Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Reduce stacking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

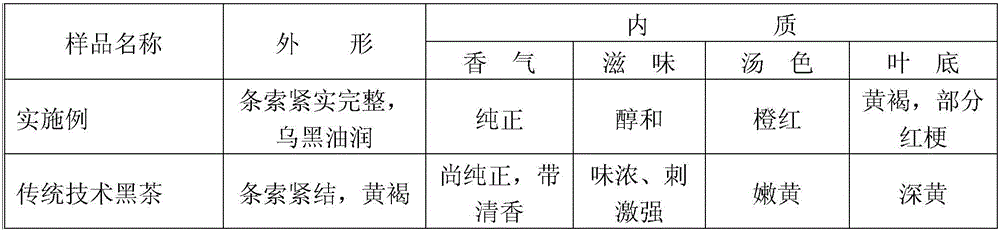

Dark tea processing method

InactiveCN103109940AImprove fresh leaf qualityExpand the scale of leaf sourcePre-extraction tea treatmentWater contentChemistry

The invention discloses a dark tea processing method. The dark tea processing method is characterized by comprising the following steps of: (1) picking fresh leaves; (2) withering the fresh leaves; (3) then removing water; (4) then twisting for 20-25 minutes; (5) heating tea bases to increase temperature to 50-60 DEG C, then blanking the tea bases and slightly spreading, and reducing the temperature of the tea bases to 35-40 DEG C, wherein the water content of the tea bases is 60%-65%; (6) lining the tea bases by using reed leaves, cladding, and then covering by using a wet cloth for pile fermentation; and (7) drying by using a drying machine for the first time, drying by using a roasting machine for the second time, drying by using the drying machine for the third time, and spreading for airing after drying every time. The dark tea processed by the dark tea processing method disclosed by the invention has the advantages of uniform and strip-shaped outline, jet-black and lubricating color and luster, golden and bright soup color similar to amber, mellow and sweet flavor, rich fragrance, fruit honey aroma, yellow brown and uniform leaf base, stable quality and drinking safety and is a high-quality loose dark tea with unique style.

Owner:刘超建

Rapid composting microbial inoculum of agricultural wastes and method for preparing organic fertilizer from the same

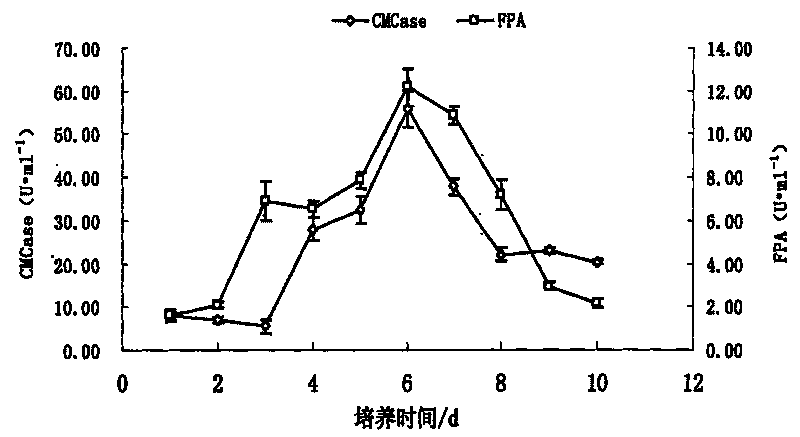

The invention relates to a rapid composting microbial inoculum of agricultural wastes and a method for preparing organic fertilizer from the same, belonging to the field of waste resource recycle. In the invention, a strain NJZ5 capable of rapidly decomposing various wastes rich in cellulose at 50 DEG C is separated. The strain NJZ5 is inoculated in a fermentation cylinder, and the obtained fermentation broth contains culturable colonies the number of which is no less than 1*109 per milliliter; after the fermentation broth and an adsorbent rice bran are mixed uniformly, the product of the rapid composting microbial inoculum of agricultural wastes can be obtained, wherein the content of the agricultural wastes in the NJZ5 strain can be no less than 1*108 per grame. The NJZ5 composting microbial inoculum can remarkably improve the composting temperature and shorten the composting period, and can control the composting period within about 30 days.

Owner:PENYAO ENVIRONMENTAL PROTECTION

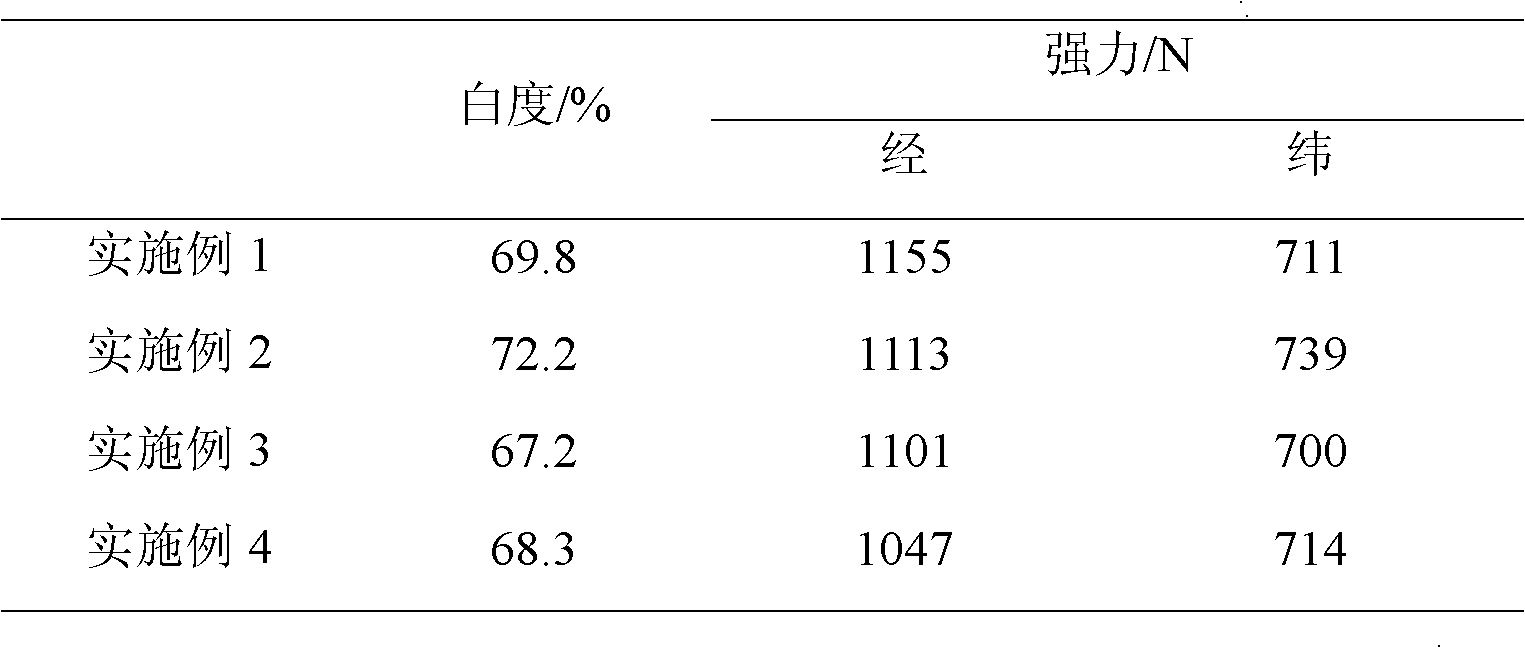

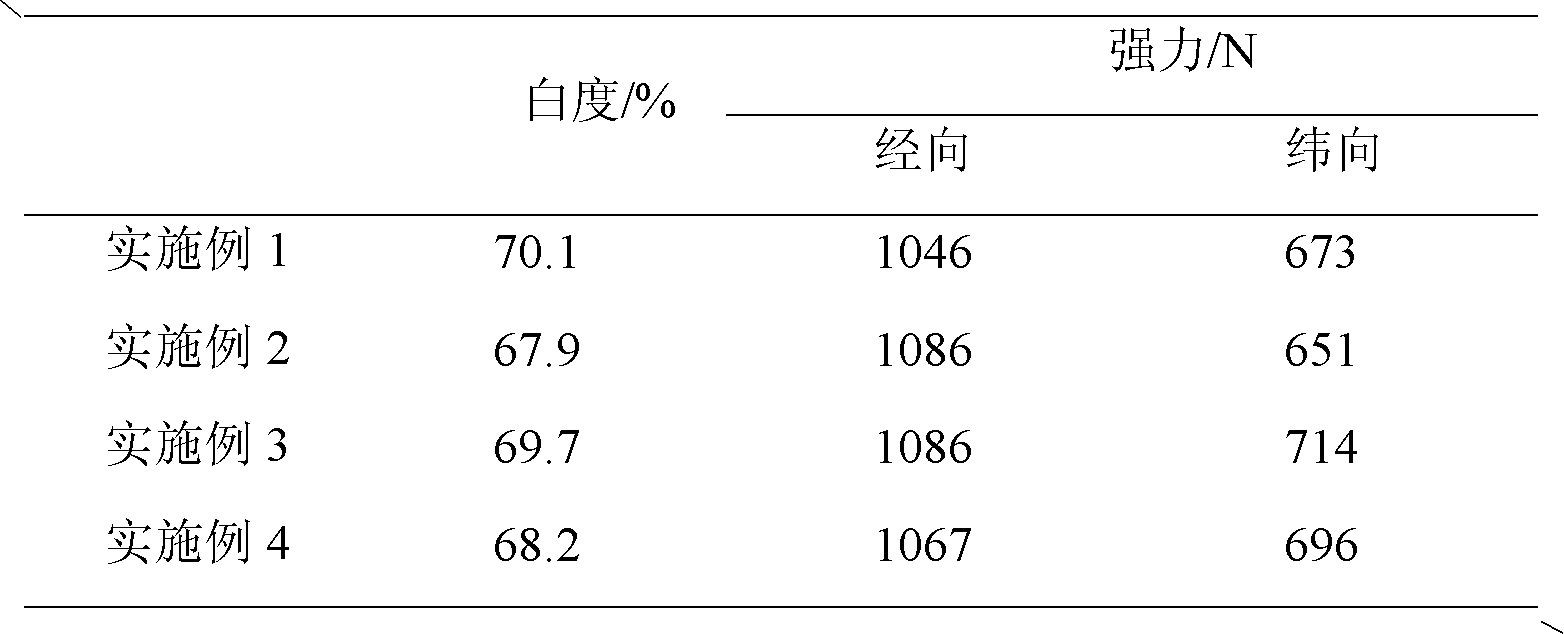

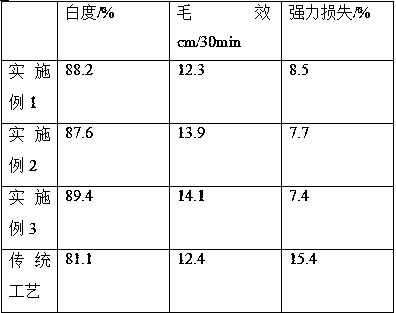

Processing method for improving easy-care performance of moist crosslinking finishing yarn-dyed fabric

ActiveCN108457082AAdequate responseGood flatness effectHeating/cooling textile fabricsWrinkle resistant fibresYarnProduct inspection

The invention belongs to the technical field of textile dyeing and finishing, and particularly relates to a processing method for improving easy-care performance of a moist crosslinking finishing yarn-dyed fabric. The processing method comprises the steps of singeing, desizing, mercerizing, liquid ammonia, pre-softening, moist crosslinking rolling, moist crosslinking, baking, primary washing, secondary washing, tentering and finished product inspection and packaging. Baking is carried out with a baker at a baking temperature of 120 to 140 DEG C for 3 to 5 minutes. According to the invention, two crosslinking is creatively adopted, the water shrinkage and heat shrinkage of a fabric are more stable, a pre-shrinking process is omitted, and thus the production cost of the fabric is reduced; the baking process is introduced into the moist crosslinking finishing process, and the time of moist crosslinking finishing piling is shortened by 6 to 12 hours, and the usage amount of resin and a catalyst is reduced by 20% to 50% compared with a traditional moist crosslinking process; the easy-care performance of the moist crosslinking finishing yarn-dyed fabric is enhanced by 0.2 to 0.5 grade, the fabric can be washed for 50 times, the easy-care degree is 4.0 or above.

Owner:LUTAI TEXTILE

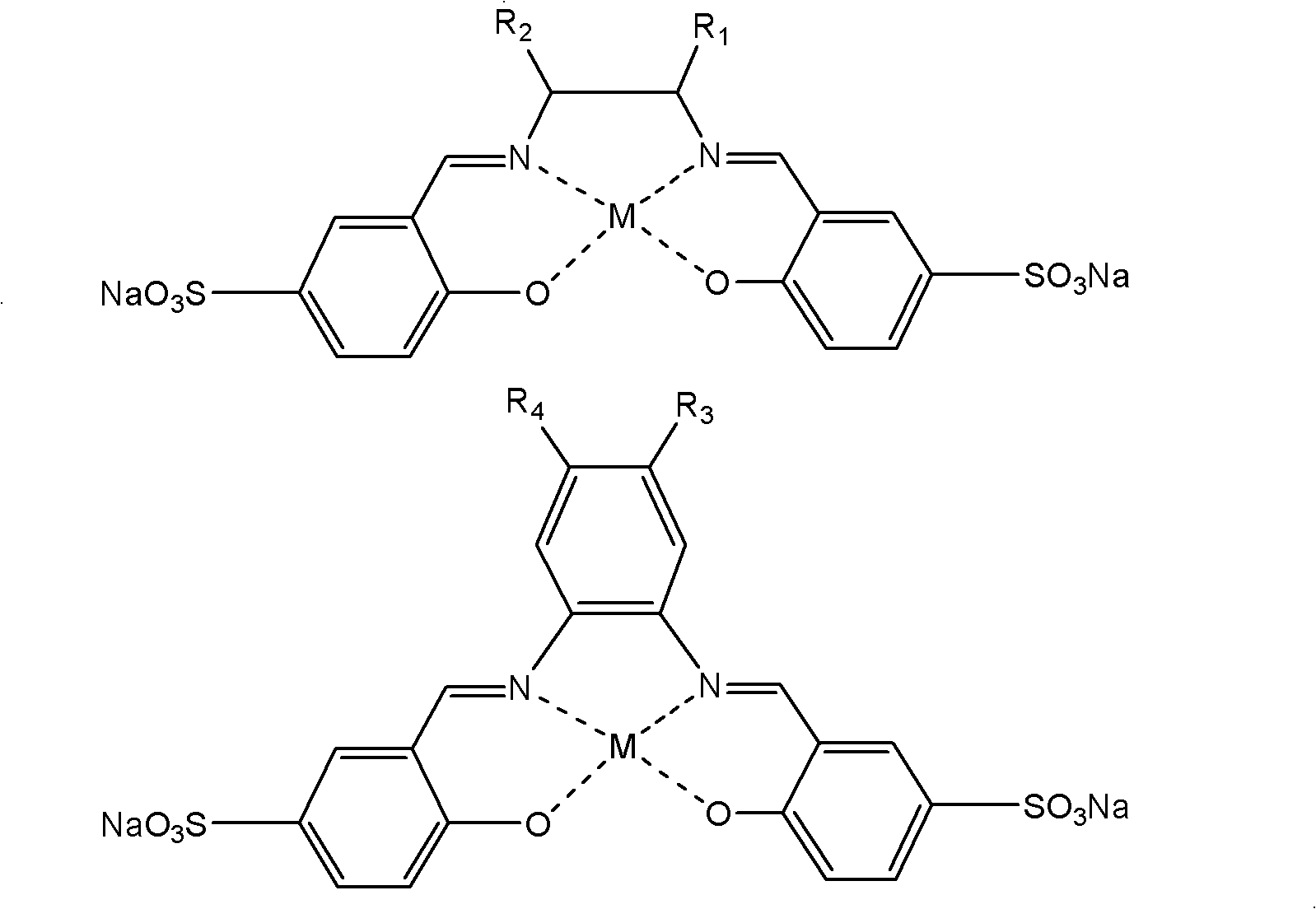

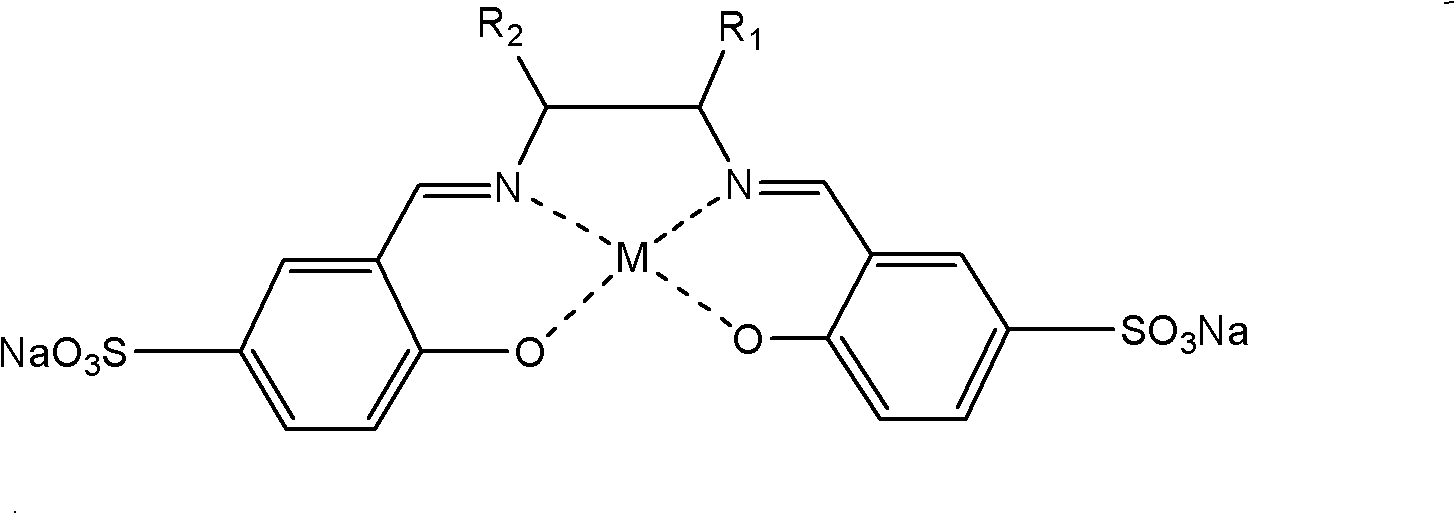

Method for low-temperature activated bleaching by using Schiff base metal complexes

ActiveCN101922109AReduce stacking timeAchieve the bleaching effectBleaching apparatusNuclear chemistryCoordination complex

The invention relates to a method for low-temperature activated bleaching by using Schiff base metal complexes, belonging to the field of methods for low-temperature activated bleaching. The method comprises the following steps: (1) taking the Schiff base metal complexes, 20-50g / L of H2O2, penetrating agents and stabilizing agents and then mixing the substances to obtain bleaching operating fluid with pH value of 7-11; (2) padding the fabrics in the bleaching operating fluid; and (3) carrying out cold pad-batch or steaming on the padded fabrics and then washing the fabrics with water. The method is simple, low in cost, high in production efficiency, environment-friendly, energy-saving and suitable for industrialization and reduces the bleaching temperature, shortens the stacking time and reduces the fabrics damage under the premise of achieving good bleaching effect.

Owner:DONGHUA UNIV

Fast-mellowing processing process of high-quality dark tea

InactiveCN106234662AImprove the mellowness of the tasteReduce processing timePre-extraction tea treatmentClimate change adaptationPolyphenolEnzyme

The invention relates to a processing process of dark tea, in particular to a fast-mellowing processing process of high-quality dark tea. The processing process includes: picking fresh tea leaves; thinly spreading the fresh tea leaves; deactivating enzymes to completely deactivate the enzymes of the tea leaves and keep part of enzymatic activity of tender stems; spreading out for cooling, and rolling; performing pile fermentation; drying. The processing process has the advantages that dark tea mellowing is achieved and pile fermentation time is shortened, the half enzyme deactivating technology is used, part of the enzymatic activity of the tea stems is kept, cells are crushed through the rolling to release enzymes and substrates, the oxidation of polyphenols is catalyzed fast during the pile fermentation, and the forming of the high-quality dark tea; the mellowness of the dark tea can be improved effectively, the taste of the dark tea is improved evidently, the pile fermentation process is accelerated, dark tea processing time is shortened, and dark tea production efficiency is increased.

Owner:湖南省茶叶研究所

Processing method of dark raw tea

ActiveCN103549049AGuaranteed qualityMeet the needs of quality formationPre-extraction tea treatmentFlavorRare earth

The invention discloses a processing method of dark raw tea. The processing method is based on a conventional processing process of the dark raw tea. The processing method comprises the procedures of picking materials, de-enzyming, primarily kneading, carrying out pile fermentation, secondarily kneading and drying. The picking of the materials is strictly executed by three fresh leaves with one bud; in the procedure of pile fermentation, the piling of the primarily-kneaded leaves lasts for 12-16 hours with the leaf temperature in the primarily-kneaded leaf pile being 48-52 DEG C, and when the leaves are tawny, the coarse smell is eliminated and the fragrant flavor is generated, unpiling and deblocking are carried out for secondary kneading; in the drying procedure, the drying is carried out till the water content is 4-6% and forming the roasted flavor. Therefore, the processing method disclosed by the invention has the advantages that the problem that the contents of fluorine and rare soil in the dark raw tea exceed the standard due to coarseness of the raw materials can be effectively solved; a new product of the dark raw tea is mellow in taste, is not coarse, has the roasted flavor, can realize the instantaneous drinking of the dark raw tea, and is used for processing and pressing the raw tea materials; the produced dark raw tea is an all-new dark raw tea product.

Owner:安化云台山八角茶业有限公司

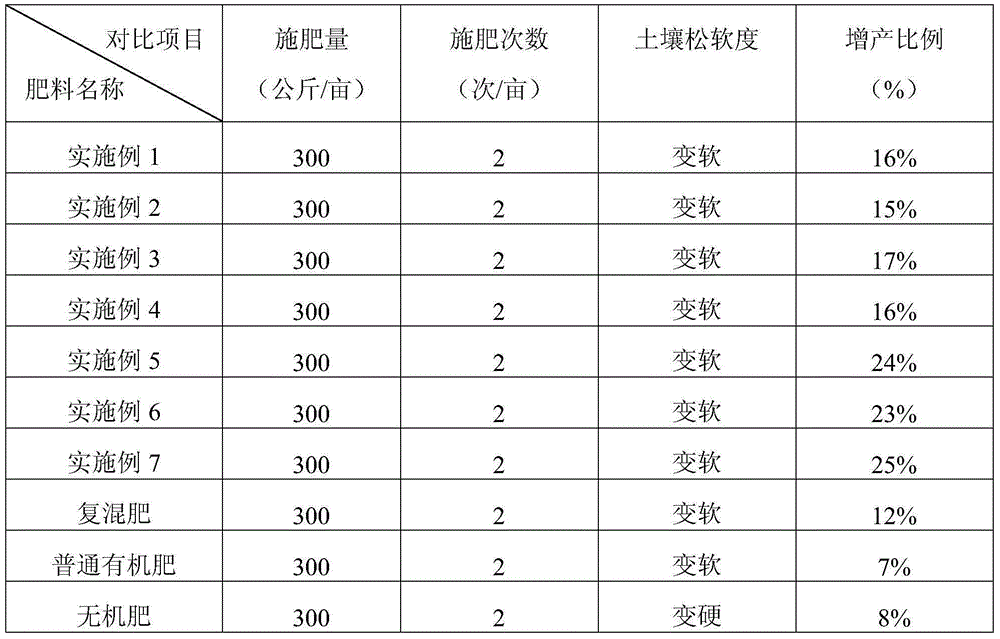

Tobacco biological organic fertilizer

InactiveCN103387426AReduce stacking timeLow costBio-organic fraction processingOrganic fertiliser preparationChemistryRoot system

The invention discloses a tobacco biological organic fertilizer which is prepared through the steps of firstly crushing a tobacco material into powder, and then adding a biological fermentation microbial inoculum; uniformly mixing the biological fermentation microbial inoculum and the tobacco material according to the weight ratio of 1:(500-600), then fermenting in a stacking way at high temperature of 58-63 DEG C for 8-10 days, wherein the material is overturned once every 2-3 days, and the water ratio of the tobacco material is 65%-70%. By adopting the mode, the tobacco biological organic fertilizer disclosed by the invention can shorten the composting time and change the wastes into valuables, is low in cost, can be used for killing and expelling pests and inhibiting and killing bacteria and can improve the soil, promote the growth of root systems, shorten the growth period of crops, increase the output of the crops and enhance the quality of the crops.

Owner:CHANGSHU CHANGFU ORGANIC COMPOUND FERTILIZER

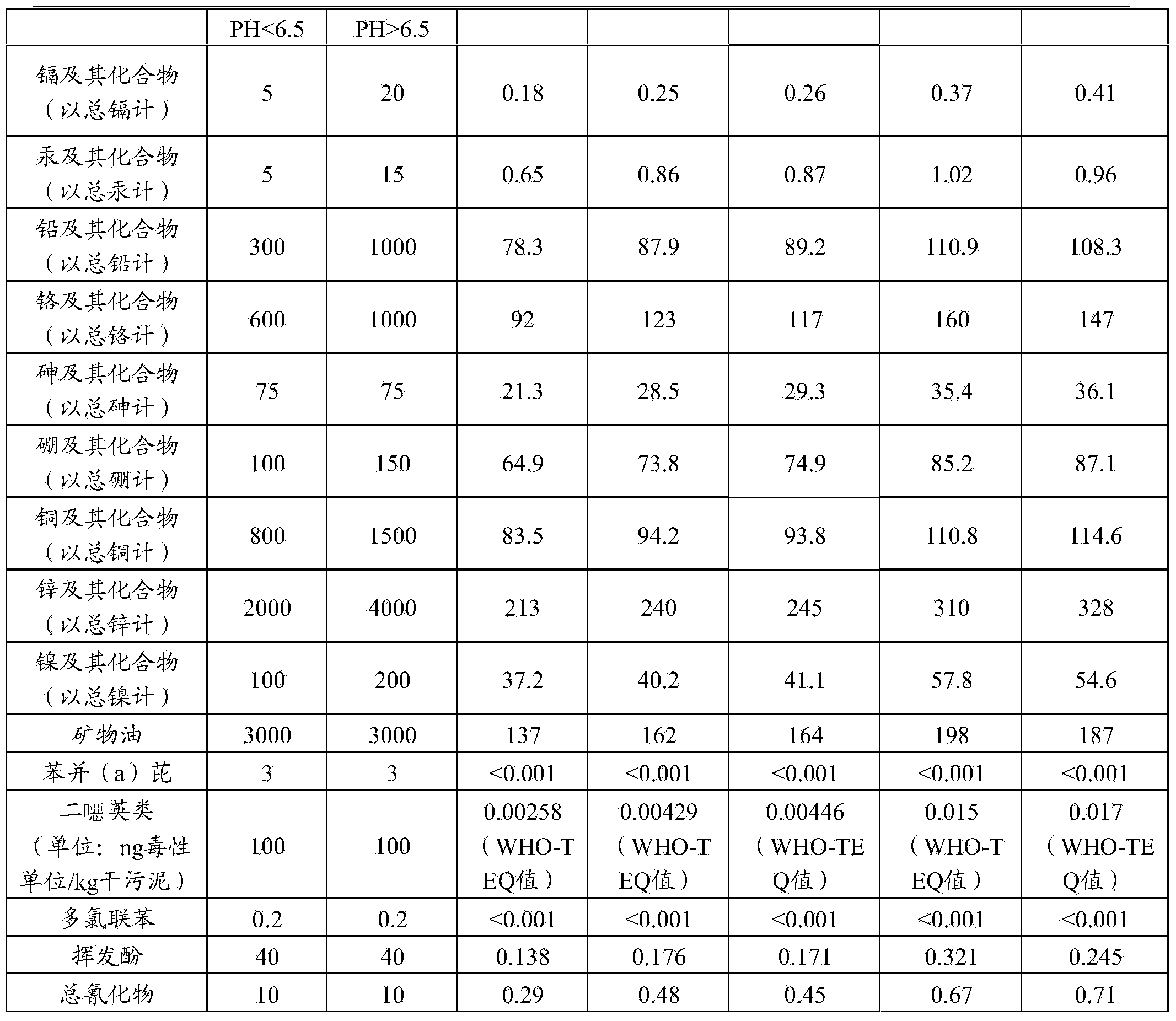

Composite sludge treatment process

ActiveCN104326634AReduce stacking timeShort disposal cycleSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentPre treatmentSludge cake

The invention relates to a composite sludge treatment process. The treatment process comprises the following steps: step a, removing impurities; step b, pre-treating the sludge to obtain first sludge and second sludge; step c, uniformly mixing the second sludge obtained in the step b with a solidifying agent by means of aeration treatment, and subsequently press-filtering and dehydrating the second sludge which is subjected to the aeration treatment to obtain a sludge cake; step d, adding a solidifying agent into the first sludge obtained in the step b and uniformly stirring; step e, sending the sludge cake obtained in the step c and the first sludge treated in the step d to a temporary storage yard, and standing for 1-2 days to finish the treatment. The composite sludge treatment process disclosed by the invention has the advantages of high efficiency, low cost and the like.

Owner:广州珞珈环境技术有限公司

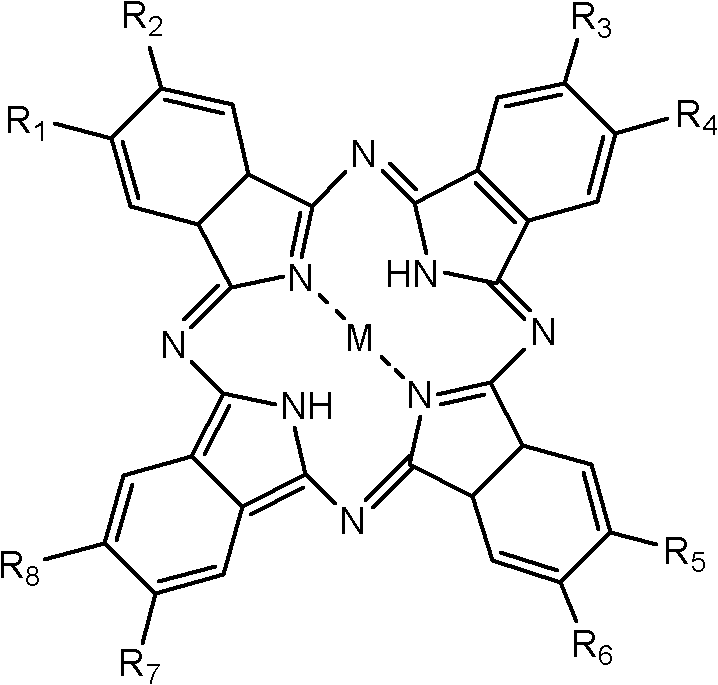

Low-temperature activation bleaching method by using water-soluble metal phthalocyanine

ActiveCN101922110AReduce stacking timeLower the pH of the working solutionBleaching apparatusWater solublePhthalocyanine

The invention relates to a low-temperature activation bleaching method by using water-soluble metal phthalocyanine and belongs to a low-temperature activation bleaching method. The method comprises the following steps of: (1) mixing the water-soluble metal phthalocyanine, H2O2, a penetrating agent and a stabilizer to obtain bleaching working solution; (2) padding fabric in the bleaching working solution; and (3) performing cold piling or steaming on the padded fabric and washing. The method has the advantages of simplicity, low cost, high production efficiency, environmental protection, energy conservation and suitability for industrial application; and on the premise of achieving good bleaching effect, the bleaching temperature is reduced, the stacking time is shortened and fabric damage is reduced.

Owner:DONGHUA UNIV

Microorganism fermented organic fertilizer

InactiveCN103382142AReduce stacking timeHigh organic contentBio-organic fraction processingOrganic fertiliser preparationBiotechnologyFeces

The invention discloses microorganism fermented organic fertilizer. A production method of the microorganism fermented organic fertilizer comprises adding 5 to 8 parts of microorganism bacterium agent, 1 to 2 parts of peat humic acid and 5 to 10 parts of chemical nitrogenous fertilizer to raw materials which are formed by 60 to 65 parts of livestock and poultry excrement, 25 to 30 parts of rape seed cakes and 10 to 15 parts of wheat bran; then uniformly mixing; placing in piles with the high temperature ranging from 50 to 55 DEG C and fermenting for 11 to 13 days. The microorganism bacterium agent comprises amylase, protease, lipase and cellulose. The microorganism fermented organic fertilizer has the advantages of enabling composting time to be reduced, being non-poisonous, harmless and free from extraneous odor, generating no pollution to the environment, enabling nutrients to be stored, enabling organic contents in the fertilizer to be improved and accordingly improving the fertilizer quality.

Owner:CHANGSHU CHANGFU ORGANIC COMPOUND FERTILIZER

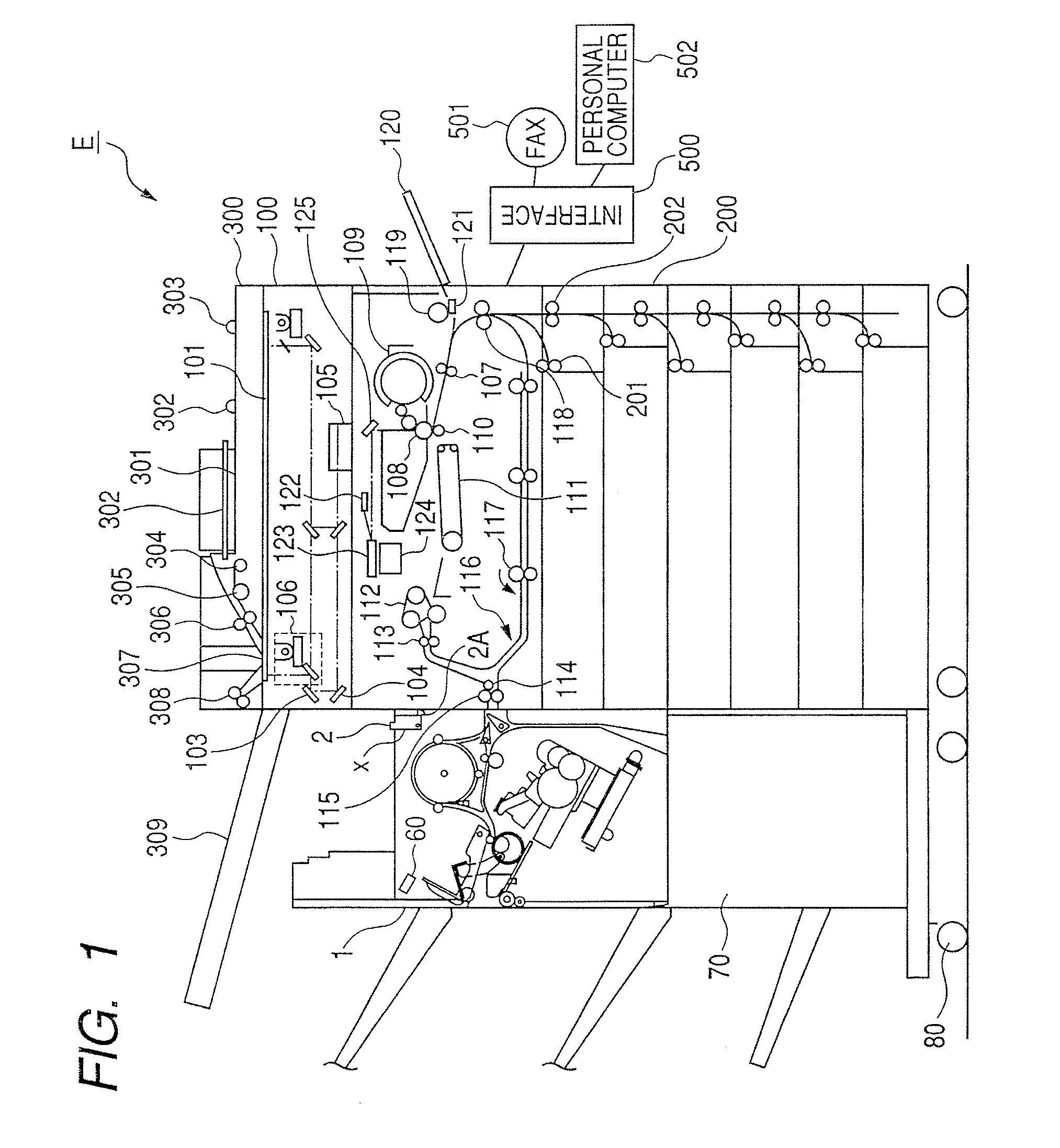

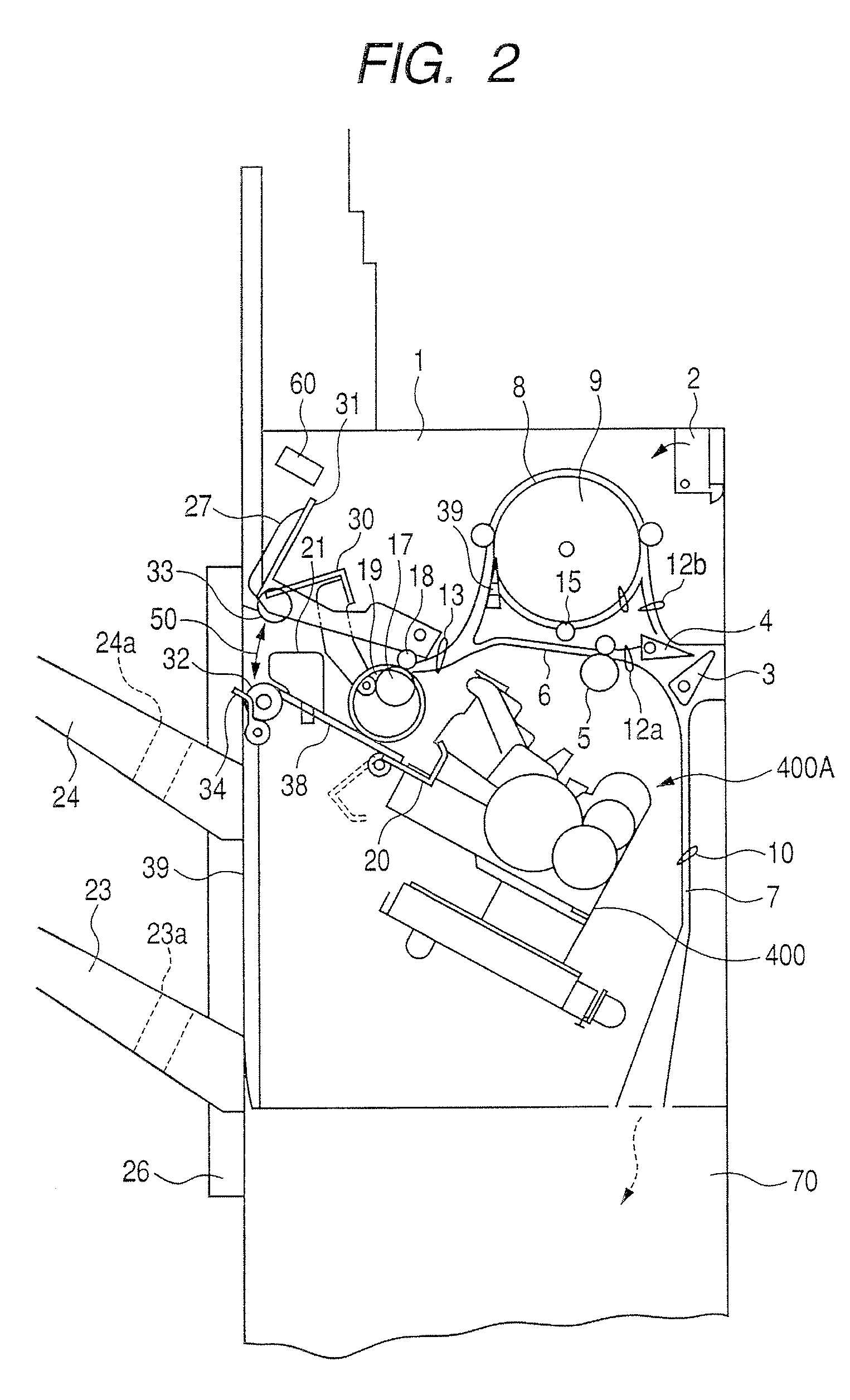

Sheet processing apparatus and image forming apparatus

InactiveUS7722041B2Increase the number ofReduce in size and weightFunction indicatorsPile receiversReliability engineeringSheet material

Provided is a sheet processing apparatus, including: a stacking unit that is capable of stacking discharged sheets; a drive mechanism that is capable of moving the stacking unit; a storage device that holds data on a moving time of the stacking unit in a rewritable manner; an arithmetic unit that is calculates an estimated value of the moving time of the stacking unit based on the data; and a correcting unit that corrects the data held in the storage device by using an actual measurement value of the moving time of the stacking unit.

Owner:COPYER

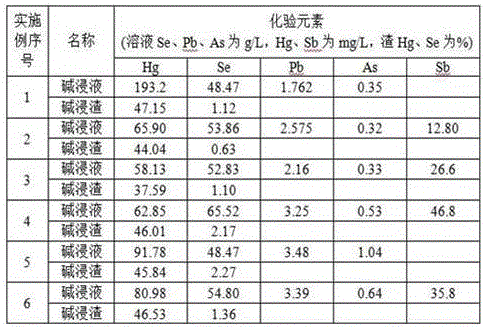

Method for separating selenium and mercury from acid mud of copper-lead-zinc smelting sulfuric acid system

ActiveCN106756038AReduce pollutionLow costProcess efficiency improvementElemental selenium/telluriumReaction temperatureSlurry

The invention discloses a method for separating selenium and mercury from acid mud of a copper-lead-zinc smelting sulfuric acid system. The method includes the steps of 1) leaching the selenium and solidifying the mercury from the acid mud by adopting the oxygen pressure-alkaline leaching process, specifically, mixing the acid mud, sodium hydroxide and lime to form slurry, adding the mixture into a reaction kettle according to a proportion, then, injecting oxygen-enriched gas into the reaction kettle, increasing the pressure to reach 1.7-2.2MPa, namely 17-22atm, carrying out heating to reach 160-220 DEG C, then carrying out oxygen pressure-alkali leaching for 1-4 hours, and condensing tail gas of the reaction kettle to remove mercury steam through a condensation tank, wherein condensed water returns to the reaction kettle to be recycled as a liquid for a alkali leaching mixture; 2) carrying out solid-liquid separation; 3) sealing and storing alkali leaching residues in the step 2), and sending the alkali leaching residues to a mercury factory to recover the mercury in a centralized mode; and 4) carrying out efficient reduction to prepare crude selenium, specifically, purifying alkali leachate in the step 2) and then carrying out reduction to recover the selenium. Compared with an existing technology for calcinating the acid mud by adding the lime, the method for separating the selenium and the mercury from the acid mud of the copper-lead-zinc smelting sulfuric acid system has the advantages that the reaction temperature is greatly reduced, the oxygen-enriched gas is used for oxidation, other oxidizing agents do not need to be added, the treatment cost is saved, and the leaching rate of the selenium is increased.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

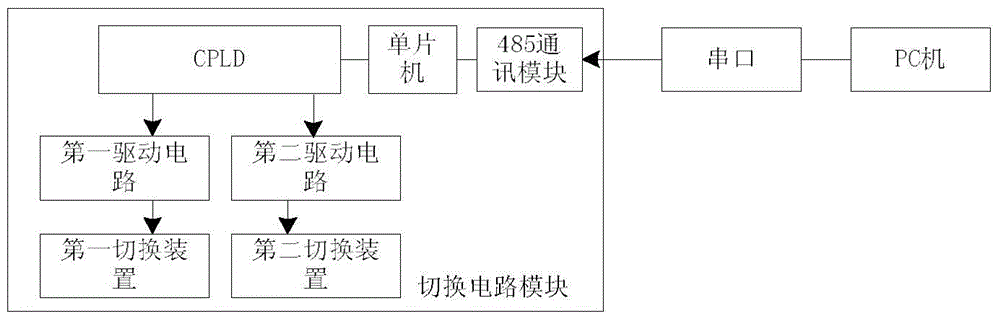

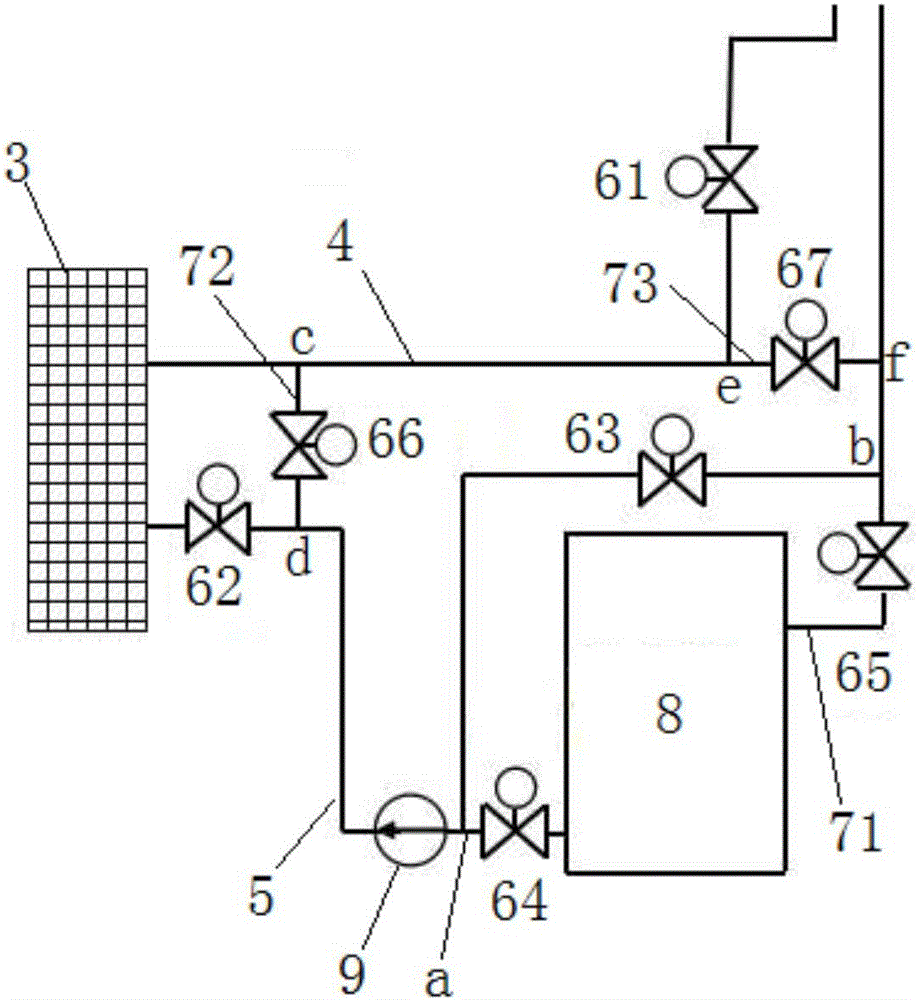

Fast charging and discharging power source device of nuclear magnetic resonance water detector

InactiveCN104009532ASave time at workReduce stacking timeBatteries circuit arrangementsElectric powerWater detectorCapacitance

The invention relates to a fast charging and discharging power source device of a nuclear magnetic resonance water detector. The fast charging and discharging power source device is characterized in that a PC is connected with an MCU control module through a serial port, the MCU control module is connected with a DC-DC high-power module through a D / A converter, the DC-DC high-power module is connected with a 24V storage battery, generates high voltage and is connected with a switching circuit module through an anti-backlash protection circuit, the two output ends of the switching circuit module are connected with a first energy-storage capacitor and a second energy-storage capacitor respectively, a voltage collecting module collects the voltage value of the first energy-storage capacitor and the voltage value of the second energy-storage capacitor, and the output end of the voltage collecting module is connected with the MCU control module through an A / D converter. Compared with a prior method with a single capacitor included, the superposition time of every time is shortened, the working time of each pulse moment is shortened, the charging and discharging time is effectively shortened, and working efficiency is improved.

Owner:JILIN UNIV

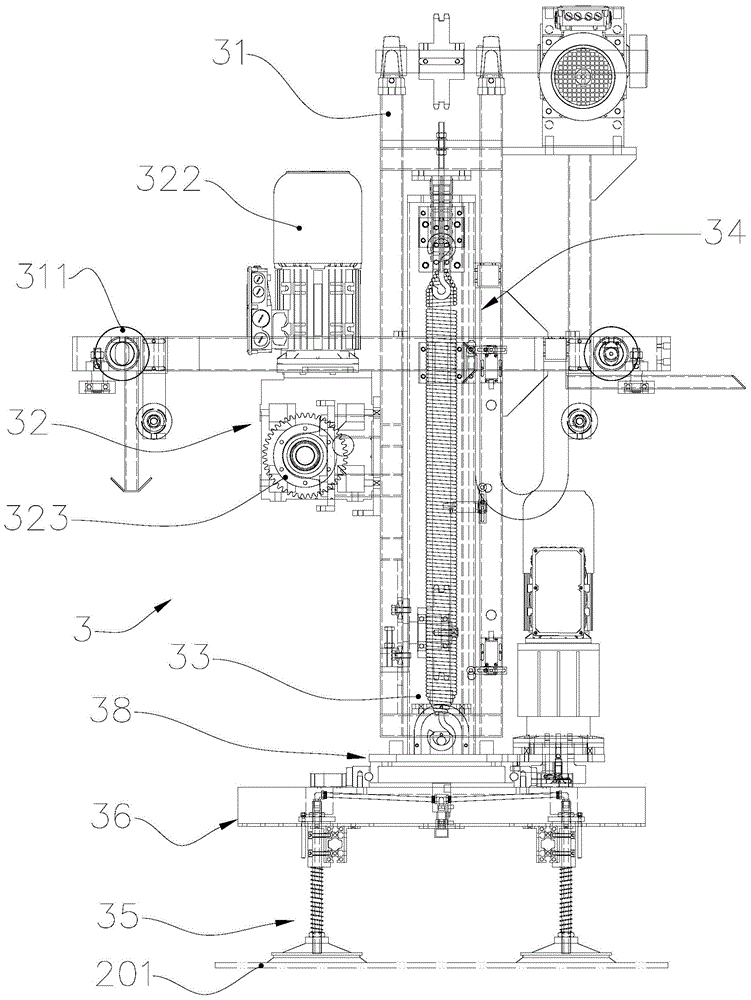

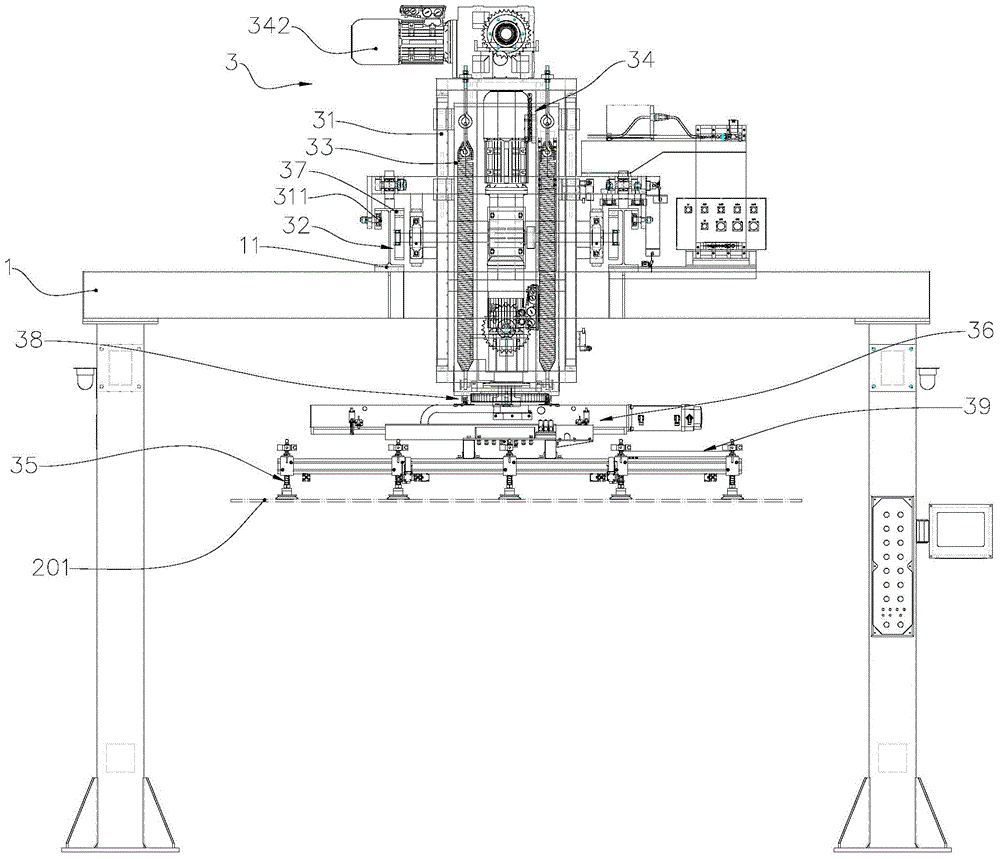

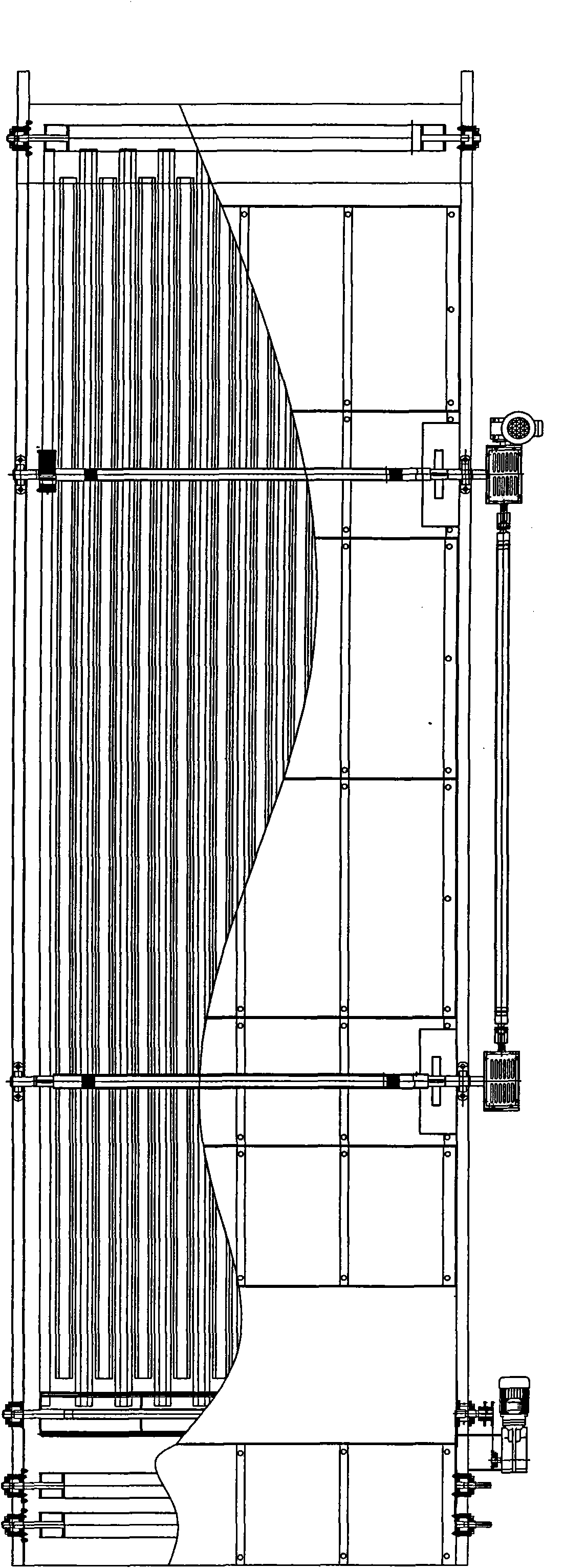

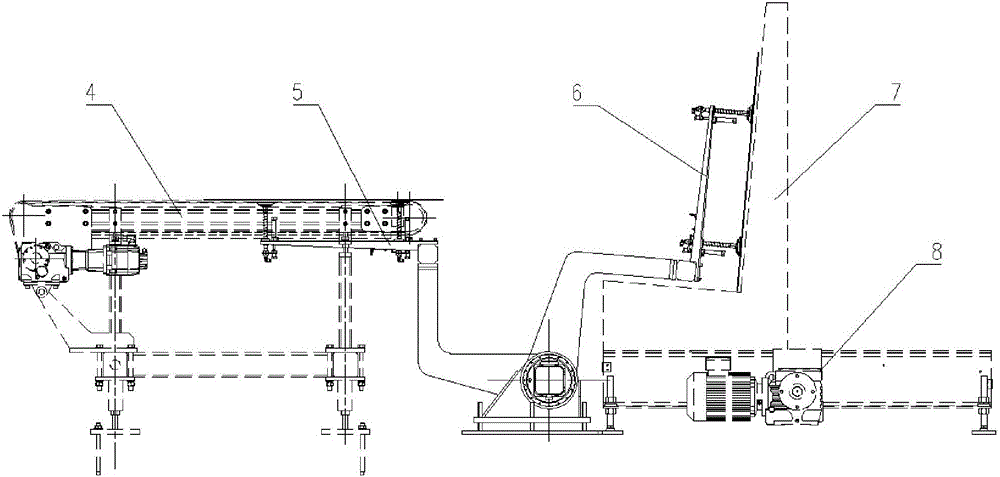

Full-automatic horizontal glass stacking machine and glass stacking method

ActiveCN105984729AImprove gripReduce stacking timeStacking articlesDe-stacking articlesState of artFixed frame

The invention relates to the technical field of float glass, and provides a full-automatic horizontal glass stacking machine and a glass stacking method. The full-automatic horizontal glass stacking machine comprises a transverse rail, stacking platform assemblies and suction main engines used for sucking glass on a glass production line and then transferring the glass to the stacking platform assemblies to be stacked. Each suction main engine comprises a fixed framework, a traveling device, a movable framework, a lifting device, a suction cup frame and a mobile device. Compared with the prior art, the full-automatic horizontal glass stacking machine provided by the invention improves the grabbing efficiency, accidents are not likely to happen in the glass grabbing process, the stacking time of each piece of glass board is shortened, and the production efficiency is improved. According to the glass stacking method, the suction cup frames are driven to move towards the glass moving direction at the speed the same as the glass moving speed while suction assemblies compress the surface of glass, so that glass is grabbed more conveniently, rapidly and firmly, and the grabbing and production efficiency is improved.

Owner:深圳市天圣实业有限公司

Pre-treatment process for textile fabric

ActiveCN108252000AEasy to useEasy to operateTextile storage in superimposed formSingeingPolyesterEngineering

The invention belongs to the technical field of the dyeing pre-treatment of textile fabric, and particularly relates to a pre-treatment process for the textile fabric. The pre-treatment process for the textile fabric specifically comprises the following steps: singeing; rolling cold-batch working solution; piling; washing in 7-10 grids by hot water, wherein the temperature is 98 DEG C; washing bycold water; and drying. The pre-treatment process is capable of, through a DF-boiling and bleaching agent and other assistants, preparing the continuous, rapid, low-temperature, and low-alkaline efficient pre-treatment working solution, the working solution is extensively applied to a pre-treatment processing technology of textiles, such as pure cotton, polyester cotton, brocade cotton, rayon, non-woven fabric, dacron, and tencel, so the piling time can be reduced from 20-24 hours of a traditional cold-batch process to 2-6 hours, and the refining effect of cotton fabrics and the uniformity ofdyeing are greatly improved. The dye-uptake of the dyeing effect is improved by 10%-20%, and the hand feeling is softer.

Owner:石狮市鼎盛漂染织造有限公司

Chin brick tea pile fermentation processing method

PendingCN106578174AImprove qualityReduce stacking timePre-extraction tea treatmentFlavorNatural ventilation

Disclosed is a chin brick tea pile fermentation processing method. The method comprises the steps that firstly, water detection is performed on a tea base, then, water adding and moistening and beneficial microorganism strain inoculation are performed, then, first-time pile turning and heat dissipation are performed, then, pile pavement and beneficial microorganism strain inoculation are performed again, then, second-time pile turning and heat dissipation are performed, then, ventilation and heat dissipation are performed, and finally natural ventilation drying ageing are performed to perform pressing to obtain the finished chin brick tea. The advantaged leading role of beneficial microorganisms in the chin brick tea pile fermentation process is sufficiently ensured, the chin brick tea pile fermentation time is shortened, and the chin brick tea pile fermentation quality is improved; it is ensured that the chin brick tea quality and flavor are pure, and the quality is stable.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

Microbial fermentation organic fertilizer and preparation method thereof

InactiveCN105198504AShorten stacking timeCompletely harmlessBio-organic fraction processingClimate change adaptationNutrientBiotechnology

The invention discloses a microbial fermentation organic fertilizer and a preparation method thereof. The method comprises steps as follows: (1), stomach content, intestinal content and animal dung of slaughtered animals are added to a drum screen to be separated and screened and then are conveyed to a drum type high-temperature furnace to be heated, and the stomach content, the intestinal content and the animal dung are dried; (2), the dried stomach content, intestinal content and animal dung are added to a high-temperature fermentation tank for aerobic fermentation, and aerobic fermentation products are obtained; (3), the aerobic fermentation products are conveyed to a fermentation workshop, a multifunctional microorganism inoculation agent is added, the mixture is uniformly mixed, compost is fermented, and the organic fertilizer is prepared. The organic fertilizer is prepared from the stomach content, the intestinal content and the dung of the animals, the microorganism inoculation agent is added, the composting time of the fertilizer is shortened, the environment pollution problem caused by stomach content, the intestinal content and the dung of the animals is solved, no toxic or harmful substances are discharged in the composting process, the organic fertilizer is completely harmless, nutrients can be preserved, the content of organic matters in the fertilizer is increased, and accordingly, the quality of the fertilizer is improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

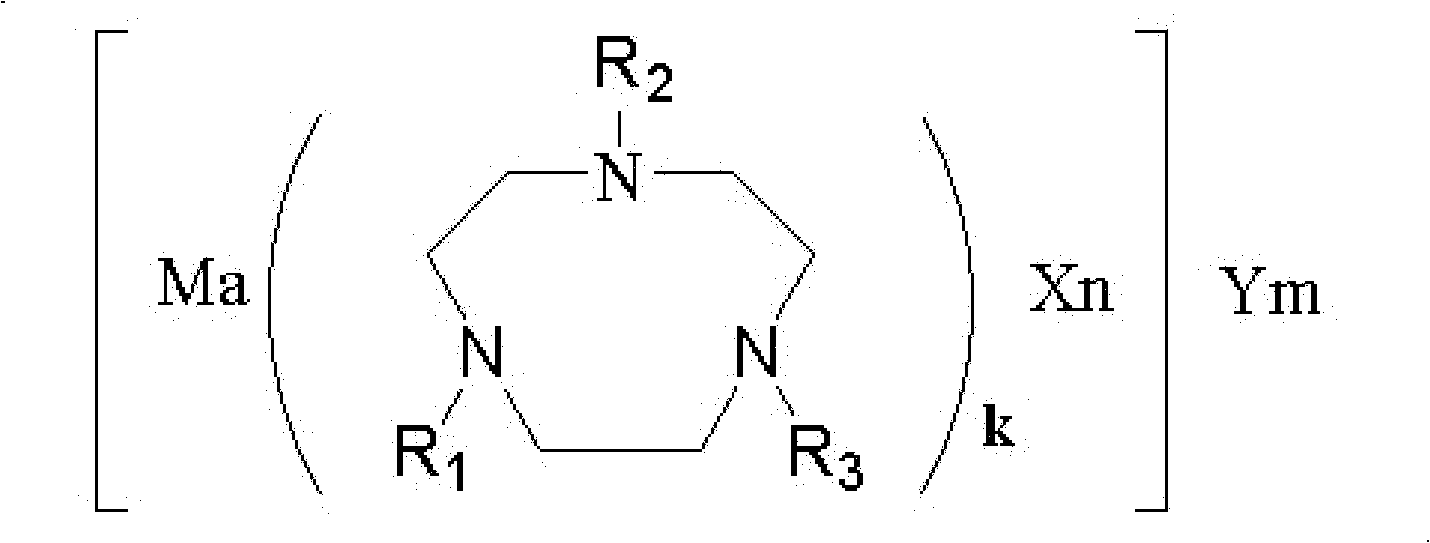

Method for activated bleaching by using 1,4,7-triazacyclononane complexes

ActiveCN101922108AReduce stacking timeAchieve the bleaching effectBleaching apparatusCoordination complexNuclear chemistry

The invention relates to a method for low-temperature activated bleaching by using 1,4,7-triazacyclononane metal complexes, belonging to the field of methods for low-temperature activated bleaching. The method comprises the following steps: (1) taking the 1,4,7-triazacyclononane metal complexes, H2O2, penetrating agents and stabilizing agents and then mixing the substances to obtain bleaching operating fluid with pH value of 7-11; (2) padding the fabrics in the bleaching operating fluid; and (3) carrying out cold pad-batch or steaming on the padded fabrics and then washing the fabrics with water. The method is simple, low in cost, high in production efficiency, environment-friendly, energy-saving and suitable for industrialization and reduces the bleaching temperature, shortens the stacking time and reduces the fabrics damage under the premise of achieving good bleaching effect.

Owner:DONGHUA UNIV

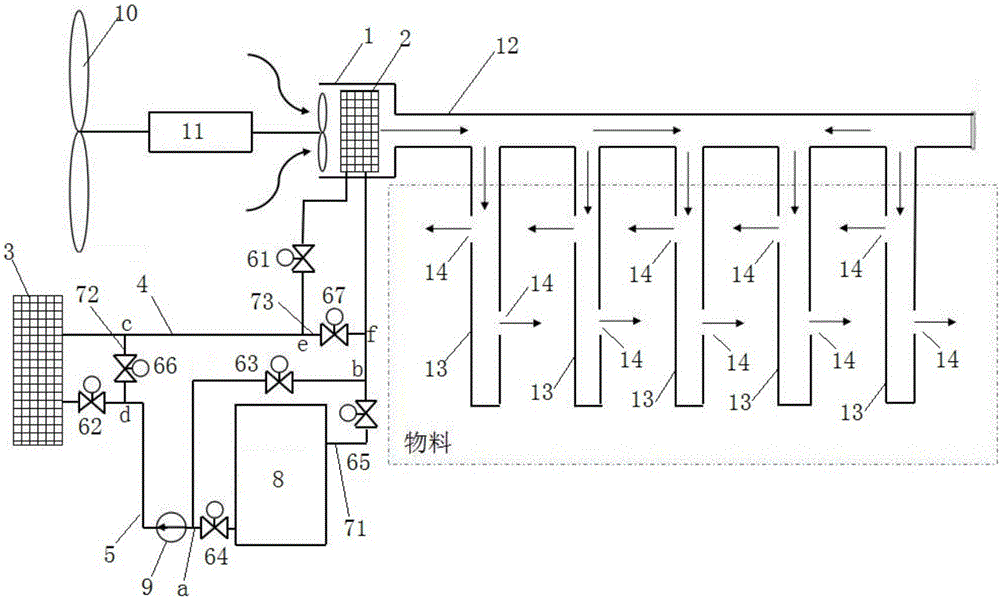

Solar heat collection type drying device and control method thereof

ActiveCN107178989AEfficient use ofEfficient heatingDrying gas arrangementsWind motor combinationsEngineeringTransferring (function)

The invention discloses a solar heat collection type drying device and a control method thereof. The solar heat collection type drying device comprises an air supply device, a heat exchange device (2) and a solar heat collection device. The air supply device comprises a fan (1) capable of rotationally absorb outside airflow and conducting acceleration and pressurization on the airflow, so that materials are dried through the accelerated and pressurized airflow. The heat exchange device (2) is arranged in the fan so as to conduct heat exchange on the airflow entering the fan. The solar heat collection device is used for obtaining solar energy and for transferring the obtained energy to the airflow in the fan through the heat exchange device so as to achieve an airflow heating function. According to the solar heat collection type drying device and the control method thereof, the solar energy can be obtained through the solar heat collection device, the obtained energy is transferred to the airflow in the fan through the heat exchange device, so that the airflow heating function is achieved, heating and heat transferring functions can be achieved on the materials effectively, the drying rate is increased, the drying efficiency is improved, the solar energy is effectively used under the circumstance of the same dry degree, and less energy is consumed.

Owner:乐陵市福惠圆农副产品有限公司

Efficient and energy-saving black raw tea processing equipment

PendingCN106472726AImprove uniformityIncrease aromaPre-extraction tea treatmentThrough transmissionPulp and paper industry

The invention discloses efficient and energy-saving black raw tea processing equipment which comprises fixation equipment, a rolling machine and pile fermentation equipment which are connected in sequence through a transmission mechanism, wherein the fixation equipment is provided with a first exhaust gas discharging opening; the first exhaust gas discharging opening is communicated with an exhaust gas input opening of the pile fermentation equipment through a first pipeline; the pile fermentation equipment comprises a barrel body; the barrel body comprises an outer barrel and an inner barrel which are connected with each other in a sleeving manner; an interlayer is arranged on the barrel body; the exhaust gas input opening is communicated with the interlayer through a second pipeline; the exhaust gas input opening is communicated with the inner barrel through a third pipeline; and exhaust gas of the fixation equipment enters the interlayer or the inner barrel of the pile fermentation equipment for heating or humidifying of tea leaves. The efficient and energy-saving black raw tea processing equipment repeatedly uses residual exhaust gas in the fixation equipment, turns wastes into treasures and effectively uses steam to solve the problem of low utilization rate of the steam of the fixation equipment; energy can be saved; furthermore, the fixation equipment, the rolling machine and the pile fermentation equipment are integrated instead of re-packaging, re-transferring and re-machining; the black raw tea processing efficiency can be improved; and efficient processing is realized.

Owner:湖南惟楚生物科技有限公司

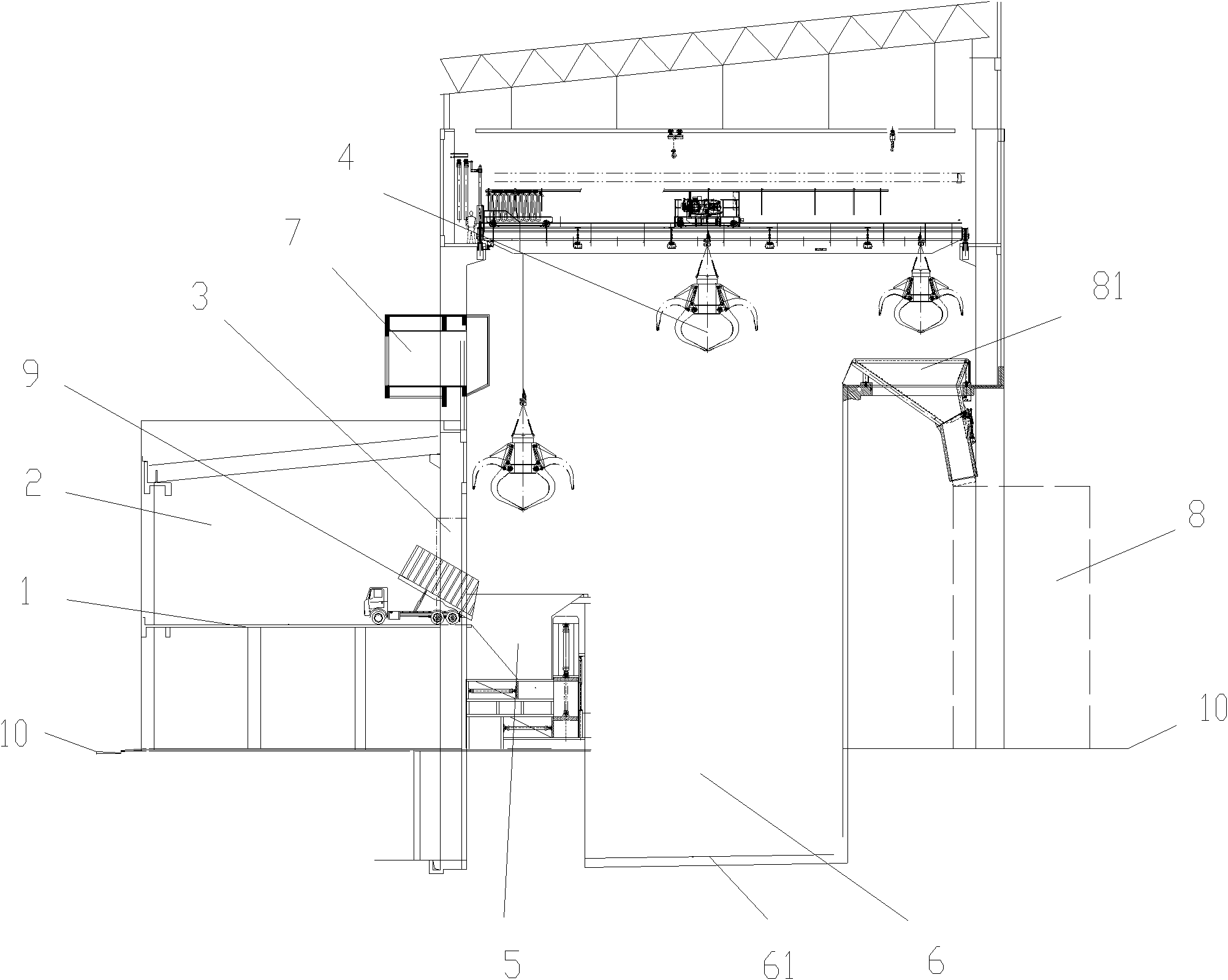

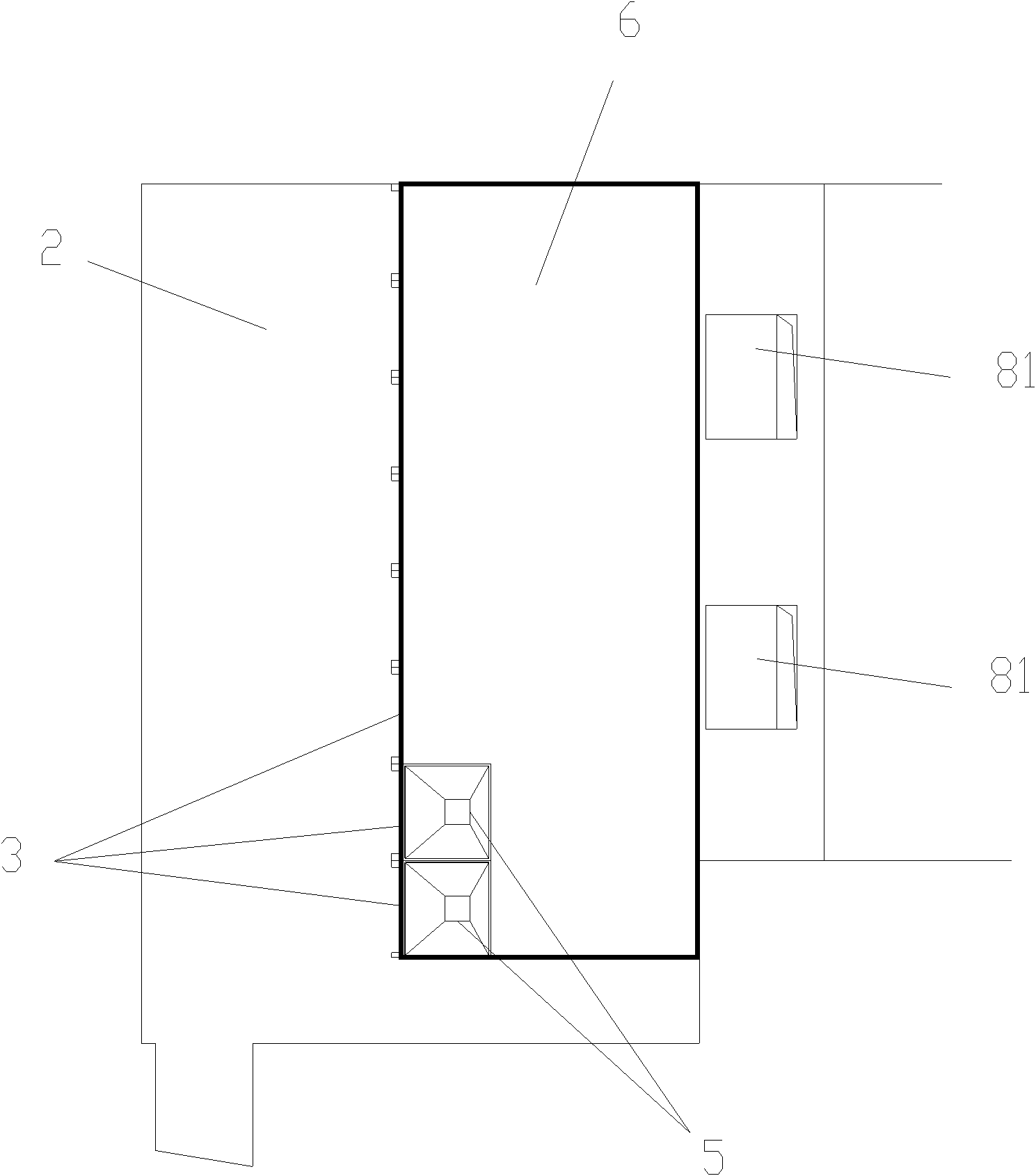

Waste storage tank for dehydrating waste

InactiveCN102091707AImprove dehydration treatment efficiencyStable combustionSolid waste disposalLitterOverhead crane

The invention discloses a waste storage tank for dehydrating waste, which comprises a waste storage tank body, a discharging door arranged at one side of the waste storage tank body, a bridge crane and a waste grab bucket arranged below the top roof of the waste storage tank body, and a compressed waste dehydrator arranged below the discharging door, wherein the compressed waste dehydrator is provided with a collecting hopper with an upward opening, the collecting hopper is positioned below the discharging door, and a discharging platform is arranged outside the discharging door. By the compressed waste dehydrator, the waste storage tank can dehydrate and store crude waste generated by factories in sequence, and also can deeply dehydrate the fermented waste stored in the tank body, remarkably improves the dehydration efficiency of waste, saves the dehydration time of waste, improved the lower heat value of waste, and reduces cost; and the volume of the whole waste storage tank can be reduced.

Owner:SHENZHEN DINGZHU ENVIRONMENTAL PROTECTION TECH

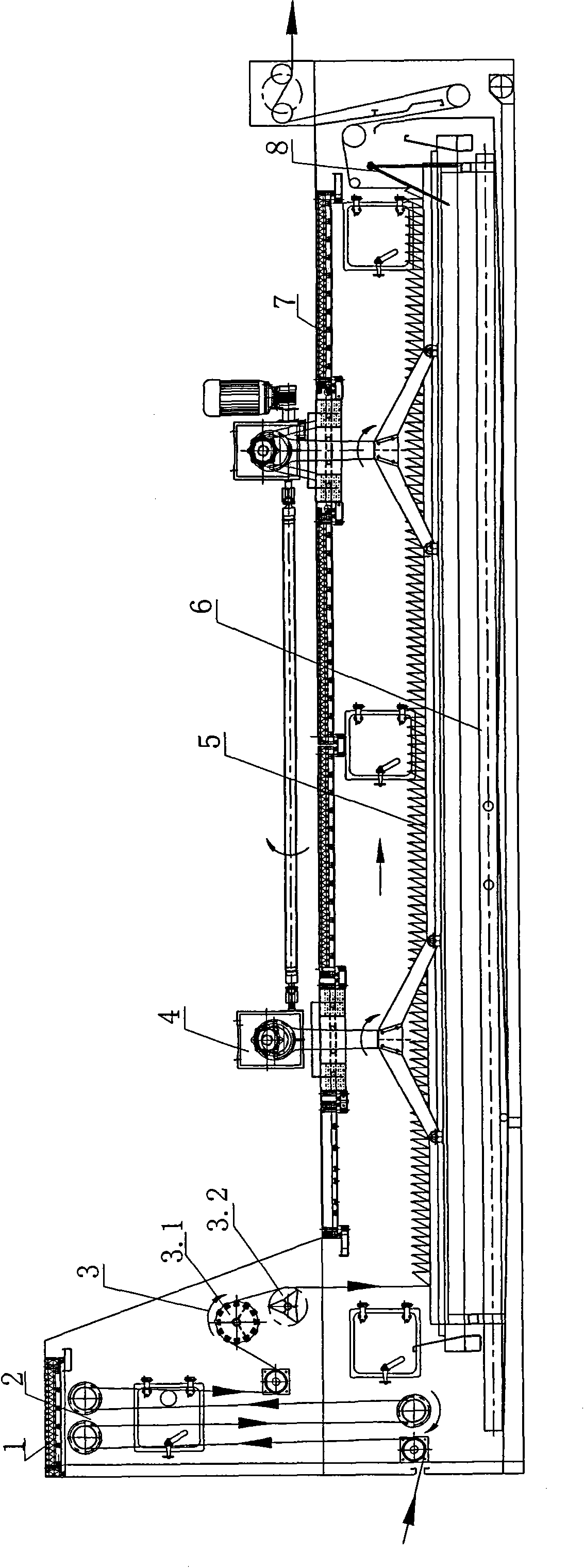

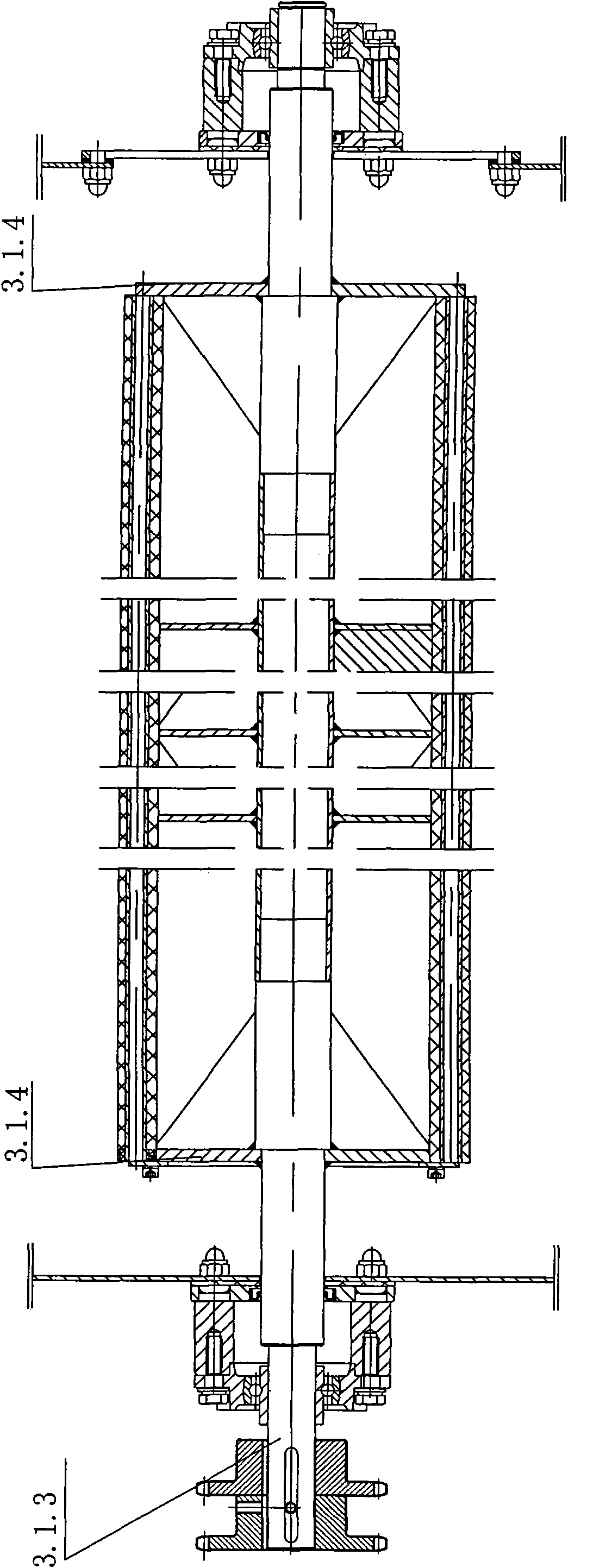

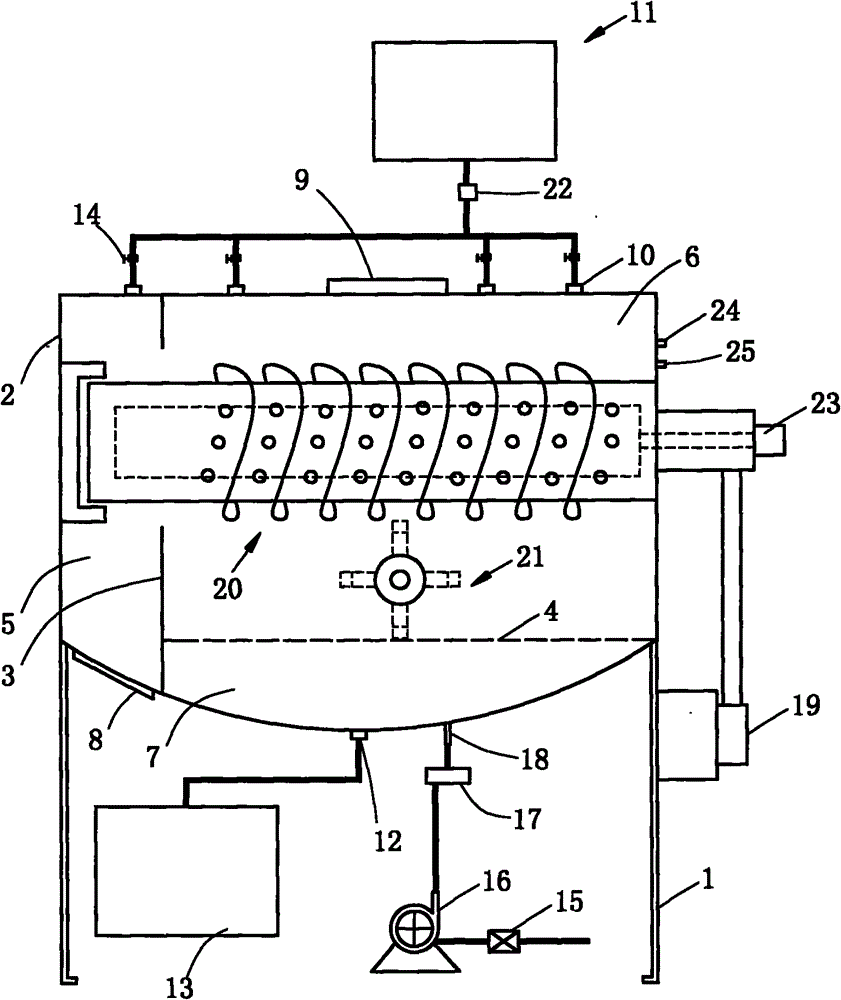

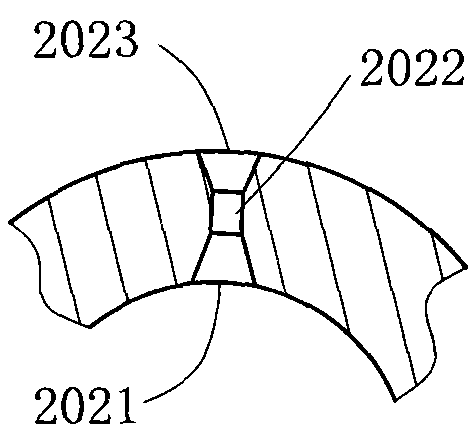

Progressive slow piling steaming box

ActiveCN101892568AReduce stacking timeWon't scratchTextile treatment machine arrangementsTextile treatment carriersPolyesterDrive shaft

The invention relates to a progressive slow piling steaming box which is suitable for the steaming and the rinsing or the dying after the cold pad-batch pretreatment and the piling and the steaming before the printing of pure cotton and cotton-polyester blended fabrics. The steaming box comprises a box body (1), a progressive slow piling device (4) and a cloth supporting basket (5), wherein the progressive slow piling device (4) and the cloth supporting basket (5) are arranged in the box body (1); the progressive slow piling device (4) comprises a gear box motor (4.15), three transmission shafts (4.14), four rocker arm mechanisms and a cloth moving basket (4.16); a plurality of cloth supporting strips I (4.16.1) and a plurality of cloth supporting strips II (5.1) are convexly arranged on the cloth moving basket (4.16) and the cloth supporting basket (5) and distributed along the length direction of the box body; and the cloth supporting strips I (4.16.1) on the cloth moving basket (4.16) and the cloth supporting strips II (5.1) on the cloth supporting basket (5) are mutually spaced. The steaming box can ensure that the surfaces of fabrics cannot be scratched to have grinding defects and can not be scalded and has uniform and thorough steaming effect.

Owner:江阴福汇纺织有限公司

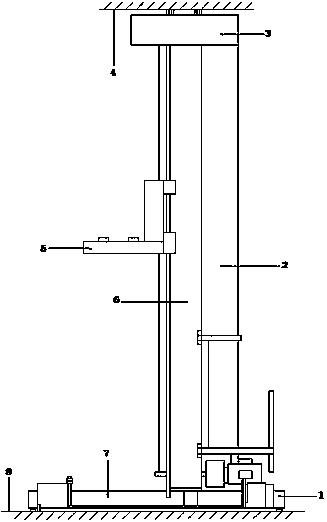

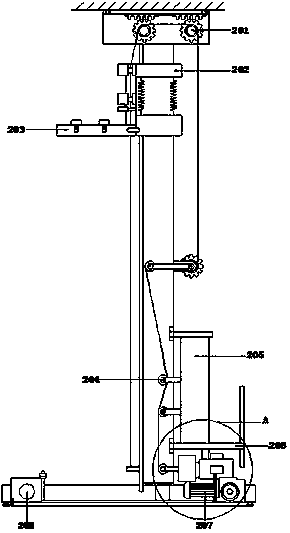

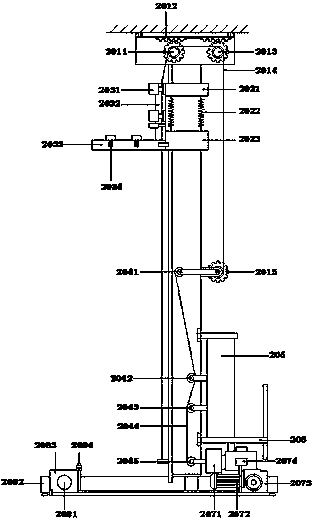

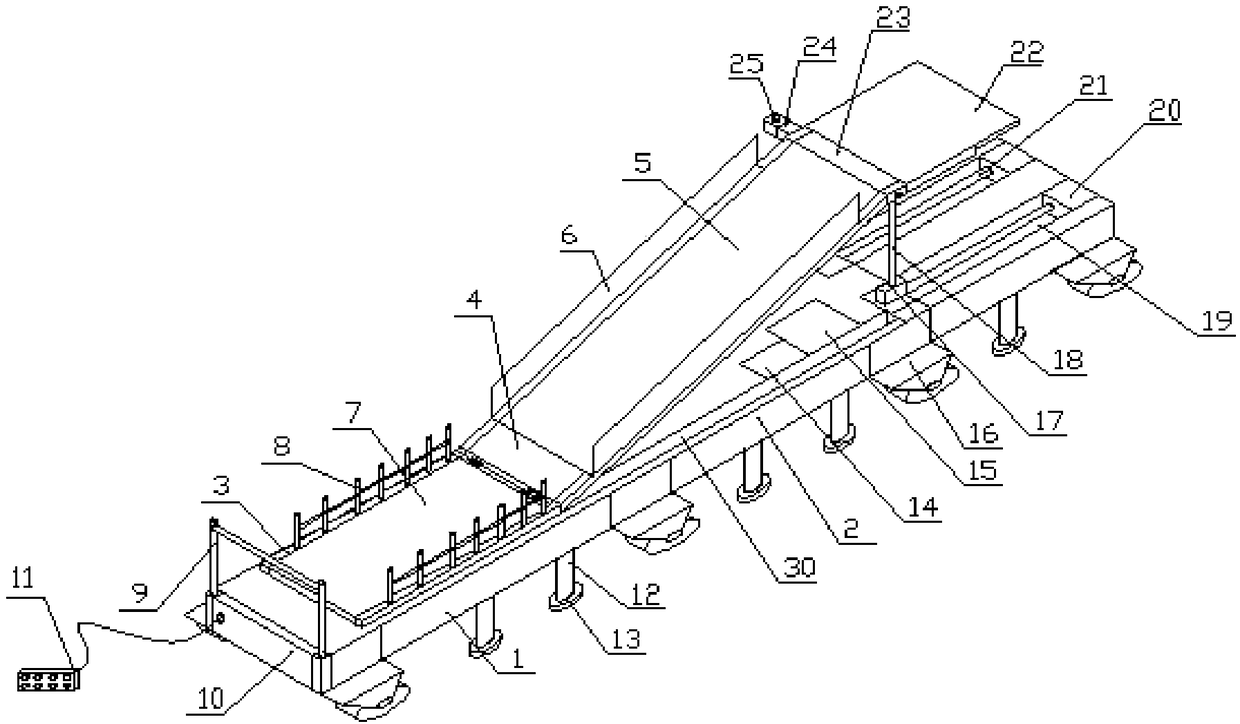

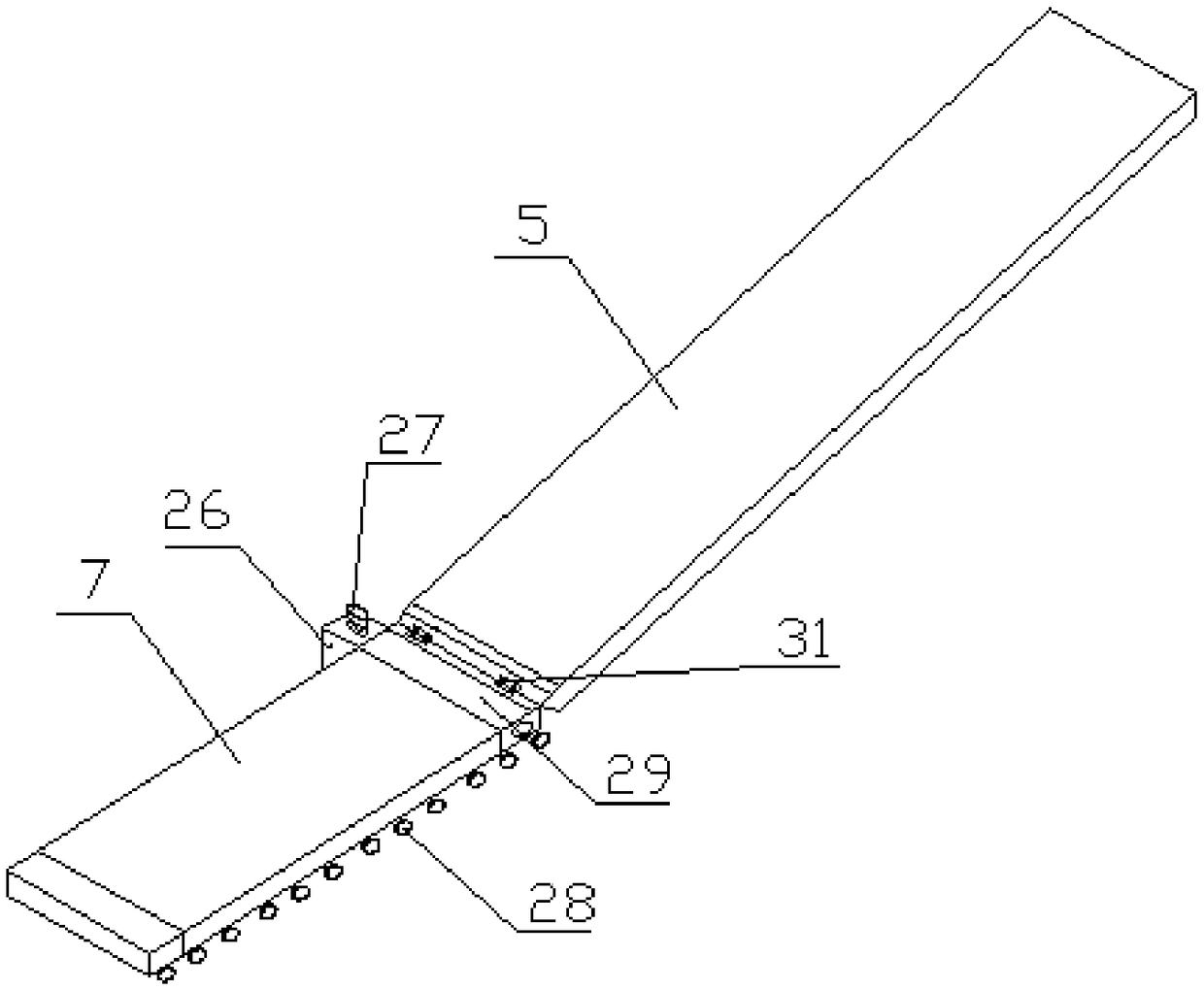

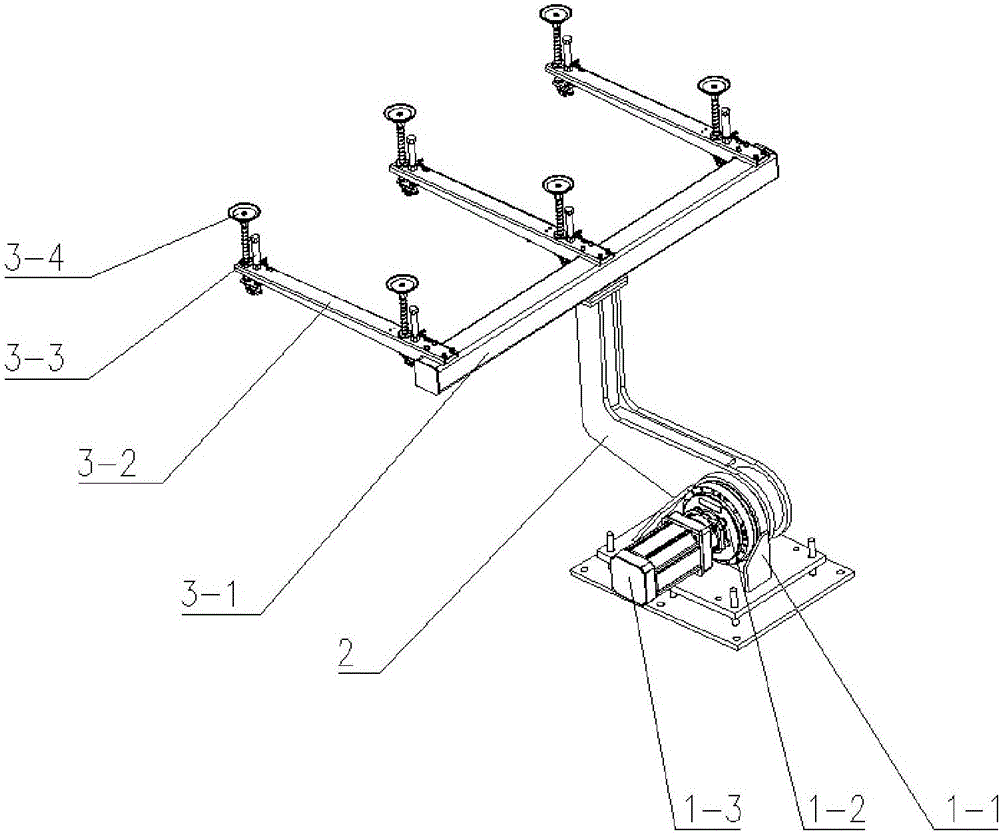

Auxiliary device for electric power construction

The invention discloses an auxiliary device for electric power construction. The auxiliary device structurally comprises an operation mechanism, an auxiliary mechanism, a lifting device, a sky rail, acarrier table, a stand column, a lower cross beam and a ground rail. The operation mechanism is horizontally installed at the right end of the lower cross beam and electrically connected with the auxiliary mechanism, the section of the auxiliary mechanism is of a rectangular structure, the auxiliary mechanism is tightly attached to the right end of the stand column and mechanically connected withthe lifting device, the auxiliary mechanism and the stand column are collinear in axial center, the lifting device is vertically fixed to the lower end of the sky rail and welded to the stand column,and the sky rail and the ground rail are collinear in axial center. By means of the auxiliary device, the defects in the prior art are overcome, a stacker is high in stability, the using effect of the stacker can be effectively ensured, the material stacking speed of the stacker is improved, stacking time is shortened, and the roadway type stacker convenient and fast to use is safe to operate andcontrol and capable of freely switching up-down ascending and descending and front-back movement.

Owner:张钧泠 +3

Mechanical logistics feeder capable of stacking and feeding goods at different heights

InactiveCN108639795ANo falling phenomenonIncrease flexibilityLoading/unloadingLogistics managementHydraulic pump

The invention discloses a mechanical logistics feeder capable of stacking and feeding goods at different heights. The mechanical logistics feeder comprises a feeder body, a base, a storage plate, a connecting plate, a second conveyor belt, a stop plate, a first conveyor belt, a guard rail, a handrail, a brake box, a power control panel, a hydraulic rod, a rubber pad, a hydraulic pump, a hydraulicoil tank, a roller, a piston seat, a second electric electric telescopic rod, a piston groove, a first electric telescopic rod, a connecting rod, a waiting plate, a first roller box, a first gear box,a first motor box, a second gear box, a second motor box, balls, a second roller box, ball grooves and hinges. The mechanical logistics feeder is high in flexibility, quick in feeding and stable in structure, prevents the goods from dropping in a conveying process, guarantees the safety of people, can convey the goods to any height of a carriage, brings convenience for a worker to stack, saves manpower and the stacking time, brings convenience for people to use, and is simple in structure and convenient to popularize.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

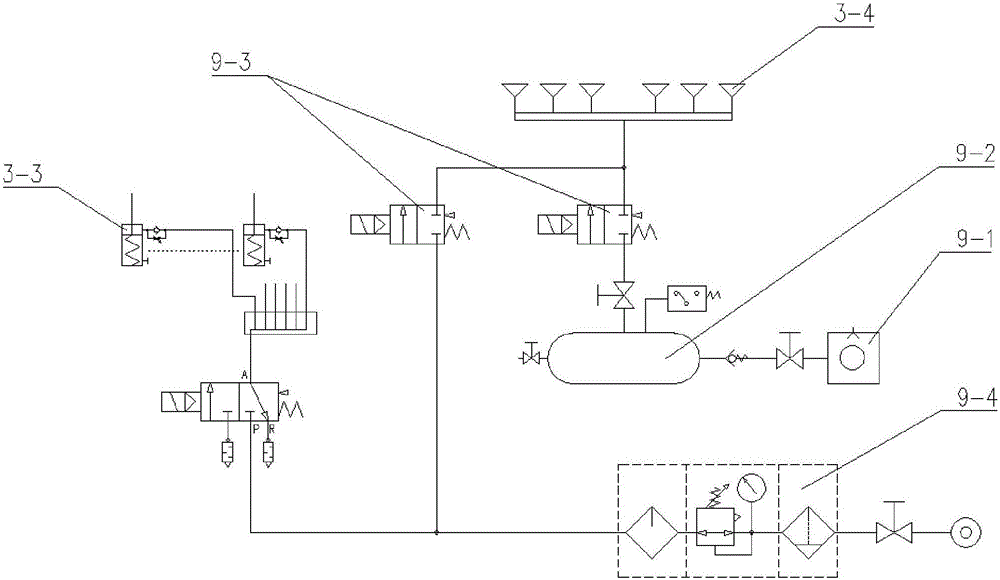

Fast batch-out equipment for rolled glasses

InactiveCN105947678ASimple equipment structureHigh control precisionConveyorsCharge manipulationElectrical controlEngineering

The invention discloses fast batch-out equipment for rolled glasses. The fast batch-out equipment for the rolled glasses comprises an independently arranged main engine seat, a turn-over arm, a sucker stand, an air circuit vacuum system and an electrical control system. A speed reducer and a servo motor are arranged on the main engine seat; one end of the turn-over arm is arranged on an output shaft of the speed reducer on the main engine seat, and the other end of the turn-over arm is connected with the sucker stand; the sucker stand comprises a cross beam, bending arms, a plurality of suckers and air cylinders; the air circuit vacuum system comprises a vacuum pump, a vacuum tank, vacuum control elements and an air source processing unit. The fast batch-out equipment for the rolled glasses provided by the invention is simple and reasonable in structural design, comprehensive in equipment function, safe, convenient and simple to use, high in adjustment accuracy, short in stacking period, and beneficial to greatly improving the production efficiency.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Organic garbage compost device

ActiveCN104829282AReduce stacking timeFully mixed oxidationBio-organic fraction processingOrganic fertiliser preparationLitterVacuum pump

The invention discloses an organic garbage compost device and belongs to the technical field of garbage treatment devices. The organic garbage compost device mainly comprises a material bin which is divided into a material discharge buffer bin, a fermentation bin and a leachate storage bin. Two spiral material feeding rollers are installed rotatably on the material bin and are used for transporting materials from the fermentation bin to the material discharge buffer bin. A stirring roller is installed rotatably in the fermentation bin and is provided with a liquid flowing channel being connected to a hydrogen peroxide pump-feeding pipeline. The stirring roller is provided with a plurality of liquid discharge holes. A plurality of waste gas outlets are formed on the top of the material bin, wherein each waste gas outlet is communicated with a gas path pipeline through a branch gas pipeline. The gas path pipeline is connected to a waste gas treatment apparatus and is provided with a vacuum pump. A leachate outlet is arranged on the bottom of the leachate storage bin and is communicated with a waste water treatment apparatus. The treatment method is reduced in treatment time, is improved in treatment efficiency, is reduced in treatment cost and can be widely applied in garbage treatment.

Owner:YANCHENG TEACHERS UNIV

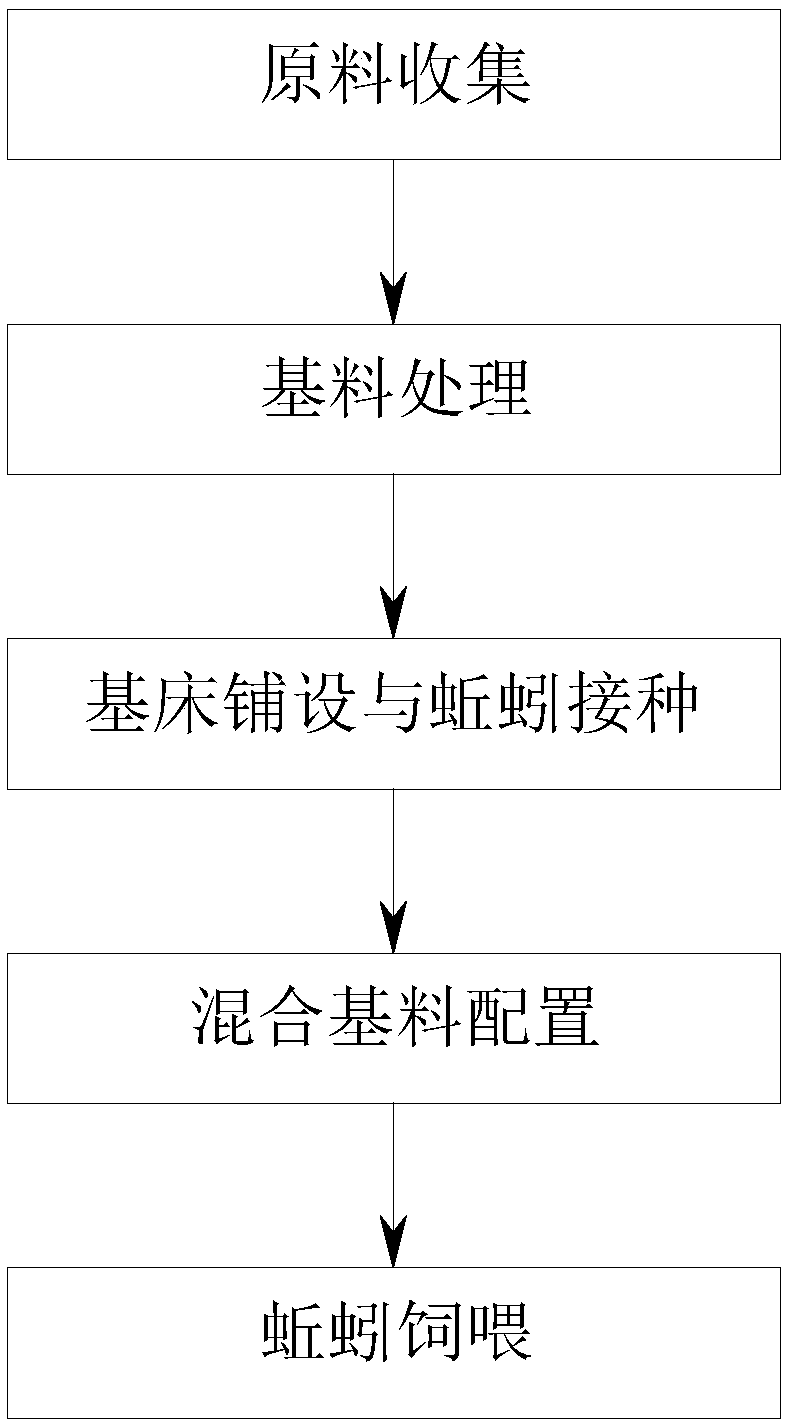

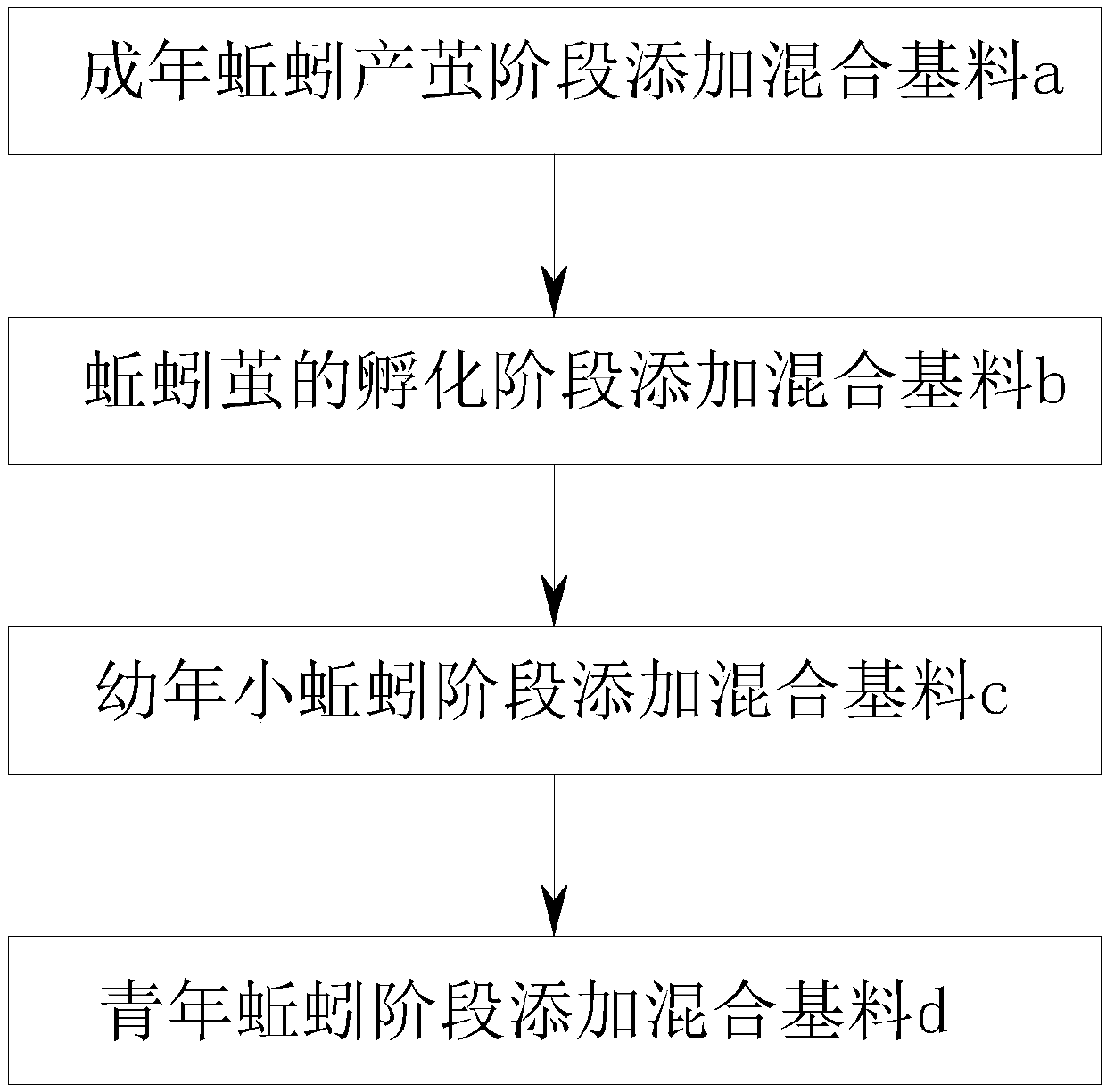

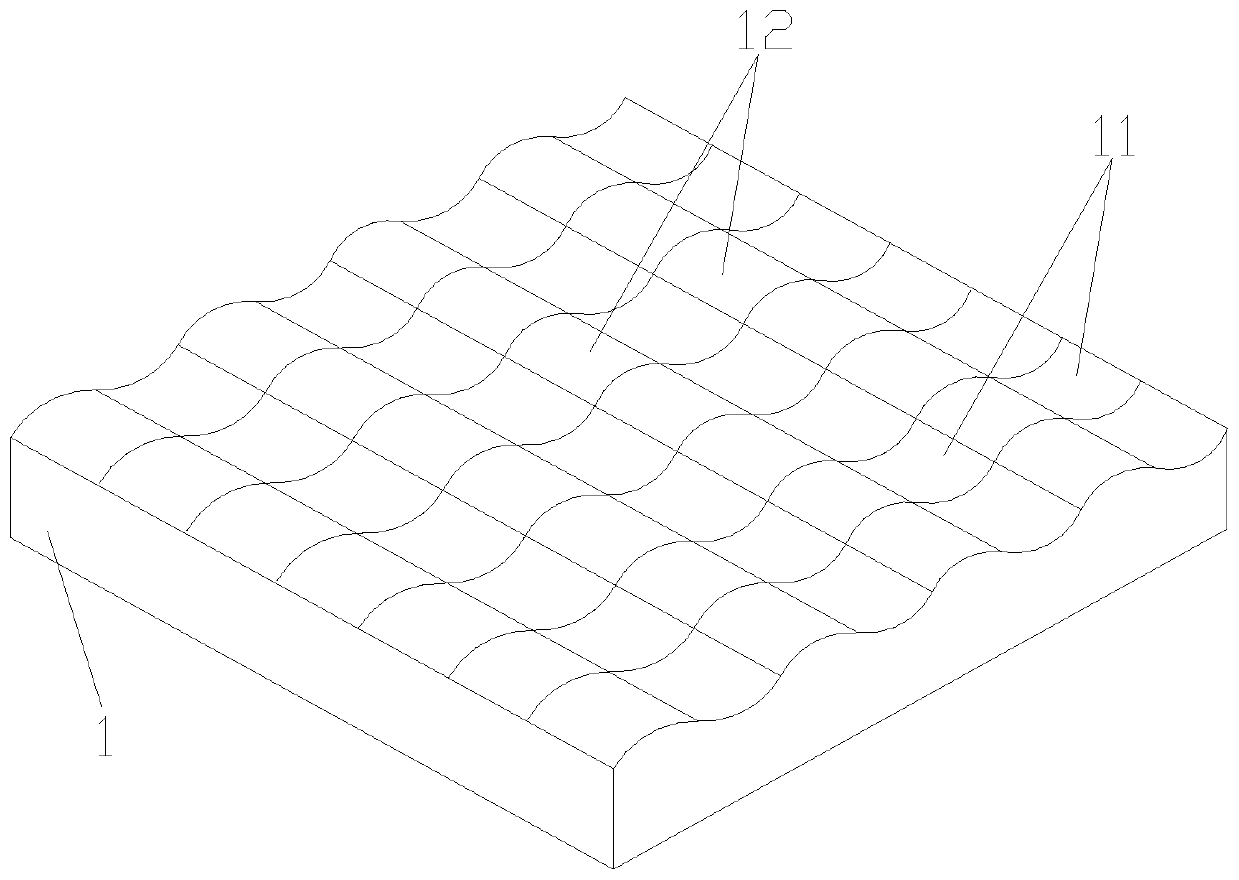

Method for raising earthworms in stages by using dung

InactiveCN109619048AEasy accessOptimum requirements for growthAnimal feeding stuffBiotechnologyTreatment effect

The invention discloses a method for raising earthworms in stages by using manure, which comprises the following steps of: S1, collecting raw materials, and carrying out classified collection treatment on four raw materials of pig manure, cow manure, sludge and straws; S2, treating base materials, measuring the carbon-nitrogen ratio of the raw materials, respectively adding the straws into the pigmanure, the cow manure and the sludge, and adjusting the carbon-nitrogen ratios of the pig manure, cow manure and sludge through the straws; S3, laying a base bed and inoculating the base bed with earthworms, paving the pig manure, cow manure, and sludge base materials prepared in step S2 on a flat ground, and inoculating the earthworms; step S4, preparing the mixed base materials, preparing a mixed base material a, a mixed base material b, a mixed base material c and a mixed base material d from the pig manure, cow manure and sludge base materials treated in step S2 according to a certain mass ratio; S5, feeding the earthworms, and adding different mixed base materials in different growth stages of the earthworms. The method solves the problems that one base material is adopted in the whole stage of earthworm culture in the prior art, the culture yield is low, and the treatment effect of the manure is not ideal.

Owner:SICHUAN PROVINCE NEIJIANG CITY ACADEMY OF AGRI SCI

Raw dark green tea and production process thereof

The invention relates to raw dark green tea and a production process thereof. The production process comprises the following steps: picking fresh leaves from tea trees; conducting enzyme deactivationwith a cylinder to obtain enzyme-deactivated tea; placing the enzyme-deactivated tea in a twisting machine for twisting the tea according to the principle of "light-heavy-light" and obtaining twistedtea; conducting pile fermentation on the twisted tea, completing pile fermentation to obtain pile-fermented tea when water droplets appear on the surface of tea base, tea leaves changes from dark green to yellowish brown, and tea masses become less viscous and can be scattered by beating; scattering and deblocking the pile-fermented tea in order to prevent the tea from being hardened and caked, and then obtaining deblocked tea; drying the deblocked tea to obtain dried tea; aggregating the dried tea and conducting secondary piling and secondary fermentation to obtained piled tea; and drying thepiled tea to obtain the raw dark green tea. According to the invention, the fermentation twice are used to adjust degree of fermentation; and the deblocking process is added to scatter the hardened tea leaves at the first time and prevent presence of masses in the raw dark green tea materials, thereby facilitating the control of product quality.

Owner:CHINATEA HUNAN ANHUA FIRST TEA FACTORY CO LTD

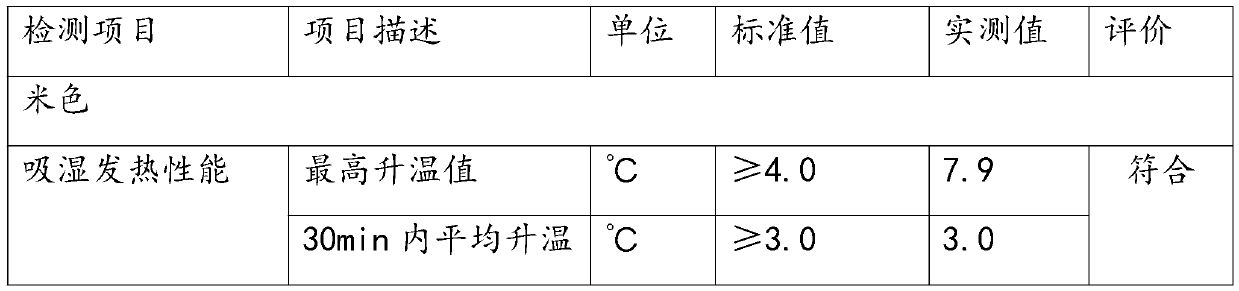

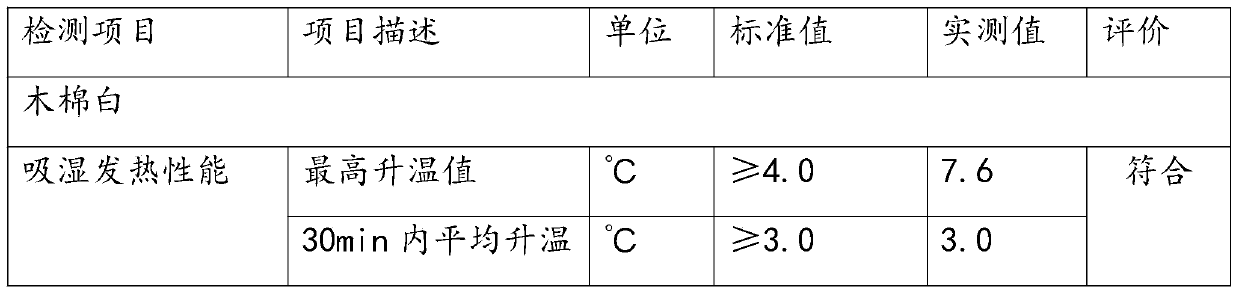

Weaving method of moisture-absorbing heating antibacterial fabric

InactiveCN111350019AImprove the performance of moisture absorption and heat generationEmission reductionWeft knittingYarnCotton fibreSodium silicate

The invention discloses a weaving method of a moisture-absorbing heating antibacterial fabric. The method comprises the following steps of step S1, spinning yarns, including: obtaining kapok fibers and cotton fibers and blending the kapok fibers and the cotton fibers into cotton kapok blended yarns, and similarly, spinning coarse yarns that meet the requirements; step S2, pre-treating the cotton kapok blended yarns to make the cotton kapok blended yarns humidified and soft; step S3, weaving on machine: weaving with a double-sided circular knitting machine to obtain the fabric; and step S4, dyeing and finishing the obtained fabric, wherein the specific process includes: scouring, dyeing, washing, drying, setting, and finally obtaining the moisture-absorbing heating antibacterial fabric; andingredients of a scouring agent used in the scouring process include: caustic soda, penetrant, sodium hydrogen sulfite, trisodium phosphate and sodium silicate. According to the method provided by the invention, the antibacterial effect of the kapok fibers can be exerted, the moisture absorption and heating performance of the fabric can be improved, the kapok fibers can be protected, and besides,the method is simple, the energy consumption can be reduced, the emission of pollutants is reduced, and environmental protection is facilitated.

Owner:杨一伟

Pretreating process for garbage without stack yard

InactiveCN1392001AReduce pollutionGuaranteed to be comparableSolid waste managementSolid waste disposalHazardous substanceEngineering

The pretreating process of garbage without stack yard includes the following steps: sorting; classifying in size; conveying to fermenting tank; and post-treatment. The post-treatment step incldues direct fermenting treatment of garbage below 15 mm in fermenting cylinder; crushing garbage over 15 mm size; sterilizing fermented organic garbage before cooling and grinding; forming organic fertilzierand packing; the present invention has the advantages of reduced used field, reduced environmental pollution caused by stacked garbage, reduced harmful matter entering to the organic fertilizer, and increased fermenting time and thus fertility of the organic fertilizer.

Owner:黄达余 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com