Automatic packaging line finished product whole box automatic turning machine and method for turning box bodies through automatic packaging line finished product whole box automatic turning machine

An automatic flipping and automatic packaging technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of increasing the production cost of the enterprise, missing turning, etc., and achieve the effect of solving warping deformation, simple operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

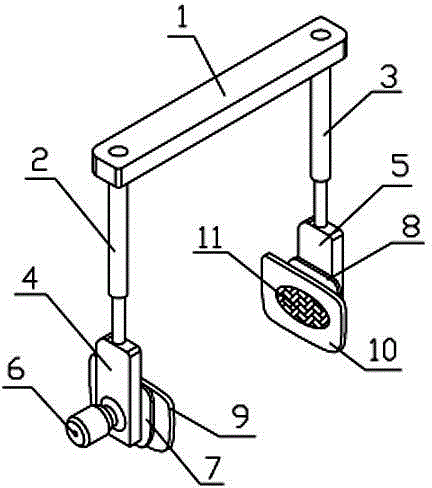

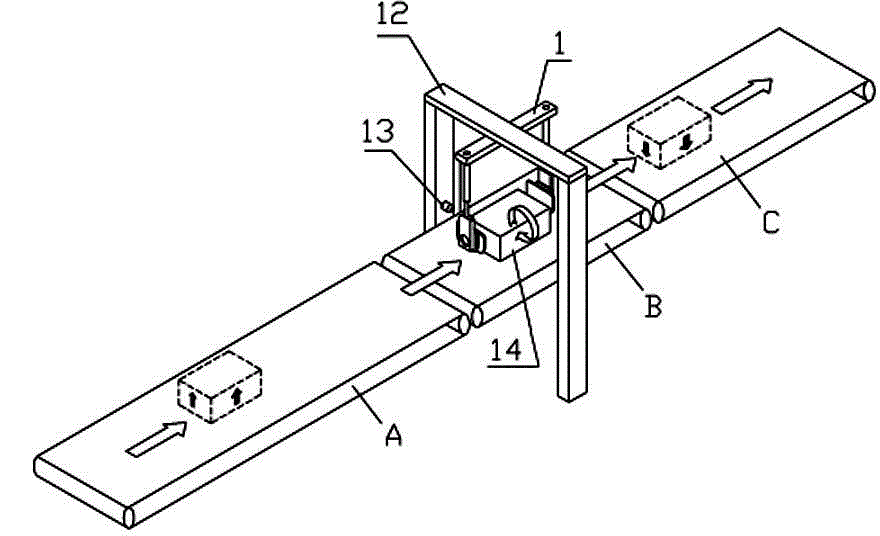

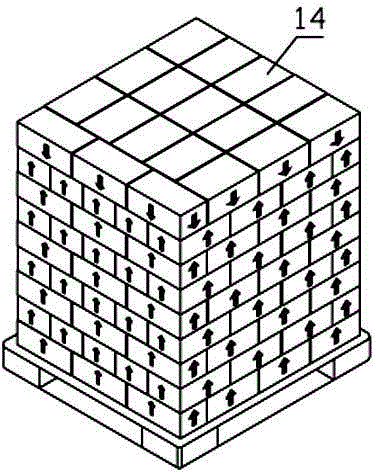

[0019] Such as figure 1 As shown, the Tetra Pak one-piece automatic packaging line finished product full-box automatic turning machine of the present invention includes a horizontally arranged fixed beam 1, and the two ends of the fixed beam 1 are vertically provided with a left elevating rod 2 and a right elevating rod 3. A left shoe block 4 and a right shoe block 5 are arranged symmetrically and fixedly on the lower ends of the left lifting rod 2 and the right lifting rod 3, and an active turntable 7 driven by a driving motor 6 is arranged on the inner side of the left shoe block 4; The inner side of the right shoe block 5 is provided with a passive turntable 8 driven by a telescopic cylinder to move back and forth, and the passive turntable 8 corresponds to the position of the active turntable 7 .

[0020] In order to facilitate maintenance and replacement of parts, the inner surface of the active turntable 7 is provided with a left chuck 9, and the inner surface of the pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com