Surface installation module

A surface-mounted, process edge technology, applied in the direction of assembling printed circuits with electrical components, electrically connecting printed components, printed circuit components, etc., can solve problems such as warping and deformation of circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

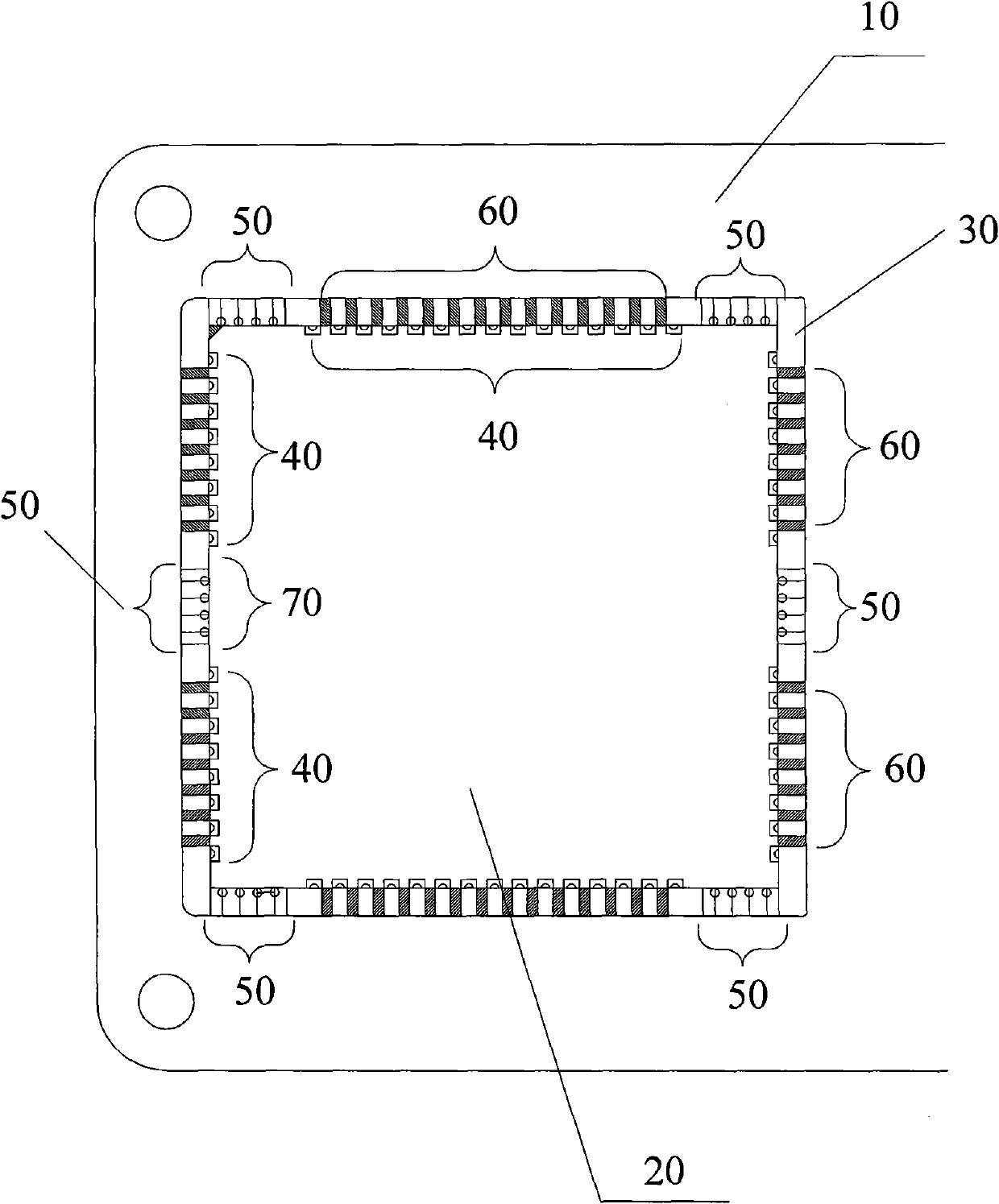

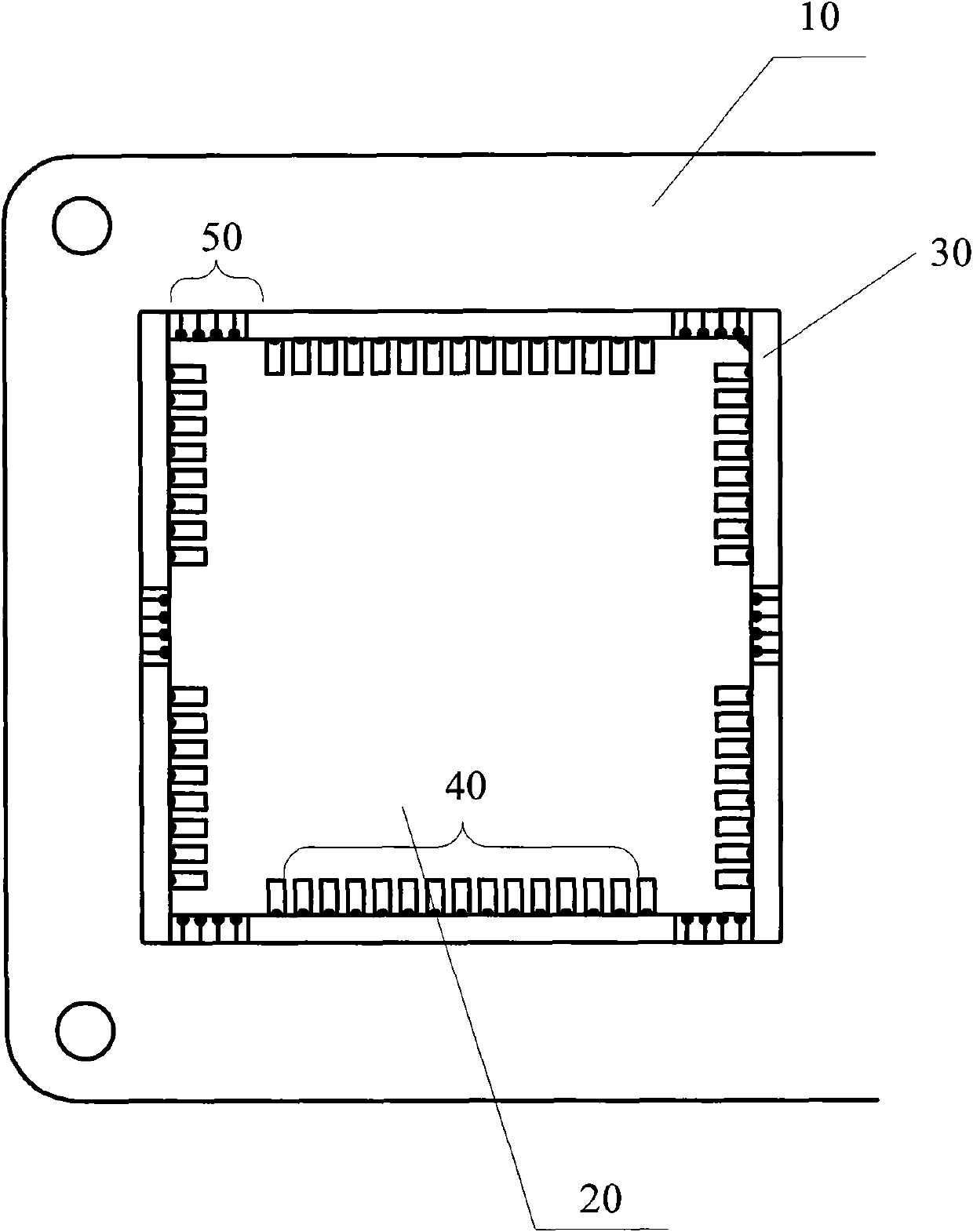

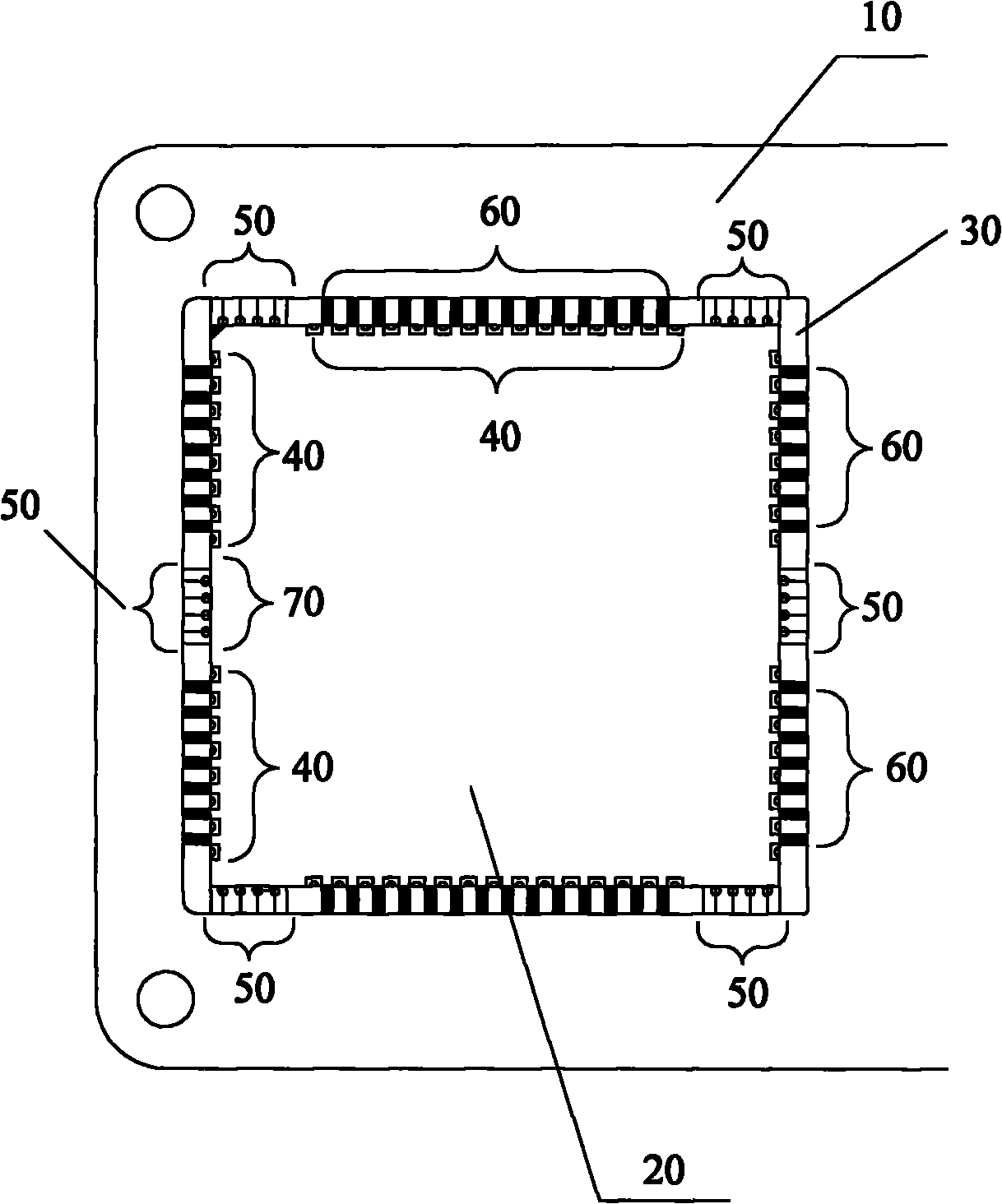

[0011] Please refer to figure 1 and figure 2 , which are respectively the front and back schematic diagrams of a surface mount (SMT) module according to a preferred embodiment of the present invention. As shown in the figure, the SMT module includes a process side 10 and a circuit board 20 , wherein the circuit board 20 is located inside the process side 10 , and there is a hollow area 30 between the circuit board 20 and the process side 10 . A plurality of pad groups 40 are provided on the edge of the circuit board 20 (for the sake of clarity, only three groups are marked in the figure, and the other three groups of symmetrical pad groups are not marked here). The circuit board 20 and the process side 10 are connected by a plurality of first rib groups 50 and a plurality of second rib groups 60, wherein the plurality of first rib groups 50 and the plurality of pad groups 40 are arranged at intervals. A second rib group 60 (for the sake of clarity, only three groups are mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com