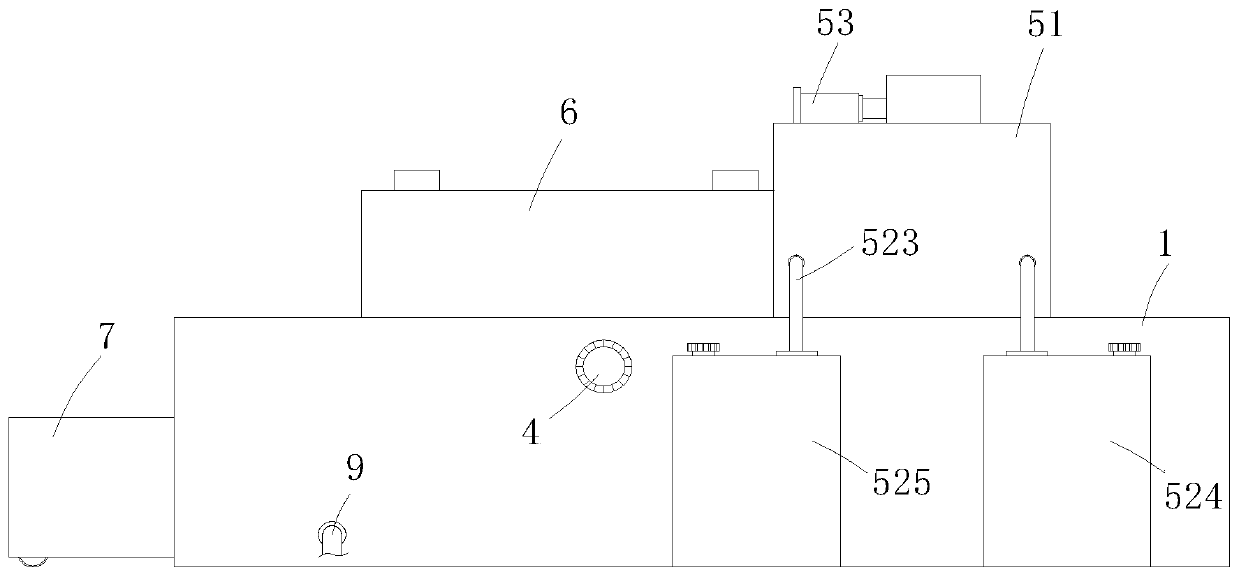

[0037] An energy-saving cleaning device for processing parts of a washing machine, comprising a strip-shaped transmission box 1 with an unclosed upper end, a transmission braided belt 2 for transporting a workpiece d is horizontally provided in the inner cavity of the strip-shaped transmission box 1, and the transmission braided There are a plurality of transmission wheels 3 rotating inside the belt 2, and the transmission wheels 3 are installed on the inside of the strip transmission box 1, and the rear axle end of one of the transmission wheels 3 extends to the outer cavity of the strip transmission box 1 and is installed in the strip transmission box 1. On the output end of the transmission motor 4, the transmission motor 4 is fixedly installed on the rear wall of the strip transmission box 1, the transmission motor 4 is started, and the transmission braid 2 is driven to transmit the workpiece d of the washing machine parts from left to right, and the strip transmission box ...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is that, as Figure 1-3 As shown, the downstream of the cleaning mechanism 5 is provided with a drying mechanism 6, the drying mechanism 6 includes a drying chamber 61 erected on the upper end of the bar-shaped transmission box 1, and S-shaped The loop heating pipe network 62, and the two sides of the top wall of the drying chamber 61 corresponding to the conveying direction of the side panels are respectively provided with an air inlet 63 and an air outlet 64, and the air inlet 63 and the air outlet 64 are respectively provided with an air inlet 65 With exhaust fan 66, the upper end inboard of air inlet 63 and air outlet 64 is all equipped with filter screen.

[0052] In this embodiment, the S-shaped loop heating pipe network 63, the air intake fan 65 and the exhaust fan 66 are started synchronously, the air is taken in from above the workpiece d just cleaned, and the air is discharged from the top of the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com