Method for measuring hydrogen concentration in containment vessel of nuclear power plant

A technology for containment and nuclear power plants, which is applied in the direction of chemical analysis using catalysis, can solve problems such as low reliability, unintentional ignition of hydrogen, and insecurity, and achieve the effects of large measurement range, reduced energy consumption, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific examples, but is not limited thereto.

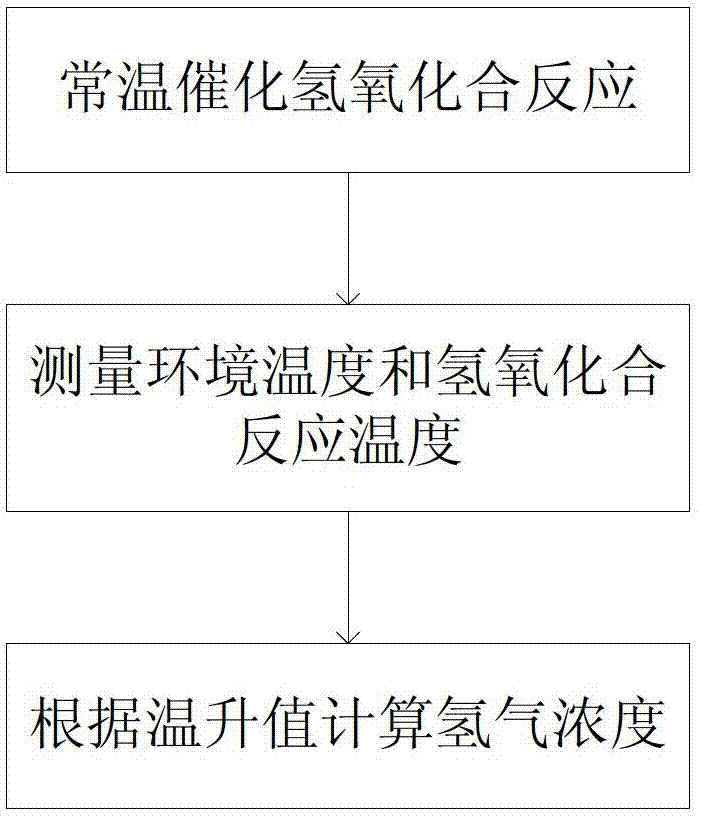

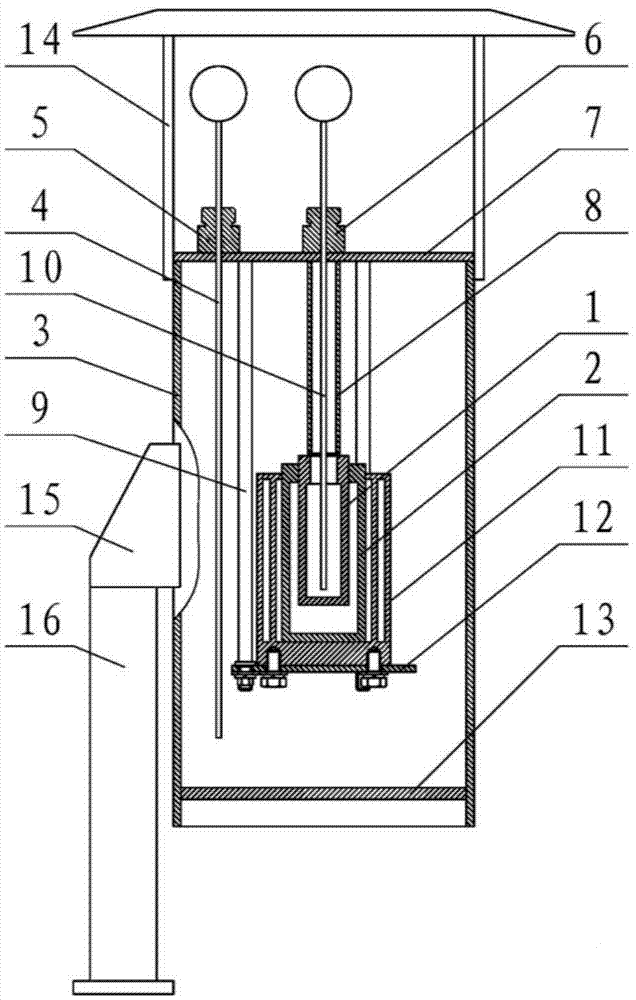

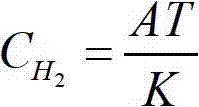

[0027] The catalytic combination reaction of hydrogen and oxygen releases a large amount of heat, and the exothermic heat of the reaction causes the temperature to rise. Proportional relationship, therefore, the reaction temperature rise is proportional to the amount of hydrogen participating in the reaction;

[0028] In the containment of a nuclear power plant, the amount of hydrogen participating in the reaction is related to the concentration of hydrogen, the greater the concentration of hydrogen, the greater the amount of hydrogen participating in the reaction, and the smaller the concentration of hydrogen, the smaller the amount of hydrogen participating in the reaction. There is also a proportional relationship between the amount of hydrogen and the concentration of hydrogen, and then it is deduced that the reaction temperature rise is propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com