Three-layer structure heat conduction powder for SLS and preparation and use method thereof

A thermally conductive powder, three-layer structure technology, applied in manufacturing, solid material additive processing, additive processing, etc., can solve the problems of low precision, easy bending deformation, etc., to achieve full contact, smooth powder spreading, Solve the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

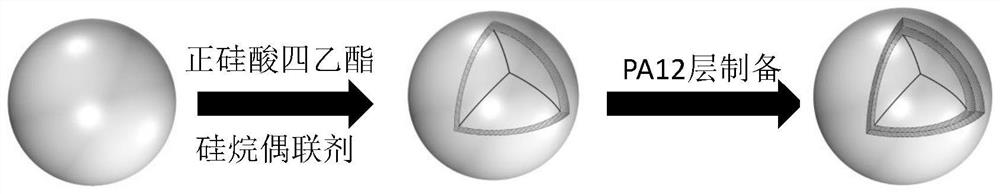

[0019] A heat-conducting powder with a three-layer structure that can be used in SLS and its preparation and use methods.

[0020] (1) The spherical heat-conducting core material powder (BN, diameter 10 μm) is uniformly dispersed in the mixed solution of water and ethanol.

[0021] (2) Add tetraethyl orthosilicate and γ-aminopropyltriethoxysilane (mass ratio 1:1) to it and stir evenly, then add catalyst (ammonia) and stir thoroughly to prepare a compound with amino graft Layered double-layer structure spherical powder.

[0022] (3) The obtained double-layer structure spherical powder with amino graft layer is filtered and dried; the obtained double-layer structure spherical powder with amino graft layer is added to the reaction kettle, and then dropped into 1,12-deca Dialkyldiamine, terephthalic acid, benzoic acid as an end-capping agent, sodium hypophosphite catalyst and deionized water (mass ratio 1:10:10:0.5:0.1:100).

[0023] (4) Vacuumize for 15 minutes, then raise the ...

Embodiment 2

[0027] A heat-conducting powder with a three-layer structure that can be used in SLS and its preparation and use methods.

[0028] (1) Spherical thermally conductive core material powder (Al 2 o 3 , diameter 20 μm) uniformly dispersed in the mixed solution of water and ethanol.

[0029] (2) Add tetraethyl orthosilicate and γ-aminopropyltriethoxysilane (mass ratio 2:1) to it and stir evenly, then add catalyst (acetic acid) and stir thoroughly to prepare a compound with amino graft Layered double-layer structure spherical powder.

[0030] (3) The obtained double-layer structure spherical powder with amino graft layer is filtered and dried; the obtained double-layer structure spherical powder with amino graft layer is added to the reaction kettle, and then dropped into 1,12-deca Dialkyldiamine, terephthalic acid, benzoic acid as an end-capping agent, sodium hypophosphite catalyst and deionized water (mass ratio 1:10:10:0.5:0.1:100).

[0031] (4) Vacuumize for 25 minutes, then...

Embodiment 3

[0035] A heat-conducting powder with a three-layer structure that can be used in SLS and its preparation and use methods.

[0036] (1) The spherical heat-conducting core material powder (SiC, diameter 30 μm) is uniformly dispersed in the mixed solution of water and ethanol.

[0037] (2) Add tetraethyl orthosilicate and γ-aminopropyl triethoxysilane (mass ratio 4:1) to it and stir evenly, then add catalyst (hydrochloric acid) and stir thoroughly to prepare a compound with amino graft Layered double-layer structure spherical powder.

[0038] (3) The obtained double-layer structure spherical powder with amino graft layer is filtered and dried; the obtained double-layer structure spherical powder with amino graft layer is added to the reaction kettle, and then dropped into 1,12-deca Dialkyldiamine, terephthalic acid, benzoic acid as an end-capping agent, sodium hypophosphite catalyst and deionized water (mass ratio 1:10:10:0.5:0.1:100).

[0039] (4) Vacuumize for 35 minutes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com