Electroplating ABS composite and preparation method thereof

A composite material and ABS resin technology, which is applied in the field of ABS composite materials for electroplating and its preparation, can solve the problems of cracking and fine lines of metal coating, increase internal stress of plastic injection parts, etc. , Enhance the effect of physical anchoring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add 45kg of SEBS-GMA graft, 5kg of dispersant, 0.1kg of bisphenol A and 0.1kg of commercially available IG-168 into a high-speed mixer and stir for 20 minutes before discharging to obtain mixture A.

[0053] Add 50kg of heat-resistant agent from the main feeding port of the twin-screw extruder, add the mixture A from the side feeding port of the twin-screw extruder, extrude and granulate to obtain heat-resistant masterbatch, and the barrel temperature of the extruder is 240-300°C, the screw speed is 180-600 rpm.

[0054] Put 62kg of emulsion method ABS resin, 20kg of bulk method ABS-GMA resin, 15kg of heat-resistant masterbatch, 0.1kg of bisphenol A and 0.1kg of commercially available IG-168 into a high-speed mixer and stir for 5-30 minutes before discharging to obtain a mixture b.

[0055] The mixture B is added from the main feeding port of the twin-screw extruder, and 3kg of nano-scale calcium carbonate is added from the side feeding port of the twin-screw extruder,...

Embodiment 2-5

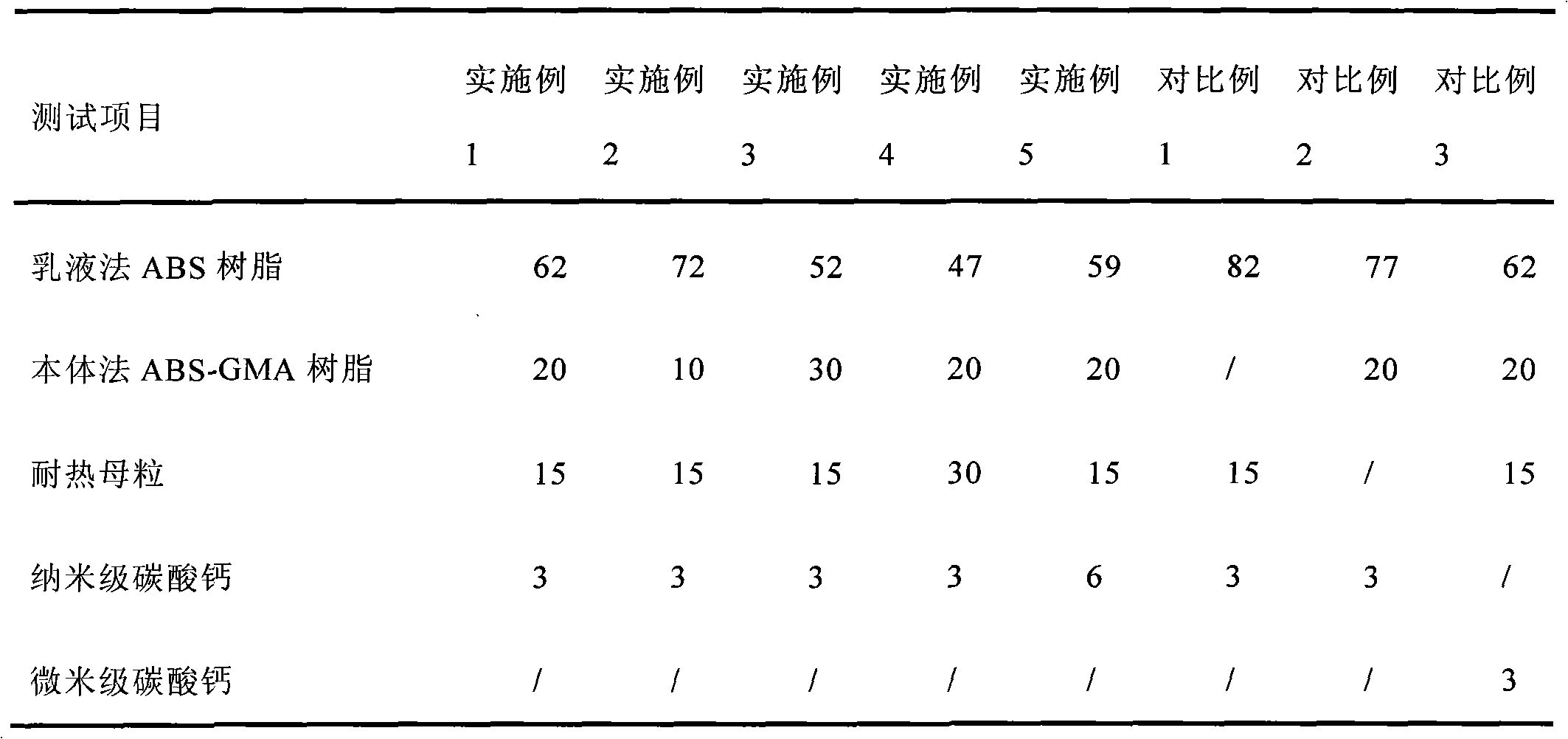

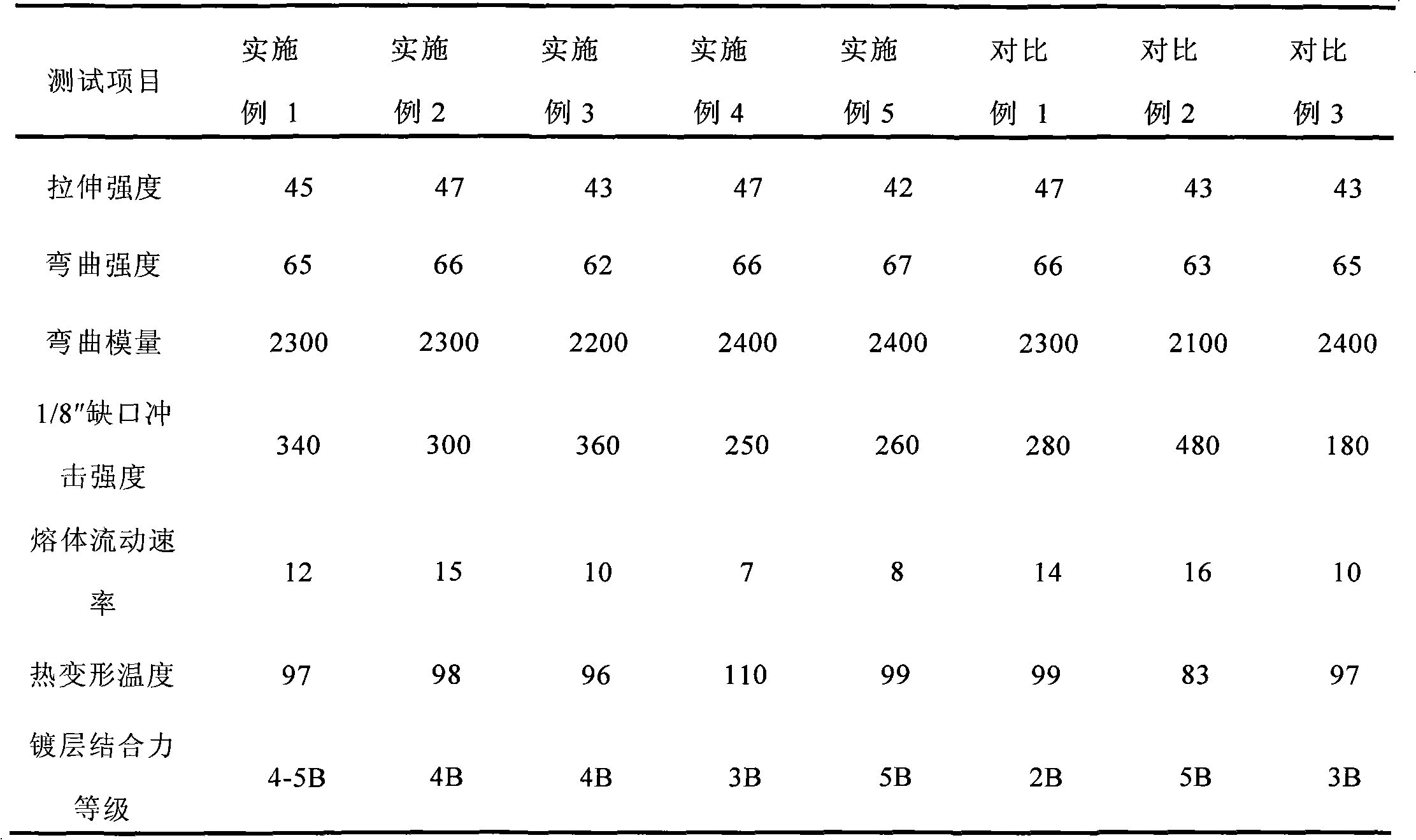

[0057] In order to better reflect the characteristics of the above-mentioned electroplated ABS, which is excellent in the high and low temperature cycle test, the present invention uses the influence of different bulk method ABS-GMA resin dosages, different heat-resistant masterbatch dosages, and different nanoscale filler dosages on product performance. The specific main ingredient formula is shown in Table 1, including the following steps:

[0058] Add SEBS-GMA graft, dispersant, bisphenol A and commercially available IG-168 into a high-speed mixer and stir for 20 minutes before discharging to obtain mixture A.

[0059] Add the heat-resistant agent from the main feeding port of the twin-screw extruder, add the mixture A from the side feeding port of the twin-screw extruder, control the barrel temperature of the extruder to 240-300°C, and the screw speed to 180- 600 rpm, extrusion granulation to obtain heat-resistant masterbatch.

[0060] Put the emulsion method ABS resin, b...

Embodiment 6

[0083] An ABS composite material for electroplating and a preparation method thereof, comprising the following steps:

[0084] (1) Preparation of heat-resistant masterbatch: 30kg of polar grafts of flexible resin, 30kg of heat-resistant agent, 3kg of dispersant, and 0.5kg of antioxidant are used as raw materials. Among them, the glass transition temperature of the polar graft of the flexible resin is lower than -40°C, and it has good compatibility with the ABS substrate. It is a maleic anhydride graft of styrene-butadiene-styrene block copolymer Copolymer, heat-resistant agent adopts the terpolymer of maleic anhydride and methyl methacrylate, styrene, and maleic anhydride content is 10% (wt%) in this terpolymer, and methyl methacrylate content is 20% (wt%), the styrene content is 70% (wt%) and the glass transition temperature is 210°C. The dispersant is a binary random copolymer of ethylene-methacrylate, and the antioxidant is hindered monophenol and A mixture of phosphite co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com