Method for separating selenium and mercury from acid mud of copper-lead-zinc smelting sulfuric acid system

A zinc smelting and acid sludge technology is applied in the field of separating selenium and mercury, which can solve the problems of complex process methods, and achieve the effects of shortening stacking time, saving processing costs, and reducing the cost of recovering mercury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] refer to figure 1 , a method of separating selenium and mercury from copper-lead-zinc smelting sulfuric acid system acid mud of the present embodiment comprises the following steps:

[0030] 1) Oxygen pressure alkali leaching acid mud leaching selenium and mercury fixation: Acid mud, sodium hydroxide, and lime are prepared into a slurry with a liquid-solid ratio of 4:1 in a weight ratio of 1:1.21:0.13, and then the reaction is started. Kettle stirring device, close the feed valve and tail gas valve, open the oxygen inlet valve, feed oxygen-enriched gas (such as industrial oxygen) into the reactor, pressurize to 2.0MPa (that is, 20 atmospheres), and then close the oxygen inlet valve. After reheating to 180°C, open the tail gas valve and oxygen inlet valve, and carry out oxygen pressure alkali leaching for 2.5 hours. The tail gas of the reactor is condensed in the condensation tank to remove mercury vapor, and the condensed water is returned to the reactor as a preparatio...

Embodiment 2~6

[0035] Compared with Example 1, a method of separating selenium and mercury from copper-lead-zinc smelting sulfuric acid system acid mud of the present embodiment, its specific operating conditions are shown in the following table:

[0036] The condition of oxygen pressure alkali leaching in the method described in table 1 embodiment 1~6

[0037]

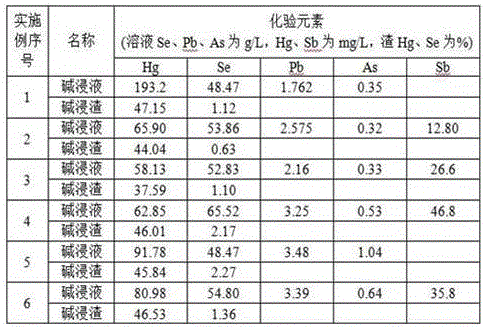

[0038] Adopt the acid mud that the method shown in embodiment 1 ~ 6 is processed, the composition and content of nonferrous metal in the alkali leaching liquid and alkali leaching residue that it obtains are as shown in table 2, come out by selenium, mercury content in the alkali leaching residue Selenium leaching rate, mercury solid residue rate, and mercury volatilization rate are shown in Table 3.

[0039] Table 2 Composition table of alkali leaching solution and alkali leaching residue corresponding to acid mud treatment in Examples 1-6

[0040]

[0041] Table 3 Selenium leaching rate, mercury solid residue rate and mercu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com