Combined type ceiling hanging part and wood veneer ceiling installing process

An installation process and technology of decorative panels, applied in the direction of ceilings, building components, walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

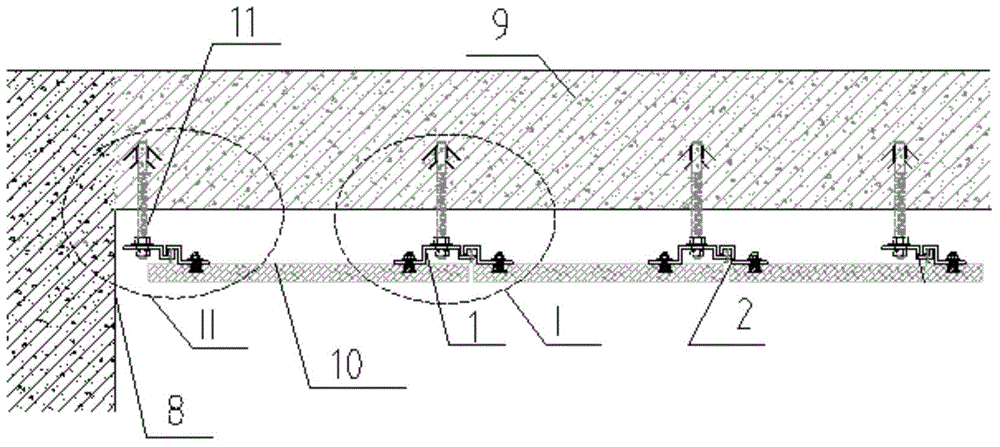

[0037] Such as figure 1 , 6 , 7, the left end of the upper horizontal portion of the Z-shaped hook 1 extends downwards with a joint 3.

[0038] Such as figure 1 , 7 As shown, the first connector 16 includes an L-shaped hook 14, the upper end of the vertical part of the L-shaped hook 14 extends to the left with a horizontal hanging part 5, and a hanging hole is provided on the horizontal hanging part 5. The horizontal portion of the L-shaped hook 14 extends upwards with a second joint 7, and an adjusting screw 4 is installed on the horizontal portion of the L-shaped hook 14.

[0039] Such as figure 1 , 6 shown, the second connector includes shaped hook 1, The top of the shaped hook 1 is provided with a hanging hole, Adjusting screw rod 4 is installed on the right side horizontal part of shaped hook 1.

[0040] In this embodiment, 2 first connectors and 2 second connectors are used, where the second connector is used at the junction of two stones, and the first conne...

Embodiment 2

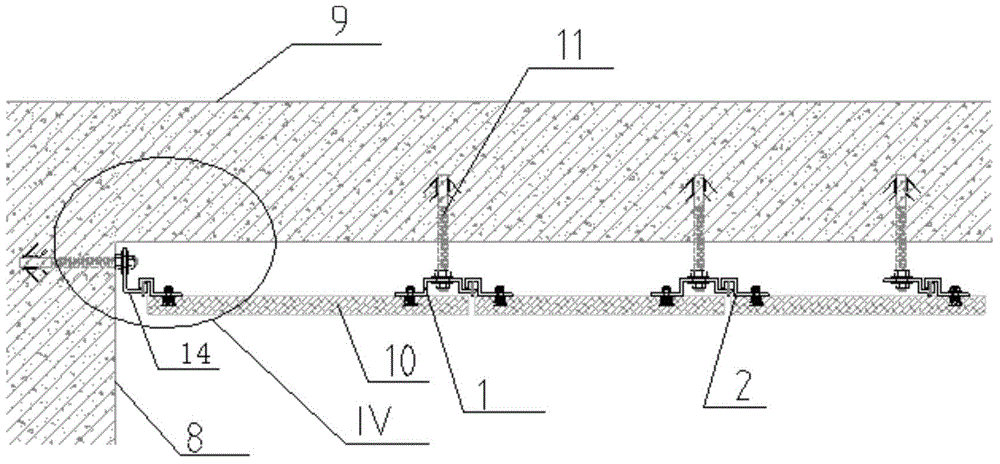

[0043] Such as figure 2 , 9 As shown, 2 first connectors and 2 second connectors are used, wherein the second connector is used at the junction of two stones, and the first connector is used at the beginning or end of the suspended ceiling. Hanging hole is offered on the vertical portion of the 1st L-shaped hitch 14, and the right end of the horizontal portion of the L-shaped hitch 14 extends upwards with a joint 2 7; Adjusting screw rod 4 is positioned at the vertical portion of the Z-shaped hitch 2 Between the joint 1 and 3.

[0044] The construction method of this embodiment is basically the same as that of Embodiment 1, except that the L-shaped hook 14 is installed on the vertical wall 8 because no keel is provided.

Embodiment 3

[0046] Such as image 3 , 8 As shown, this embodiment uses one L-shaped hook, two second connectors, and one Z-shaped piece 13 . The right end of the horizontal part of the L-shaped hook extends upwards with a hook joint 2 7 . The right end of the right horizontal portion of the shaped hook 1 extends upwards with a hook joint 3 6 .

[0047] The construction method of this embodiment is basically the same as that of Embodiment 1, the difference is that due to the L-shaped hook, Shaped hooks are all provided with hanging joints, after hooking, hanging joints two and three are located between the vertical part of the Z-shaped hanging piece and the first joint, and the second joint and the third joint have played a role in preventing Z. At this time, it is not necessary to adjust the screw to prevent the sliding of the Z-shaped hook. The upper end of the adjustment screw 4 is in contact with the bottom ends of the second joint and the third joint. When it is necessary to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com