Pre-treatment process for textile fabric

A textile fabric and pretreatment technology, which is applied in the field of textile fabric pretreatment technology, can solve the problems of lack of serialization, specialization, standardization and unified test standards, product whiteness, wool effect, unstable strength, and unsatisfactory cold rolling. Heap process development requirements and other issues to achieve the effect of avoiding holes, improving dyeing effect, and improving chicken paw prints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

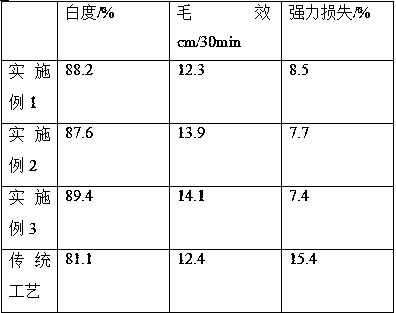

Examples

Embodiment 1

[0032] The pretreatment process of textile fabrics specifically includes: singeing→rolling and cold-stacking working fluid (temperature 30°C)→stacking→hot water washing for 7-10 grids, temperature (98°C)→cold water washing→drying.

[0033] (1) Singeing: wind the dried fabric on the roll of the singeing machine, and use the gas singeing machine for singeing treatment; at the same time, turn the dust removal roller to perform dust removal treatment on the singeed fabric surface;

[0034] (2) Padding and cold-batch working liquid: the fabric after singeing is subjected to one dipping and one padding process; the dyeing tank is filled with padding liquid (temperature 30°C);

[0035] (3) Stacking: Roll the padded fabric on a coiling machine, and then stack it for 2 hours after wrapping;

[0036] (4) Then wash with hot water at 98°C for 7 compartments; then wash with cold water;

[0037] (5) Finally dry.

[0038] Among them, the liquid carrying rate of the padding liquid is ≥85%, ...

Embodiment 2

[0047] The pre-treatment process of textile fabrics specifically includes: singeing→rolling and cold-stacking working fluid→stacking→hot water washing for 8 grids, temperature (98°C)→cold water washing→drying.

[0048] (1) Singeing: wind the dried fabric on the roll of the singeing machine, and use the gas singeing machine for singeing treatment; at the same time, turn the dust removal roller to perform dust removal treatment on the singeed fabric surface;

[0049] (2) Padding and cold-batch working liquid: the fabric after singeing is subjected to one dipping and one padding process; the padding liquid is filled with a temperature of 30~40°C in the dyeing tank;

[0050] (3) Stacking: roll the padded fabric on a coiling machine, and then stack it for 4 hours after wrapping;

[0051] (4) Then wash in hot water at 98°C for 8 compartments; then wash in cold water;

[0052] (5) Finally dry.

[0053] Among them, the liquid carrying rate of the padding liquid is ≥85%, and its spec...

Embodiment 3

[0062] The pretreatment process of textile fabrics specifically includes: singeing→rolling and cold stacking working fluid→stacking→hot water washing for 10 grids, temperature (98°C)→cold water washing→drying.

[0063] (1) Singeing: wind the dried fabric on the roll of the singeing machine, and use the gas singeing machine to perform singeing treatment; at the same time, turn the dust removal roller to perform dust removal treatment on the singeed fabric surface;

[0064] (2) Padding and cold-batch working fluid: the fabric after singeing is subjected to a dipping and padding process; the dyeing tank is filled with padding liquid (temperature 40°C);

[0065] (3) Stacking: Roll the padded fabric on a coiling machine, and then stack it for 6 hours after wrapping;

[0066] (4) Then wash in hot water at 98°C for 10 grids; then wash in cold water;

[0067] (5) Finally dry.

[0068] Among them, the liquid carrying rate of the padding liquid is ≥85%, and its specific components inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com