Method for shaping gear shaver

A technology for gear shaving cutters and gears, which is applied to components with teeth, gear teeth, and gear tooth manufacturing tools, etc. It can solve the problems of reduced production efficiency of shaving gears, poor modification targets, and many times of grinding, and achieves the goal of repairing The effect of strong shape and goal, reducing blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

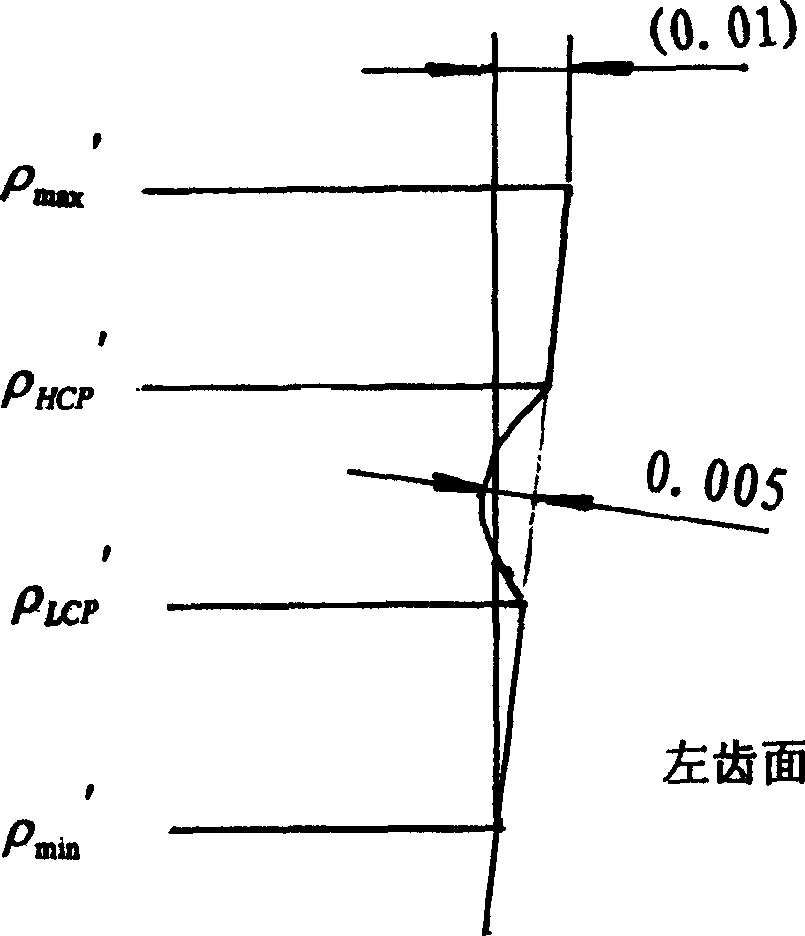

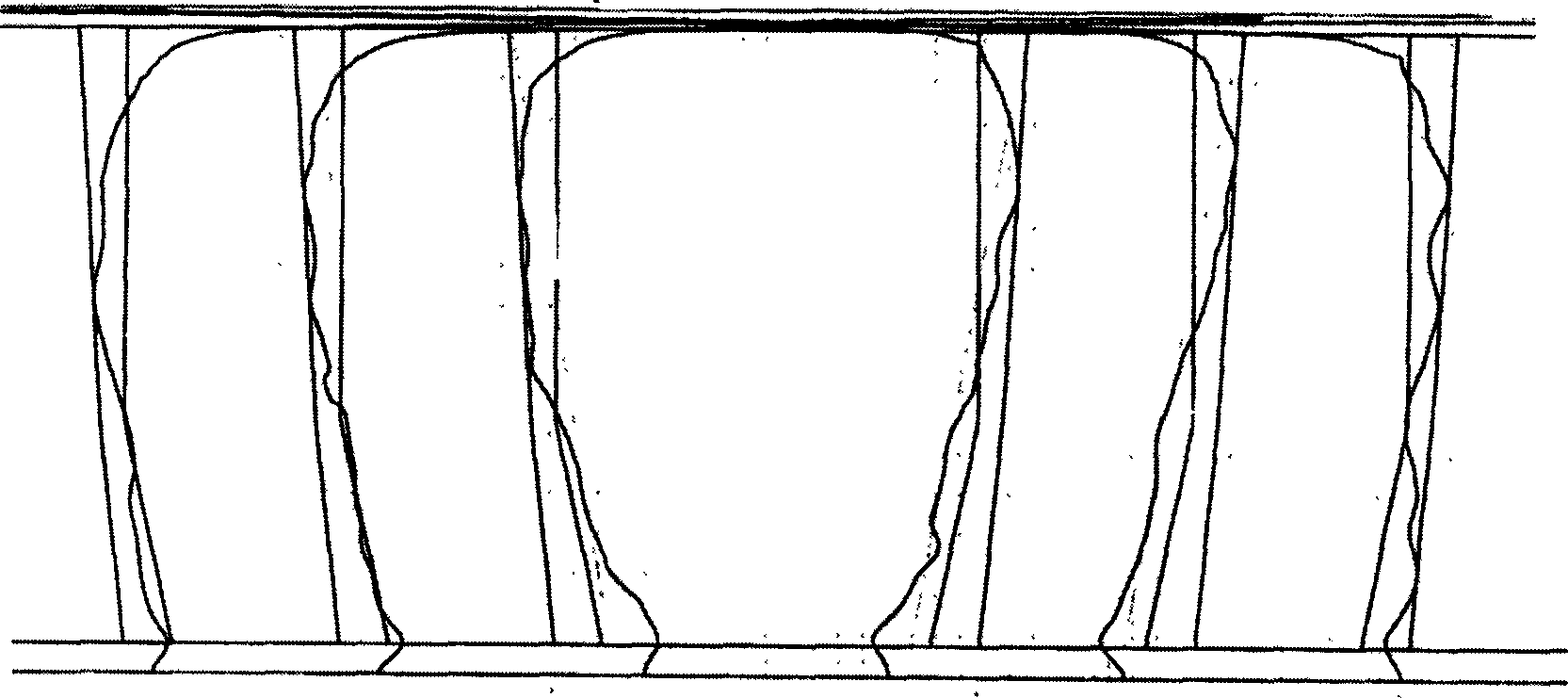

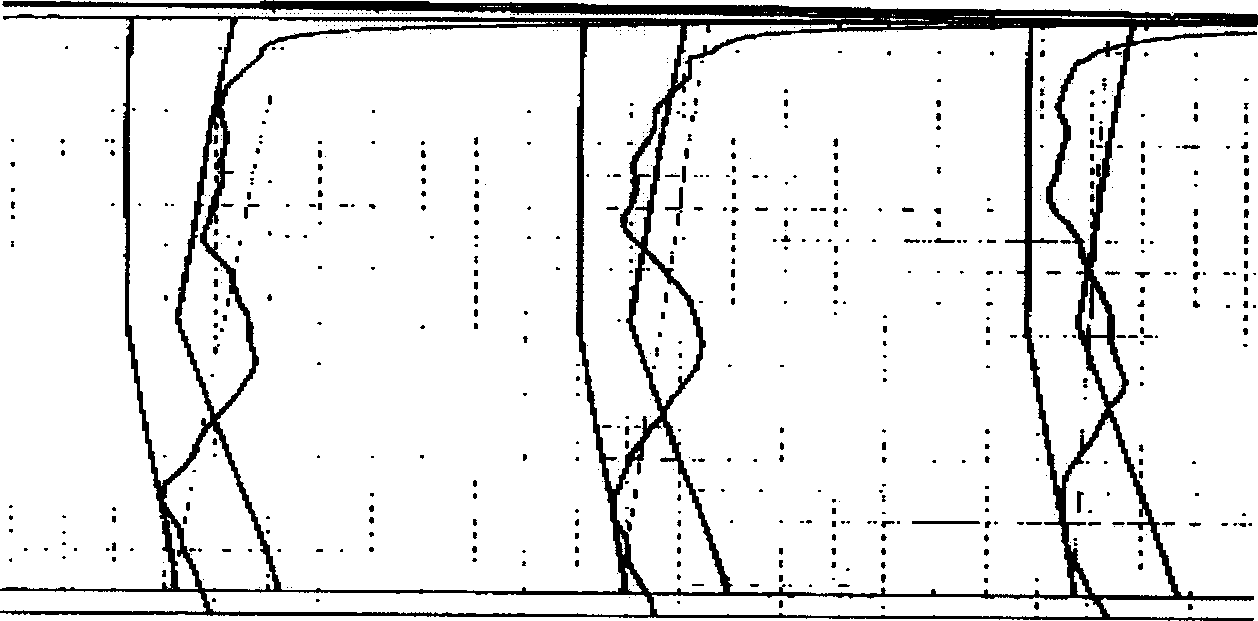

[0033] Utilize the shaving cutter modification method of the present invention below to carry out the modification with the shaving cutter to the gear that needs shaving processing;

[0034] The relevant parameters of the known processed gears are

[0035] Number of teeth Z 1 =17

[0036] Normal modulus m n =4.7736

[0037] Normal pressure angle α of subcircle n =18.80°

[0038] Circle helix angle β 1 = 0°

[0039] arc tooth thickness S ) n 1 = 8.939

[0040] The radius of curvature of the involute end point ρ max =27.5

[0041] Involute starting circle radius of curvature ρ min =7.82

[0042] Tooth shaving excess δ=1.5

[0043] The relevant parameters of the gear shaving cutter used are:

[0044] Number of teeth Z 2 =47

[0045] Normal modulus m n =4.7736

[0046] Normal pressure angle α of subcircle n =18.8°

[0047] Circle helix ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com