Rapid forming working platform

A workbench and rapid technology, applied in the field of rapid prototyping workbench, can solve the problems of complex forming process of rapid prototyping equipment, difficult to observe, unable to handle in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

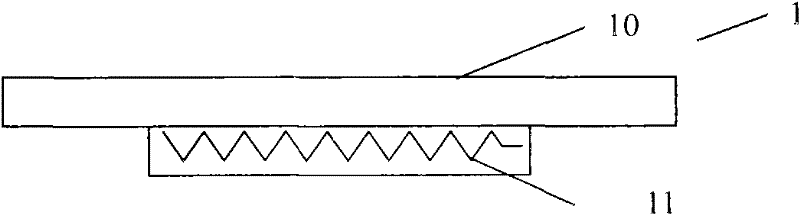

[0037] refer to figure 1, is a structural schematic diagram of the first embodiment of the rapid prototyping workbench of the present invention. The rapid prototyping workbench 1 includes a metal platform 10 and a heating device 11 sequentially from top to bottom, wherein the metal platform 10 can be an aluminum platform, a copper platform, an iron platform, etc., and the heating device 11 can be a resistance wire heating, a heating tube or Heating rod heating and other commonly used heating devices. During the forming process, the thermoplastic filament extruded from the nozzle solidifies and accumulates on the upper surface of the metal platform 10, that is, the support surface. During the extrusion and solidification process, the temperature of the thermoplastic filament is only cooled from the melting temperature to the softening temperature of the plastic. Warping deformation caused by excessive cooling of plastic is avoided. The softening temperature is provided by the...

Embodiment 2

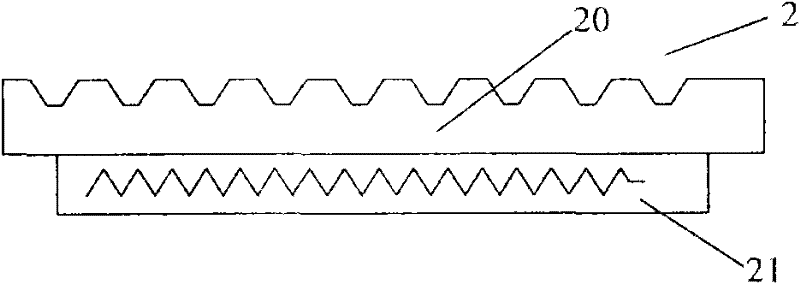

[0039] See figure 2 , is a schematic structural view of the second embodiment of the rapid prototyping workbench of the present invention. The rapid prototyping workbench 2 includes a glass platform 20 and a heating device 21 sequentially from top to bottom, grooves are evenly distributed on the upper surface (i.e. the support surface) of the glass platform 20 of the rapid prototyping workbench 2, the purpose is: its 1. Use a convex-concave surface instead of a smooth plane to increase the bonding area between the support surface and the bottom surface of the formed part, and improve the support force of the support surface to the formed part; 2. The thermal conductivity of glass is worse than that of metal materials. Opening grooves on the glass platform can partially reduce the thickness of the glass platform, which is more conducive to heat conduction. Of course, it is not limited to the form of opening grooves, and the concave holes or grid structures and other convex-co...

Embodiment 3

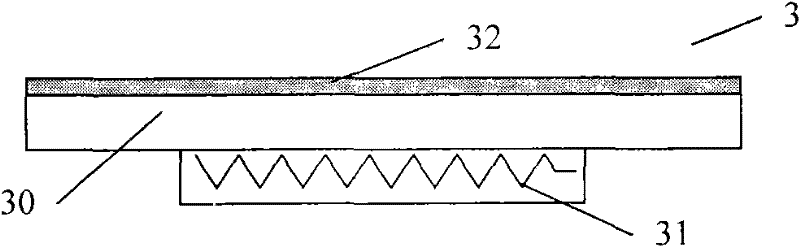

[0041] See image 3 , is a structural schematic diagram of the third embodiment of the rapid prototyping workbench of the present invention. Same as the rapid prototyping workbench 1 in embodiment 1, the rapid prototyping workbench 3 in this embodiment includes a metal platform 30 and a heating device 31 in order from top to bottom, but it is different from the rapid prototyping workbench 1 in embodiment 1 The difference is: the upper surface (i.e. the support surface) of the metal platform 30 of the rapid prototyping workbench 3 is coated with a polymer material layer, preferably a plastic layer 32, in order to increase the supporting force of the forming material during the forming process, Because the support surface of the metal platform 30 does not have enough bonding strength to the cured plastic forming part, it will easily cause the plastic forming part to shift on the metal support surface, which will affect the forming of the part. After the plastic layer 32 is coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com