Die forging single-sided thin-walled structure beam part variation compensation machining method

A technology of thin-walled structure and processing method, applied in the fields of compensation method processing and mechanical processing, can solve the problems of large deformation, cracks in parts, scrapping and other problems, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Examples of traditional crafts, such as figure 1 , 2 , 3:

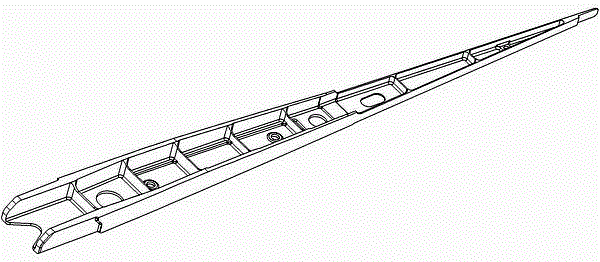

[0030] In the field of aerospace, it is often necessary to machine die forging single-sided thin-walled structural beam parts, typical structures such as figure 1 Shown:

[0031] The part material is 7B04 T6 (MD), the size is 1625mm×140 mm×δ52 mm, and the part width gradually changes from 140 mm to 2mm.

[0032] According to the existing mechanical processing scheme, the steps are:

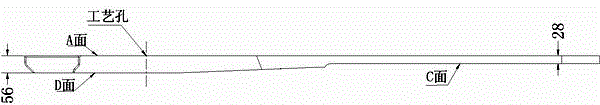

[0033] (1) Roughly machine planes A, D, and C first, with a margin of 2mm on one side, such as figure 2 shown;

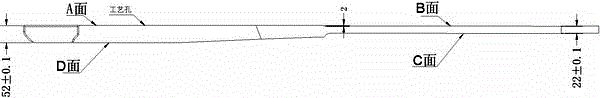

[0034] (2) The processing planes A, B, C, and D are in place, such as image 3 shown;

[0035] (3) The inner shape of the part, the height of the web and the ribs are in place.

[0036] After processing, the parts will be twisted and warped, the deformation amount is 5-9mm, and the shape needs to be corrected. Due to the large amount of deformation, the parts are prone to cracks and scrapped during the calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com