Plastic pencil and preparation method thereof

A technology of pencils and plastics, applied in non-active pencils, printing, writing utensils, etc., can solve problems such as poor stroke and vividness of a single refill, affect children's health, and easy slag of graphite refills, etc., to increase the market Competitive, easy to cut, not easy to break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

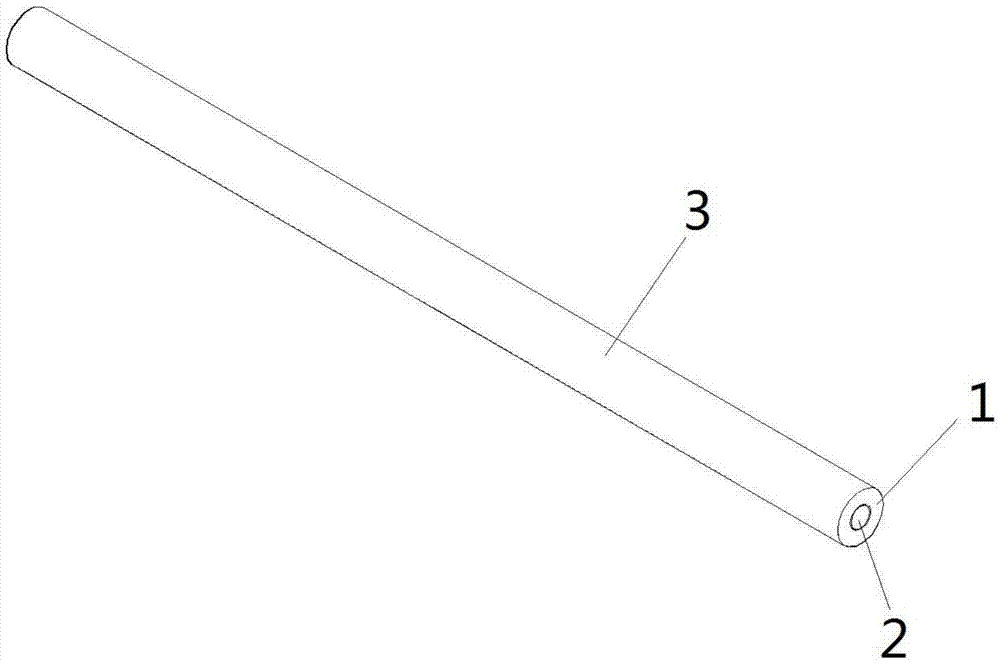

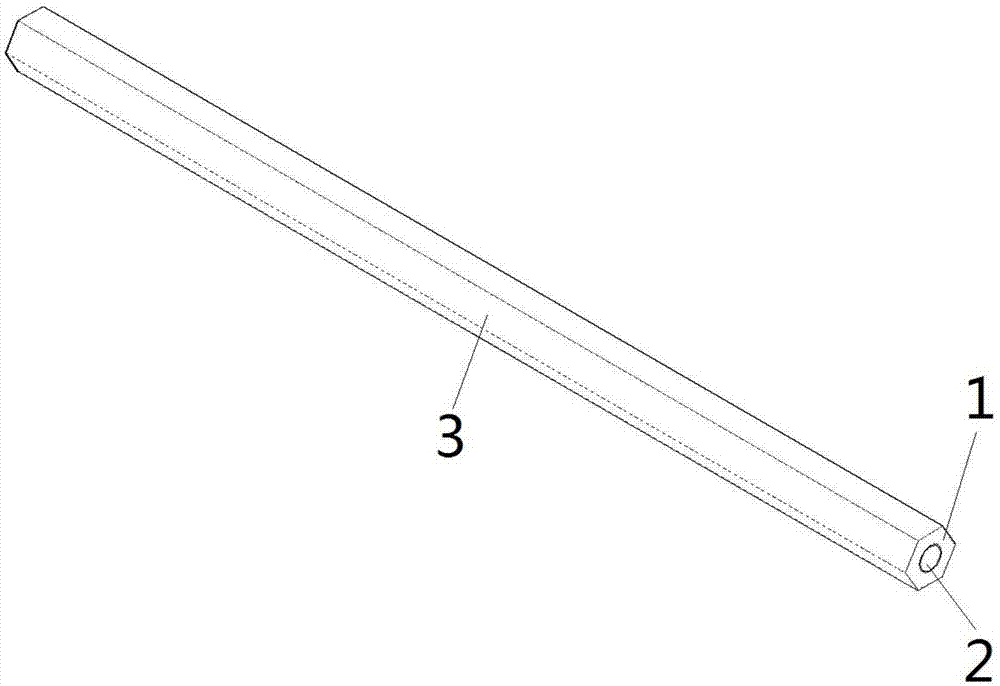

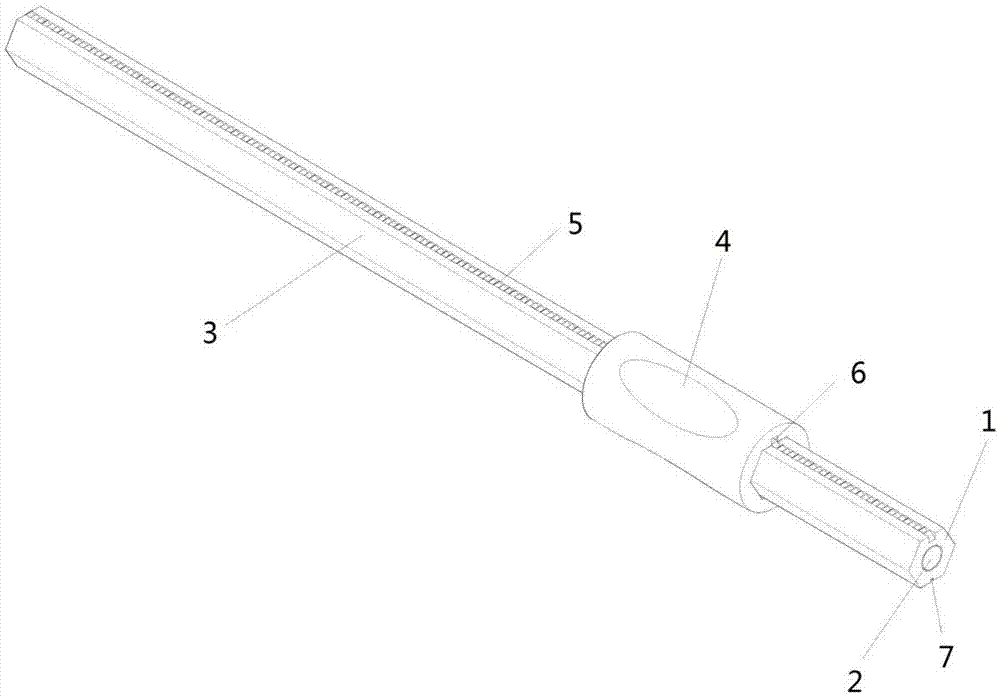

[0067] Such as figure 1 Shown, a kind of plastic pencil comprises pen holder, pen core, pen skin, wherein: described pen holder comprises 25wt% polystyrene (PS), 5wt% polyethylene (PE), 30wt% synthetic rubber, 5wt%, nucleation Agent, 30wt% talcum powder, 5wt% calcium stearate; The pen core includes 20wt% polystyrene (PS), 10wt% organosilicon polymer, 60wt% graphite powder, 2wt% hydrogenated palm oil, 2wt% oleic acid Amide, 6wt% synthetic rubber; the pen cover includes 70wt% polystyrene (PS), 20wt% color masterbatch, 10wt% hydrogenated palm oil; in each component of the appeal, wt% is a percentage by weight; The section is circular, and the cross section of the pen core is circular.

[0068] The manufacture method of above-mentioned plastic pencil, comprises the steps:

[0069] (1), polystyrene pellets, polyethylene pellets, and synthetic rubber are respectively added to granulation equipment to granulate to obtain pellets, which are set aside;

[0070] (2), according to the...

Embodiment 2

[0076] The method and raw material of the manufacture plastic pencil of embodiment 2 and embodiment 3 are identical with embodiment 1, and difference is that the formula of adopted pen holder, pen core, pen skin is different, and detailed formula sees table one, table two, table three.

Embodiment 4

[0078] Such as figure 1 Shown, a kind of plastic pencil comprises pen holder, pen core, pen skin, wherein: described pen holder comprises 30wt% polystyrene (PS), 7wt% polyethylene (PE), 15wt% synthetic rubber, 8wt%, nucleation Agent, 30wt% talcum powder, 7wt% calcium stearate, 3wt% color powder; The pen core includes 35wt% polystyrene (PS), 5wt% organosilicon polymer, 45wt% graphite powder, 5wt% hydrogenated palm Oil, 5wt% oleic acid amide, 5wt% synthetic rubber; Described pen skin comprises 76wt% polystyrene (PS), 16wt% masterbatch, 8wt% hydrogenated palm oil; Appeal in each component, wt% is percentage by weight ; The cross-section of the pen holder is circular, and the cross-section of the pen core is circular.

[0079] The manufacture method of above-mentioned plastic pencil is with embodiment 1.

[0080] The method and raw material of the manufacture plastic pencil of embodiment 5~10 are identical with embodiment 4, and difference is that the formula of adopted pen hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com