Accurate machining method for complex thin-wall variable-thickness large covering cap

A technology of precise processing and variable thickness, applied in the field of machinery and sheet metal processing, can solve the problems of large deformation, obvious vibration, large vibration deformation, etc., and achieve the effect of ensuring wall thickness, solving warping deformation, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

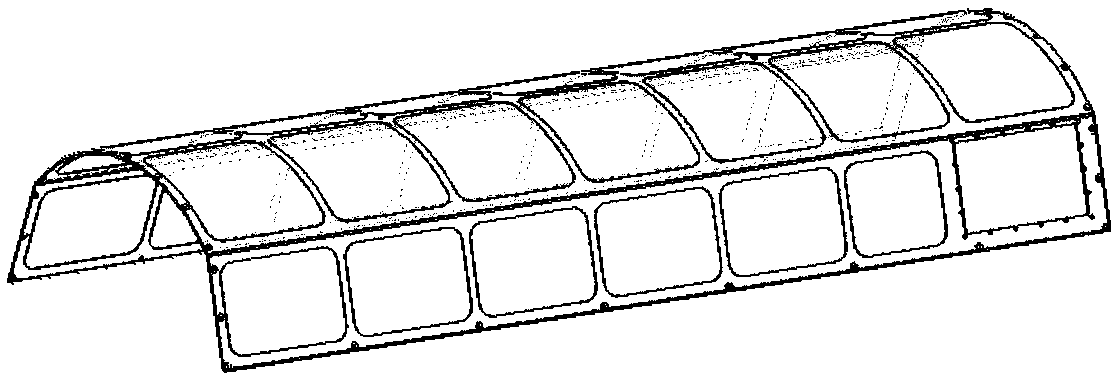

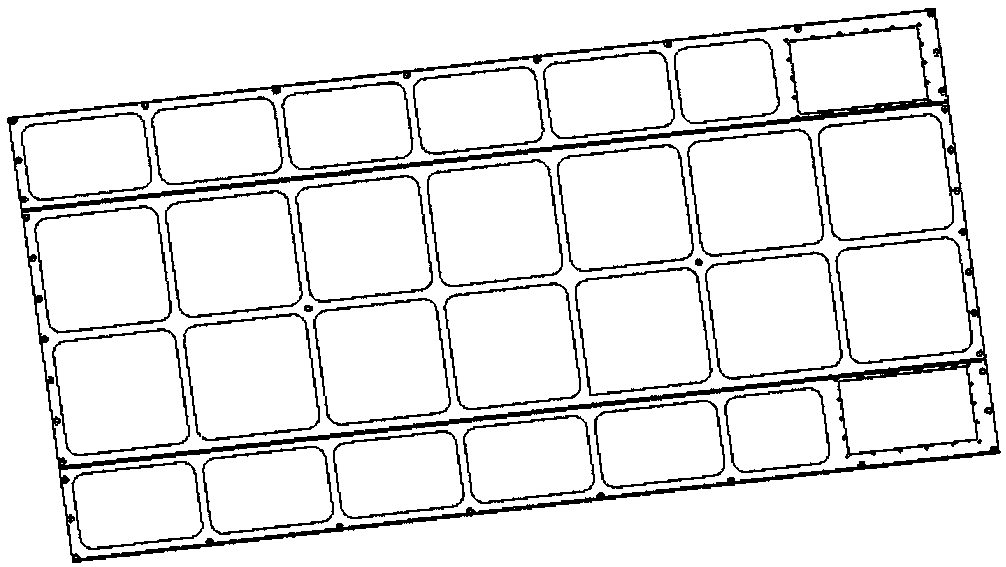

[0024] The selected test part of the present invention is a large mouth cover of a certain type of aircraft lap section. The material of this part is 5A06 aluminum alloy plate. The product structure is a large thin-walled variable-thickness part with a complex inner cavity. The wall thickness of the large surface of the large mouth cover is 3mm, and the length, width and thickness of the flattened state are 1600×750×3mm, for example figure 1 , figure 2 shown. The specific implementation is as follows:

[0025] (1) Collect the geometric parameters of the original large mouth cover, use the UG8.0 3D modeling software to construct the three-dimensional model of the large mouth cover, and simulate and flatten it, and then calculate the parameters that can envelop the part according to the flattened parameters Minimum blank size.

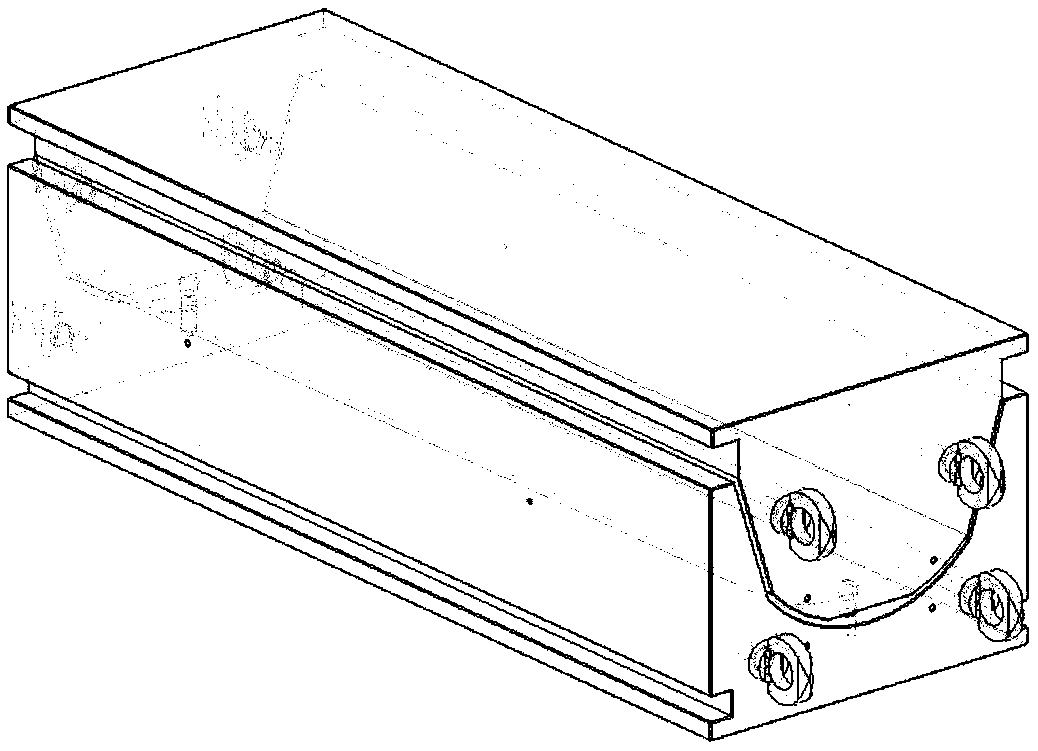

[0026] Principle: According to the specific structure and size of the required large mouth cover, as well as the characteristics of flat sheet metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com