Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Solve warping deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

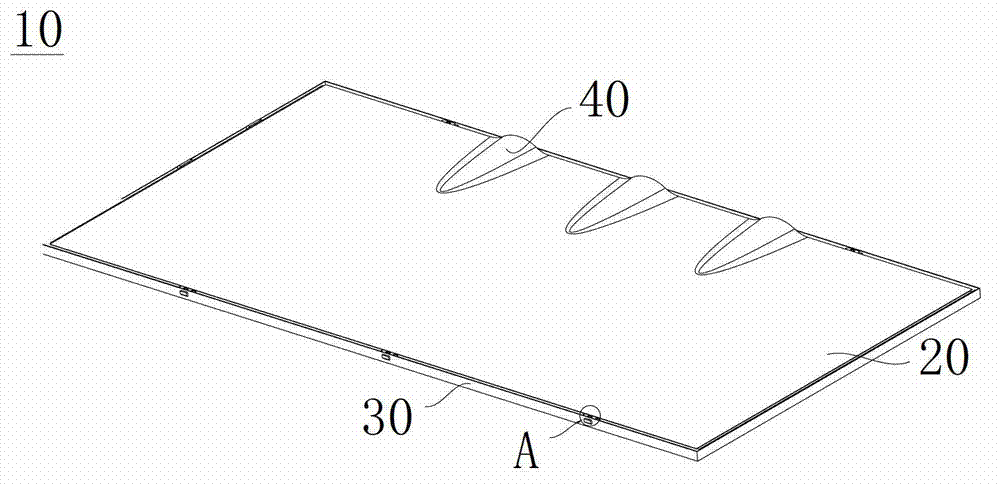

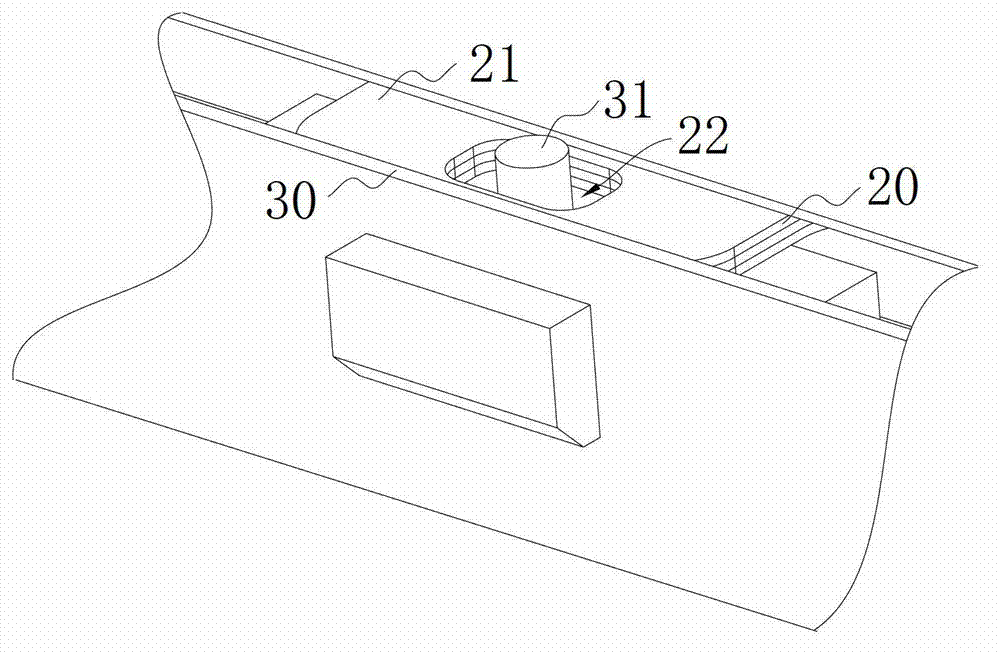

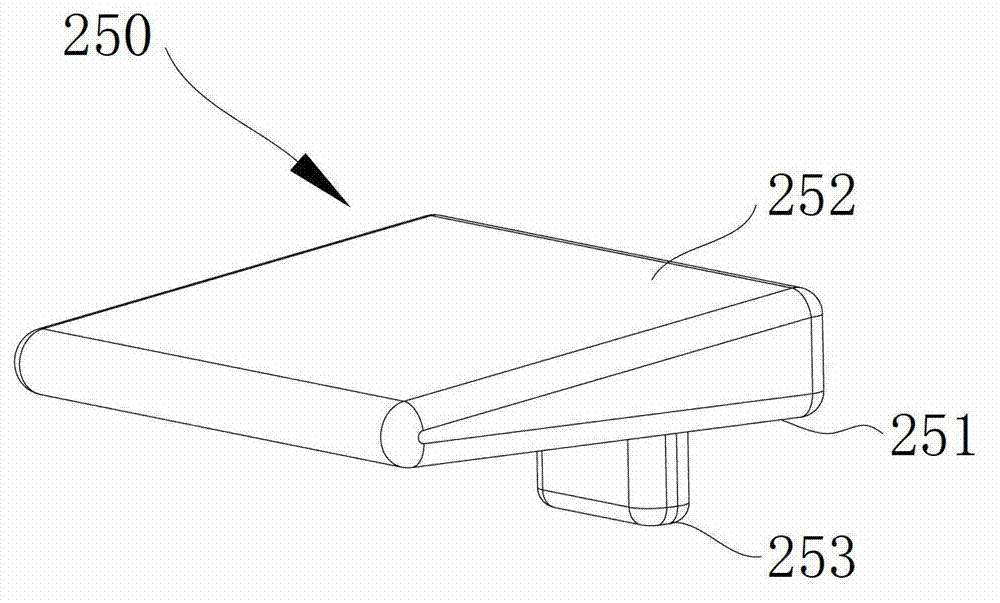

Diaphragm positioning structure and backlight module thereof

ActiveCN103090323ASolve warping deformationImprove Optical TasteLight fasteningsNon-linear opticsEngineeringExtrusion

The invention discloses a diaphragm positioning structure and a backlight module thereof. The positioning structure is used for positioning a diaphragm, and at least one positioning hole is formed in the diaphragm. The diaphragm positioning structure further comprises a positioning framework provided with a first slope facing the diaphragm and a slide block. The slide block is located between the positioning framework and the diaphragm and is provided with a bottom face which contacts with the diaphragm, and a second slope which correspondingly contacts with the first slope. The obliquity of the second slope is gradually raised towards the direction of the outer edge of the diaphragm. A positioning protrusion corresponding to the positioning hole is arranged on the outer edge of the slide block, and the positioning protrusion is arranged in the positioning hole in a penetrating mode. By means of the mutual extrusion between the slope of the positioning frame and the slope of the slide block in the diaphragm positioning structure, the slide block moves towards the outer side of the diaphragm, and the positioning protrusion is used for hanging the positioning hole to exert an outward tensile stress on the diaphragm to tension the diaphragm,. The invention further provides another connecting structure of the slide block and the positioning frame. Through utilization of the slide block to exert the tensile stress on the diaphragm, the harmomegathus quantity of the diaphragm due to temperature change can be adjusted to solve the problem of warping of the diaphragm.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

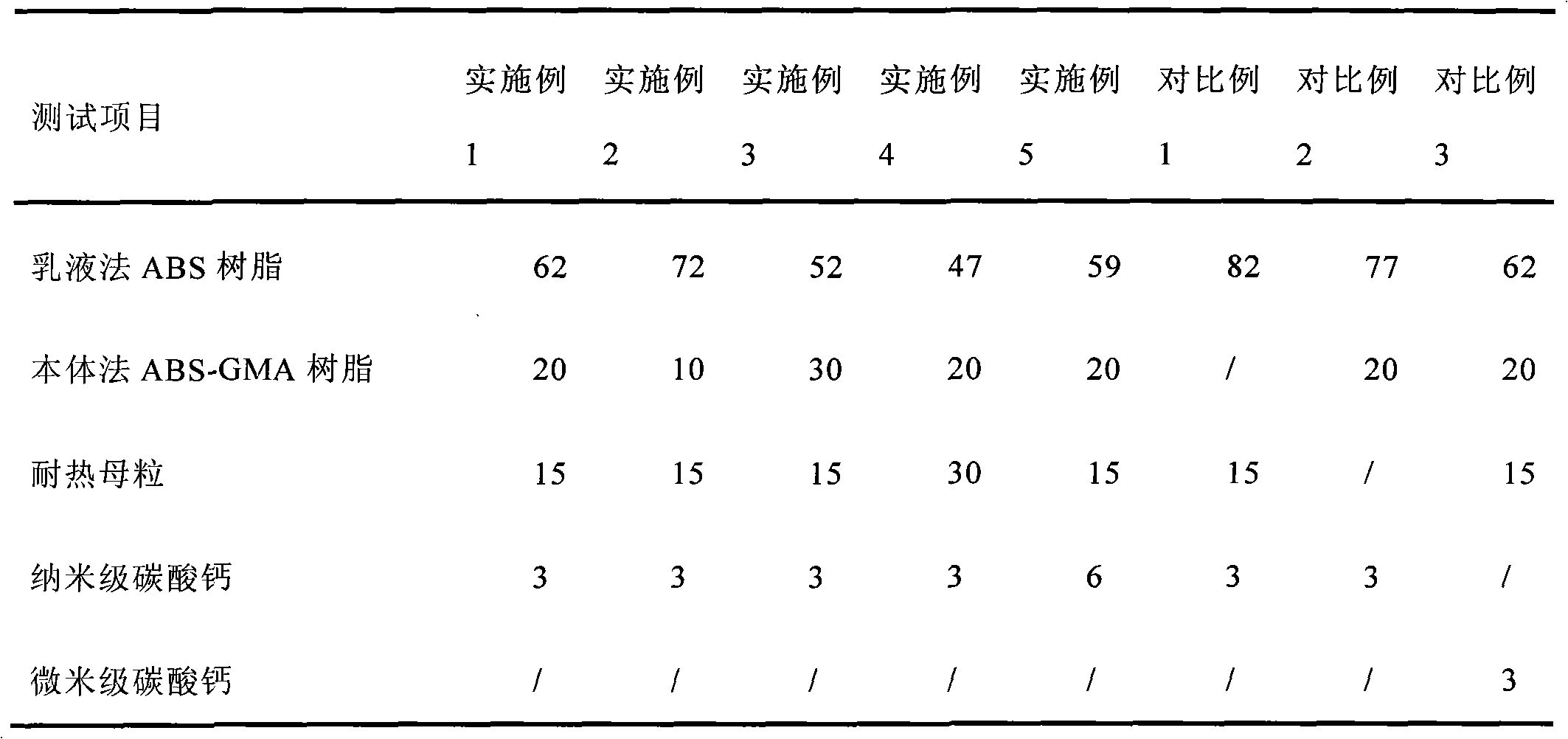

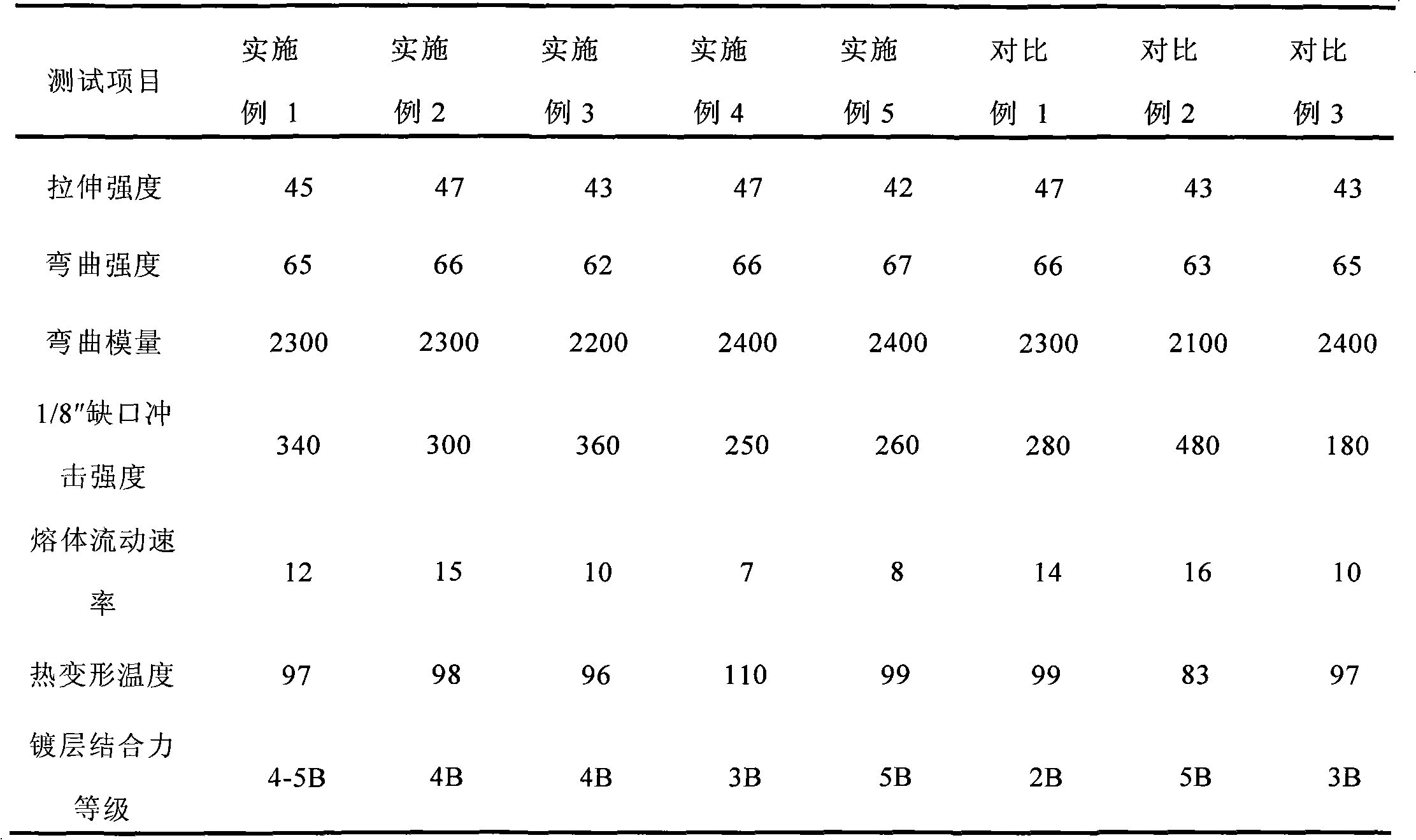

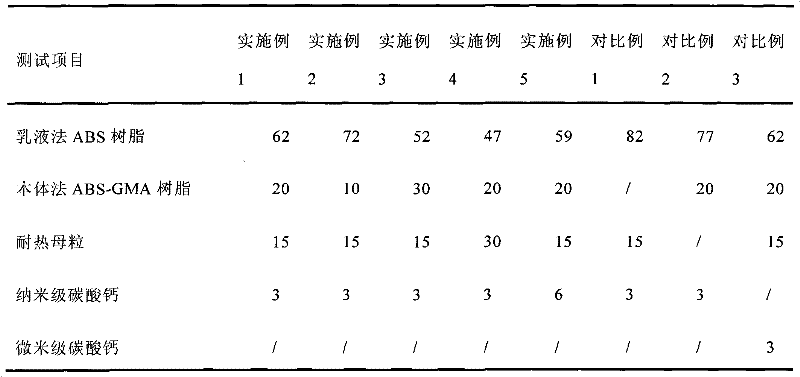

Electroplating ABS composite and preparation method thereof

InactiveCN101817967AEnhance physical anchoring strengthStrengthen the bonding force of molecular bondsElectrolytic organic material coatingEmulsionElectrical polarity

The invention relates to an electroplating ABS composite and a preparation method thereof. The composite comprises the following components in part by weight: 40 and 80 parts of emulsion process ABS resin, 5 to 30 parts of mass ABS polar graft, 10 to 30 parts of heat-resisting master batch, 2 to 8 parts of nano stuffing and 0.1 to 0.5 part of antioxygen. The preparation method comprises the following steps of: putting the components except the nano stuffing into a high-speed stirrer and stirring the components to obtain a mixture; adding the mixture into a two-screw extruder from a main feed inlet of the two-screw extruder and adding the nano stuffing into the two-screw extruder from a lateral feed inlet; and extruding and granulating the obtained product to obtain samples. The electroplating ABS composite prepared by the method has a good electroplating effect, the high solidity of a metal electroplated layer, high temperature resistance, high dimensional stability and high impacting strength, avoids part buckling deformation, metal coat cracking, bubbling, plastic exposure, even large area obscission and the like in a high and low-temperature cycling test and is particularly applied to automotive electroplated parts such as a radiator grille and an instrument frame of an automobile.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

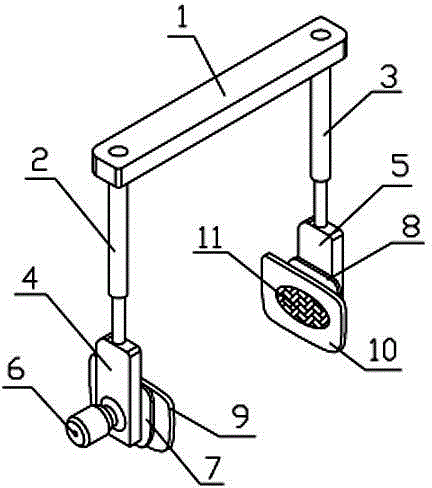

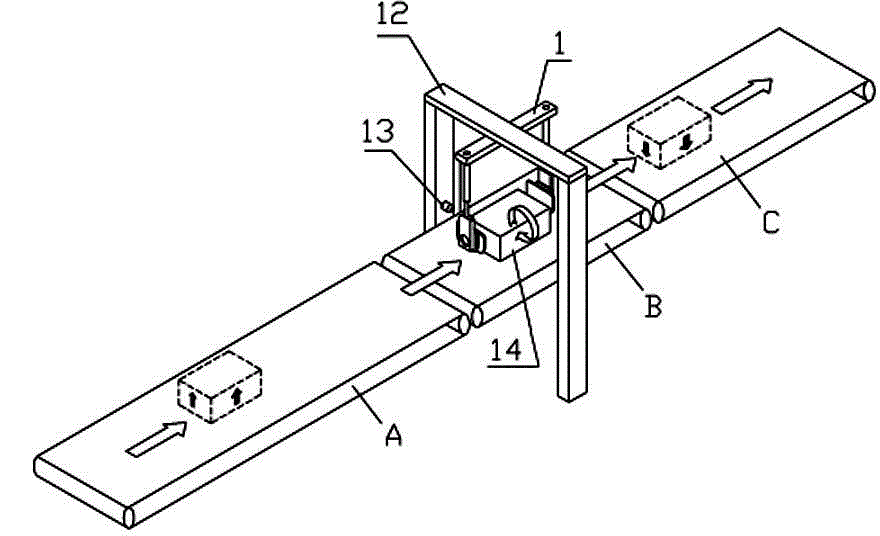

Automatic packaging line finished product whole box automatic turning machine and method for turning box bodies through automatic packaging line finished product whole box automatic turning machine

InactiveCN104444283ASolve warping deformationMake up for design flawsConveyor partsProduction lineDrive motor

The invention discloses an automatic packaging line finished product whole box automatic turning machine which comprises a horizontal fixed beam. A left lifting rod and a right lifting rod are vertically arranged at the two ends of the fixed beam downwards. A left shoe block and a right shoe block are symmetrically and fixedly arranged at the lower end of the left lifting rod and the lower end of the right lifting rod. A driving rotating disc driven by a drive motor to rotate is arranged on the inner side of the left shoe block. A driven rotating disc driven by a telescopic cylinder to move forwards and backwards is arranged on the inner side of the right shoe block. The position of the driven rotating disc corresponds to the position of the driving rotating disc. The invention further discloses a method for turning finished product box bodies through the automatic turning machine. The automatic turning machine is simple in structure and convenient to use, the problem that top layer box covers are warped up and deform after the finished product box bodies conveyed out of an automatic packaging production line of a workshop are stacked can be fundamentally solved, and the design defects of the automatic packaging production line are overcome. Meanwhile, operation is easy, a control device can selectively turn the box bodies placed on the uppermost layer of a stack according to a set value of a counter, and the work requirements of the high-speed packaging line are completely met.

Owner:HENAN XINDOUCAI PRINTING

SiC ceramic thin-layer bullet-resistant material for laminated armor, and preparation method of material

The invention relates to a SiC ceramic thin-layer bullet-resistant material for a laminated armor and a preparation method of the SiC ceramic thin-layer bullet-resistant material. The SiC ceramic thin-layer bullet-resistant material is a gel-casting sheet prepared from the following raw materials: silicon carbide micro powder, boron carbide micro powder, acrylamide monomer, N'N-methylene bisacrylamide, tetramethyl ammonium hydroxide, tributyl phosphate, deionized water and ammonium persulfate. The invention also provides the preparation method of the SiC ceramic thin-layer bullet-resistant material. According to the SiC ceramic thin-layer bullet-resistant material, a silicon carbide ceramic sheet which is large in size, compact and smooth can be prepared; the SiC ceramic thin-layer bullet-resistant material is adjustable in size, good in hardness and good in fracture toughness, and is high in protective capability as a bullet-resistant material for the laminated armor.

Owner:SHANDONG UNIV

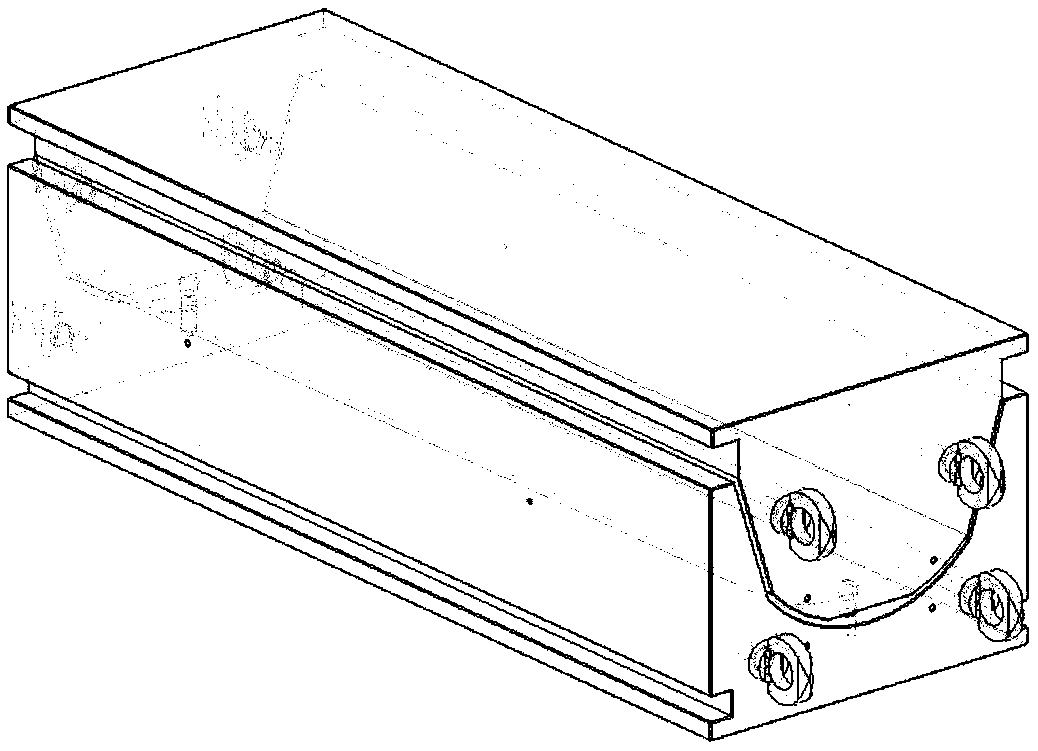

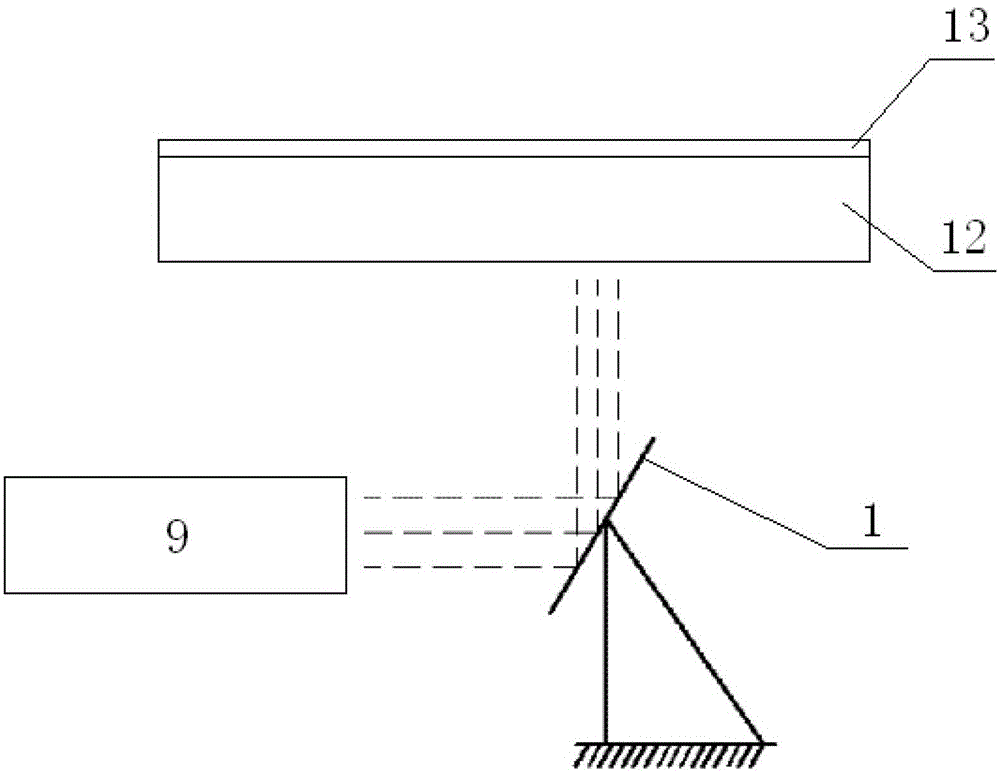

Heat radiating process method for printed-circuit board

ActiveCN103037670AExcellent heat dissipationImprove insulation performanceCooling/ventilation/heating modificationsConductive materialsTemperature wave

The invention discloses a heat radiating process method for a printed-circuit board, belongs to electron technology, and applies to the technical field of avionics. The a cold plate is bonded on a printed-circuit board through a dedicated bonding device, a component is enabled to grovel on the cold plate, and heat radiating is carried out through the bonding membrane material and the cold plate, wherein the membrane material is arranged among the printed-circuit board base materials, the metal conducting materials on the inner portion and the surface of the printed-circuit board, the printed-circuit board and the cold plate. The cold plate is formed by arranging holes in an aluminium alloy plate according to the welding locating of the components of the printed-circuit board through hard anodic oxidation surface treatment. The bonding material between the printed-circuit board and the cold plate is a polyimide double-faced adhesive membrane. The bonding device is a convex thick steel mold plate and a concave thick steel mold plate with a certain curvature, and enables the printed-circuit board and the cold plate can be completed a flattening function simultaneously with bonding. The heat radiating process method for the printed-circuit board achieves the processing of the bonding and the flattening of the cold plate and the printed-circuit board at one time, solves the problem of product performance deterioration due to the fact that heat emitted by component after being powered on can not be released in time, increases the mechanical strength, the antiseptic property and the insulating property of the printed-circuit board, and restrains the layer splitting and the deformation of the printed-circuit board generated by high-temperature wave soldering.

Owner:SHAANXI QIANSHAN AVIONICS

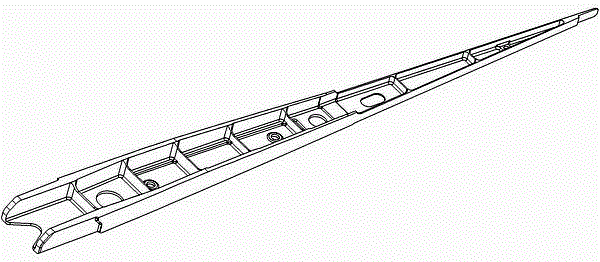

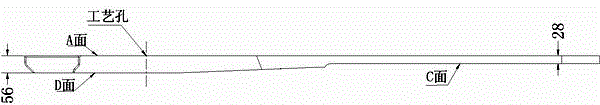

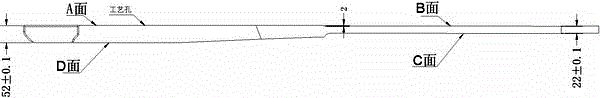

Die forging single-sided thin-walled structure beam part variation compensation machining method

The invention relates to a die forging single-sided thin-walled structure beam part variation compensation machining method, and belongs to the field of machining methods. After die forging single-sided thin-walled structure beam parts are machined by the compensation machining method, the warping deformation amount of the parts is controlled within 3mm, all the parts are qualified after slight calibration, and the quality of the parts is effectively ensured. Machining of the die forging single-sided thin-walled structure beam parts is popularized in factories, and the problem of warping deformation of the parts is effectively solved.

Owner:JIANGXI HONGDU AVIATION IND GRP

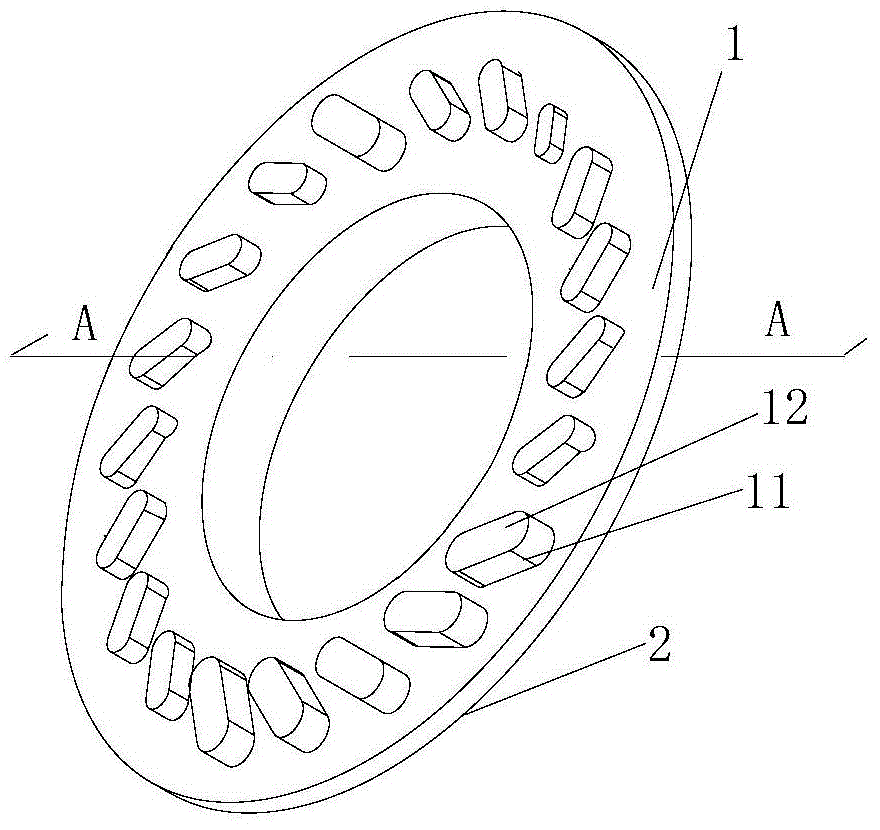

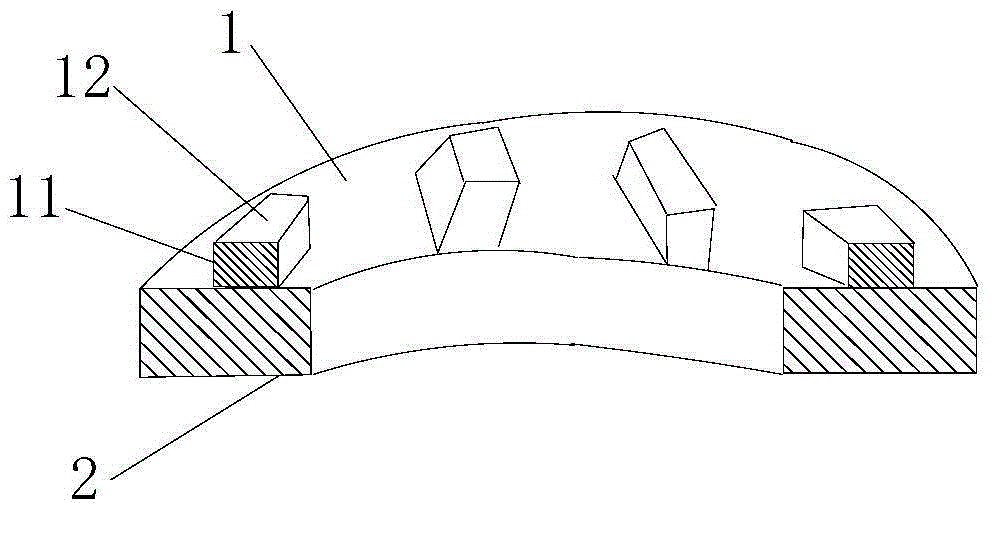

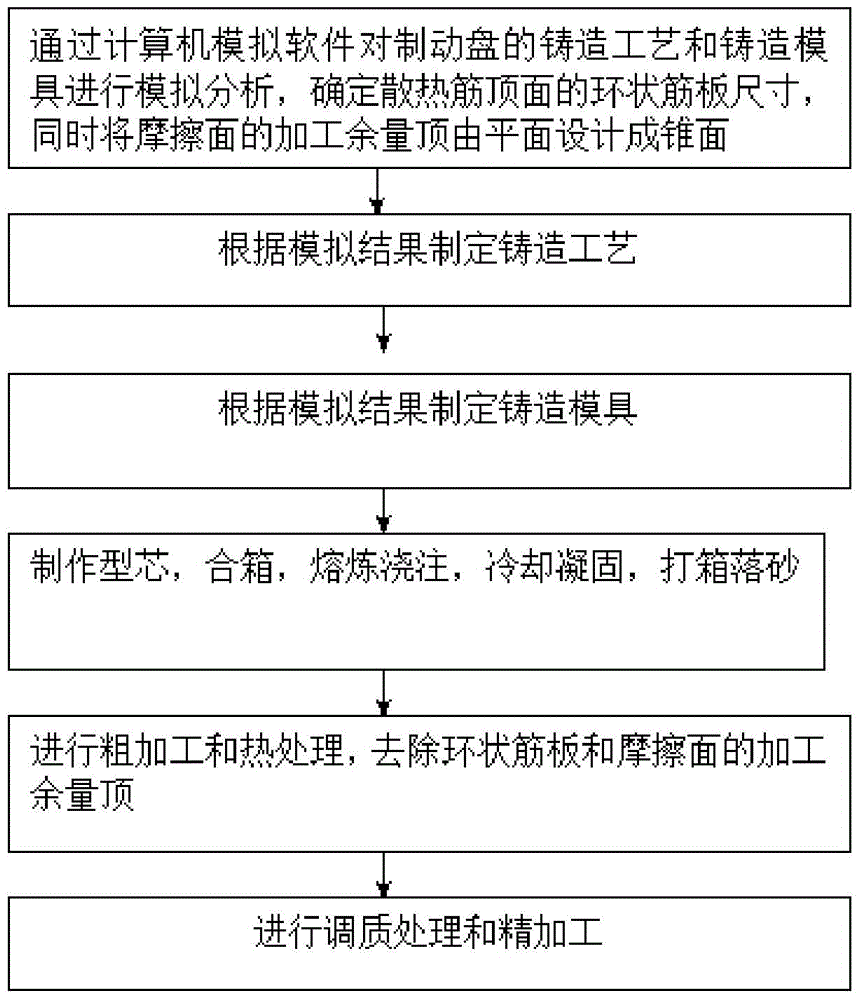

Wheel-like braking disc production method and wheel-like braking disc produced by using wheel-like braking disc production method

ActiveCN106392016ASolve warping deformationSolve defects that form wavy surfacesBraking discsFoundry mouldsDynamic balanceEngineering

The present invention relates to a wheel-like braking disc production method and a wheel-like braking disc produced by using the wheel-like braking disc production method. According to the present invention, during the wheel-like braking disc casting process, an integral and annular rib plate is additionally arranged on the heat dissipation rib top surface of the heat dissipation surface of a braking disc, the annular rib plate and the braking disc are subjected to one casting molding, and the heat dissipation rib top surfaces are connected one by one to form a stable annular frame structure with double rings arranged on the upper surface and the lower surface; during the cooling solidification process after the casting, the annular rib plate on the heat dissipation rib top surface is firstly solidified so as to fix a heat dissipation rib, such that the shrinkage is significantly uniform when the cast is cooled, and the warping deformation generated due to the asymmetric geometrical size of the cast can be avoided; the machining allowance top surface of the friction surface of the braking disc is designed into to a tapered surface so as to increase the cast deformation resistance and make the cast maintain the stabilized shrinkage; and after the cooling molding, the annular rib plate is removed through the machining and the machining allowance top surface of the friction surface is processed into the plane, such that the cast structure shape is not affected, and the product dynamic balance detection qualification rate is substantially improved.

Owner:JIANGSU DINGTAI ENG MATERIAL

Technical method for controlling warping deformation of aluminum alloy thin-wall part in 3D printing process

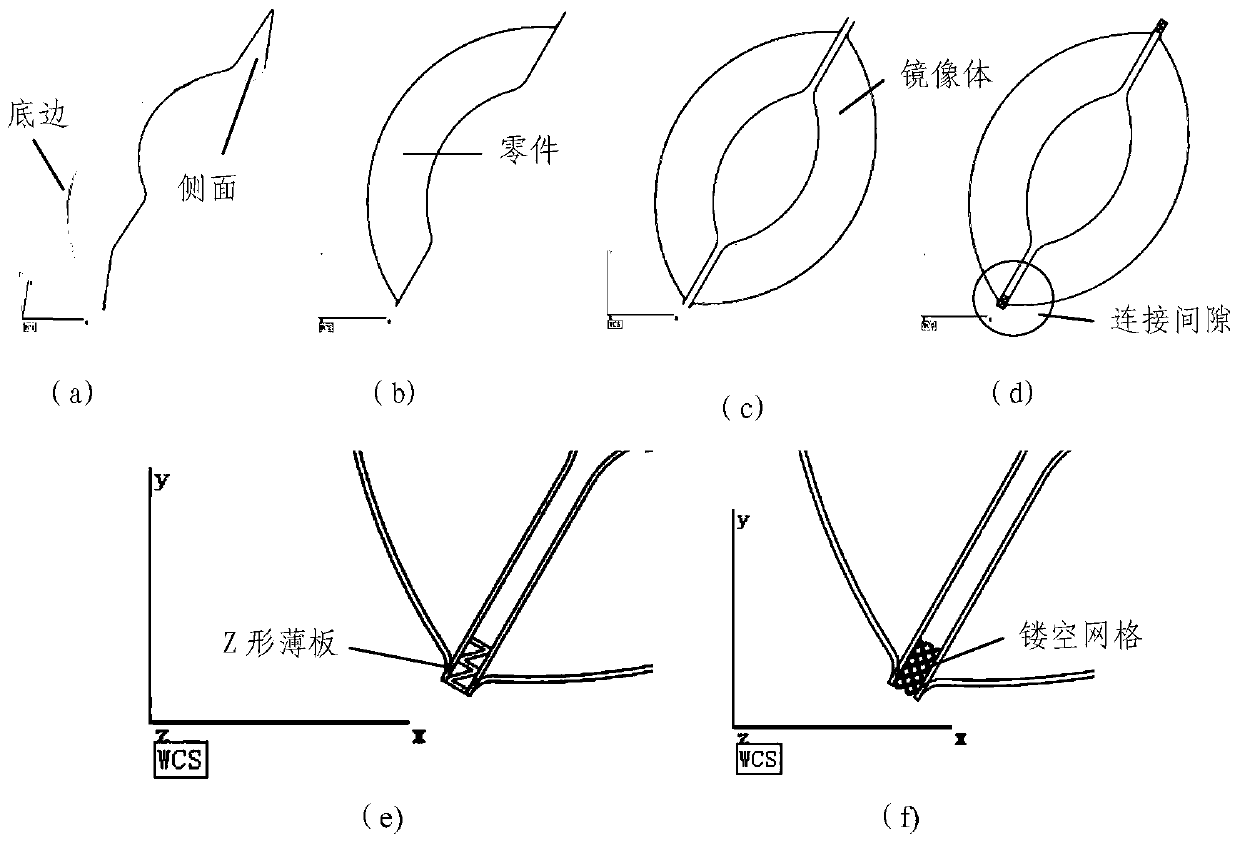

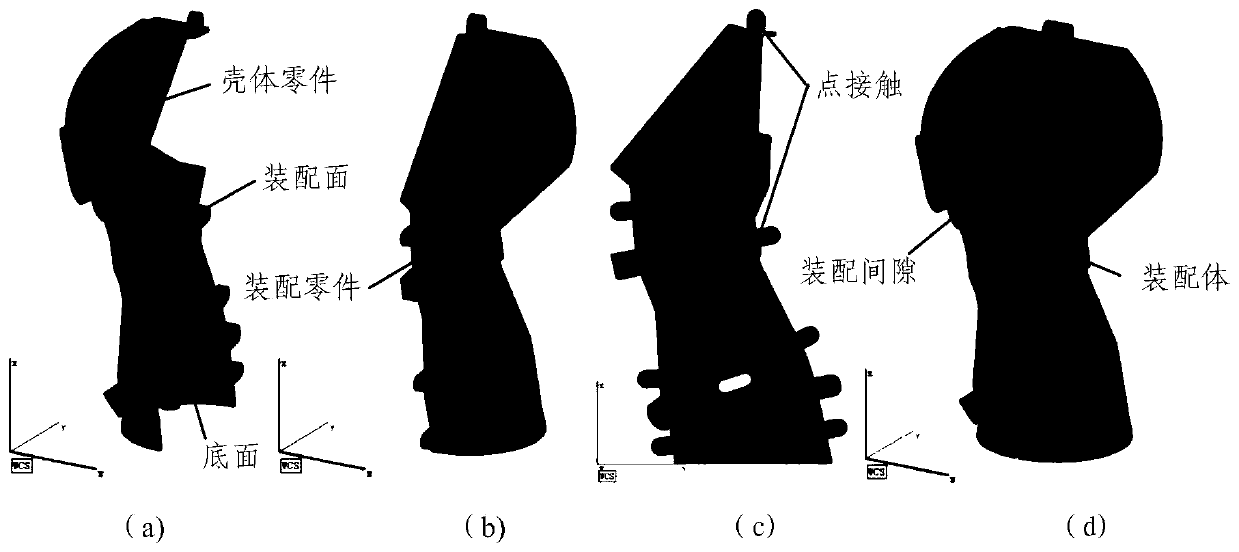

ActiveCN110695355AReduce post-processing costsImprove printing success rate and qualityAdditive manufacturing apparatusIncreasing energy efficiencyMesh gridEngineering

The invention relates to a technical method for controlling warping deformation of an aluminum alloy thin-wall part in the 3D printing process. By designing a novel technical support, the plane in theforming direction (Z direction) serves as a mirror face, a mirror body of a part is generated, the section of the mirror body and the part on a forming face (XOY face) forms a closed structure, the gap between the part and the mirror body is 3-5 mm and is filled with a Z-shaped sheet (the wall thickness is the same with that of the part) or a hollowed-out grid structure, the part is connected with the mirror body, a supporting structure is removed through linear cutting, and a printing part is obtained. According to the technical method, the effect that the thin-wall part is free of warping deformation in the printing process can be ensured, in addition, the support quantity is not increased, the post-processing cost is reduced, and the printing success rate and quality of the thin-wall part are improved. Thus, the technical method has the important significances to improvement of the quality and success rate of the same kind of thin-wall parts.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

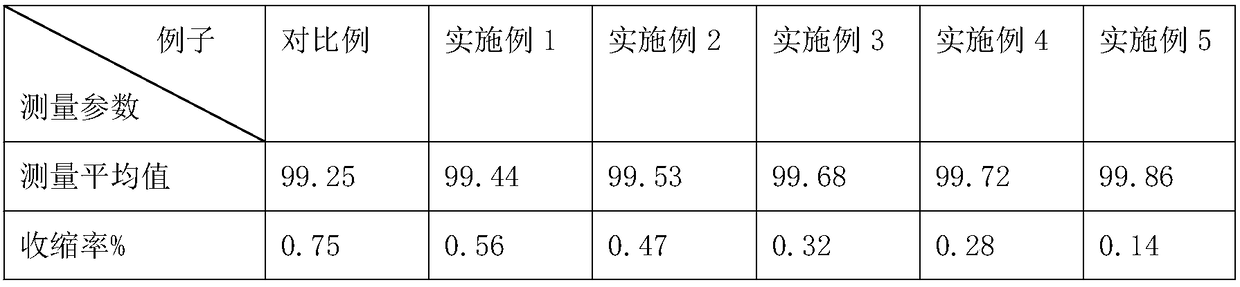

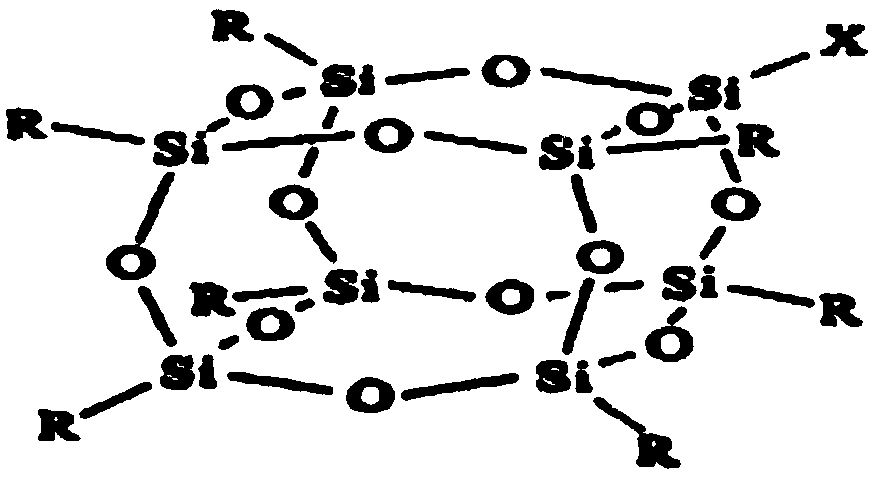

Light-cured resin for 3D (Three-dimensional) printing

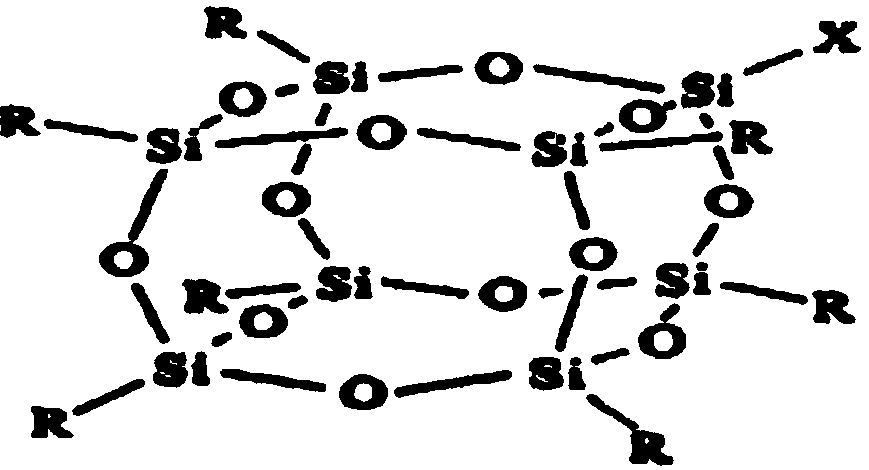

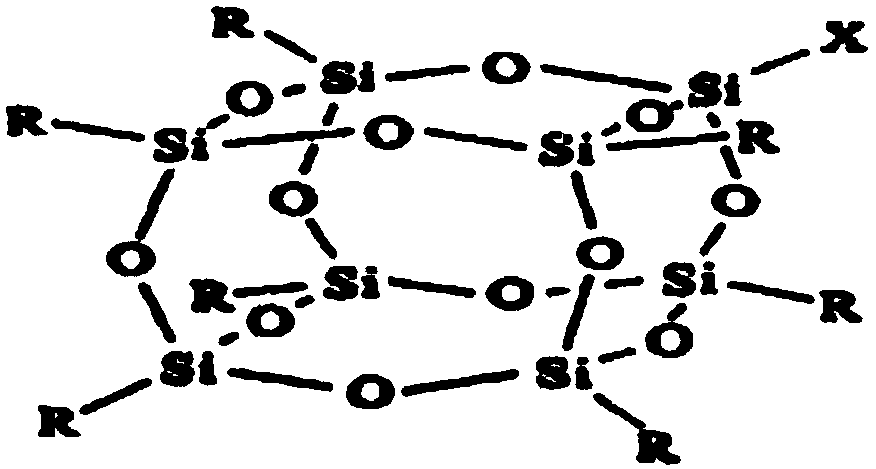

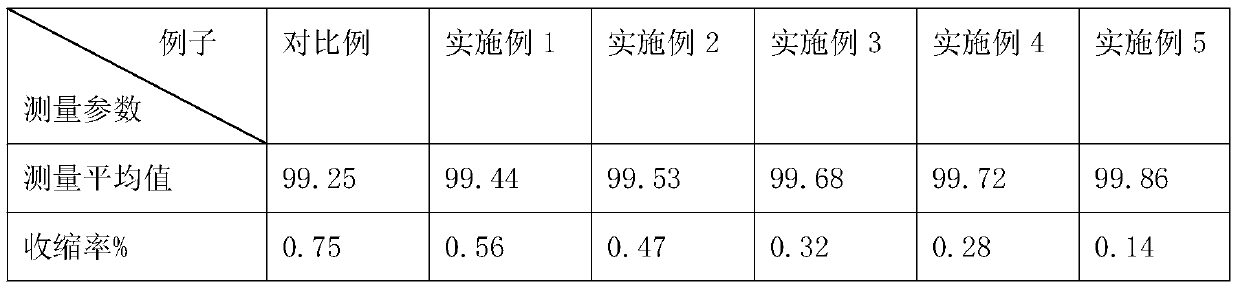

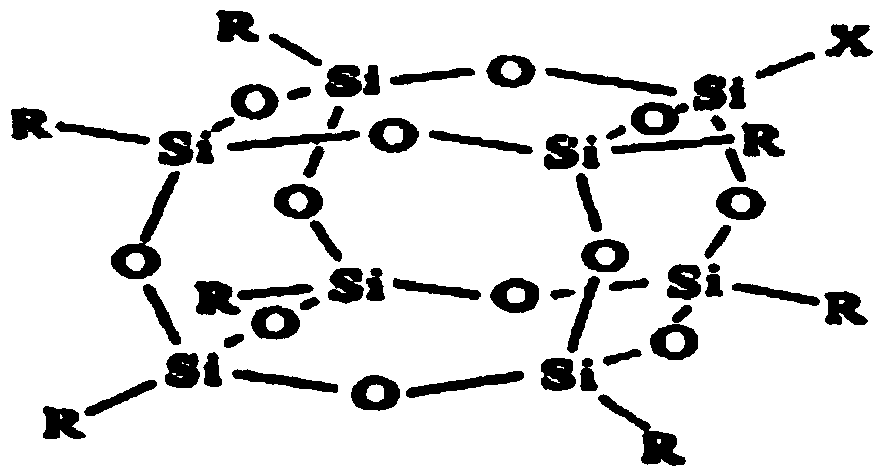

ActiveCN108102277ASmall shrinkageLow shrinkageAdditive manufacturing apparatusMechanical property3d printed

The invention relates to a light-cured resin for 3D (Three-dimensional) printing, which is prepared from the components in percentage by mass: 50 to 80 percent of epoxy resin, 5 to 20 percent of acrylic ester prepolymer, 10 to 40 percent of reactive diluent, 1 to 6 percent of photoinitiator, and 2 to 15 percent of filler. The filler is rigid polysiloxane, and a cage structure of the rigid polysiloxane is used as a framework or a support, so that the volume shrinkage of a material is reduced; an acrylic acid group is arranged on a side group, can be uniformly dispersed into a matrix resin, andhas good compatibility with the resin, so that a mechanical property is improved, and the problem that the shrinkage of the common inorganic filler can be reduced but the mechanical property is also reduced due to low inorganic-organic compatibility is solved.

Owner:XI AN JIAOTONG UNIV +1

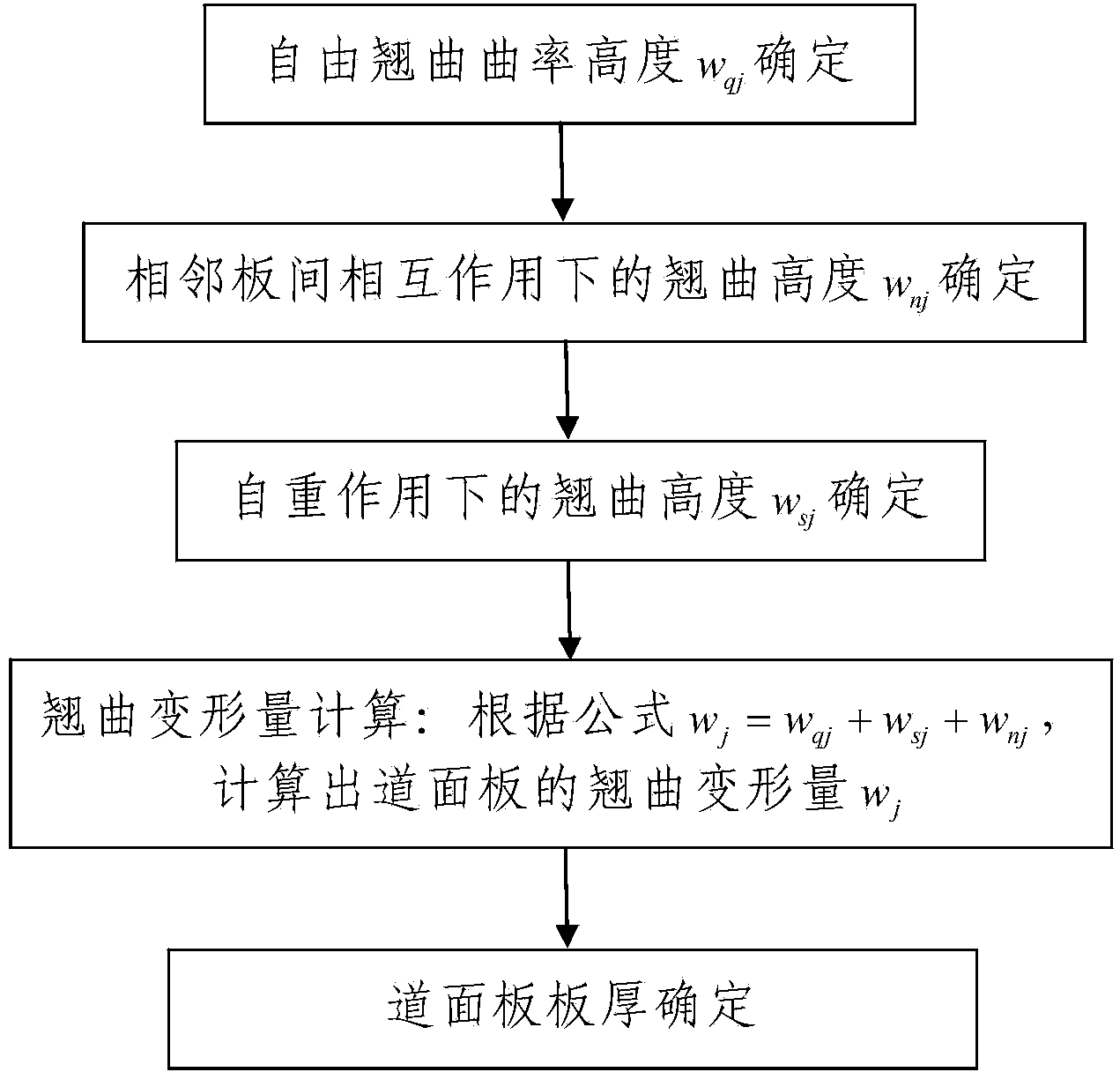

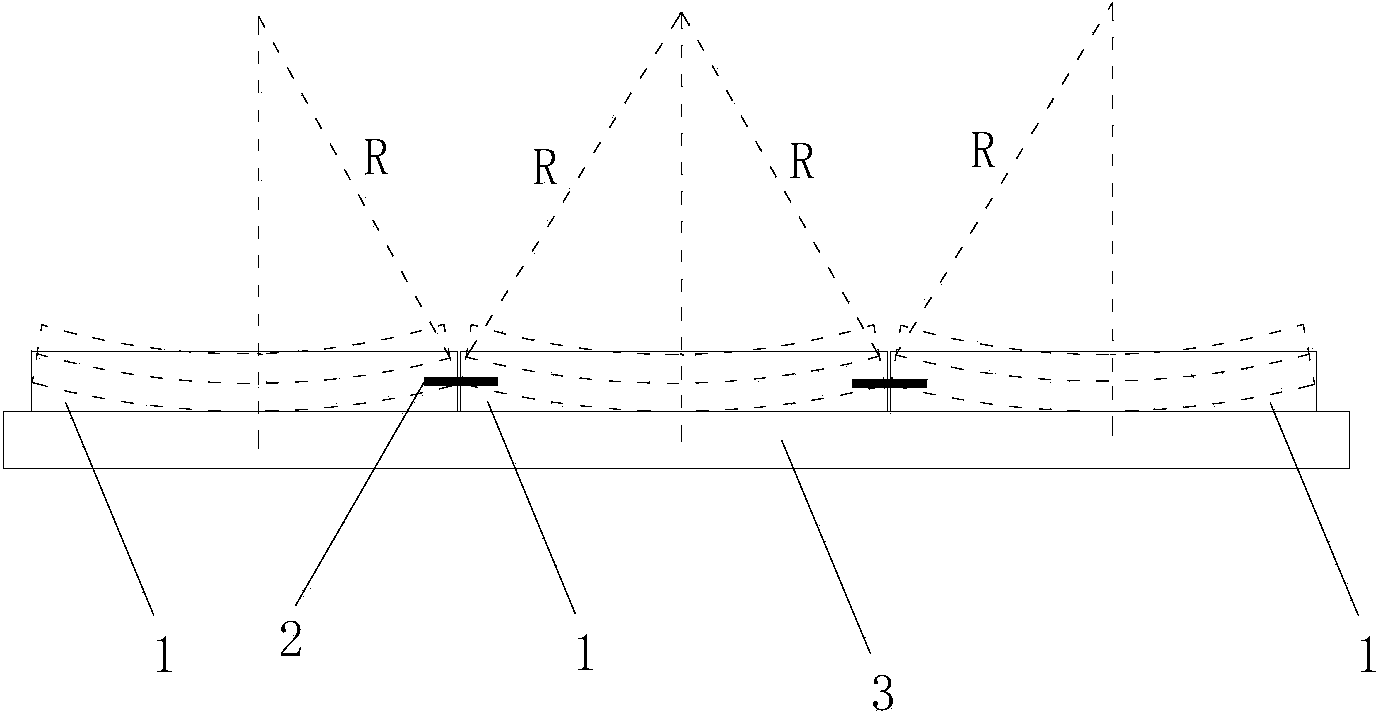

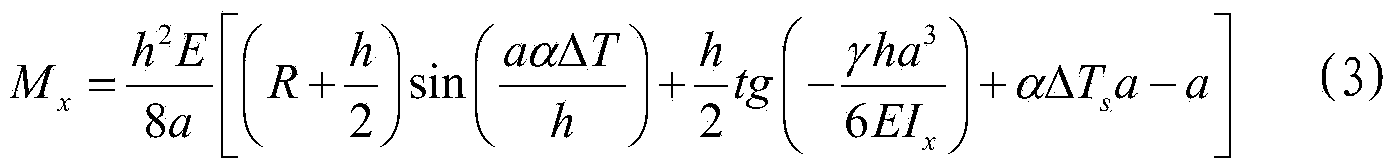

Design method for preventing buckling deformation of cement concrete pavement slabs of airport

InactiveCN103823948ASimple methodEasy to implementSpecial data processing applicationsDesign methodsMaterials science

The invention discloses a design method for preventing buckling deformation of cement concrete pavement slabs of an airport. The constructed airport pavement is formed by splicing a plurality of pavement slabs, and the pavement slabs are rectangular cement concrete plates. The design method comprises the following steps that the free buckling curvature height wqi is determined; the buckling height wnj under mutual action of adjacent slabs is determined; the buckling height wsj under the action of self gravity is determined; the buckling deformation amount is calculated, the buckling deformation amount wi of the pavement slabs is worked out according to the formula that wj= wqj+ wsj+ wnj; the thickness of each pavement slab is determined, and the value of the thickness h of each pavement slab when wj= c is solved and recorded as hc; the c is a buckling deformation threshold and c= 0 or cs, and the cs is the maximally permitted buckling deformation amount of the pre-designed pavement slabs; the designed thickness hs of each pavement slab is determined according to the worked out hc, and hs<=hc. The design method is simple in step, reasonable in design, convenient to achieve, good in use effect and capable of resolving the problem of buckling deformation of the cement concrete pavement slabs under the action of high temperature.

Owner:AIR FORCE UNIV PLA

Electroplating ABS composite and preparation method thereof

InactiveCN101817967BEnhance physical anchoring strengthStrengthen the bonding force of molecular bondsElectrolytic organic material coatingEmulsionElectrical polarity

The invention relates to an electroplating ABS composite and a preparation method thereof. The composite comprises the following components in part by weight: 40 and 80 parts of emulsion process ABS resin, 5 to 30 parts of mass ABS polar graft, 10 to 30 parts of heat-resisting master batch, 2 to 8 parts of nano stuffing and 0.1 to 0.5 part of antioxygen. The preparation method comprises the following steps of: putting the components except the nano stuffing into a high-speed stirrer and stirring the components to obtain a mixture; adding the mixture into a two-screw extruder from a main feed inlet of the two-screw extruder and adding the nano stuffing into the two-screw extruder from a lateral feed inlet; and extruding and granulating the obtained product to obtain samples. The electroplating ABS composite prepared by the method has a good electroplating effect, the high solidity of a metal electroplated layer, high temperature resistance, high dimensional stability and high impactingstrength, avoids part buckling deformation, metal coat cracking, bubbling, plastic exposure, even large area obscission and the like in a high and low-temperature cycling test and is particularly applied to automotive electroplated parts such as a radiator grille and an instrument frame of an automobile.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

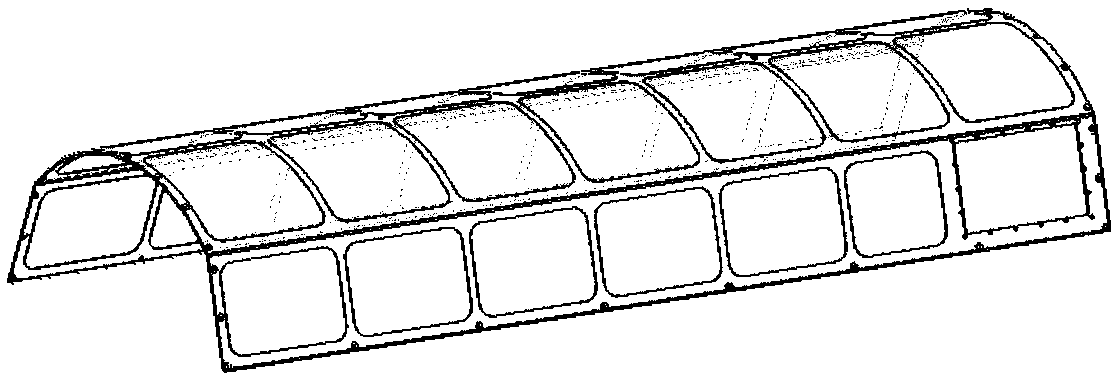

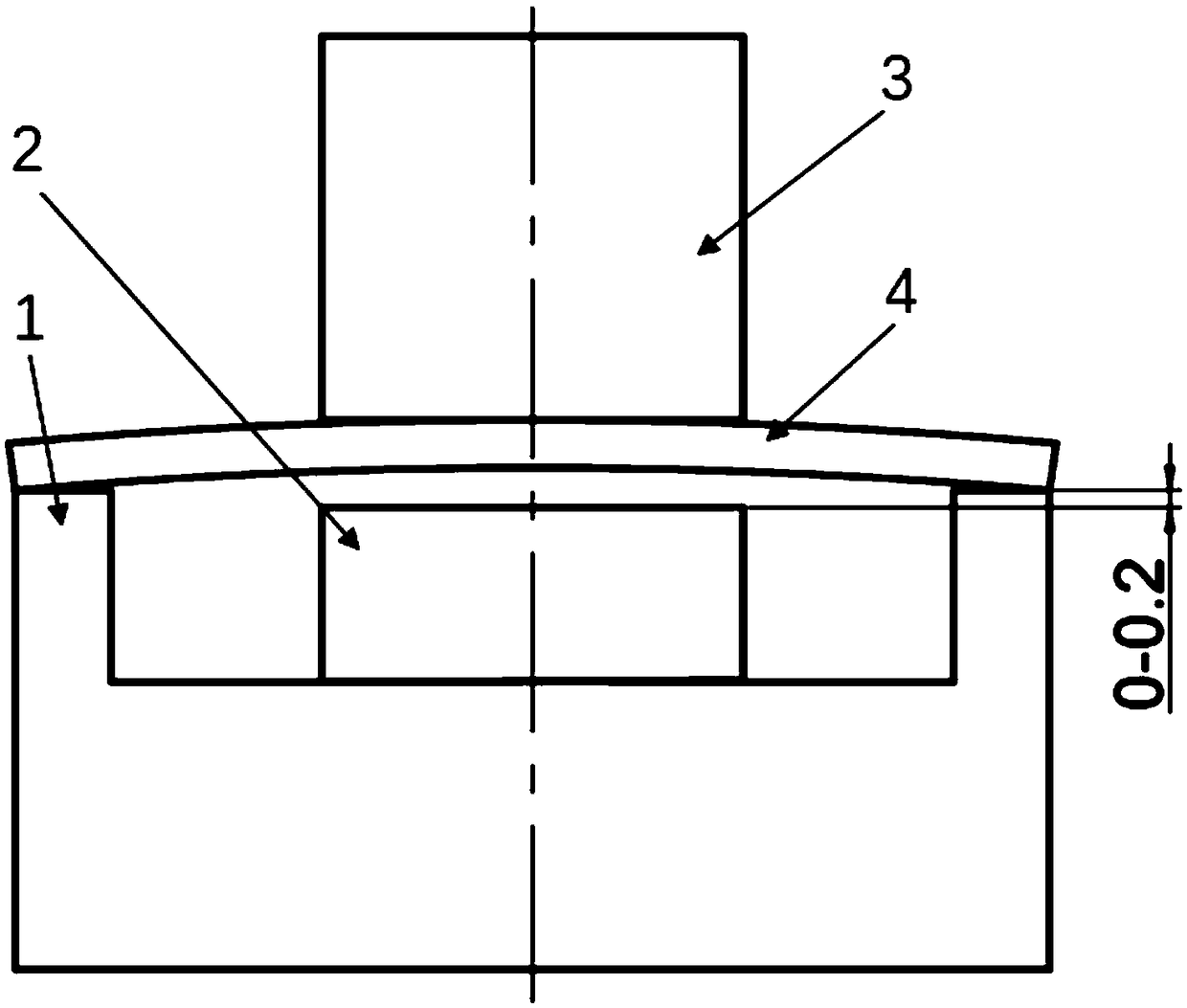

Accurate machining method for complex thin-wall variable-thickness large covering cap

ActiveCN109623265AImproved profile and dimensional accuracySolve warping deformationThin walledCorrosion

The invention discloses an accurate machining method for a complex thin-wall variable-thickness large covering cap. The accurate machining method for the complex thin-wall variable-thickness large covering cap comprises the following steps: simulating and flattening according to the geometrical parameters of the large covering cap, and calculating the smallest blank; designing and producing a concave-convex fixture die needed for hot-pressing forming according to the specific structure and dimensions of the large covering cap; carrying out the hot-pressing forming on the large covering cap bymeans of die-assembly hot-pressing forming; carrying out corrosion machining on a weight-reducing cavity in the internal profile of the large covering cap by means of chemical milling; designing and producing a follow-up fixture needed for machining for the large covering cap according to the specific structure and dimensions of the large covering cap; clamping and fixing the large covering cap through the follow-up fixture, filling a gap between the large covering cap and the fixture by virtue of solid paraffin, and integrally bonding the large covering cap with the fixture; and carrying outfinish machining forming on the large covering cap through a five-axis numerically-controlled machining center. According to the accurate machining method for the complex thin-wall variable-thicknesslarge covering cap, the vibration and deformation of a large-dimension thin-wall part in the machining process are effectively controlled and reduced, and the profile and dimension accuracy of the large covering cap are obviously improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

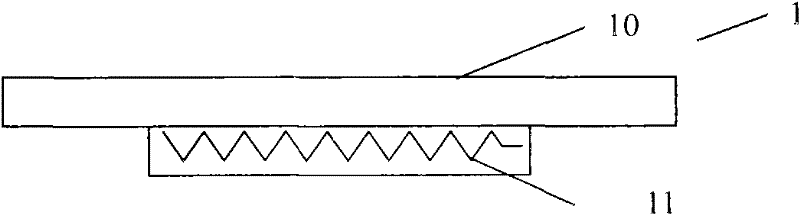

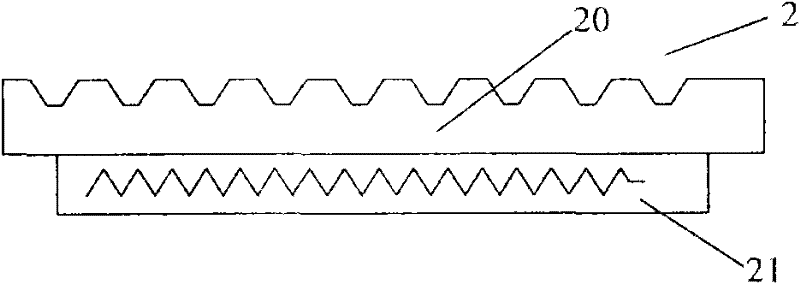

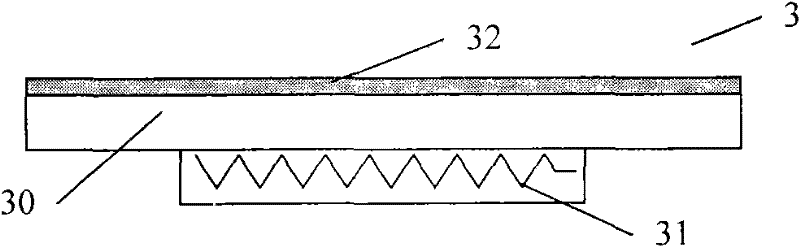

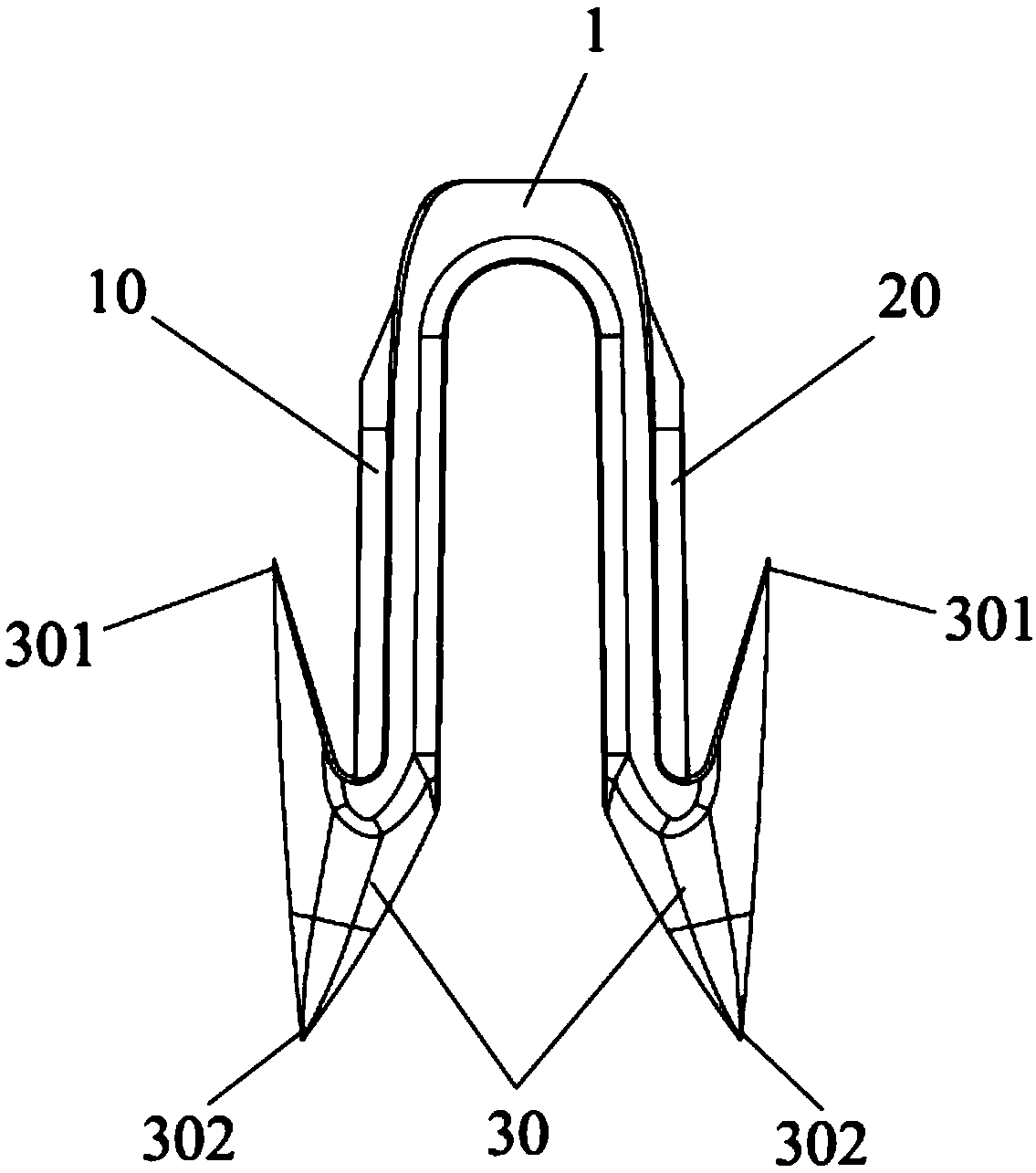

Heat treatment method for correcting plane warping deformation of injection molded product

The invention provides a heat treatment method for correcting the plane warping deformation of an injection molded product and belongs to the technical field of injection molding. A correcting tool isdivided into three parts including a U-shaped correcting support frame, a regulating block and a pressure application block. The heat treatment method comprises the steps: placing the regulating block in the middle of the U-shaped correcting support frame, placing a corrected injection molded product above the regulating block and the U-shaped correcting support frame, and mounting the pressure application block above the corrected injection molded product; then, placing a combined body into a drying oven or completing the combination in the drying oven, carrying out heat insulation, meanwhile, keeping a drying environment, setting the temperature of the drying oven to be 10-20 DEG C lower than the glass transition temperature of the material of the injection molded product, keeping the temperature for 1-2 h, and then, taking out and separating each part; and cooling a to-be-corrected injection molded product to the room temperature, and repeating the process once or twice. Accordingto the heat treatment method, a plastic product is subjected to heat treatment, and the internal stress of the plastic product is firstly released under the assistance of correcting measures, so thatthe problem of injection molding plane warping deformation is effectively solved.

Owner:DALIAN UNIV OF TECH

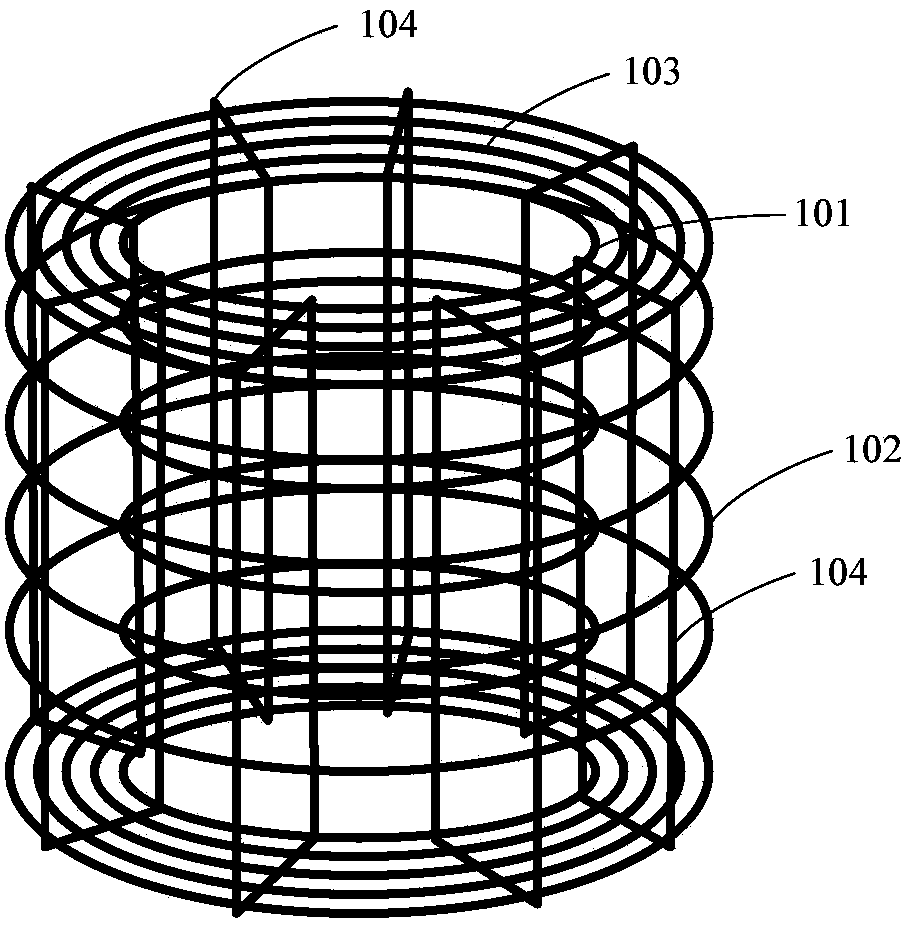

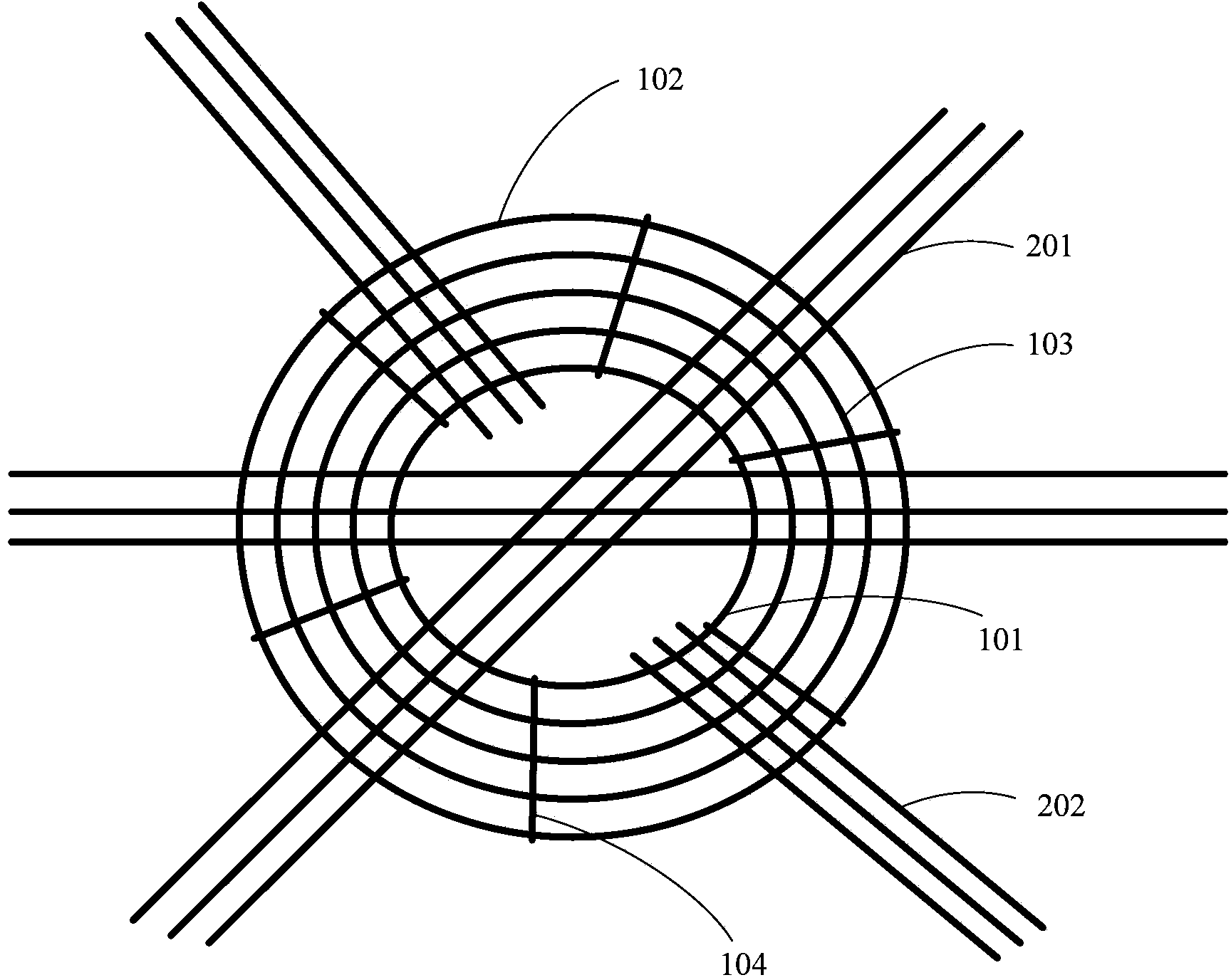

Ring-beam reinforcing connection structure and ring-beam construction method

ActiveCN103882994ASolve warping deformationGuaranteed connection strengthBuilding constructionsRebarAnnular beam

The invention relates to a ring-beam reinforcing connection structure and a ring-beam construction method. The ring-beam reinforcing connection structure comprises a ring-beam reinforcing cage, beam column reinforcing ribs and floor reinforcing ribs. The ring-beam reinforcing cage comprises an inner ring beam, an outer ring beam, annular beams and longitudinal beam ribs, and the ring-beam beams and the longitudinal beam ribs are different in diameter and are arranged between the inner ring beam and the outer ring beam. The longitudinal beam ribs are connected with the inner ring beam, the outer ring beam and the annular beams in an enclosed manner to form an annular cylindrical structure. The beam column reinforcing ribs are penetratingly arranged in the cavity of the ring-beam reinforcing cage and connected with the same. The floor reinforcing ribs include first beam reinforcing ribs and second beam reinforcing ribs, the first reinforcing ribs penetrate the ring-beam reinforcing cage and are connected with the same, the second beam reinforcing ribs are penetratingly arranged in the ring-beam reinforcing cage, the ends of the second beam reinforcing ribs are located inside the ring-beam reinforcing cage and are connected with the same. By the adoption of the ring-beam reinforcing cage, the problem about buckling deformation produced in construction of ring beams is solved, and connection strength between beam columns and floors can be guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

High-rigidity, high-toughness and high-fluidity polypropylene composite material and preparation method thereof

The invention discloses a high-rigidity, high-toughness and high-fluidity polypropylene composite material and a preparation method thereof. The polypropylene composite material is composed of the following raw materials in percentage by mass: 52-71.2% of polypropylene, 20-30% of an inorganic filler, 8-15% of a toughening agent, 0.2-1% of a lubricant, 0.4-1% of an antioxidant, and 0.2-1% of a nucleating agent. The polypropylene composite material has the advantages that the prepared polypropylene composite material has the characteristics of high modulus, high impact resistance and high flowability; the polypropylene composite material meets the requirements of thin-walled materials for vehicles, can reduce the mass of the whole vehicle and achieve the effect of light weight, can achieve more ideal rigidity and toughness balance compared with traditional polypropylene, and is simple in preparation process, low in cost and easy for large-scale industrial production.

Owner:四川鑫达企业集团有限公司

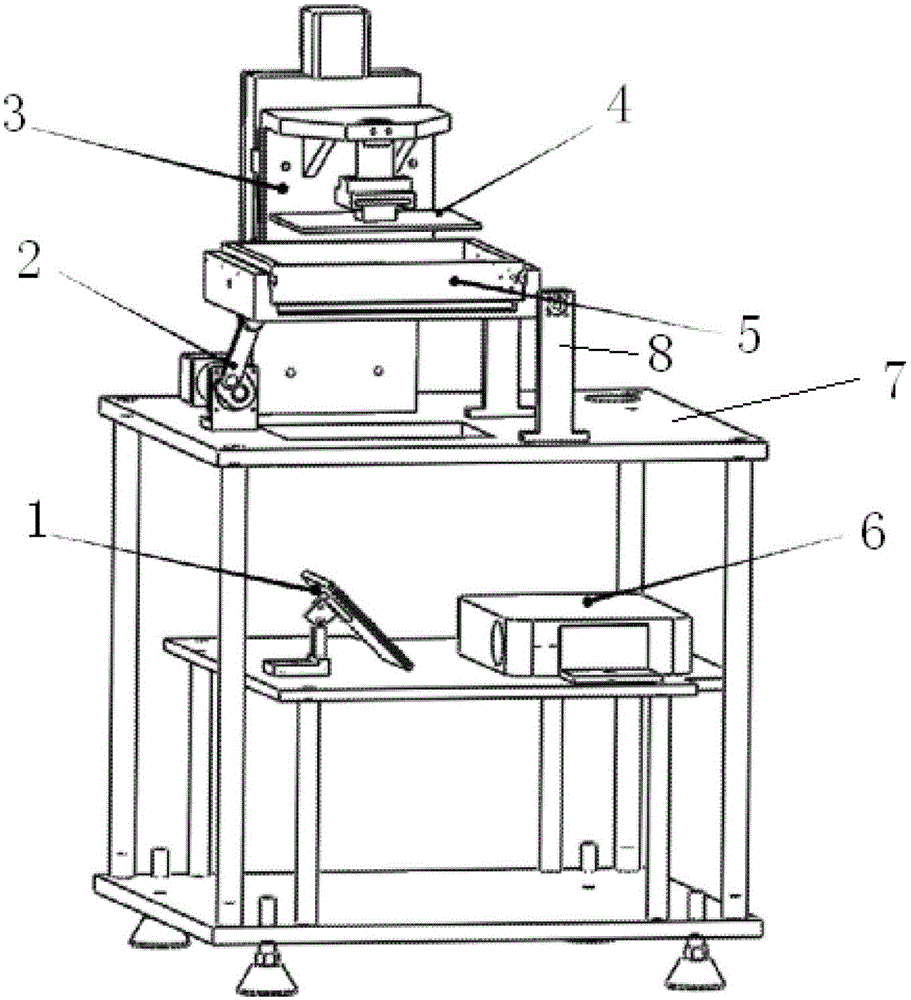

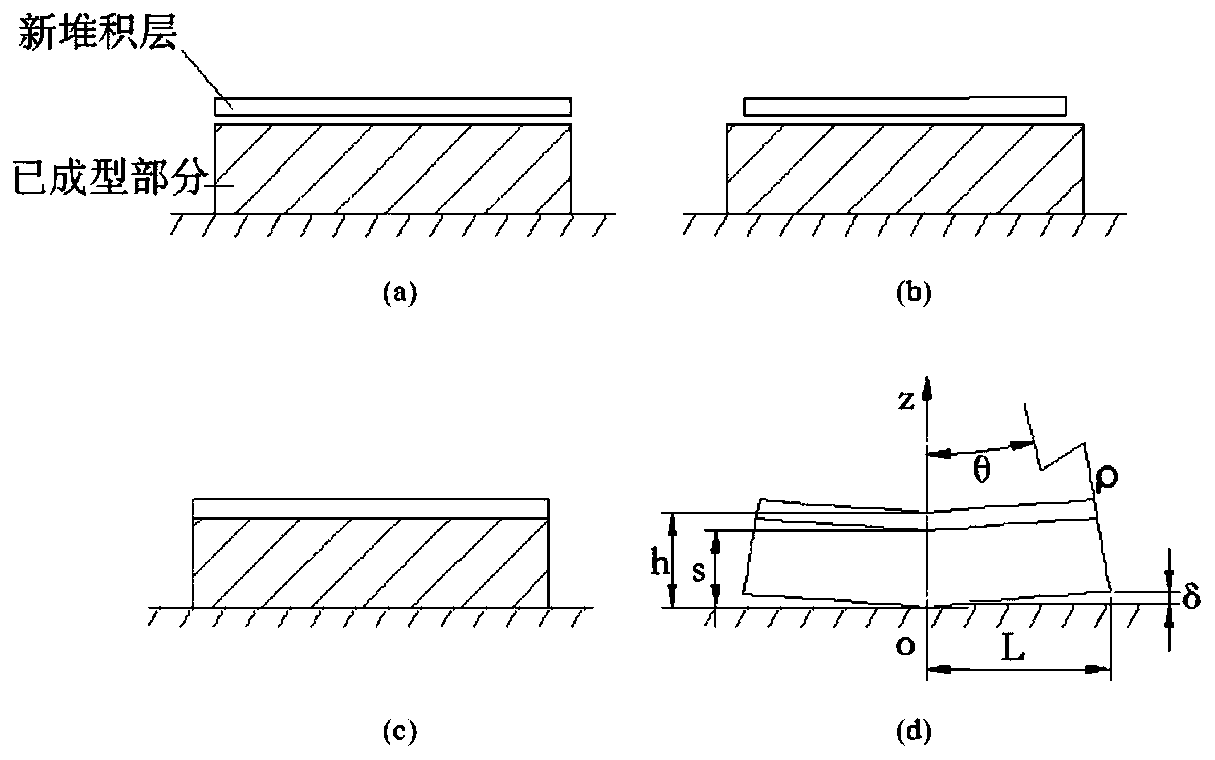

A kind of planar photocuring rapid prototyping device and method

The invention provides a planar stereo lithography apparatus and method. The apparatus comprises an ultraviolet light digital projector, a resin storage tank and a workbench, wherein the bottom of the resin storage tank is prepared from glass which allows ultraviolet light to be transmitted, and a gap used for filling resin liquid is arranged between the lower end face of the workbench and the bottom of the resin storage tank. The resin liquid is injected into the gap located between the resin storage tank and the workbench; the contour of an ultraviolet light layer of an entity part generated by using a digital projection method forms an image on the resin liquid through a base plate of the resin storage tank so as to obtain a solidified layer with the contour of a corresponding layer; the workbench is lifted a layer higher, then the resin liquid is injected into a gap between the lower end face of the solidified layer and the resin storage tank, and exposure and solidification of a next layer are carried out. According to the invention, the problem of buckling deformation after stereo lithography is overcome, and the advantages of high molding precision, a fast molding speed, a simple process and low cost are obtained.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

Rapid forming working platform

Rapid forming equipment in the prior art needs to be additionally provided with a forming chamber so as to provide an environmental temperature for preventing over-fast temperature reduction speed of forming materials; therefore causing the defects of complex rapid forming equipment and hardly observed forming process as well as various problems generated in real time due to unable timely processing caused by the defects of complex rapid forming equipment and hardly observed forming process. The invention provides a rapid forming working platform, which comprises a support device and a heating device. The upper surface of the support device comprises a support surface used for supporting a forming piece; the heating device is used for heating the support device so as to improve an environmental temperature for squeezed forming materials. The working platform is a self-heated open type working platform and is provided with the heating device for guaranteeing the environmental temperature of the forming materials. When the working platform is adopted, a forming chamber is not needed; therefore, the material forming process is completely visible so that various problems generated in real time can be timely processed.

Owner:WUXI TIERTIME TECH CO LTD

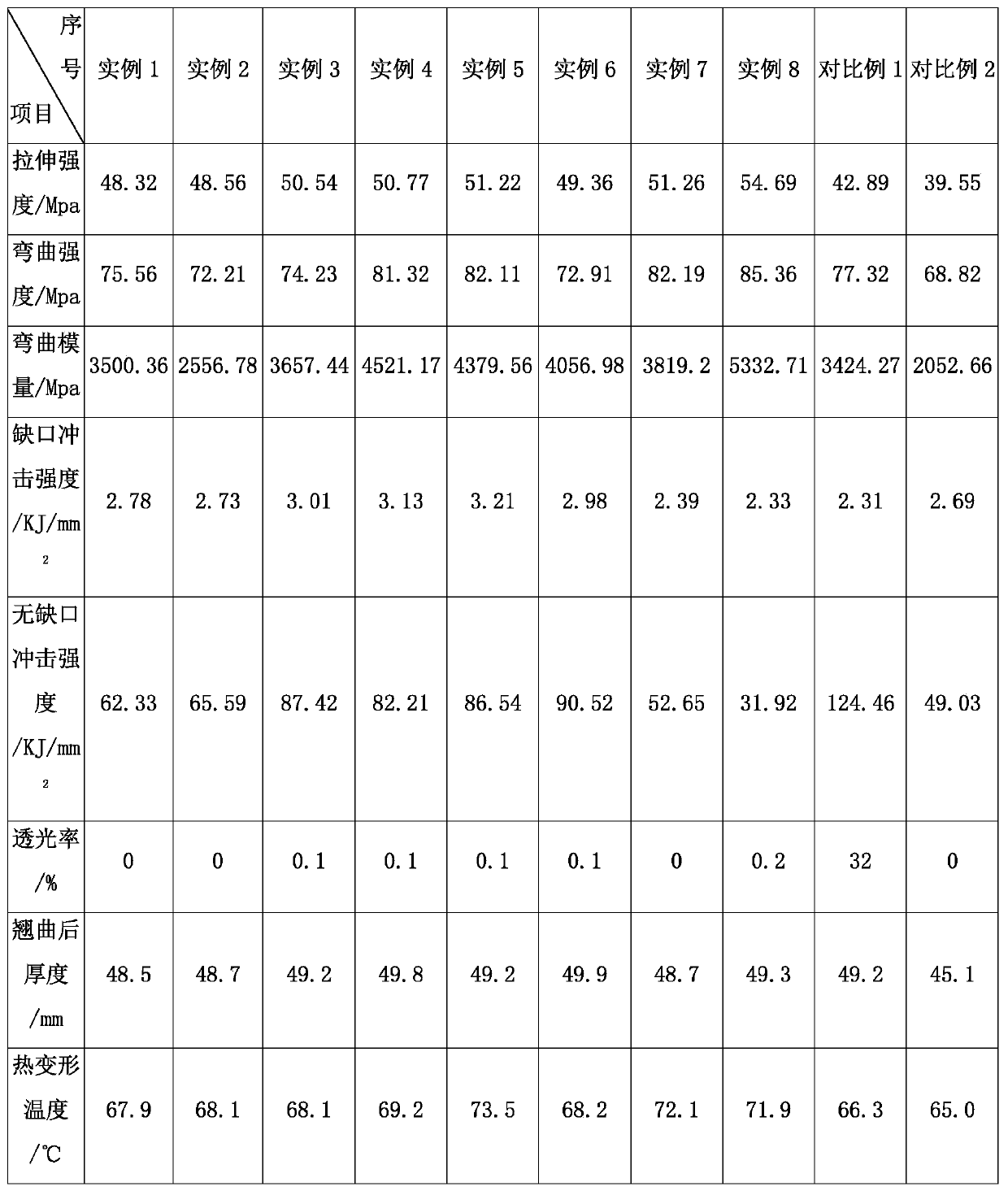

Shading warping-resistant polyester material for 3D printing and preparation method thereof

ActiveCN110615973AExcellent mechanical properties and heat resistanceGood anti-warping and shading performanceChemistryAntioxidant

The invention relates to a shading warping-resistant polyester material for 3D printing and a preparation method thereof. The preparation method comprises the following steps: drying matrix resin in adrying oven; putting the dried matrix resin into a high-speed mixer for stirring and mixing; adding diffusion oil and a coupling agent, and mixing the mixture at a high speed; adding the toughening agent, an inorganic filler, an opacifying agent, an antioxidant, a lubricating agent and an anti-UV agent, and uniformly mixing the mixture; adding the mixed materials into a double-screw extruder forextrusion and granulation to obtain particles; putting the particles into an airflow dryer for drying; and putting the dried particles into a single-screw extruder to extrude a melt, cooling, preparing a wire rod under the traction action of a traction machine, and winding the wire rod to obtain the shading warping-resistant polyester material for 3D printing. The polyester material has good mechanical properties and heat resistance, and has good warping resistance and shading performance.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Rapid laser sintering molding material based on polycarbonate powder

The invention relates to a rapid laser sintering molding material based on polycarbonate powder. Polycarbonate, stilbene flexibilizer, ABS resin and styrene / maleic anhydride copolymer and ABS graft copolymer are mixed for granulation and crushed into polycarbonate power material at low temperature; sulfonic acid surfactant and silane coupling agent are dissolved in absolute alcohol and evenly sprayed on the surface of the polycarbonate powder material, and absolute alcohol is removed to be made into base material; benzophenone light absorber, nano carborundum powder, and non-ionic antistatic agent and organic filler are added into the base material and mixed to be uniform, thus obtaining the rapid laser sintering molding material based on polycarbonate powder. The rapid laser sintering molding material of the invention can better solve buckling deformation problem of a sintering piece, greatly improves mechanical property of the sintering piece and has great advantages in rapid makingof thin-wall spare parts, precision parts, complex parts and parts resistant to high temperature and low temperature.

Owner:ZHONGBEI UNIV

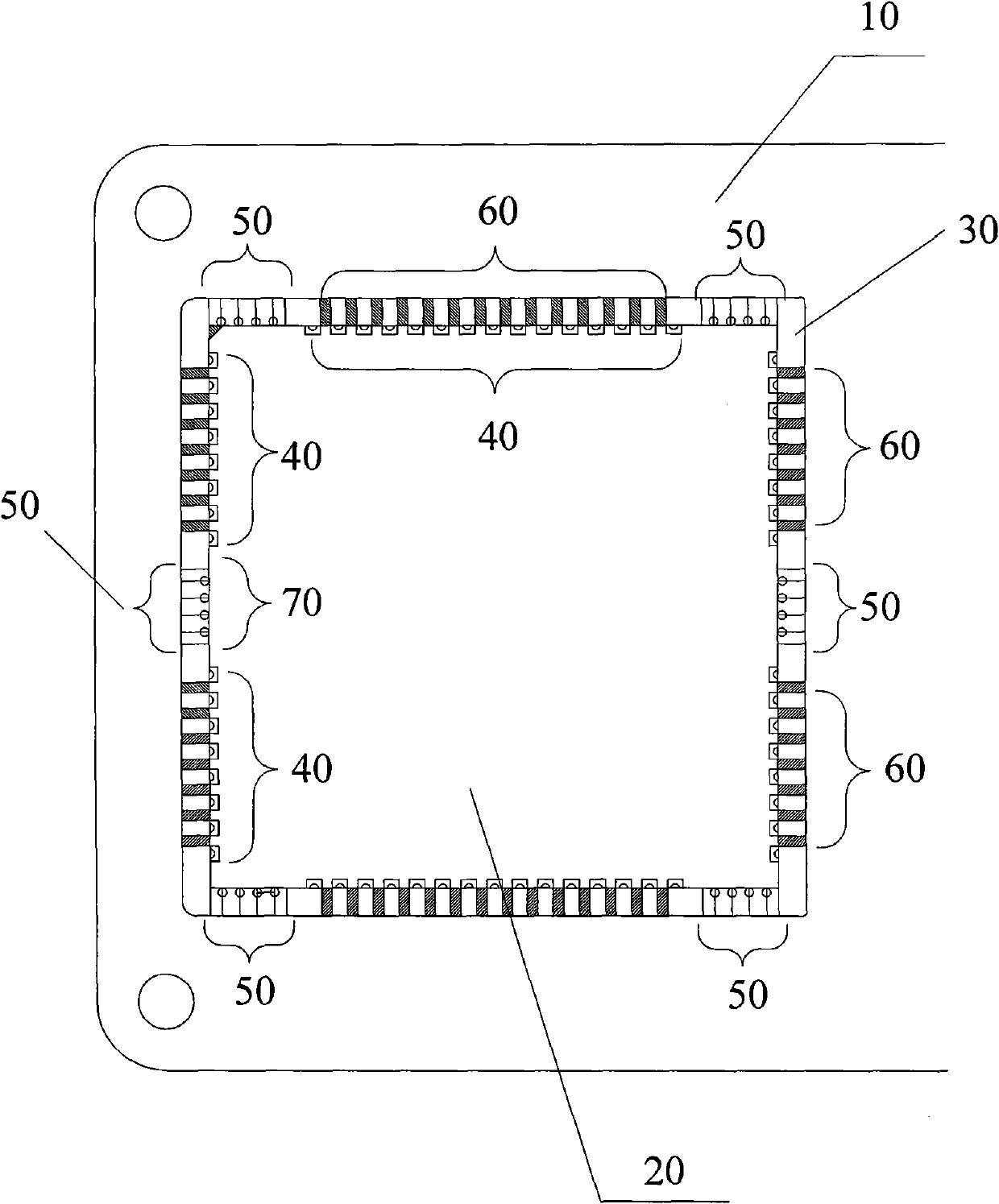

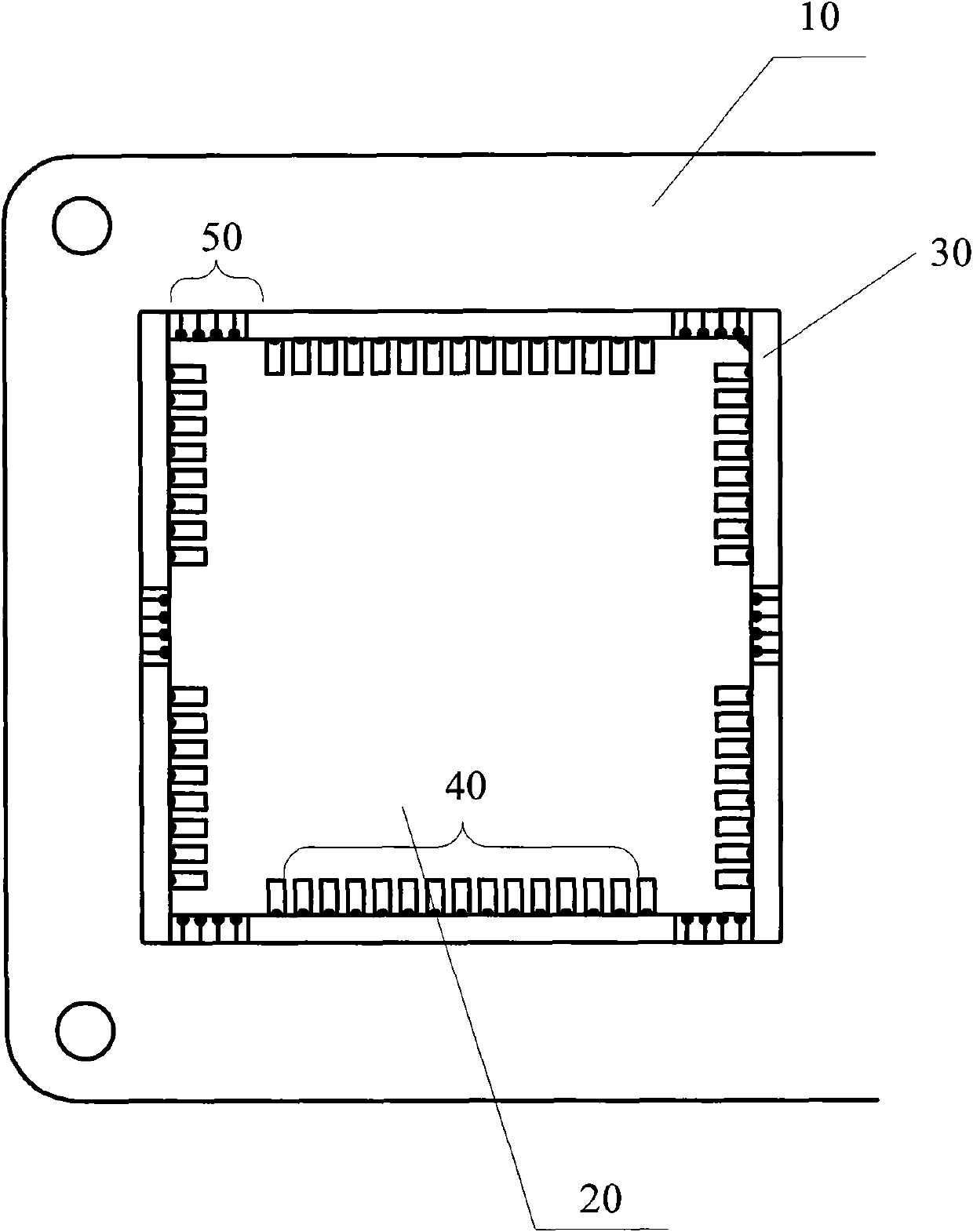

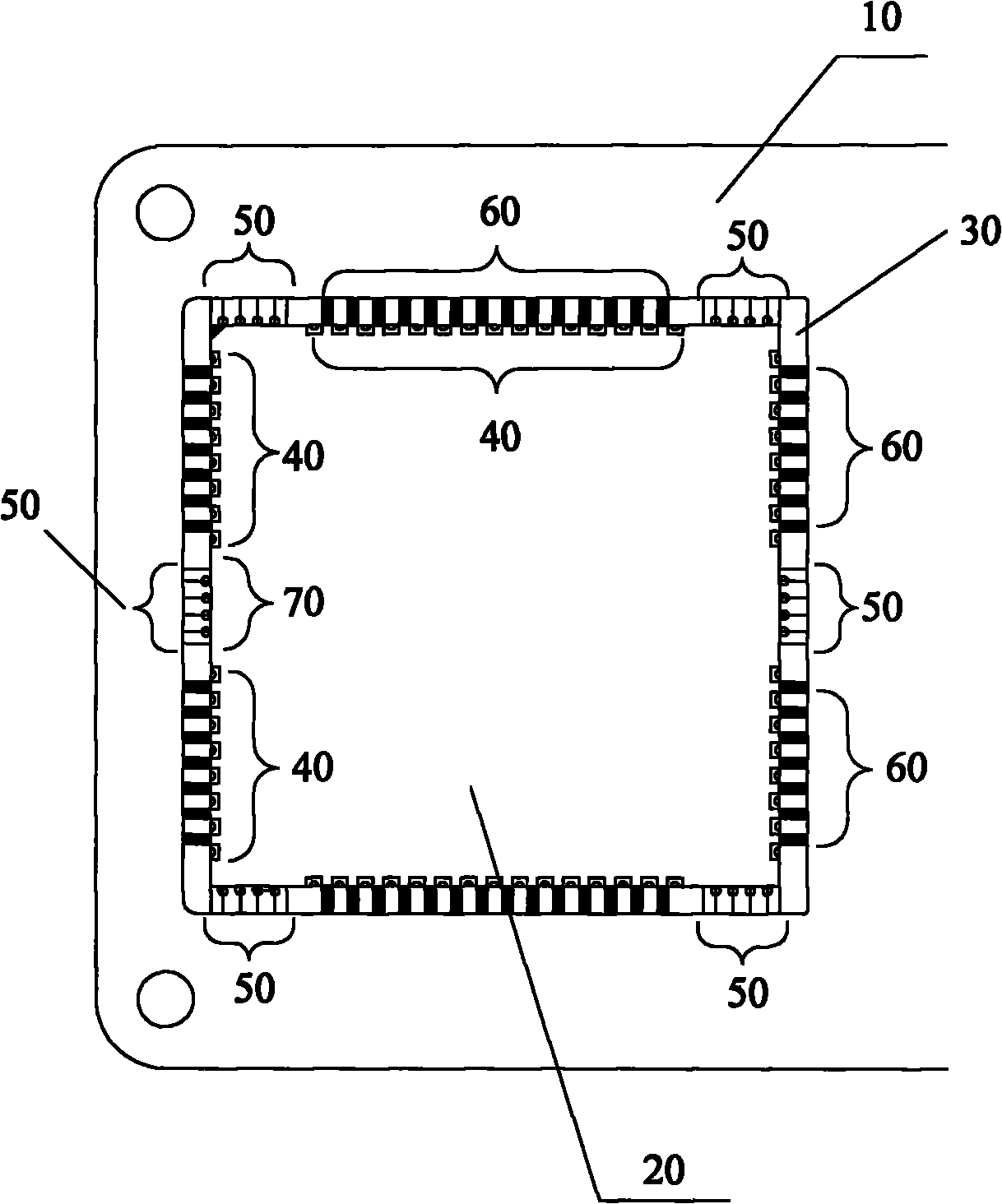

Surface installation module

InactiveCN102026472AAnti-warping stress pointsIncrease anti-warping designPrinted circuit assemblingElectrical connection printed elementsStress pointSurface mounting

Owner:SHANGHAI SIMCOM LTD

Hernia patch fixing nail and preparation method thereof

The invention relates to the technical field of absorbable biological materials and medical devices, in particular to a hernia patch fixing nail. The hernia patch fixing nail is obtained through injection molding of an absorbable biological material, the absorbable biological material is a blend formed by a composition of a heterogeneous polymer, the blend comprises, by molar ratio, 70-90% of lactide and 30-10% of glycolide; the preparation method of the hernia patch fixing nail comprises the steps that a general molecular weight and low molecular weight of rich lactide and rich glycolide arefirstly prepared, then melt mixing, dyeing, prilling, drying, injection molding and annealing are carried out in sequence to obtain the fixing nail. The prepared fixing nail has excellent comprehensive properties such as high strength, good toughness, strong resistance to heat deformation and high dimensional stability in the early stage and the initial stage of application; degradation is in a continuous state when carried out, the polymer is significantly degraded in an important period of internal tissue recovery and adjustment and is basically absorbed by the human body within 10-20 months; mixing is simple and the synthesis cost is low.

Owner:广东晨曦医疗科技有限公司

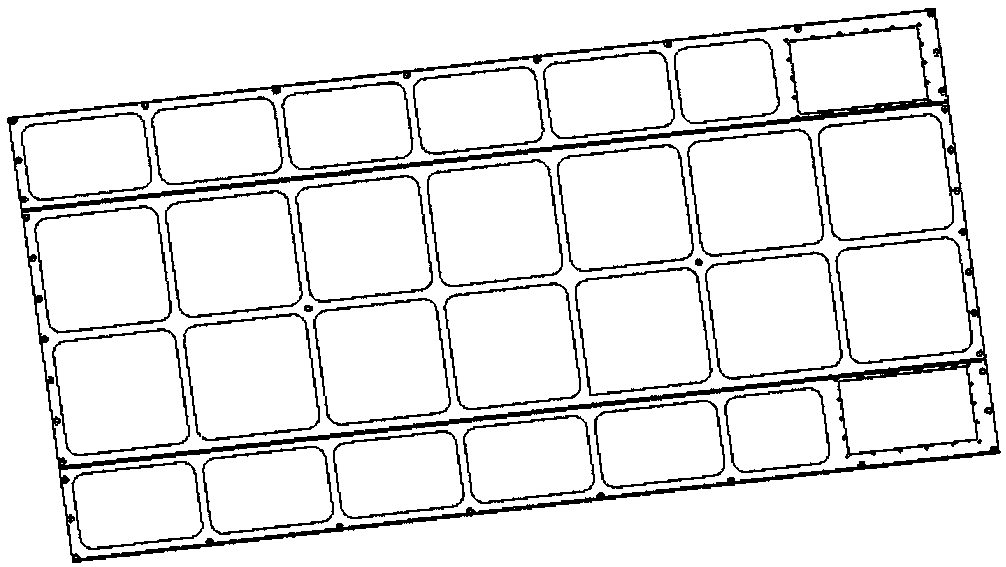

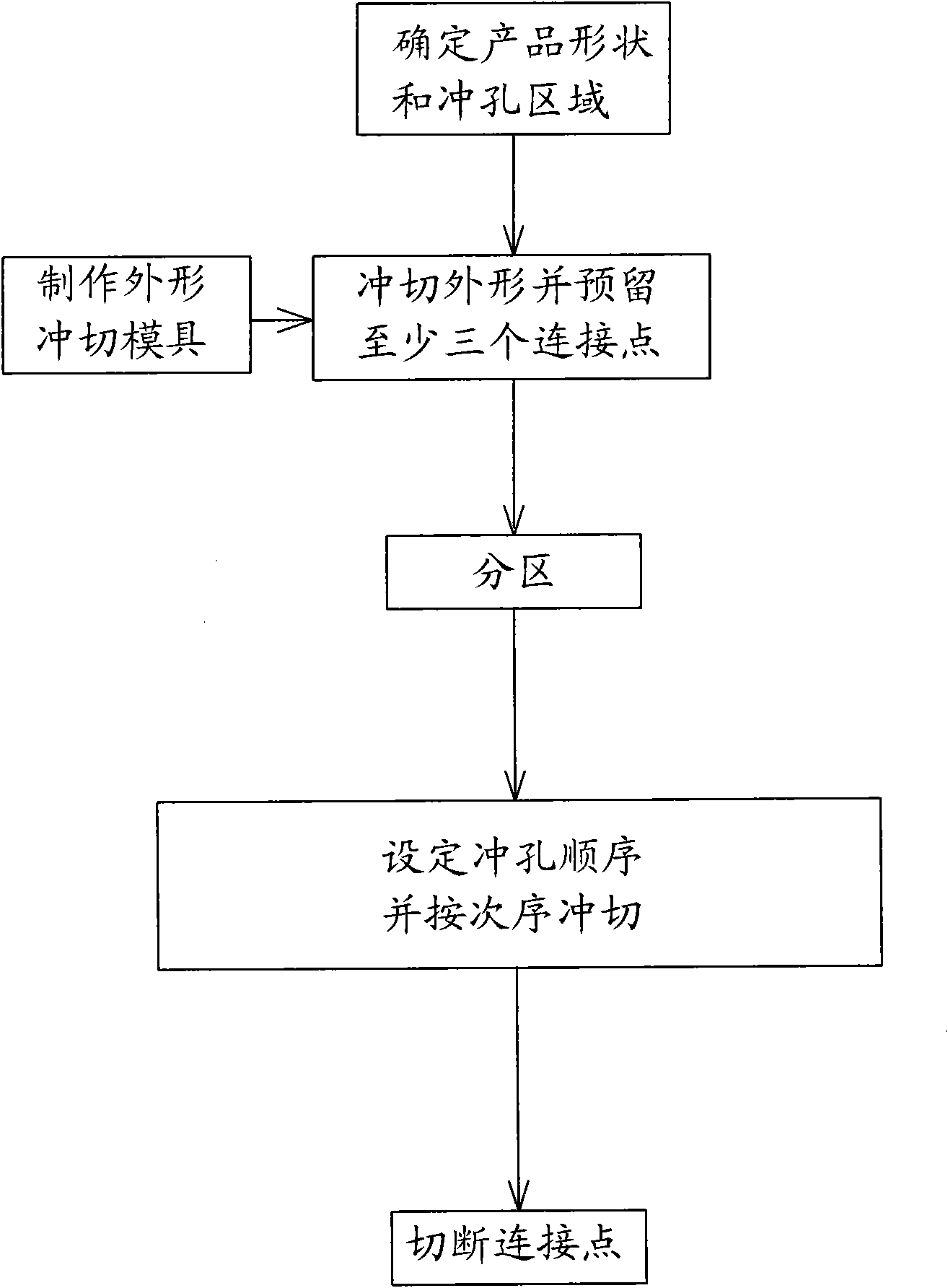

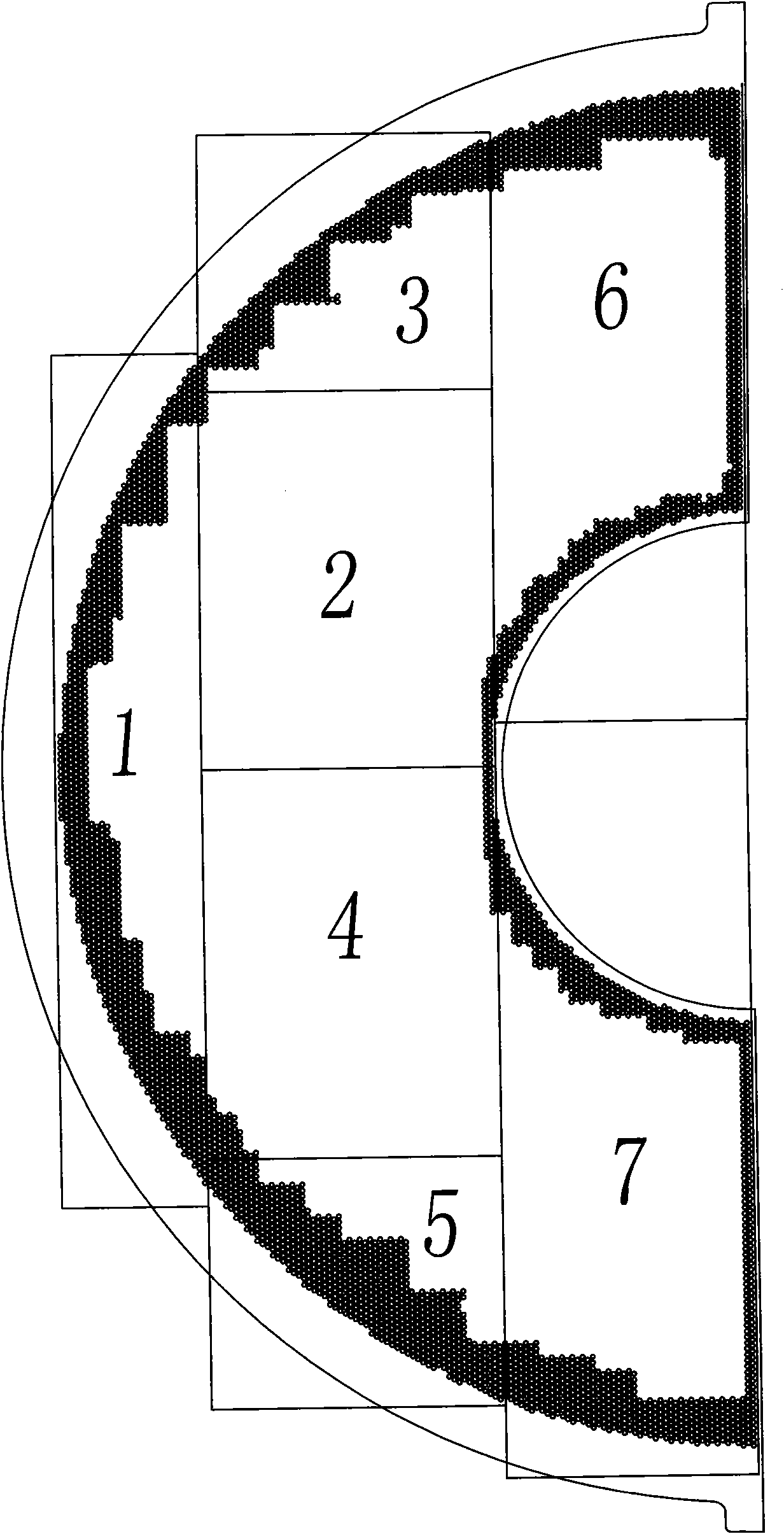

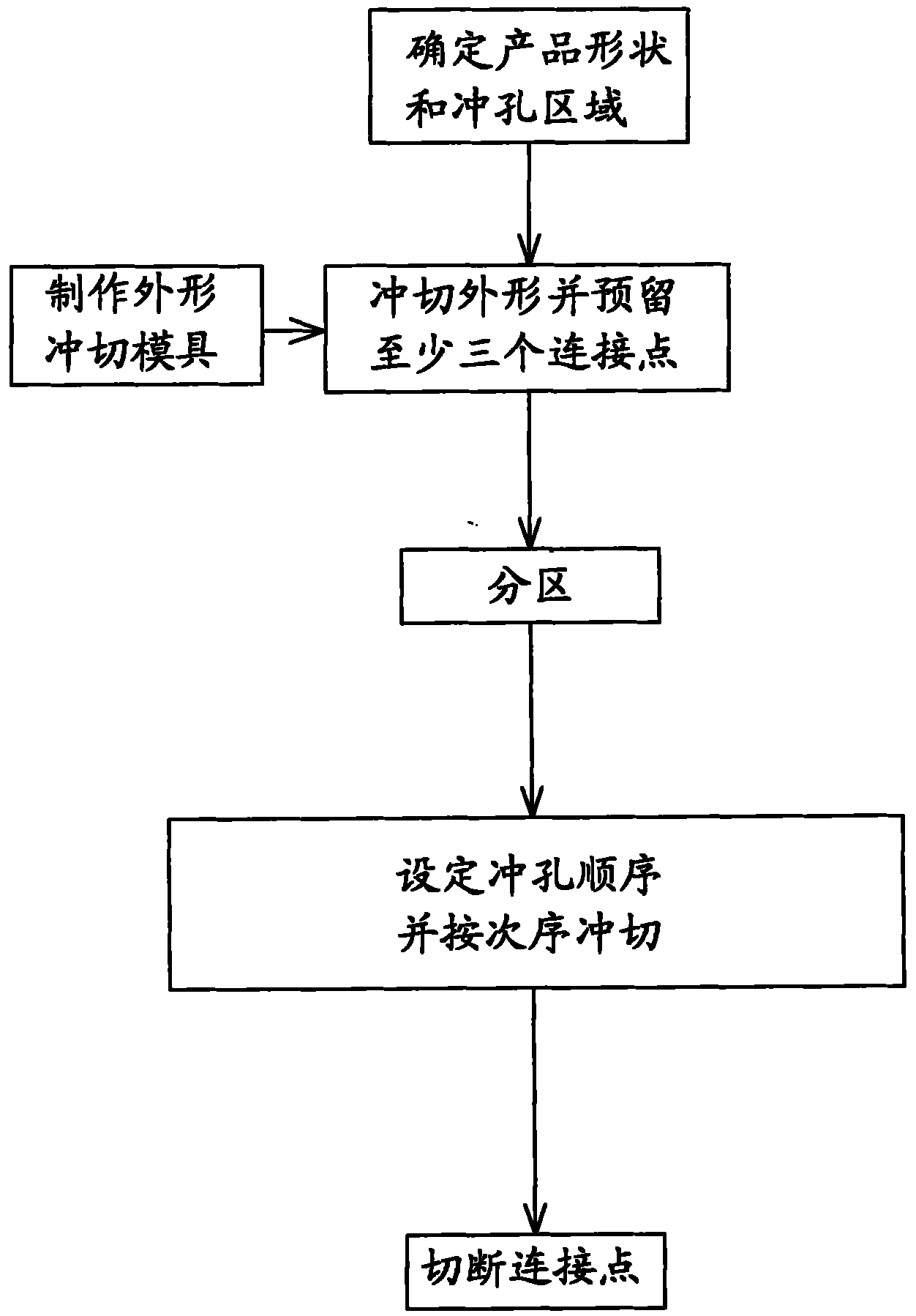

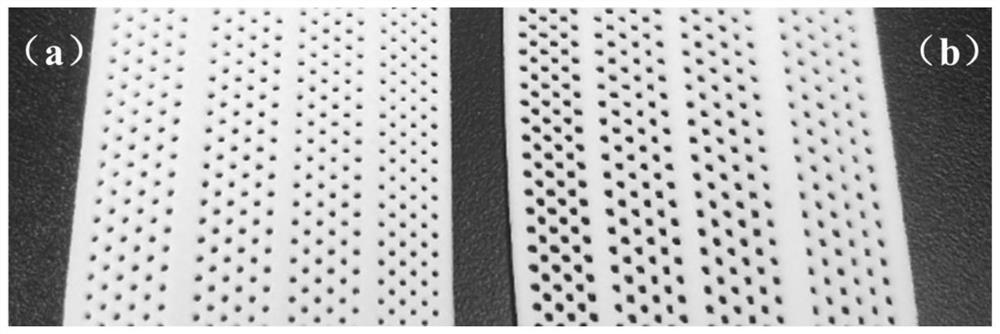

Punching method for high-density stainless steel mesh plate

InactiveCN102416417ASolve warping deformationSolve the problem of punching through adjacent holesHigh densityMaterials science

The invention discloses a punching method for a high-density stainless steel mesh plate. Holes to be punched are divided into different parts according to the spacing and the holes in different parts are processed sequentially. The problems of sheet warping deformation and penetration of adjacent holes caused by sequential and one-by-one processing of the adjacent holes in the traditional process can be solved.

Owner:苏州尚品科技有限公司

A kind of 3D printing light curing resin

ActiveCN108102277BSmall shrinkageLow shrinkageAdditive manufacturing apparatus3d printPolymer science

A 3D printing photocurable resin, comprising 50-80% by mass of epoxy resin, 5-20% by mass of acrylate prepolymer, and 10-40% by mass of reactive diluent, The mass percent content is 1-6% photoinitiator, the mass percentage content is 2-15% filler, the filler is rigid polysiloxane, and the rigid polysiloxane cage structure acts as a skeleton or support, thereby reducing the volume of the material Shrinkage, and because its side group has acrylic group, it can be uniformly dispersed in the main resin, and has good compatibility with the resin, improving the mechanical properties, and will not reduce shrinkage like ordinary inorganic fillers, but due to inorganic and Poor organic compatibility leads to lower mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

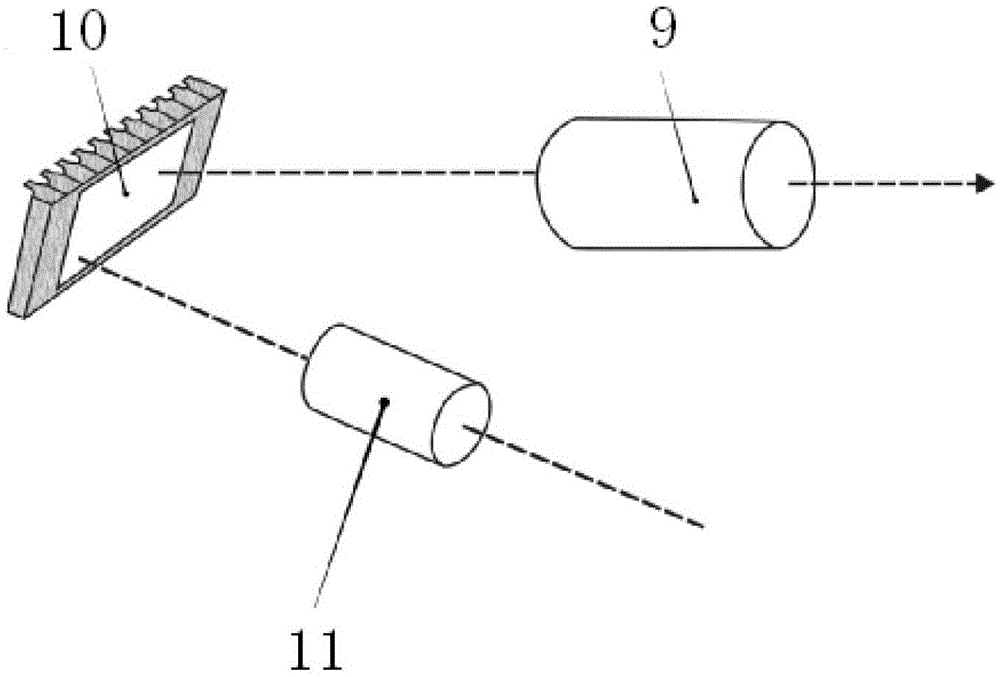

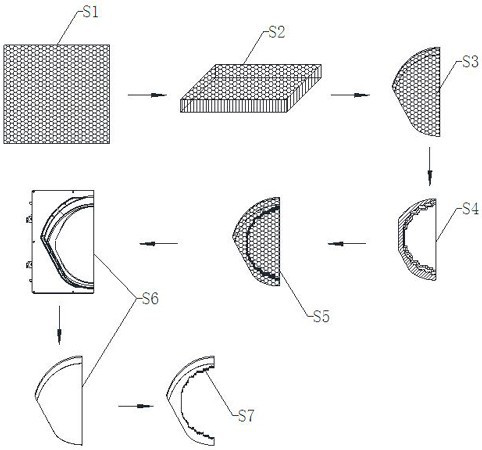

Forming method of L-shaped variable cross-section hollow-structure composite material wave-absorbing component with sawteeth

The invention relates to a forming method of an L-shaped variable cross-section hollow-structure composite material wave-absorbing component with sawteeth. The forming method comprises the following steps of: S1, according to the appearance size of a product, cutting a honeycomb after leaving a margin, and cutting to obtain a honeycomb blank meeting the processing requirement; S2, preparing a soaked material into a wave-absorbing honeycomb blank; S3, machining the wave-absorbing honeycomb blank to prepare a honeycomb part blank; S4, exposing the part where the sawteeth need to be machined; S5, filling low-dielectric pouring sealant in the part, where the sawteeth need to be machined, of the part blank; S6, adopting a forming tool to lay and cure soaked material skin; and S7, adopting a milling tool for sawtooth machining, and thus obtaining the product through preparation. The forming method has the advantages that the size precision control of a part meets the design requirement, the size stability is good, the appearance quality of the formed part is good, the temperature resistance of the part is improved, and the problems that the part is prone to buckling deformation and surface wrinkles are solved; and the sawtooth parts are filled and reinforced by the pouring sealant, so that the sawteeth are not easy to break.

Owner:成都佳驰电子科技股份有限公司

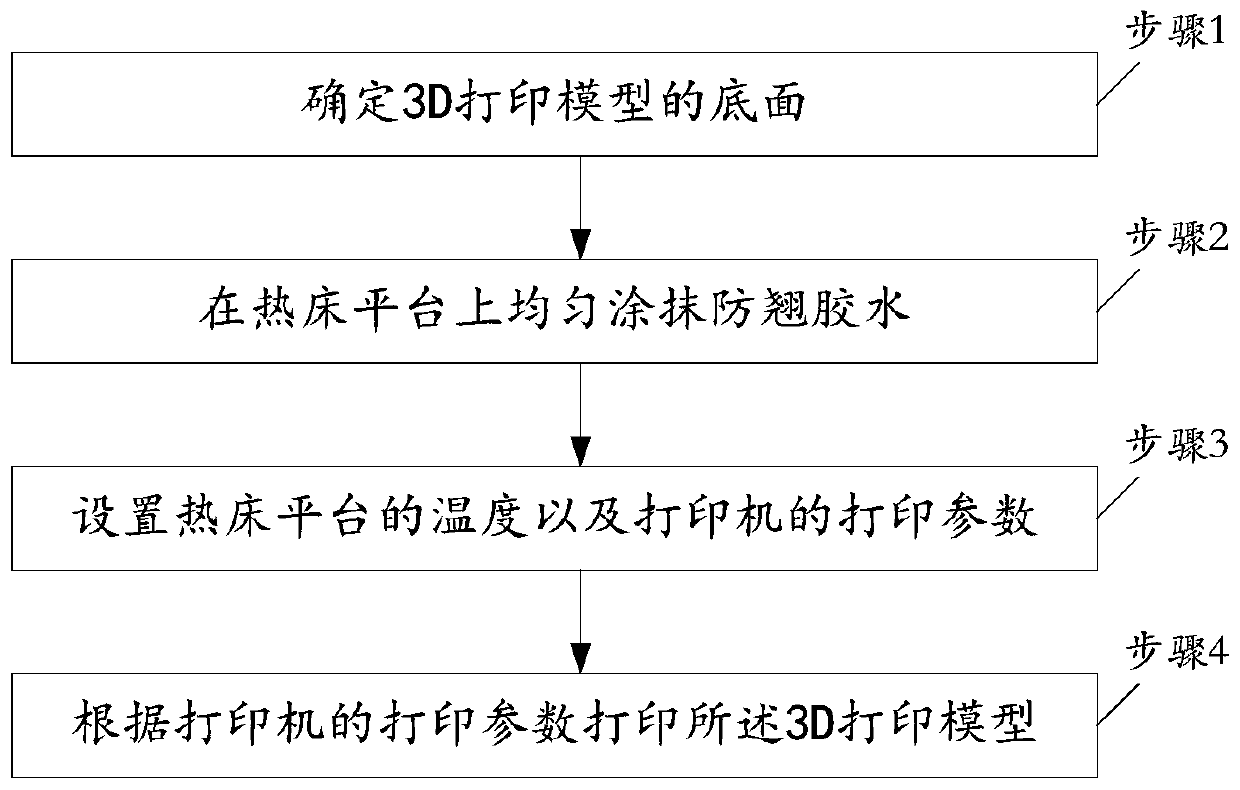

Method for preventing 3D printing model from warping in FDM (Fused Deposition Modeling) printing

InactiveCN110539479ASolve warping deformationGuaranteed to print successfullyAdditive manufacturing apparatus3D object support structuresEngineeringAerospace manufacturing

The invention belongs to the technical field of aerospace manufacturing, and discloses a method for preventing a 3D printing model from warping in FDM (Fused Deposition Modeling) printing. The methodcomprises the steps of (1) determining the bottom surface of the 3D printing model, wherein the bottom surface of the 3D printing model expresses the surface, which is printed first to make contact with a hot bed platform, in all surfaces of the 3D printing model; (2) uniformly applying anti-warping glue to the hot bed platform; (3) setting the temperature of the hot bed platform and printing parameters of a printer; and (4) printing the 3D printing model according to the printing parameters of the printer. The warping deformation of a 3D printed piece can be effectively solved, and the successful printing of a 3D product is guaranteed.

Owner:SHAANXI QIANSHAN AVIONICS

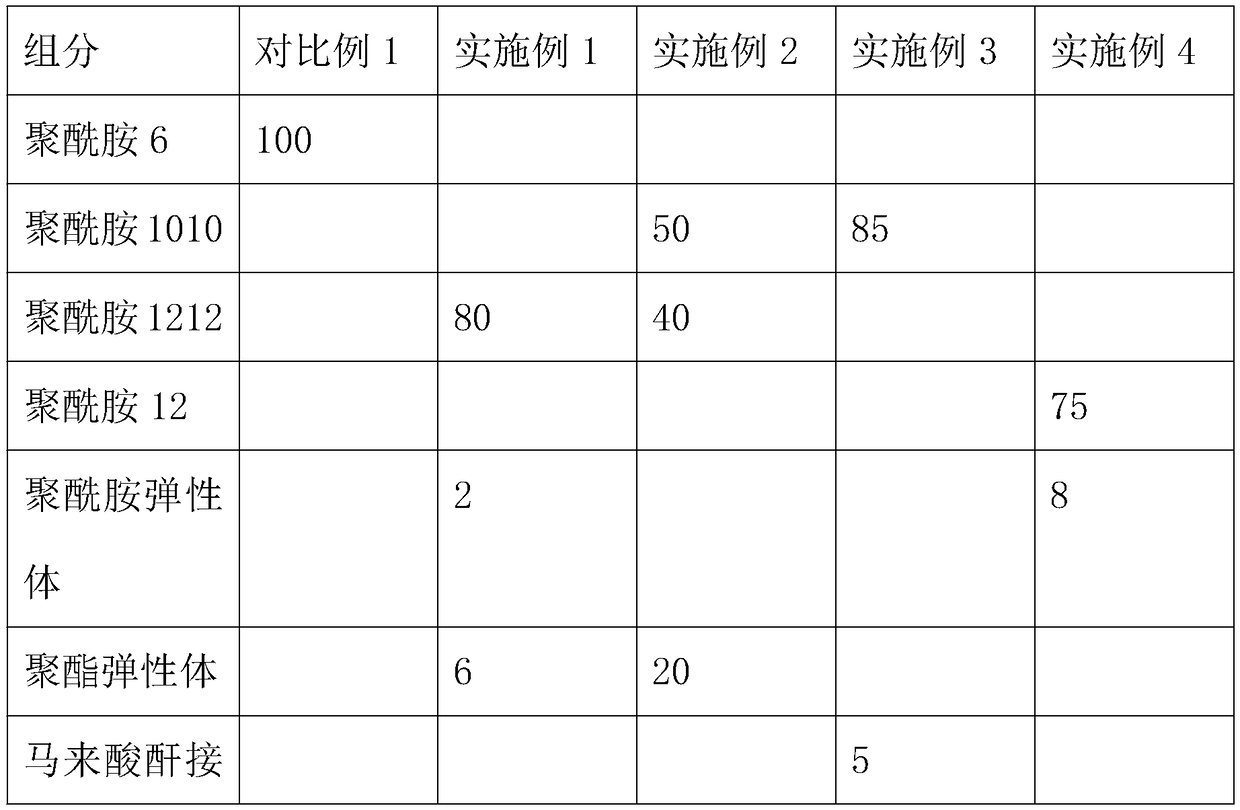

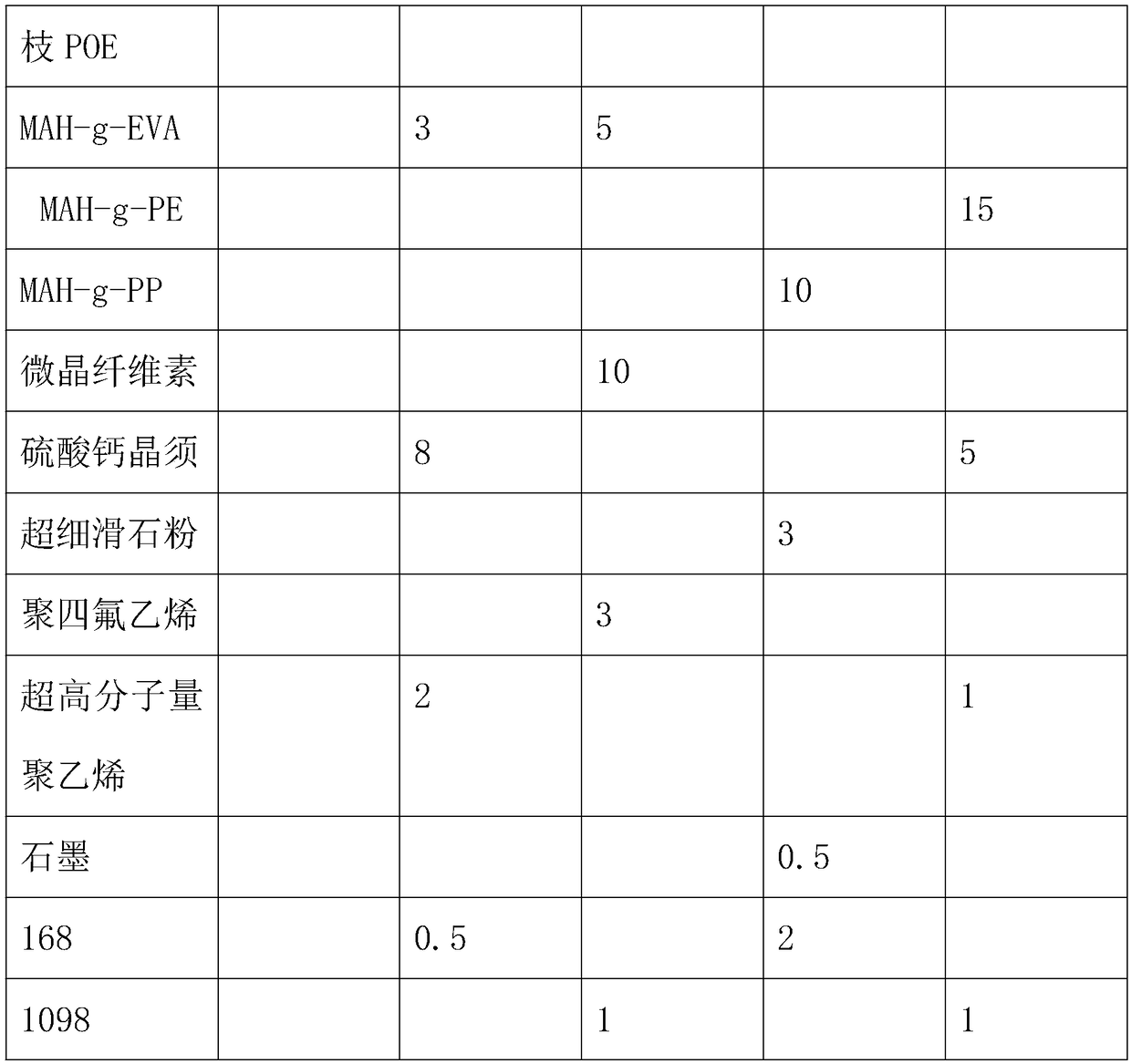

Coffeepot stirrer material and preparation method thereof

The invention relates to a stirrer material and a preparation method thereof, in particular to a coffeepot stirrer material and a preparation method thereof. The material comprises, by weight, 75-90 parts of polyamide, 5-20 parts of functional elastomers, 3-15 parts of functionalized polyolefin, 3-10 parts of fillers, 0.5-3 parts of wear-resistant assistants and 0.5-2 parts of other assistants. The coffeepot stirrer material has the advantages of high strength, high rigidity, low linear expansion coefficient, high dimensional stability, no warpage deformation, high wear resistance and the like, and the long-term normal use of a coffeepot stirrer in high-speed stirring, high temperature and low temperature environments is satisfied; the long-standing problems of stirrers, including easinessin adsorption and difficulty in removal of coffee stains, are solved, the food use requirements are met, and no toxic or harmful substance is precipitated or left.

Owner:NANJING JULONG SCI&TECH CO LTD

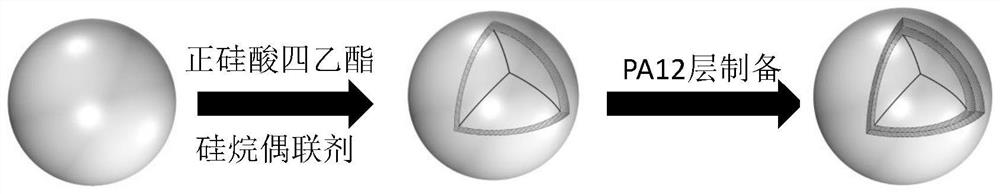

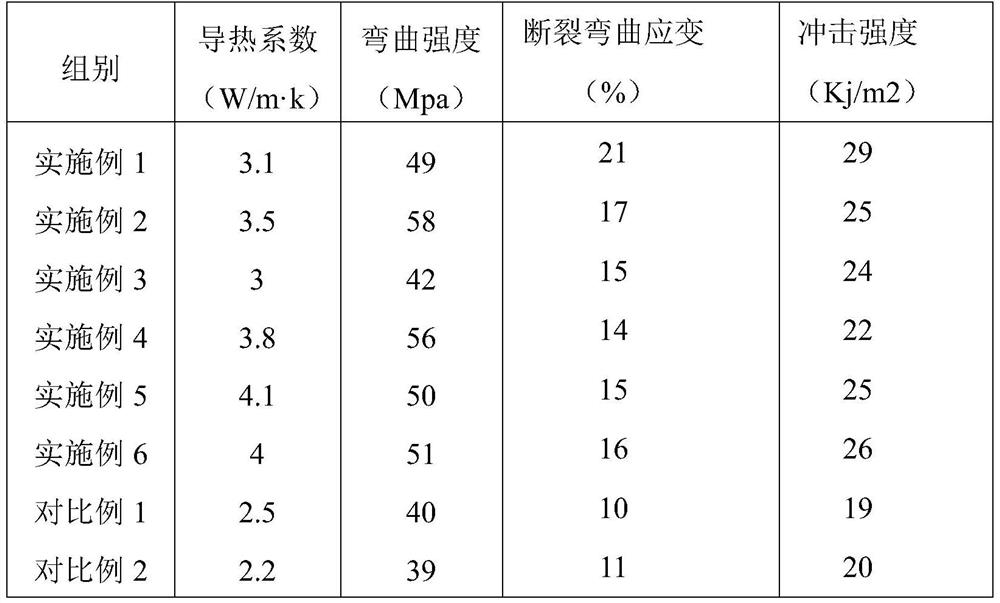

Three-layer structure heat conduction powder for SLS and preparation and use method thereof

PendingCN112679727AImprove bindingImprove thermal conductivityAdditive manufacturing apparatusAdditive manufacturing with solidsHeat conductingPhysical chemistry

The invention belongs to the field of heat conduction materials, and particularly relates to a three-layer structure heat conduction powder for SLS and a preparation and use method thereof. According to the invention, enough amino sites are prepared in a manner of firstly preparing a grafting layer on a spherical heat-conducting powder material, and then a PA12 layer is prepared at the periphery of the grafting layer in a polymerization manner, so that the powder with a three-layer structure is obtained, as shown in Figure 1. The powder can be used for preparing a heat conduction structural part rough blank through SLS printing, and then the heat conduction structural part is prepared in a sintering mode. The problem that conventional mixed powder cannot be completely and uniformly mixed is solved, the problem that buckling deformation is easily caused by uneven heating, too fast cooling and the like when a heat conducting sheet is prepared from conventional heat conducting powder SLS is also solved, and meanwhile the beneficial effects of being smooth in powder laying, sufficient in contact, convenient in SLS printing and the like are further achieved. And the prepared heat conduction part has outstanding heat conduction performance and excellent mechanical performance.

Owner:OECHSLER PLASTIC PROD TAICANG

Method for moisturizing and anti-warping of paraffin milk of plant fiberboard

The invention relates to a method for moisturizing and anti-warping of paraffin milk of a plant fiberboard. The method comprises the following steps: placing gum acacia powder in a dry container, uniformly grinding, then adding liquid paraffin, grinding to be mixed uniformly, then adding distilled water, and grinding uniformly to obtain the paraffin milk; placing the paraffin milk and a plant fiber material in a high-speed ball mill, mixing uniformly, obtaining a mixed material; placing the mixed material in a high-temperature mould pressing machine, pressing and molding, and finally demolding and cooling to room temperature to obtain the plant fiberboard, wherein the plant fiber material is rice husk fiber synthetic resin powder or plant fiber synthetic resin powder. According to the invention, the gum acacia powder and the liquid paraffin are mixed uniformly and dissolved in the distilled water to prepare a humectant, and are mixed with the plant fiber material uniformly to obtain a product by pressing and molding. The humectant can lock the easy-to-lose water and prevent a molecular chain from being deformed, the steps are simple, the design is reasonable, implementation is convenient, and the effect is good.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

A kind of SIC ceramic thin-layer bulletproof material for laminated armor and preparation method thereof

The invention relates to a SiC ceramic thin-layer bullet-resistant material for a laminated armor and a preparation method of the SiC ceramic thin-layer bullet-resistant material. The SiC ceramic thin-layer bullet-resistant material is a gel-casting sheet prepared from the following raw materials: silicon carbide micro powder, boron carbide micro powder, acrylamide monomer, N'N-methylene bisacrylamide, tetramethyl ammonium hydroxide, tributyl phosphate, deionized water and ammonium persulfate. The invention also provides the preparation method of the SiC ceramic thin-layer bullet-resistant material. According to the SiC ceramic thin-layer bullet-resistant material, a silicon carbide ceramic sheet which is large in size, compact and smooth can be prepared; the SiC ceramic thin-layer bullet-resistant material is adjustable in size, good in hardness and good in fracture toughness, and is high in protective capability as a bullet-resistant material for the laminated armor.

Owner:SHANDONG UNIV

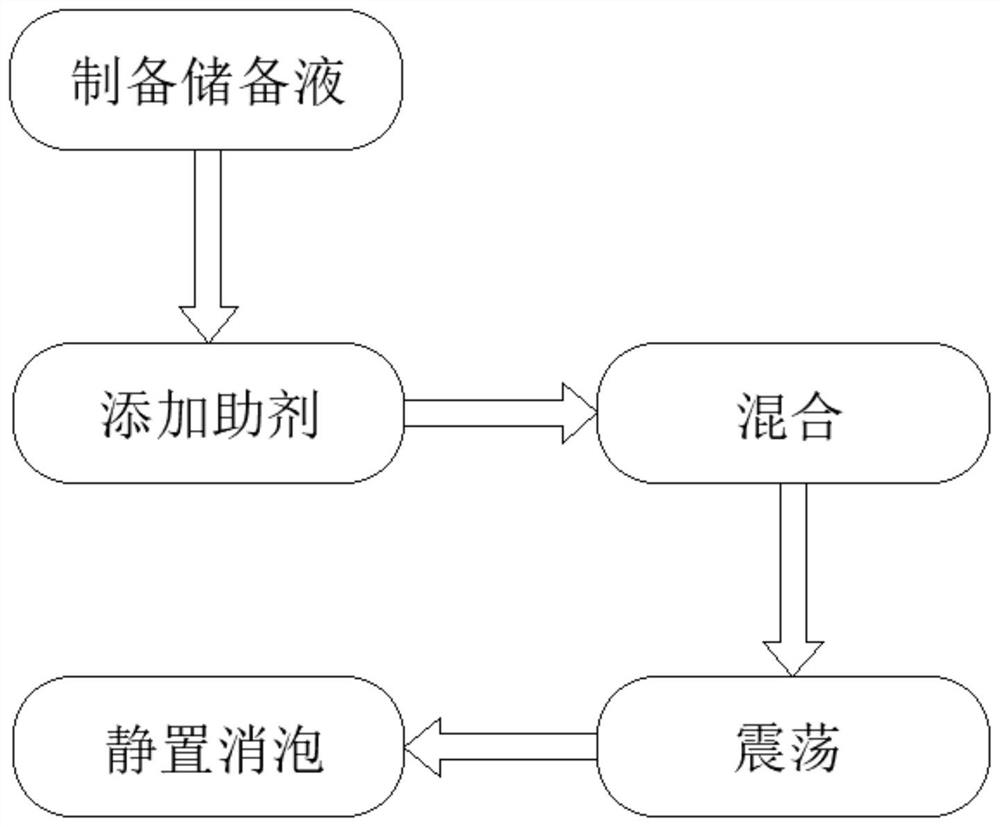

High-toughness hybrid 3D printing light-cured resin and preparation method thereof

PendingCN113861355AImprove cohesionImprove mechanical propertiesAdditive manufacturing apparatusPolymer scienceOrganic dye

The invention relates to the technical field of 3D printing, and discloses a high-toughness hybrid 3D printing light-cured resin. The high-toughness hybrid 3D printing light-cured resin is prepared from, by weight, 45 to 75 parts of monofunctional acrylate, 18 to 45 parts of a bifunctional reactive diluent, 10 to 18 parts of rigid polysiloxane, 1.2 to 5.8 parts of a photoinitiator, 2.5 to 4.6 parts of an organic dye, and 0.1 to 4.5 parts of an auxiliary agent. The invention also discloses a preparation method of the high-toughness hybrid 3D printing light-cured resin. The preparation method comprises the following steps: S1, preparing a stock solution: pouring the photoinitiator and the organic dye into a container, mixing, and heating and stirring to obtain a stock solution. According to the invention, the resin has higher toughness through the monofunctional acrylate, and meanwhile, the shrinkage of the light-cured resin in the curing process can be effectively reduced through the rigid polysiloxane, so that the mechanical property is improved.

Owner:南京君智拓新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com