Full-automatic horizontal glass stacking machine and glass stacking method

A stacker, fully automatic technology, applied in the field of fully automatic glass horizontal stacker, can solve the problems of long stacking time of glass plates, low production efficiency, low grabbing efficiency, etc., and achieve convenient and stable glass grabbing, The effect of improving production efficiency, improving gripping and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

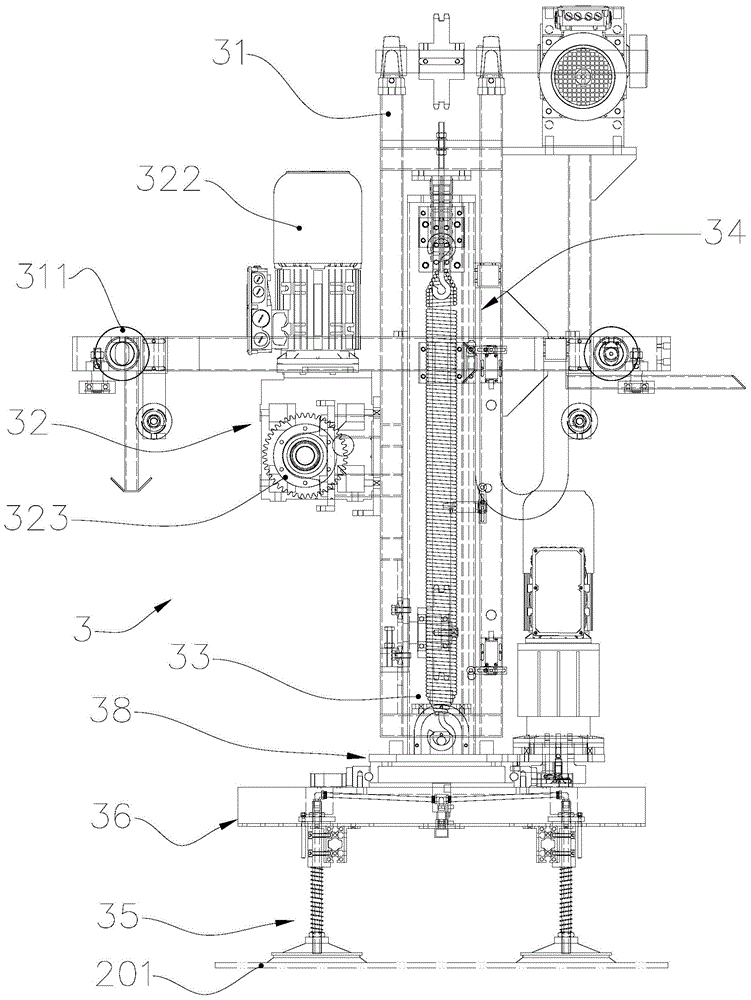

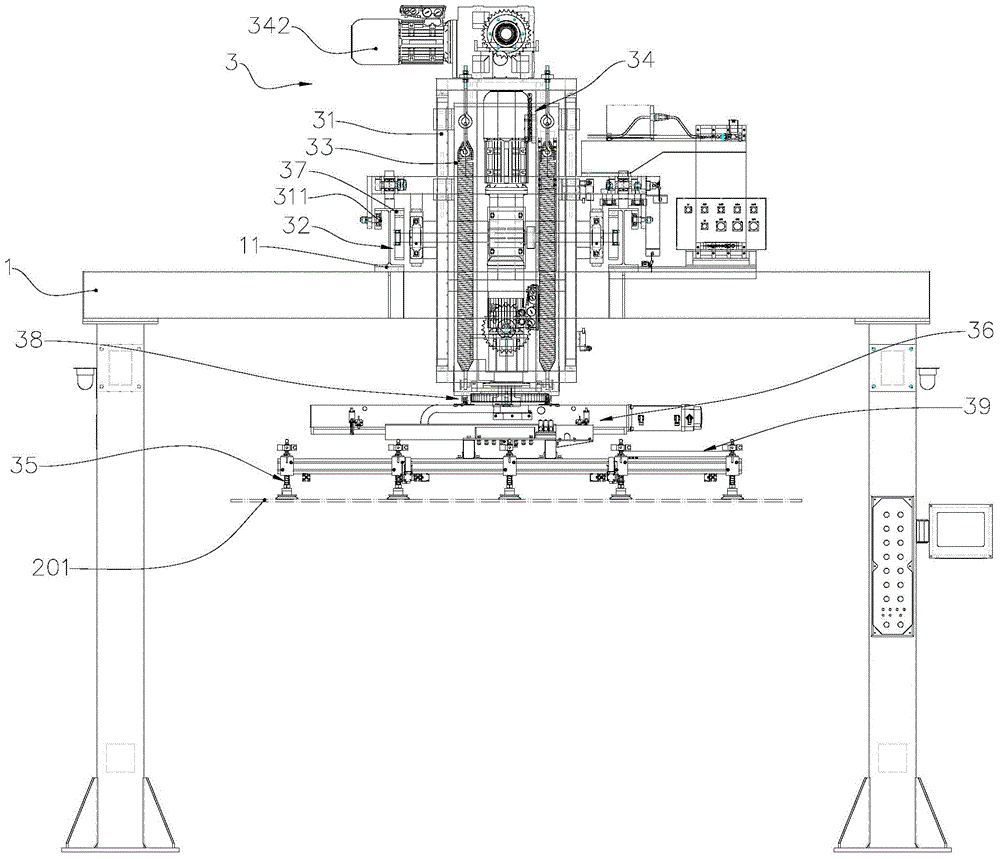

[0035] Such as Figure 1 to Figure 6 Shown is a preferred embodiment provided by the present invention.

[0036] In this embodiment, the float glass production line 200 (hereinafter, for the sake of simplicity, this term is simplified as "glass production line") includes a system for conveying glass sheets 201 (hereinafter, for the sake of simplicity, this term is simplified as "glass") conveying roller table 202, on which a plurality of pieces of glass 201 arranged side by side are placed on the conveying roller table 202. direction of movement) to move.

[0037] The fully automatic glass horizontal stacker 100 provided in this embodiment includes a truss assembly 1 with a cross rail 11 , two stacking platform groups 2 and two suction main machines 3 . Two suction hosts 3 are installed on the cross rail 11 of the truss assembly 1, and can absorb the glass 201 and then move relatively outward, place the glass 201 on the stacking platform group 2 and move relatively inward towa...

Embodiment 2

[0057] The following is attached Figure 7 and Figure 8 , and only describe in detail the differences from Embodiment 1:

[0058] Each stacking platform group 2 includes two rotating and turning platforms 23 , and the two rotating and turning platforms 23 in each stacking platform group 2 are arranged side by side and alternately in the first direction D1 . Each rotary turning platform 23 includes a third base 231, a second rotating shaft 232, a turntable 233, a fourth power member (not shown) for driving the turntable 233 to rotate around the axis of the second rotating shaft 232, a The turning plate 235 and the second turning mechanism 236 that drives the turning plate 235 to turn outward. The bottom of the third base 231 is provided with a third roller 237 and a fifth power member (not shown) that drives the third roller 237 to move along the first direction D1. , another rotating and turning platform 23 is in a waiting state. When the rotating and turning platform 23 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com