Graphene polylactic acid bicomponent composite fiber and preparation method and equipment thereof

A kind of polylactic acid and composite fiber technology, which is applied in the field of melt spinning fibers, can solve the general effect of side-by-side fiber curling, and the strength and wear resistance of polylactic acid polybutylene succinate bicomponent fibers have not been compared. Good improvement, elasticity and hand feeling have not been improved, to achieve the effect of improving non-wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0051] Crush 6kg of polylactic acid slices into powder, add 2kg of graphene powder, mix the two powders evenly, and then melt and extrude granules through a granulator. The extrusion temperature of the granulator is 195°C to obtain graphene masterbatches .

preparation example 2

[0053] Crush 9.5kg of polylactic acid slices into powder, add 0.5kg of graphene powder, mix the two powders evenly, and then melt and extrude granules through a granulator. The extrusion temperature of the granulator is 200°C to obtain graphene Masterbatch.

preparation example 3

[0055] Crush 8.8kg of polylactic acid slices into powder, add 1.2kg of graphene powder, mix the two powders evenly, and then melt and extrude granules through a granulator. The extrusion temperature of the granulator is 190°C to obtain graphene. Masterbatch.

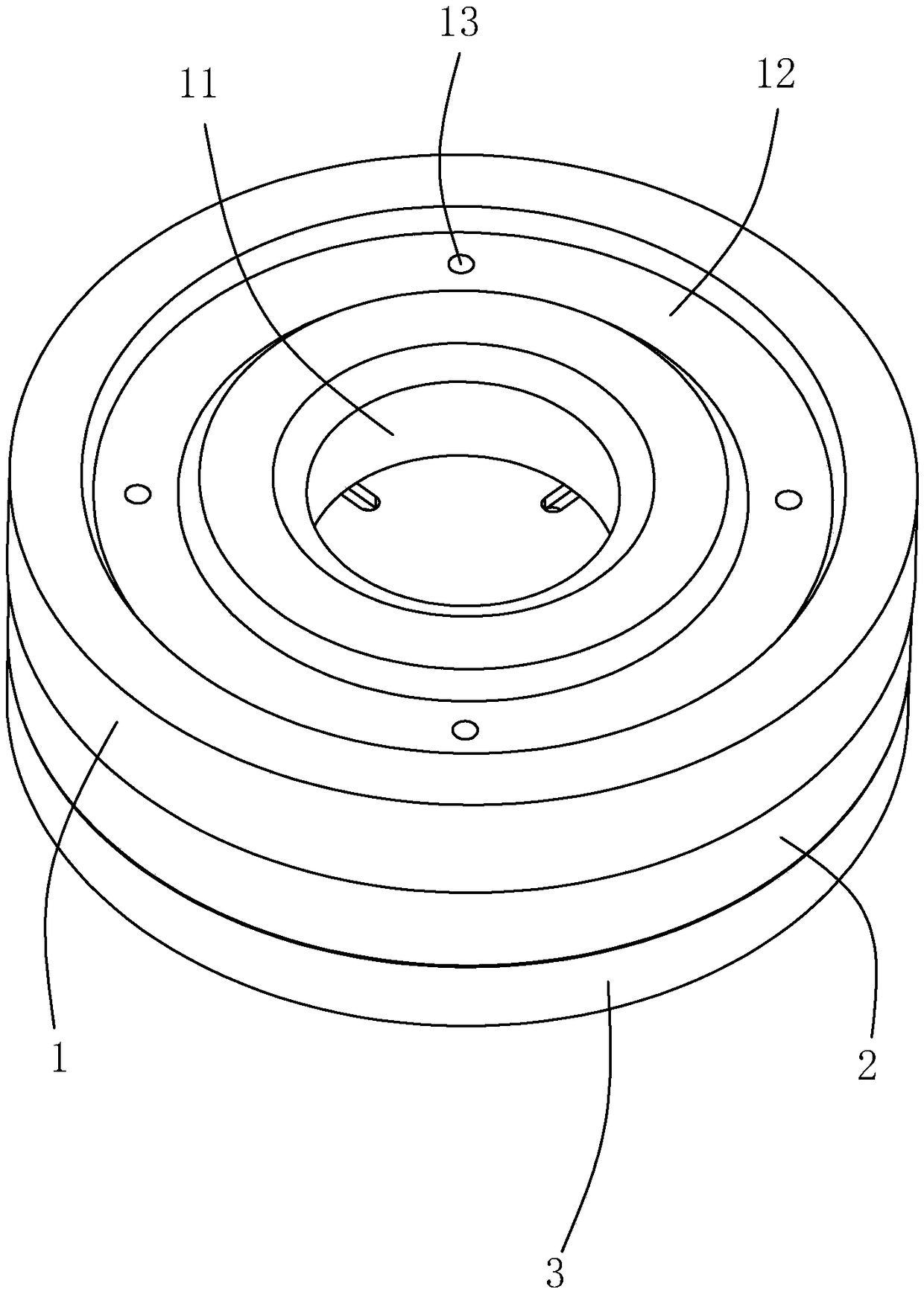

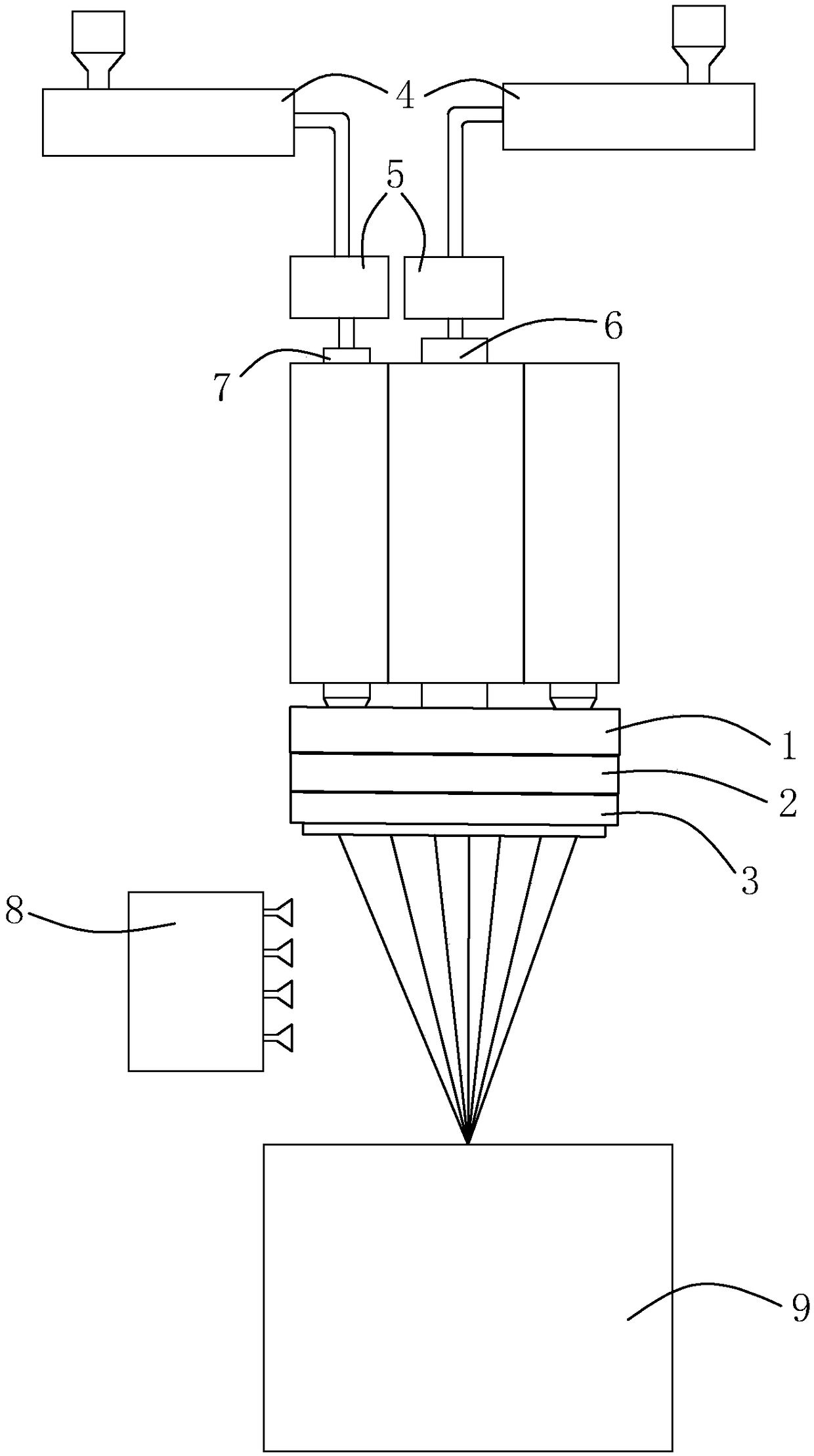

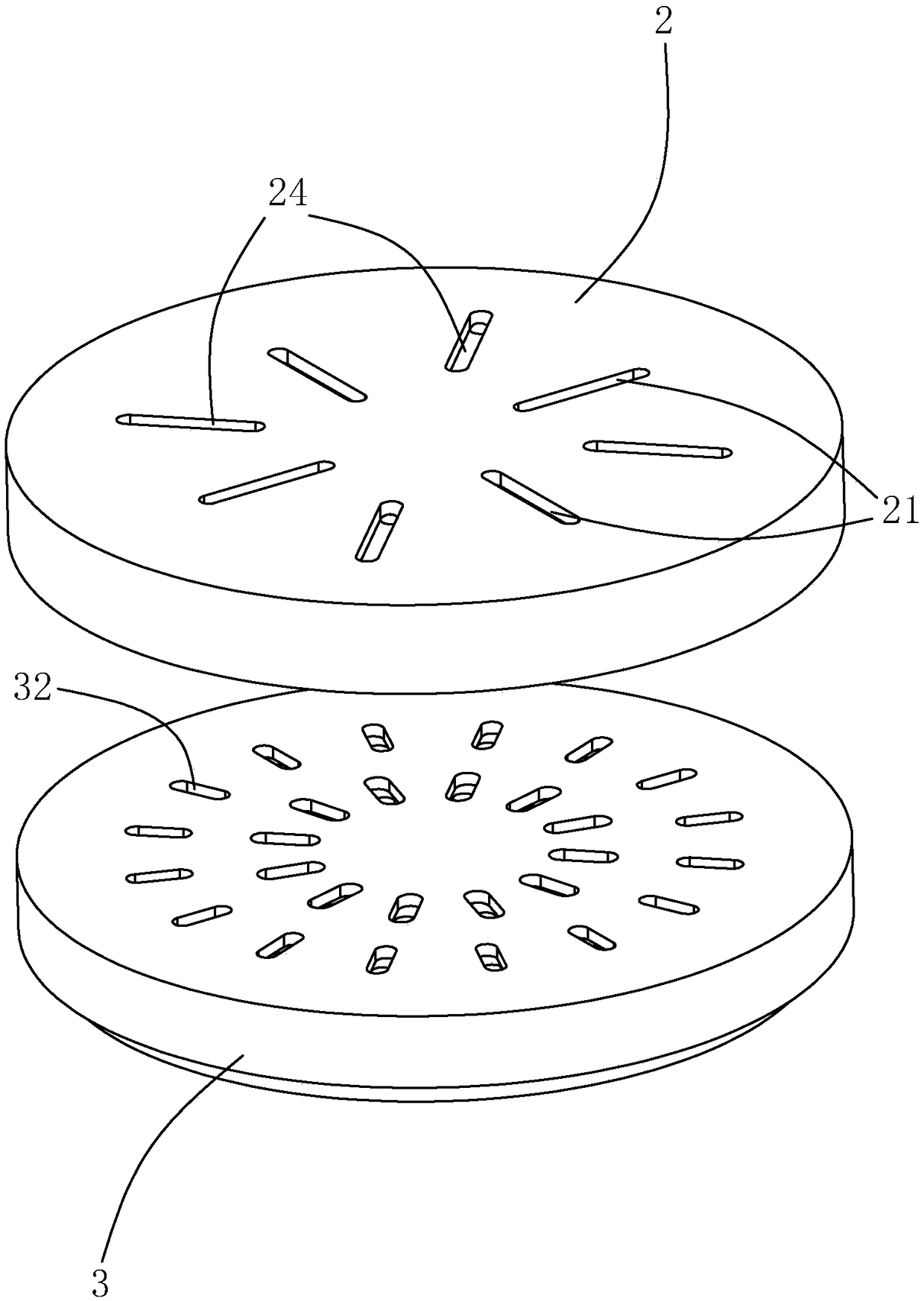

[0056] Examples of spin packs

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com