Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "Curl suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic recording medium

InactiveUS20050260456A1Increased strengthEnhance in durability , storabilityMagnetic materials for record carriersBase layers for recording layersPolyesterMagnetic layer

A magnetic recording medium comprising: a nonmagnetic support; and a magnetic layer containing ferromagnetic powder and a binder, wherein the nonmagnetic support contains polyester, the nonmagnetic support has gauche / trans peak intensity ratio of 0.50 or less as determined by a ATR-FT-IR method, and a shrinkage percentage of the magnetic recording medium after storage for 1 week under a conditions of 70° C. and 5% RH is 0.040% or less.

Owner:FUJIFILM HLDG CORP +1

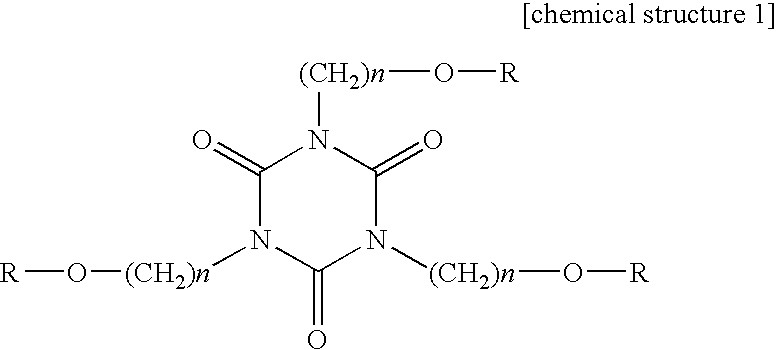

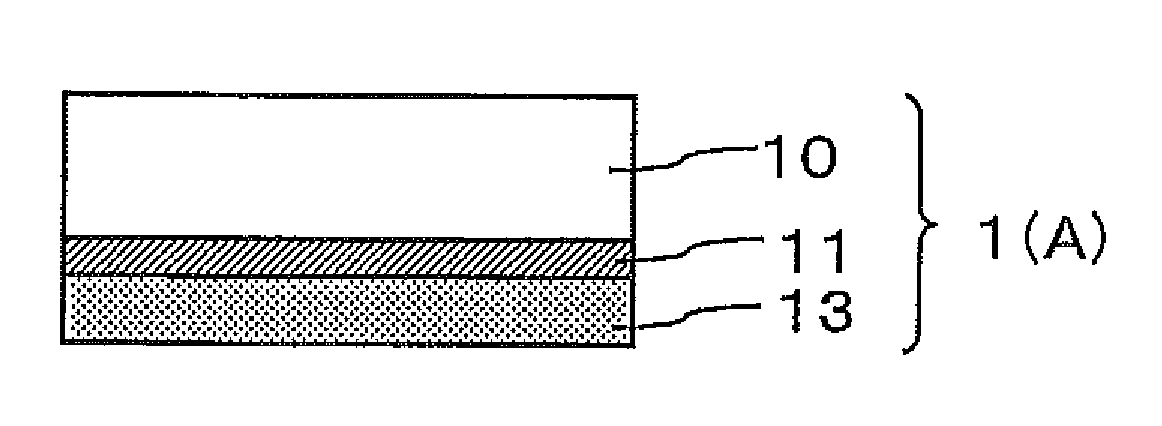

Hard coat film, antireflection hard coat film, optical element and image display

InactiveUS20070178297A1Suppress cracksCurl suppressionSynthetic resin layered productsCellulosic plastic layered productsOptoelectronicsHardness

A hard coat film of the present invention comprises a hard coat layer, which is a cured coat layer, provided on at least one side of a transparent plastic film substrate, wherein a hard coat layer forming material comprises urethane acrylate (A); isocyanuric acid acrylate (B) and inorganic ultrafine particles (C), and has a high hardness and suppresses curling due to cracking and cure shrinkage.

Owner:NITTO DENKO CORP

Inkjet ink, inkjet recording method, and inkjet recording device

ActiveUS20140002539A1Excellent quality imageExcellent responseDuplicating/marking methodsInksWater contentEquilibrium moisture content

An inkjet ink, which contains water, an organic solvent, a surfactant, and a colorant, wherein the organic solvent contains at least one polyhydric alcohol having an equilibrium moisture content of 30% by mass or higher at a temperature of 23° C. and humidity of 80% RH, at least an amide compound represented by the general formula (I), and at least one selected from the group consisting of compounds represented by the following general formulae (II) to (IV):

Owner:RICOH KK

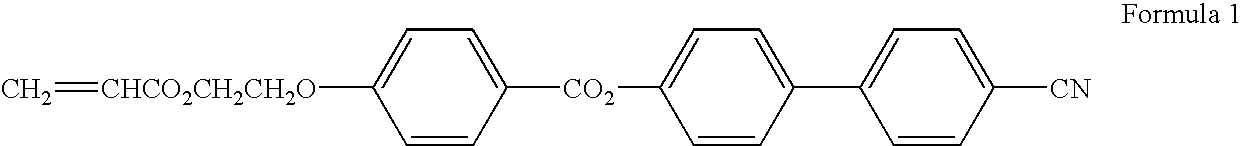

Ink composition, ink set and image forming method

ActiveUS20090202724A1Excellent ejection propertyExcellent liquid stabilityDuplicating/marking methodsInksImage formationSolvent

An ink composition, including: a water-soluble solvent A; a pigment; and water. The water-soluble solvent A contains at least a water-soluble solvent having an SP value of 27.5 or less at an amount of 90 mass % or more and a compound represented by the following Formula (1), wherein the compound represented by Formula (1) is the same as or different from the water-soluble solvent having an SP value of 27.5 or less:wherein, in Formula (1), l, m and n each independently represent an integer of 1 or more, the total of l, m and n is from 3 to 15, and AOs each independently represents an ethyleneoxy group or propyleneoxy group.

Owner:FUJIFILM CORP

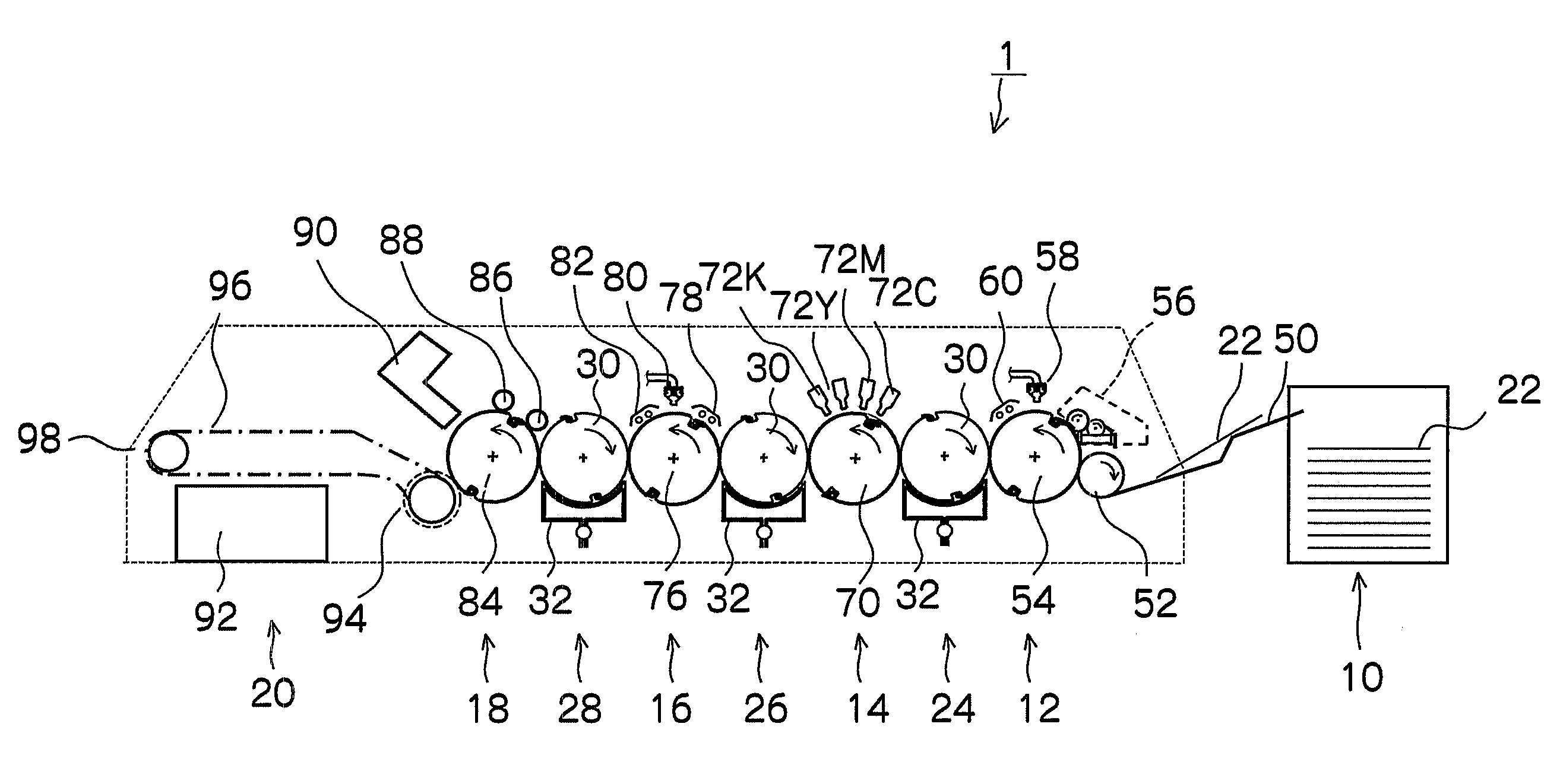

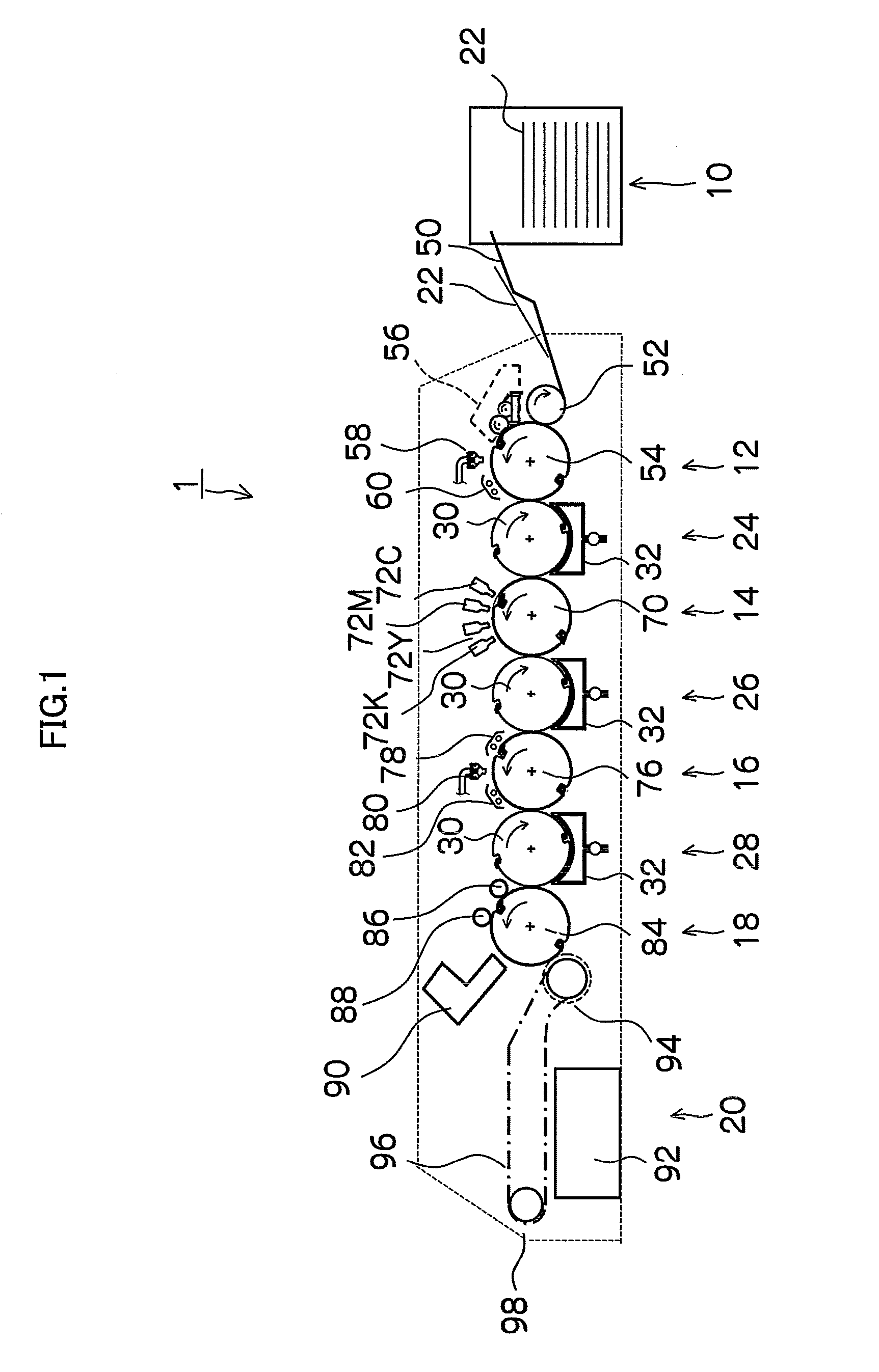

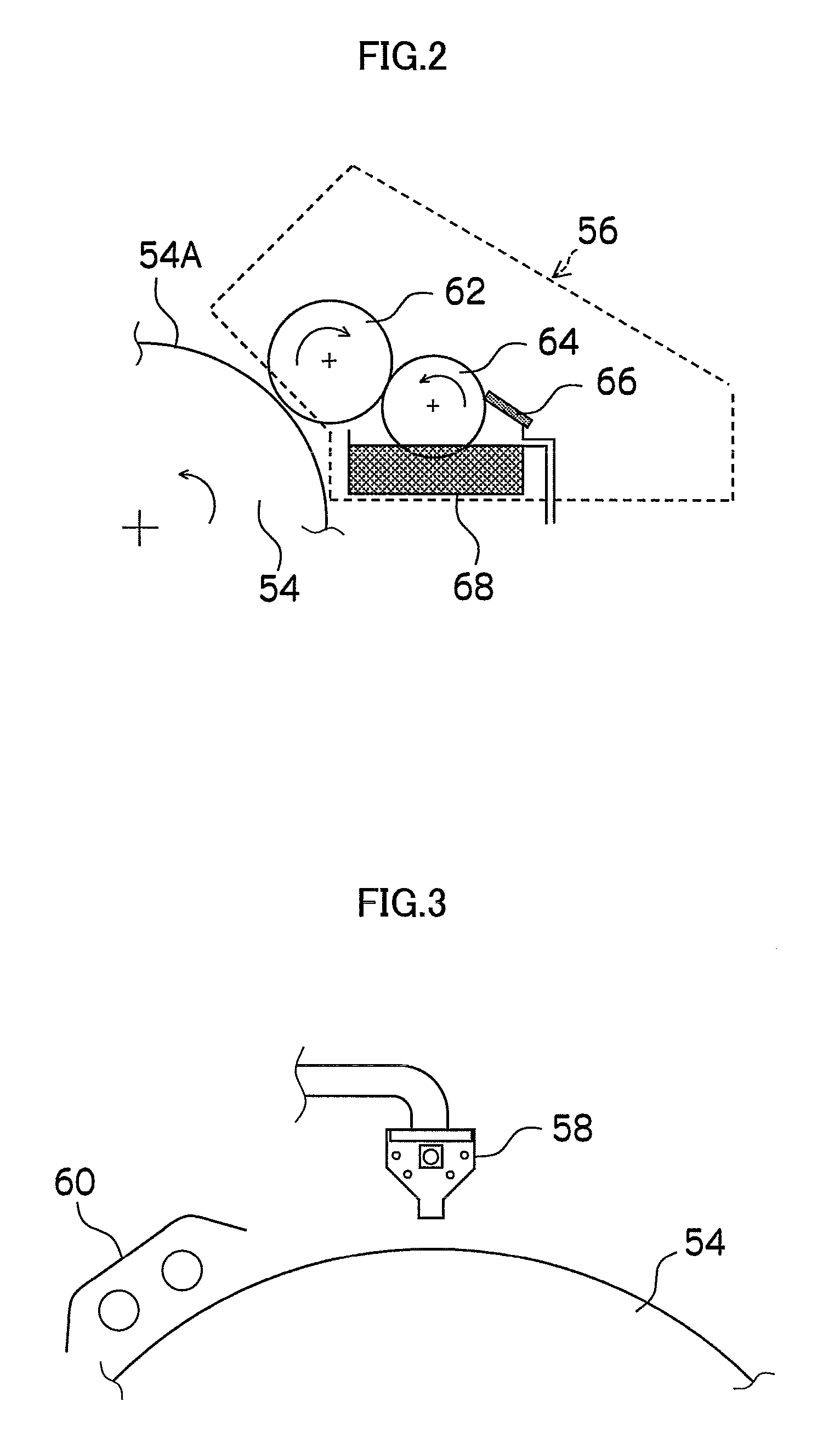

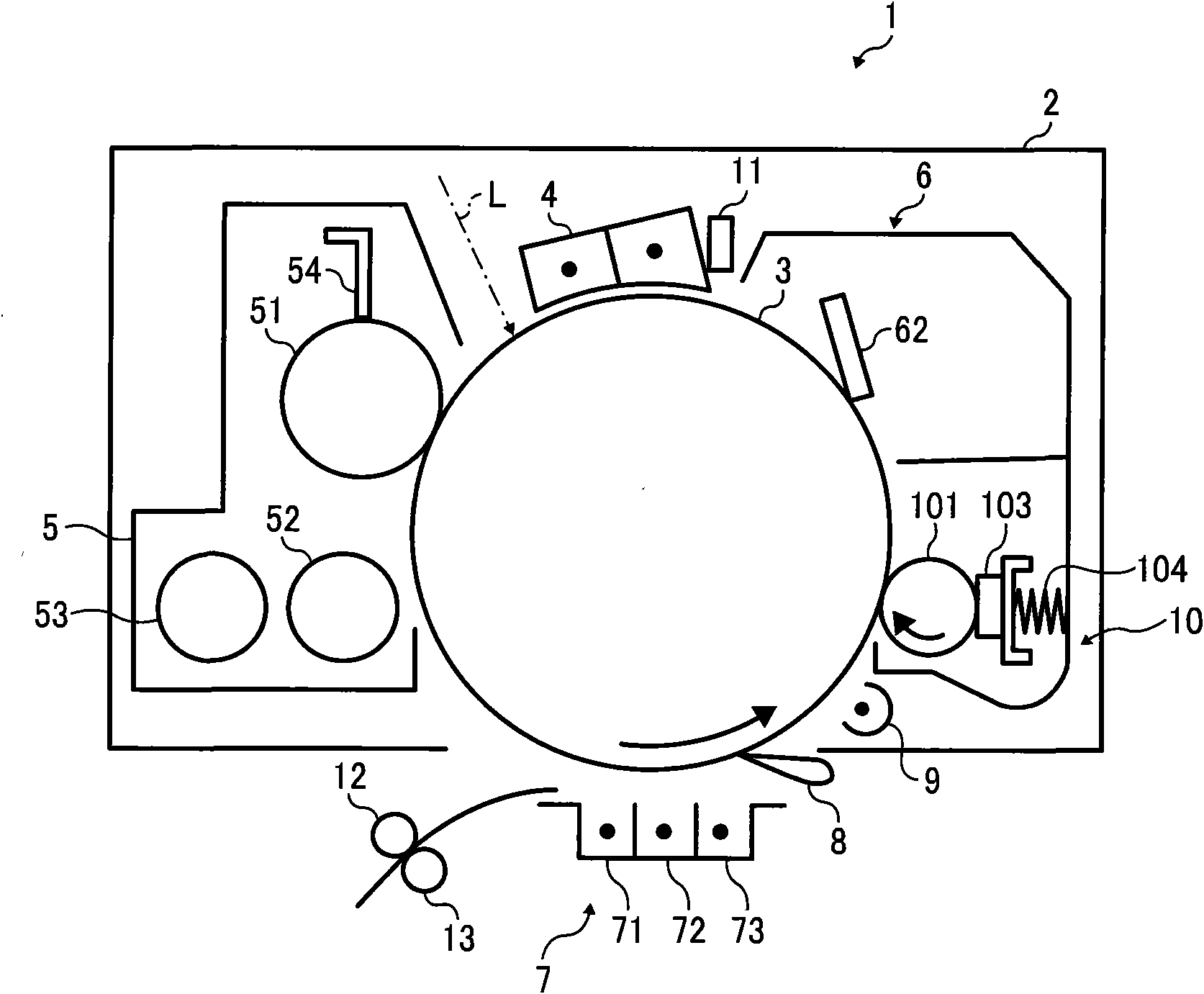

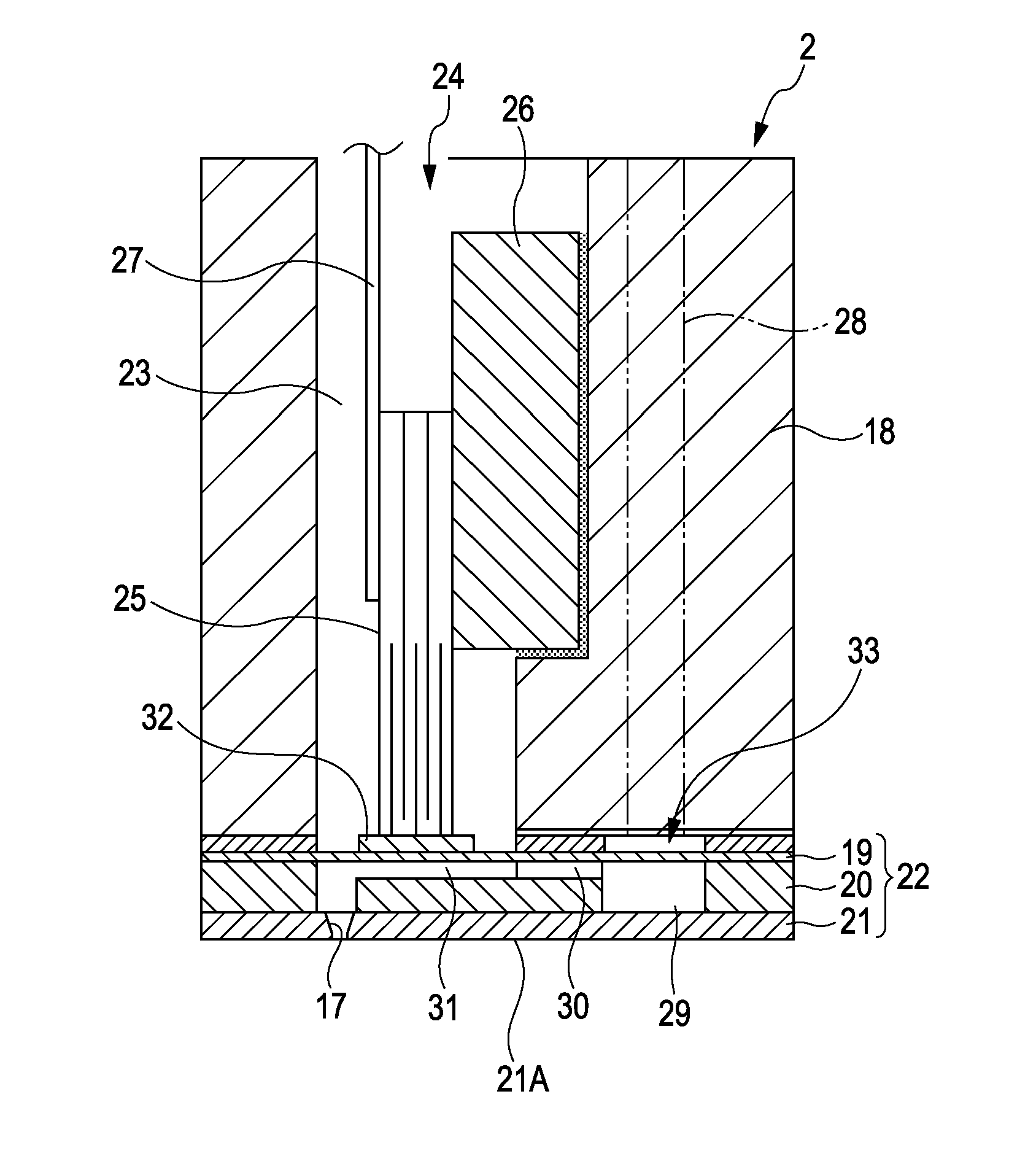

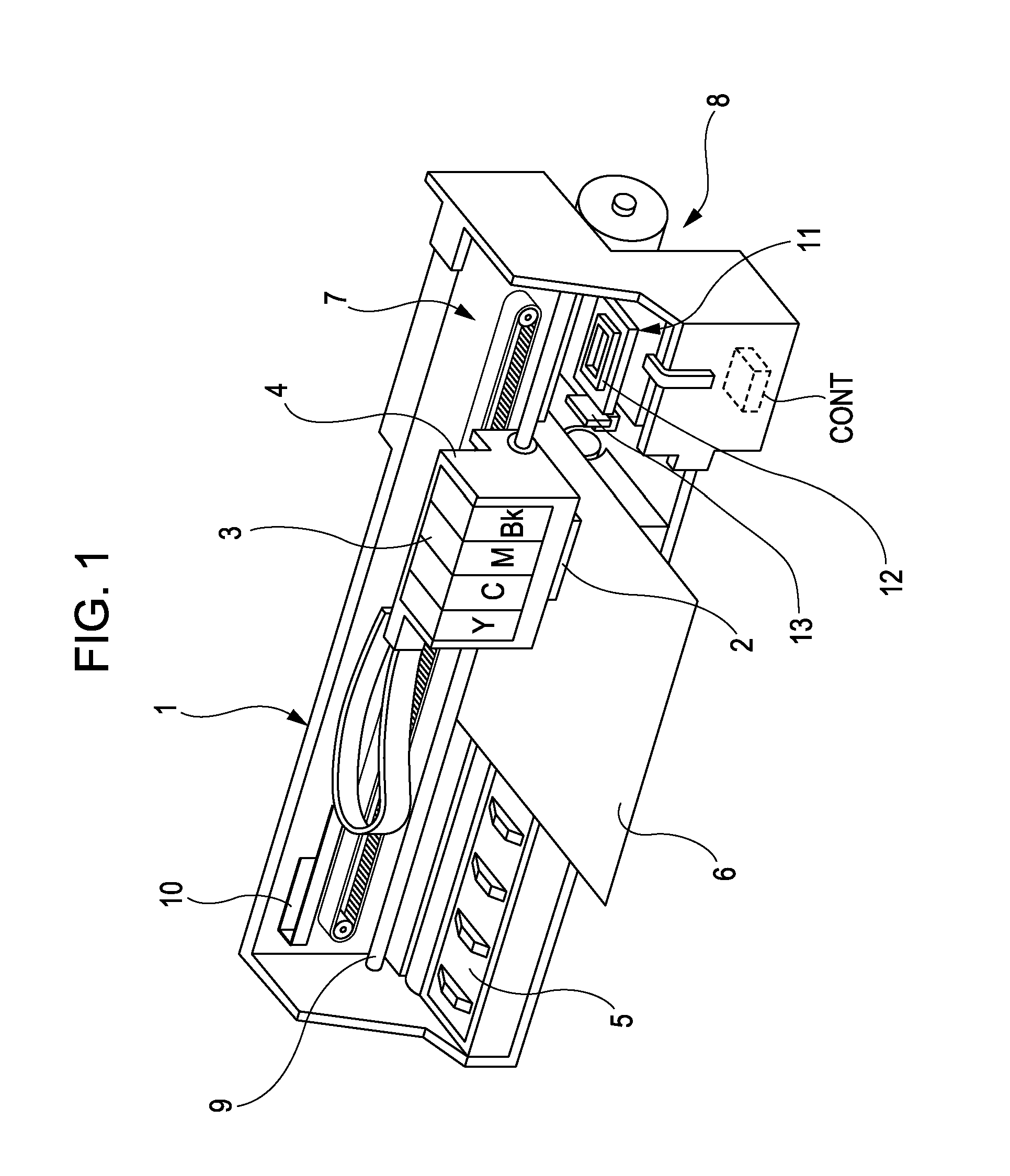

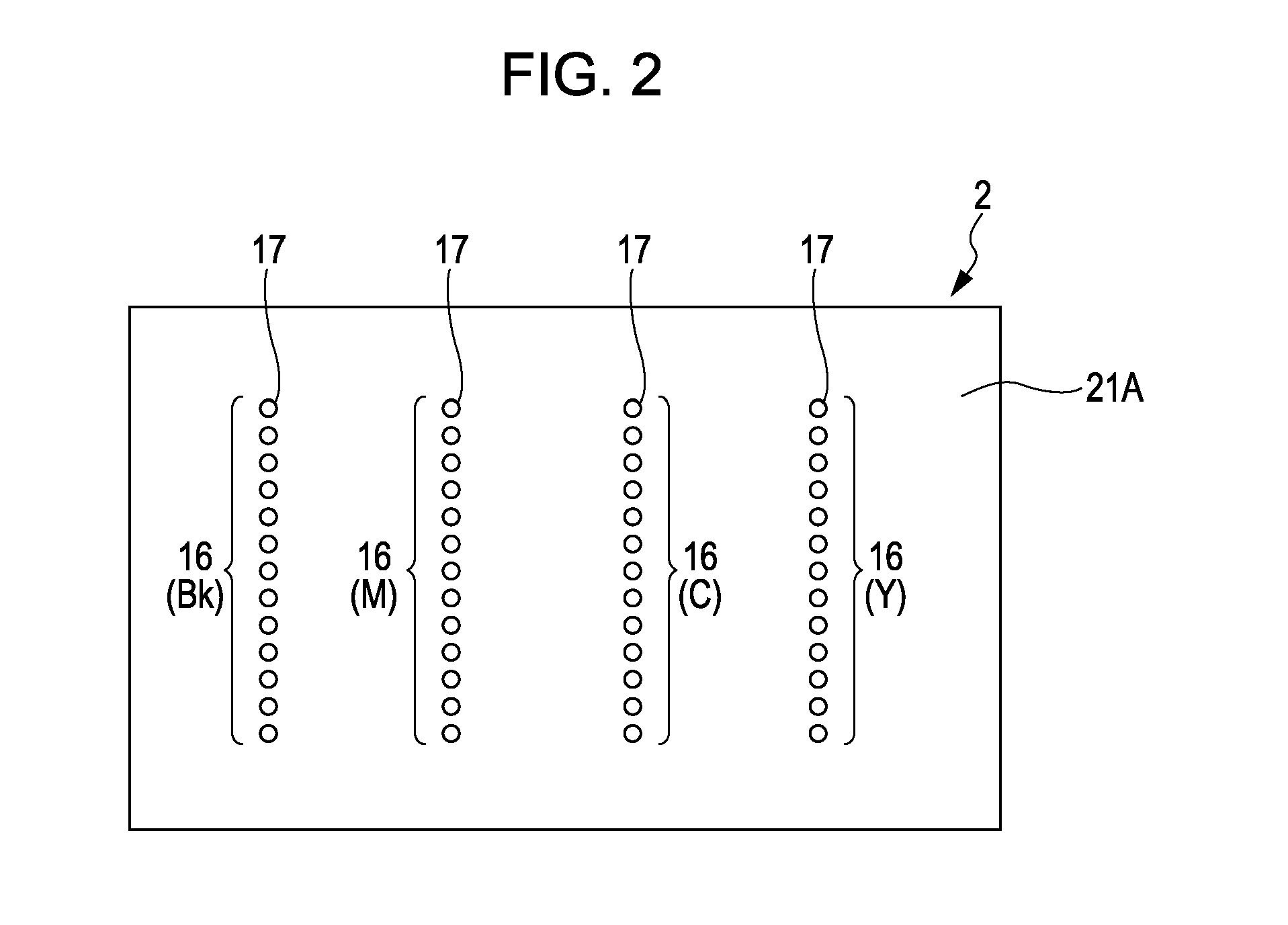

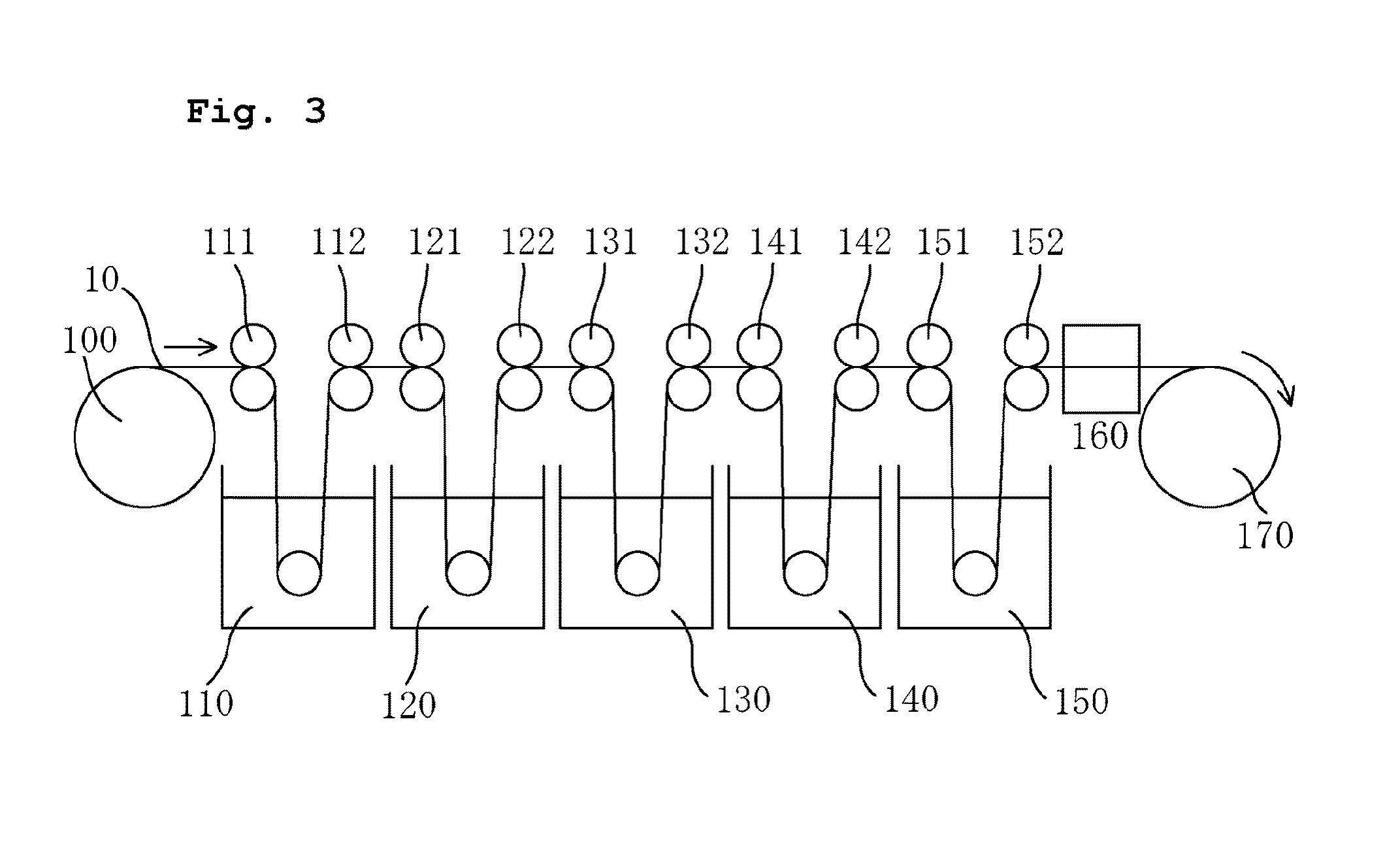

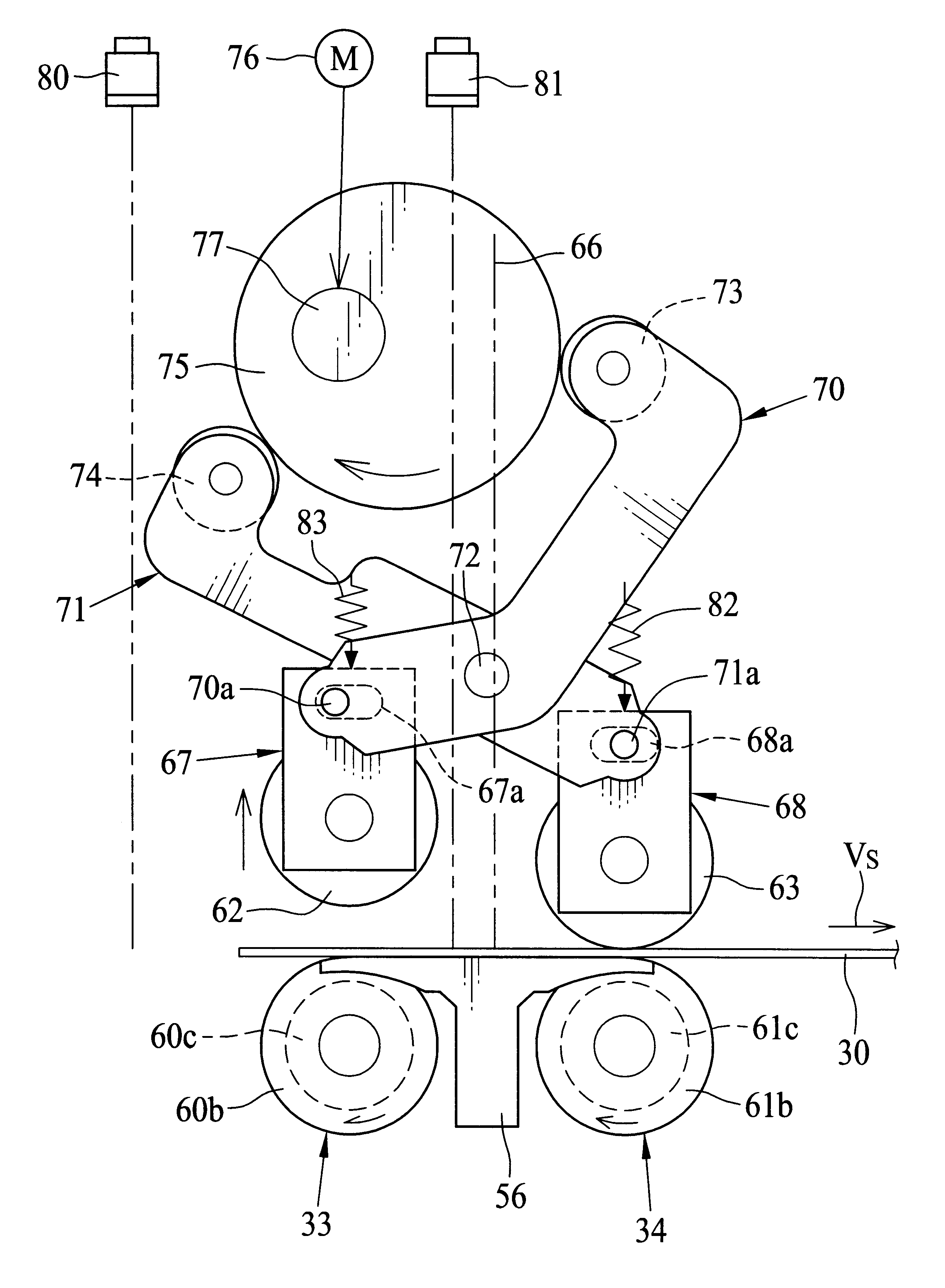

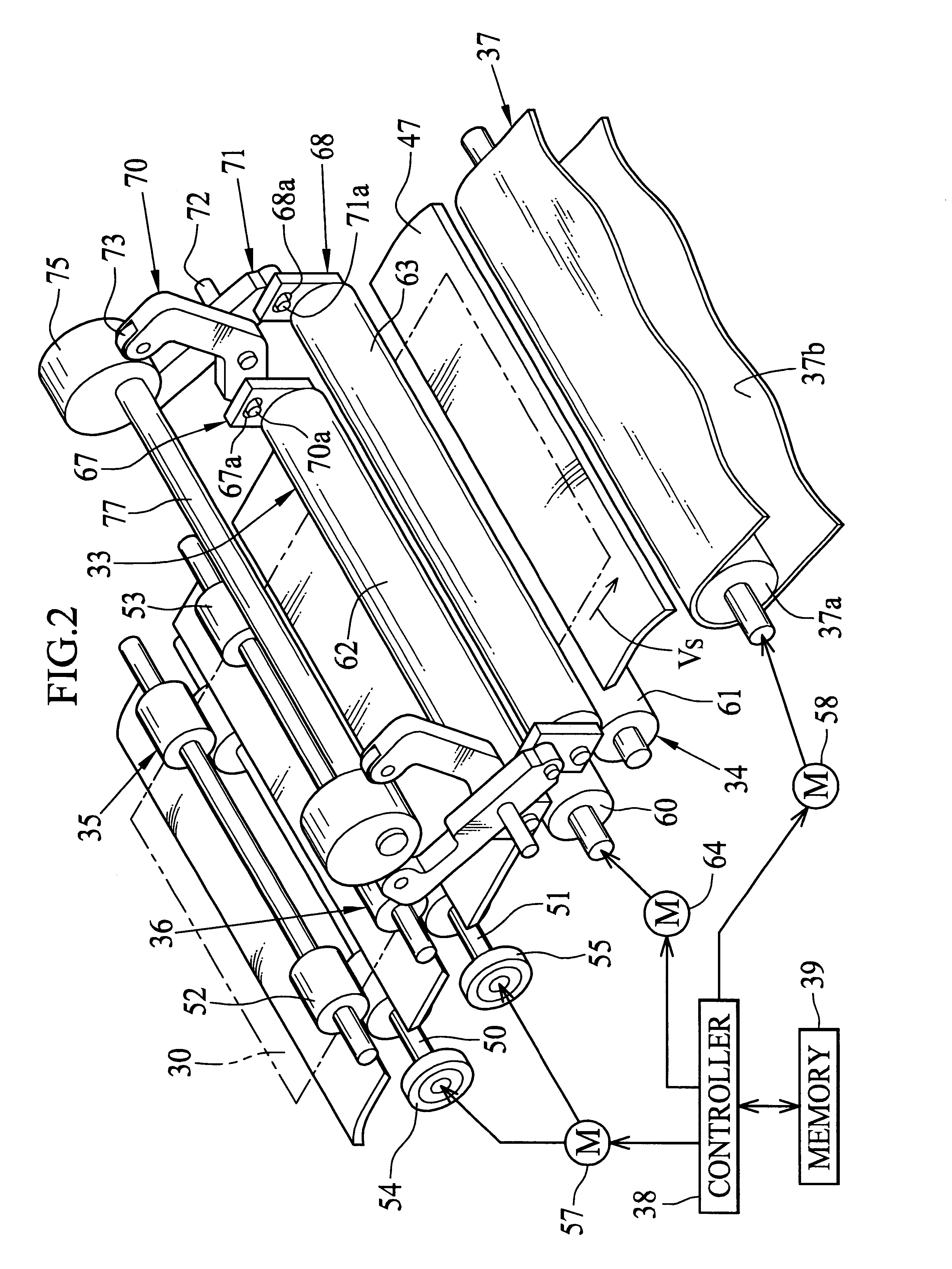

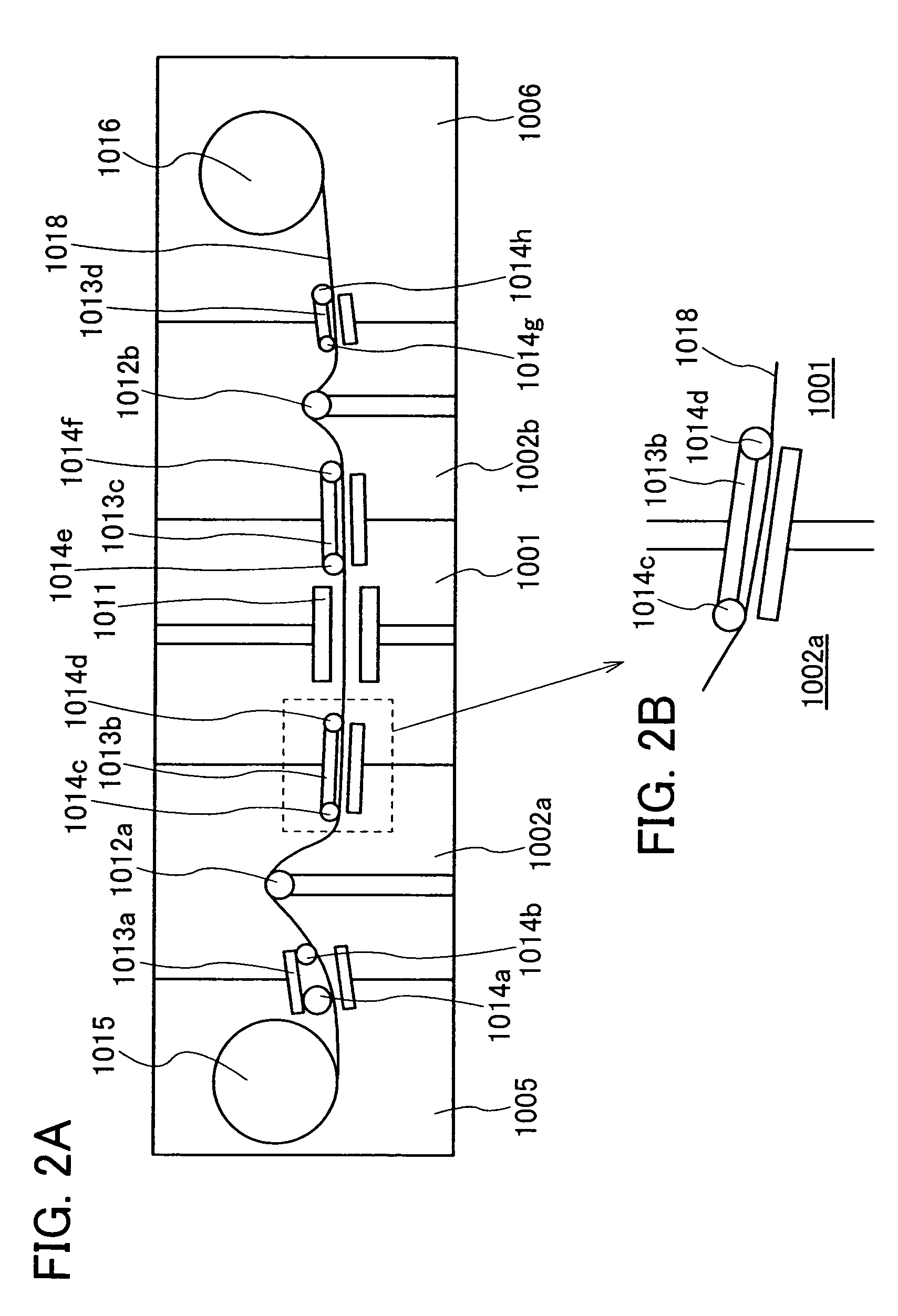

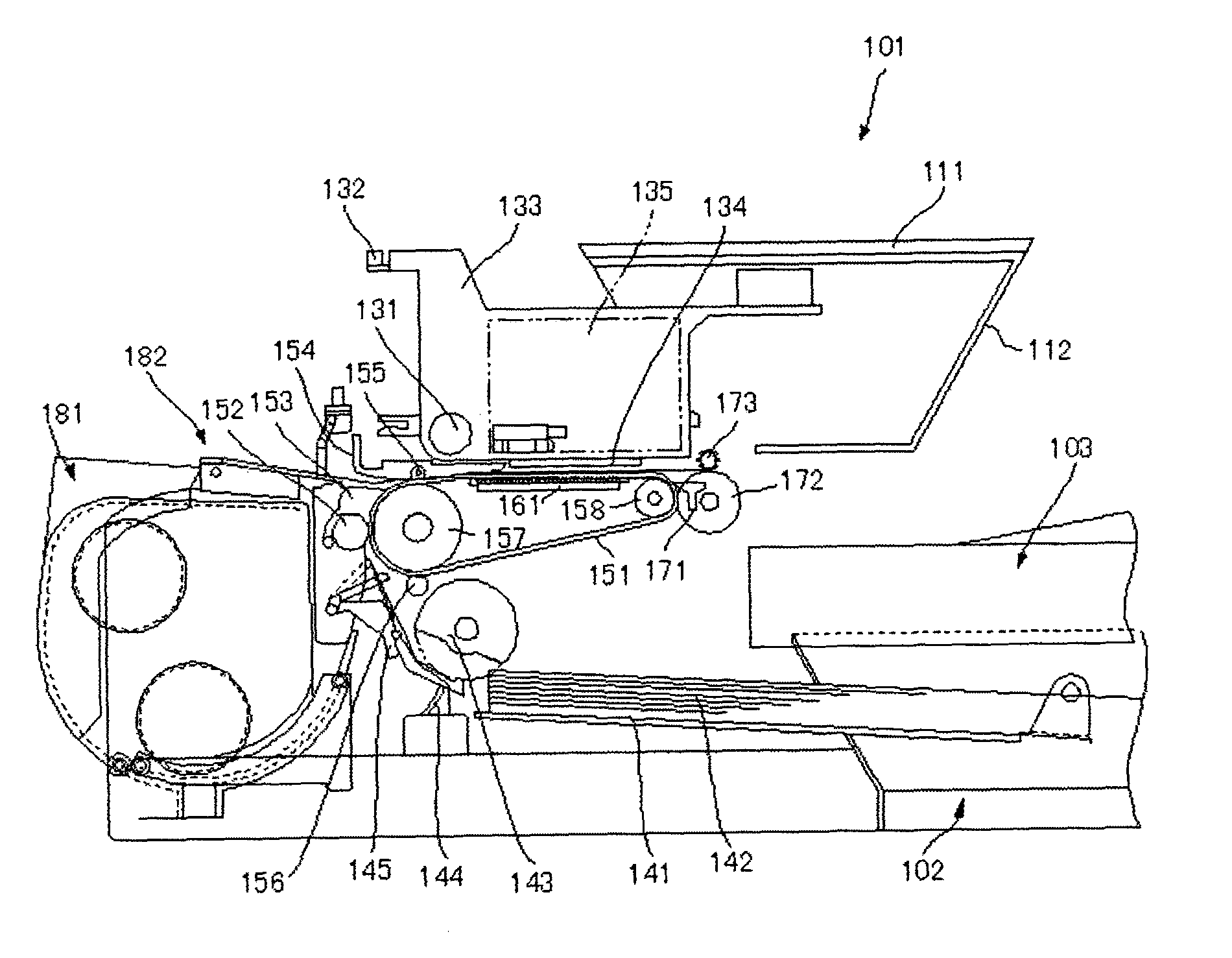

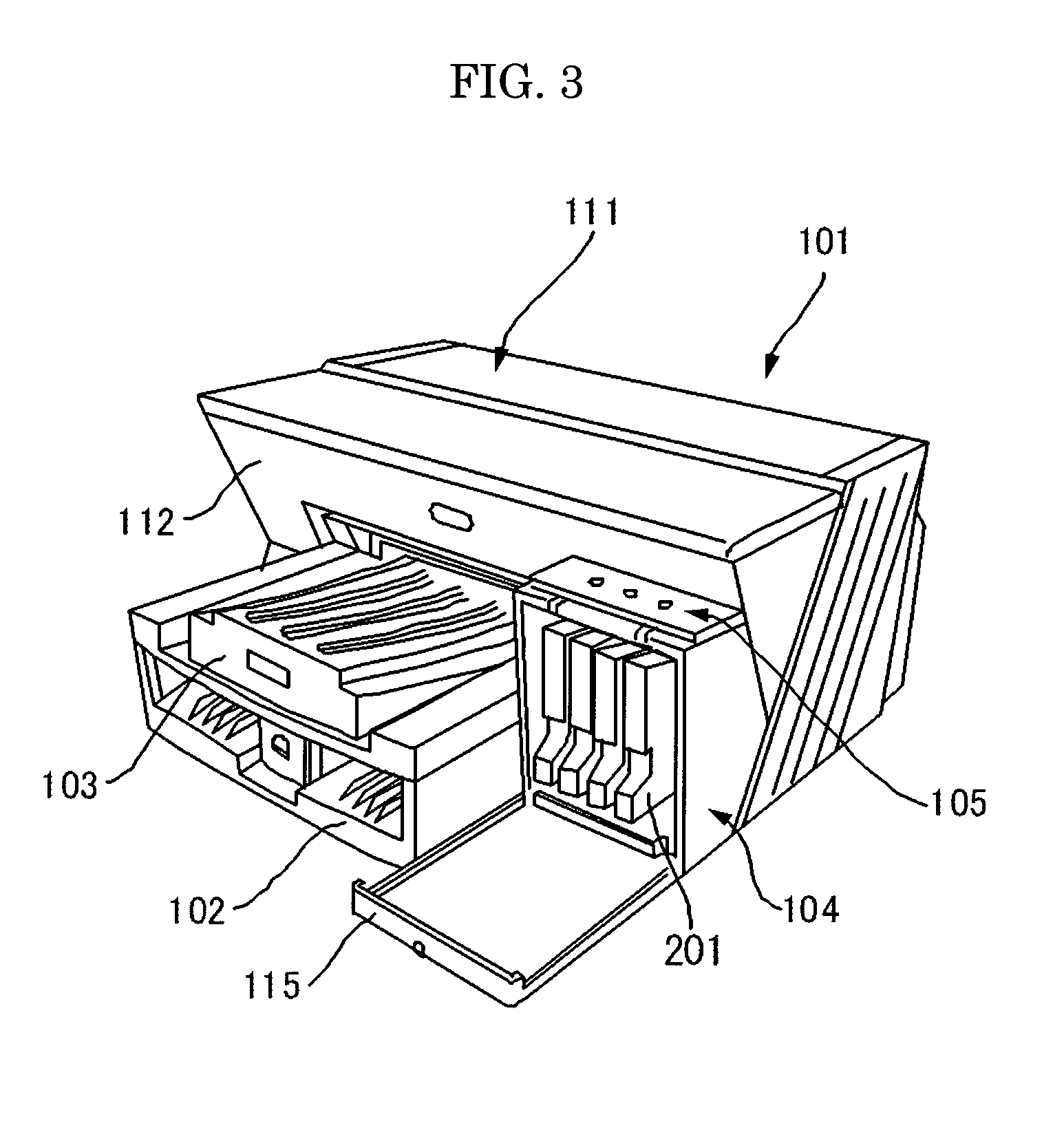

Inkjet recording method and apparatus

ActiveUS20090311426A1Improve image qualityCurl suppressionDuplicating/marking methodsPretreated surfacesSolid componentLiquid medium

The inkjet recording method includes: a treatment liquid depositing step of applying treatment liquid onto a recording medium while holding the recording medium on a circumferential surface of a treatment liquid drum and conveying the recording medium by rotating the treatment liquid drum, and drying at least a portion of a solvent in the treatment liquid; an image forming step of ejecting ink from a line type inkjet head to deposit the ink onto the recording medium on which the treatment liquid has been deposited, while holding the recording medium on a circumferential surface of an image formation drum and conveying the recording medium by rotating the image formation drum, the ink containing at least a resin dispersant (A), a pigment (B) that is dispersed by the resin dispersant (A), self-dispersible polymer micro-particles (C) and an aqueous liquid medium (D), the ink having one of a solid component that is aggregated upon making contact with the treatment liquid and a solid component that is precipitated upon making contact with the treatment liquid; and a drying step of drying a solvent in the ink having been deposited on the recording medium while holding the recording medium on a circumferential surface of a drying drum and conveying the recording medium by rotating the drying drum.

Owner:FUJIFILM CORP

Hard coat film, antireflection hard coat film, optical element and image display

InactiveUS7569269B2High hardnessCurl suppressionSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceCarbamate

Owner:NITTO DENKO CORP

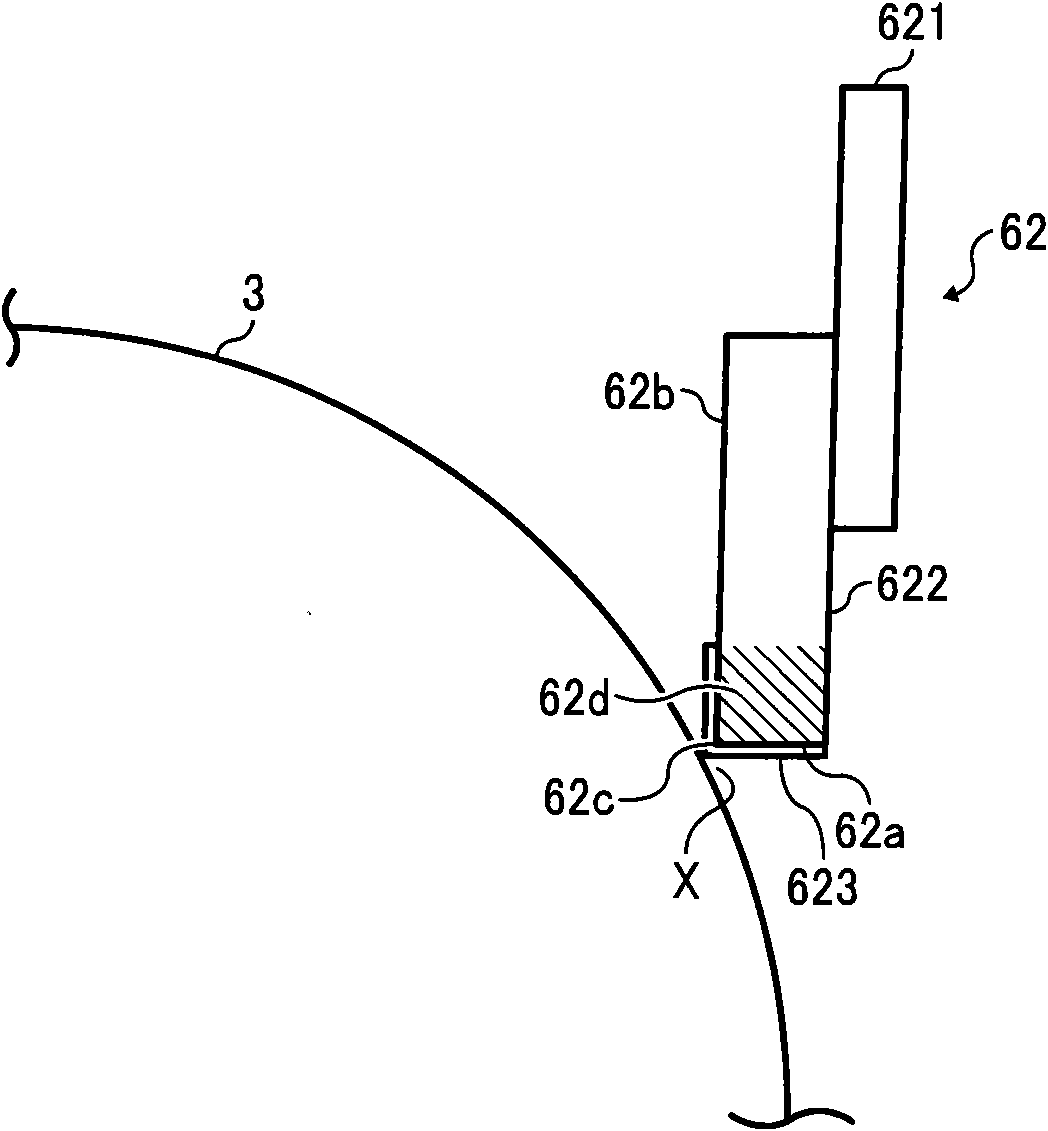

Cleaning blade and image forming apparatus, process cartridge, and image forming method using the same

InactiveCN101604138AAvoid deformationSuppression of Minor ChangesElectrographic process apparatusElastomerLeading edge

The invention relates to a cleaning blade and an image forming apparatus, a process cartridge, and an image forming method using the same. A cleaning blade for removing fine particles from a cleaning target by contact with the cleaning target is provided. The cleaning blade includes an elastic blade A leading edge of the elastic blade includes a friction coefficient of 0.5 or less. The cleaning blade also includes a surface layer that covers the leading edge of the elastic blade. A thickness of the surface layer is between 1 to 50 mu m at a position 50 mu m away from the leading edge, and a hardness of the surface layer is greater hardness than the elastic blade.

Owner:RICOH KK

Pigment ink, ink jet recording apparatus, and ink jet recording method

ActiveUS20120162307A1Suppress satellite droplet formationHigh quality imagingInksPrintingEthyl groupEngineering

A pigment ink includes an acetylene glycol or 2-ethyl-1,3-hexanediol, and an unsaturated fatty acid, an amino acid, an alkali metal hydroxide and an amine.

Owner:SEIKO EPSON CORP

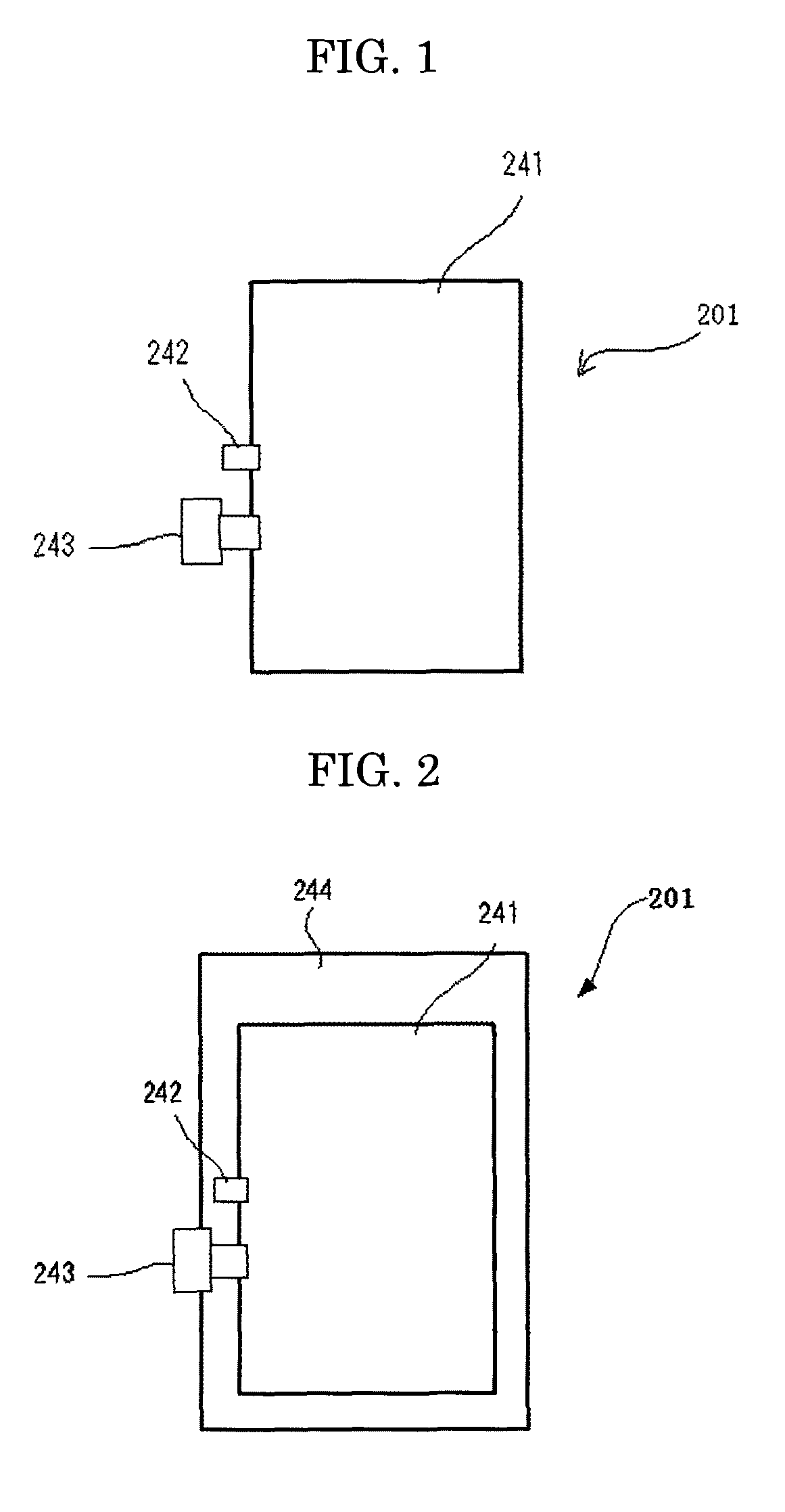

Resin film with pressure-sensitive adhesive layer, laminated film, and touch panel

InactiveUS20130194221A1Satisfied levelGood lookingFilm/foil adhesivesSynthetic resin layered productsOligomerRefractive index

A resin film with pressure-sensitive adhesive layer of the invention includes a first transparent resin film, an oligomer blocking layer, and a pressure-sensitive adhesive layer laminated in this order, wherein the oligomer blocking layer is a cured layer formed by curing a composition containing a curable compound and inorganic oxide particles, the oligomer blocking layer has a thickness of 120 nm or more, the oligomer blocking layer has a refractive index difference of 0.04 or less from the pressure-sensitive adhesive layer, and an anchoring strength between the oligomer blocking layer and the pressure-sensitive adhesive layer is 1 N / 25 mm or more.The resin film with pressure-sensitive adhesive layer can prevents the oligomer blocking layer from causing interference fringes, in which even when made thin, the oligomer blocking layer satisfies the requirements including oligomer blocking properties and scratch resistance, and also has good adhesion to the pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

Method of manufacturing polarizing film

InactiveUS20130149546A1Good lookingCurl suppressionSynthetic resin layered productsPolarising elementsPolymer sciencePolyvinyl alcohol

A method of manufacturing a polarizing film according to an embodiment of the present invention includes forming a polyvinyl alcohol-based resin layer on a thermoplastic resin substrate having a crystallinity of 7% or less to produce a laminate and subjecting the laminate to a wet treatment followed by a drying treatment with a heat roll.

Owner:NITTO DENKO CORP

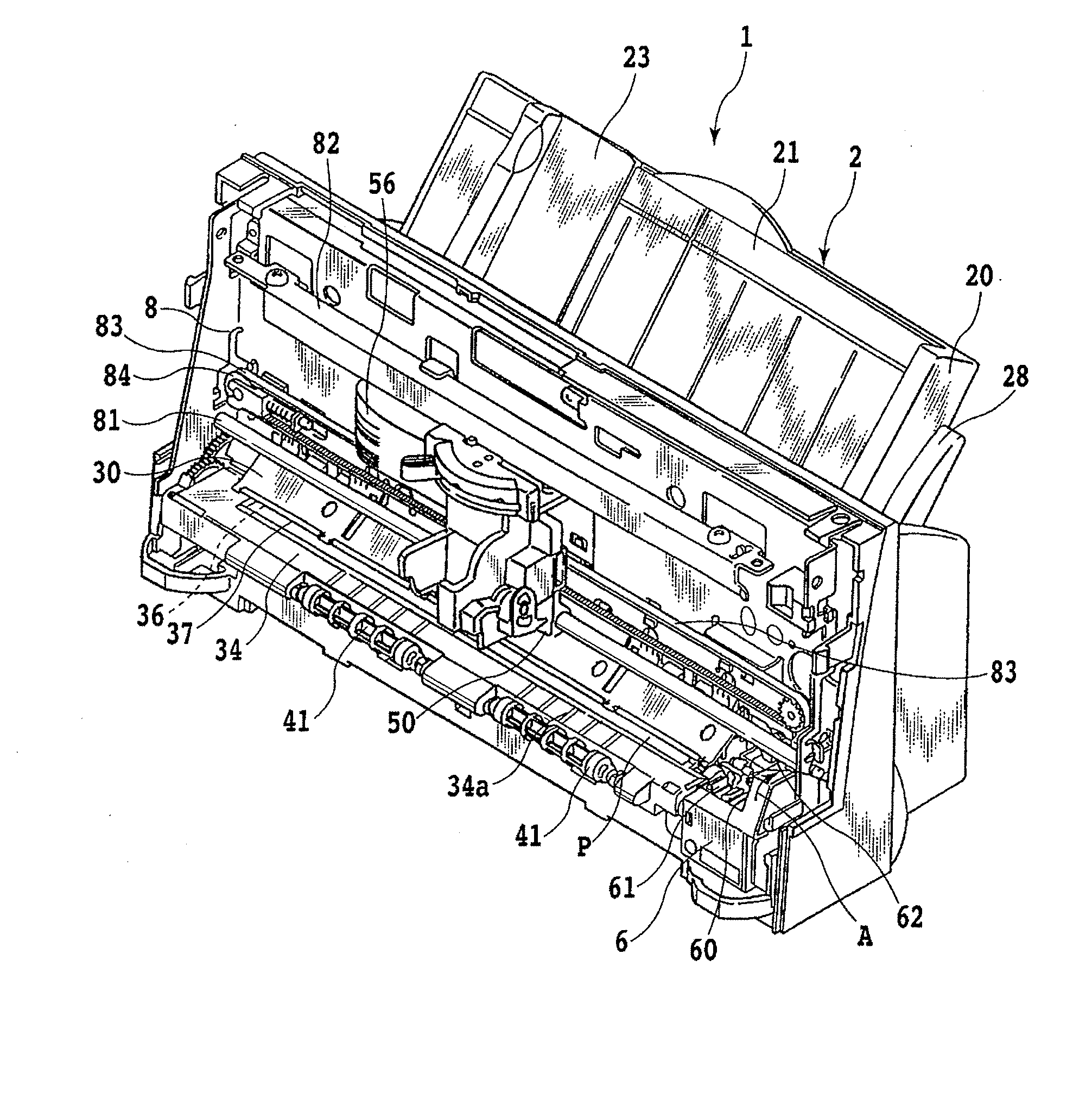

Recording unit

InactiveUS20110221845A1Reduced form requirementsInhibit outputElectrographic process apparatusPile receiversRecording mediaElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

Aqueous ink for inkjet

ActiveUS20090025605A1Avoid curlPrevent evaporationInksGranular deliveryOrganic solventPolyethylene glycol

An aqueous ink for an inkjet, comprising a pigment, a water-soluble organic solvent A, a water-soluble organic solvent B, and water, whereinthe water-soluble organic solvent A comprises at least one of diglycerol and polyglycerol, andthe water-soluble organic solvent B comprises a polyethylene glycol monoalkyl ether represented by a general formula (1): RO—(CH2CH2O)n—H (wherein, R represents an alkyl group of 4 to 6 carbon atoms, and n represents an integer from 4 to 6).

Owner:RISO KAGAKU CORP

Recording sheet feeding device

InactiveUS6505833B2Curl suppressionAvoid exposureFunction indicatorsArticle feedersEngineeringPaper sheet

First and second feeding roller pairs are disposed at positions upstream and downstream of a recording position to record an image onto a recording sheet. Each of the first and second feeding roller pairs includes a capstan roller and a pinch roller, which are located below and above a passage of the recording sheet. The capstan roller and the pinch roller has plural orbital grooves arranged along an axial direction, to relax the strain of the recording sheet with respect to the widthwise direction of the recording sheet. The depth of the orbital grooves of the pinch rollers are set to 0.3 mm, which is shallower than that of the orbital grooves of the capstan rollers. The shallow orbital grooves of the pinch rollers are capable of suppress the curl of the recording sheet effectively.

Owner:FUJIFILM CORP +1

Polarization plate, method for manufacturing same, and image display device

InactiveUS20160018578A1Reduce thicknessCurl suppressionPolarising elementsLaminationPolarizerPhysics

A polarization plate includes a polarizer having polarization performance; a first protective film bonded to one surface of the polarizer through an adhesive layer 1; and a second protective film bonded to the other surface of the polarizer through an adhesive layer 2, in which a modulus of elasticity of the first protective film at 25° C. and relative humidity of 60% in an absorption axis direction of the polarizer is greater than or equal to 1.0 GPa and less than 4.0 GPa, a ratio of the modulus of elasticity of the first protective film at 25° C. and relative humidity of 60% in the absorption axis direction of the polarizer to a modulus of elasticity of the first protective film at 25° C. and relative humidity of 60% in a direction orthogonal to the absorption axis of the polarizer is less than or equal to 0.8, a modulus of elasticity of the second protective film at 25° C. and relative humidity of 60% in the absorption axis direction of the polarizer is greater than or equal to 2.0 GPa and less than 5.0 GPa, and (Expression 1) and (Expression 2) described below are satisfied, suppresses curling of the polarizer in the absorption axis direction (d1 and d2 are thicknesses of the first protective film and the second protective film (unit: μm)).d2 / d1≦0.8; (Expression 1)d2≦40 μm (Expression 2)

Owner:FUJIFILM CORP

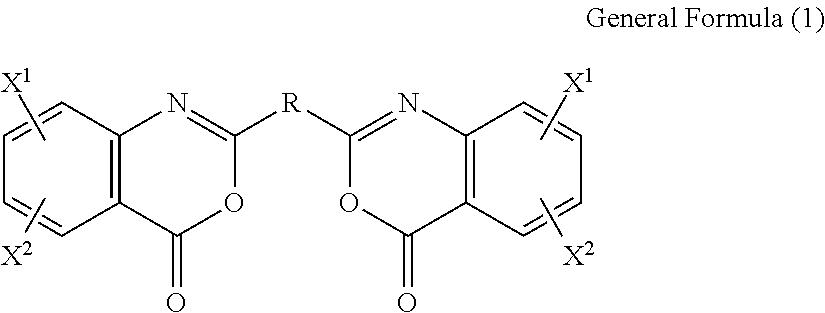

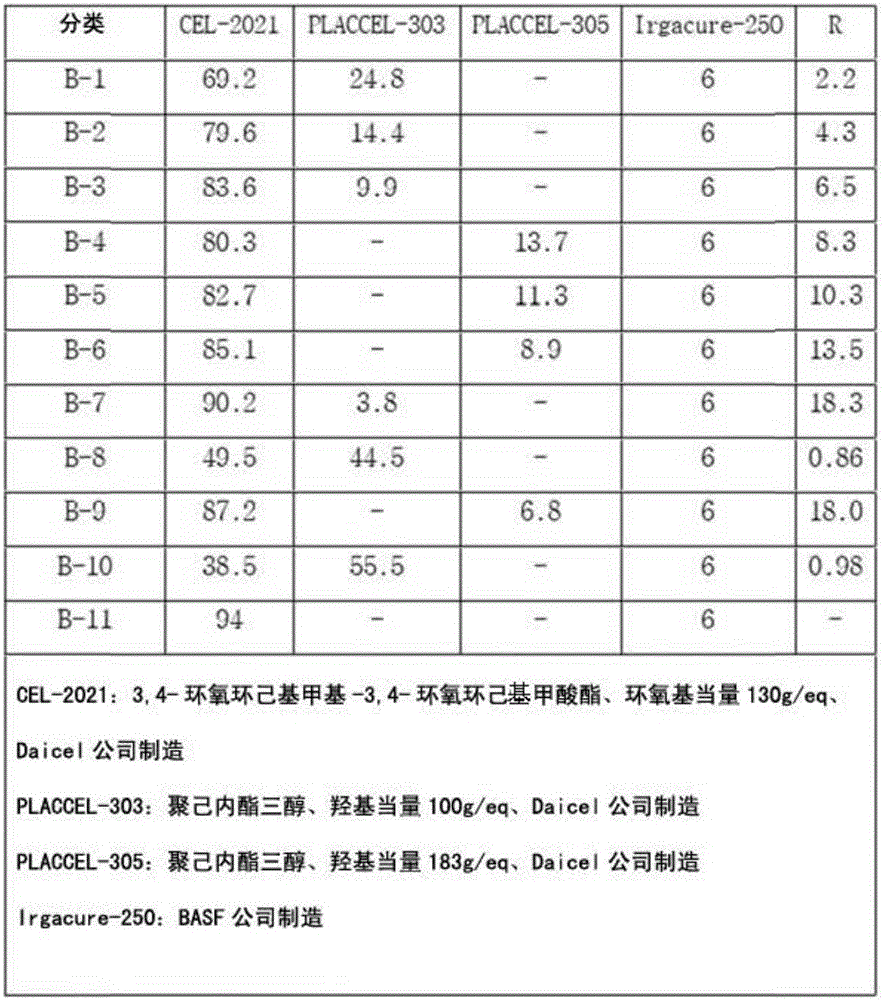

Composition for making hard coating layer

ActiveCN106010022AHigh hardnessGood flexibilityEpoxy resin coatingsPolyester coatingsCrack resistanceHardness

Disclosed is a composition for making a hard coating layer. The composition exhibits excellent hardness and flexibility through containing a photo free radical polymerizable compound, a photo free radical polymerizable initiator, an epoxy photo positive ion polymerizable compound, a polyol compound and a photo positive ion polymerizable initiator. Therefore, a hard coating layer with improved scratch resistance and adhesion, inhibited rolling performance, and excellent bending crack resistance is formed.

Owner:DONGWOO FINE CHEM CO LTD

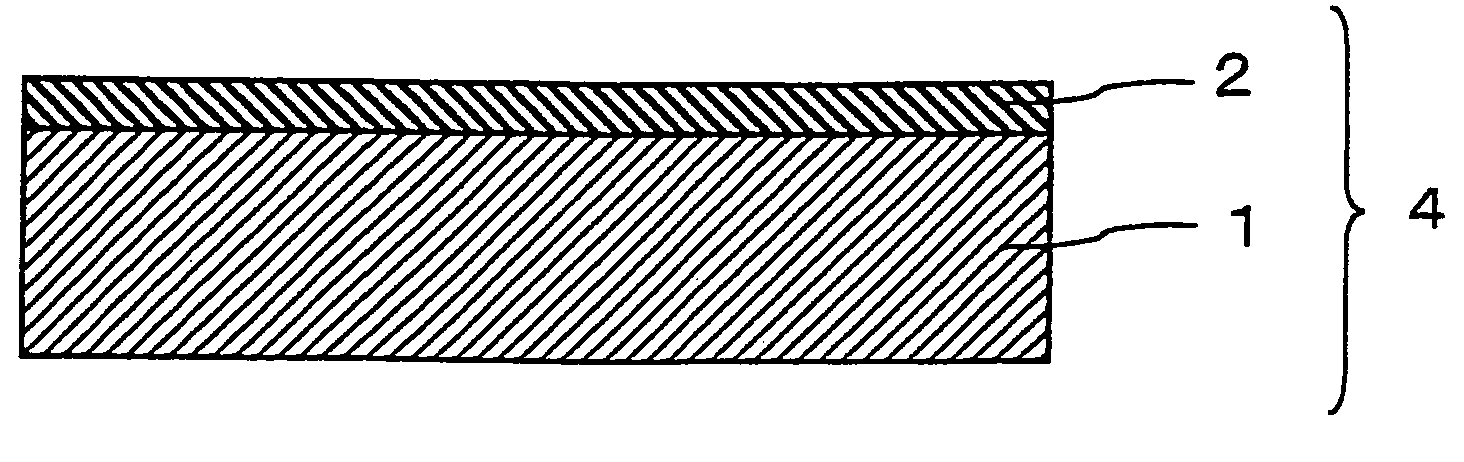

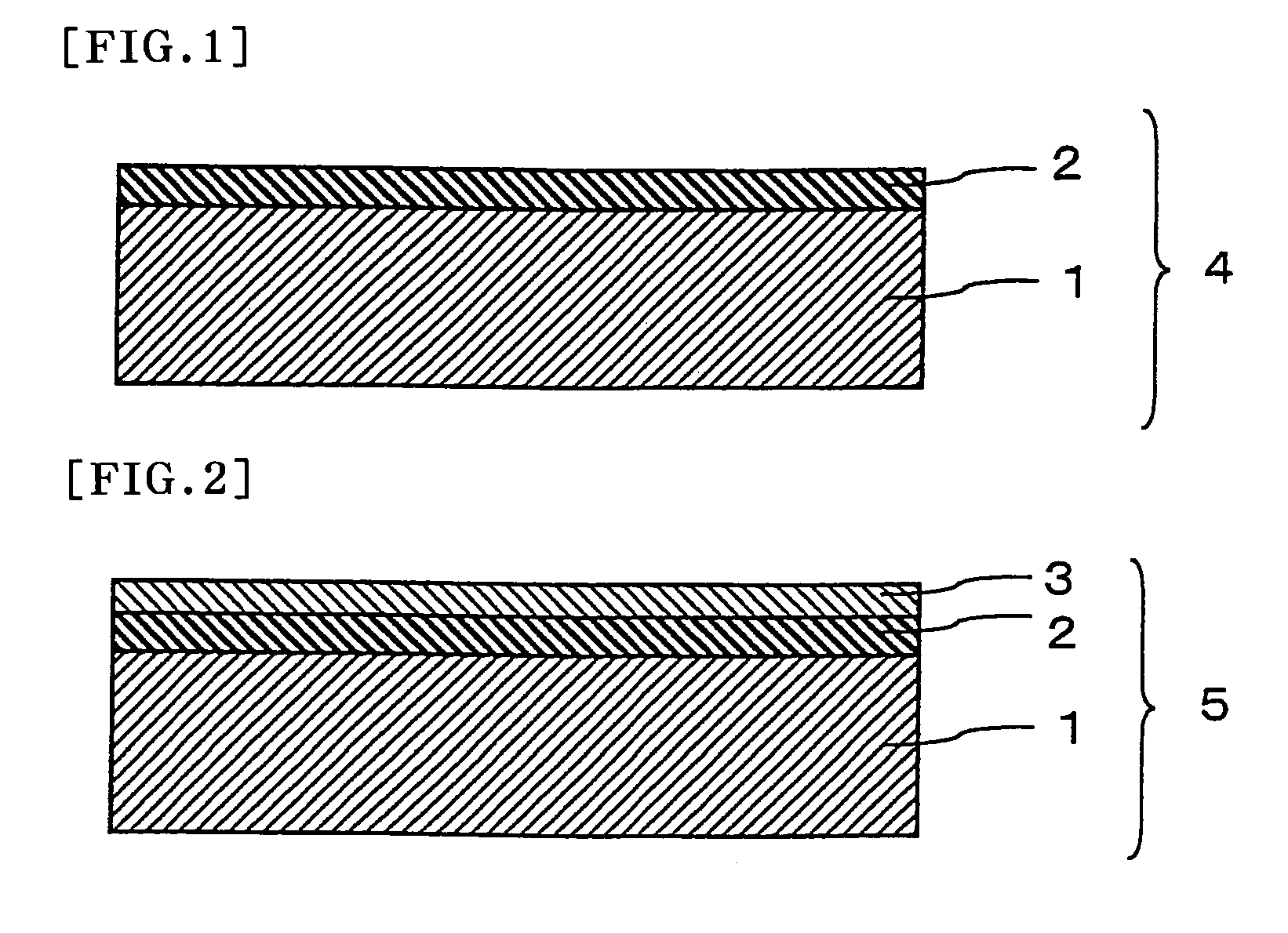

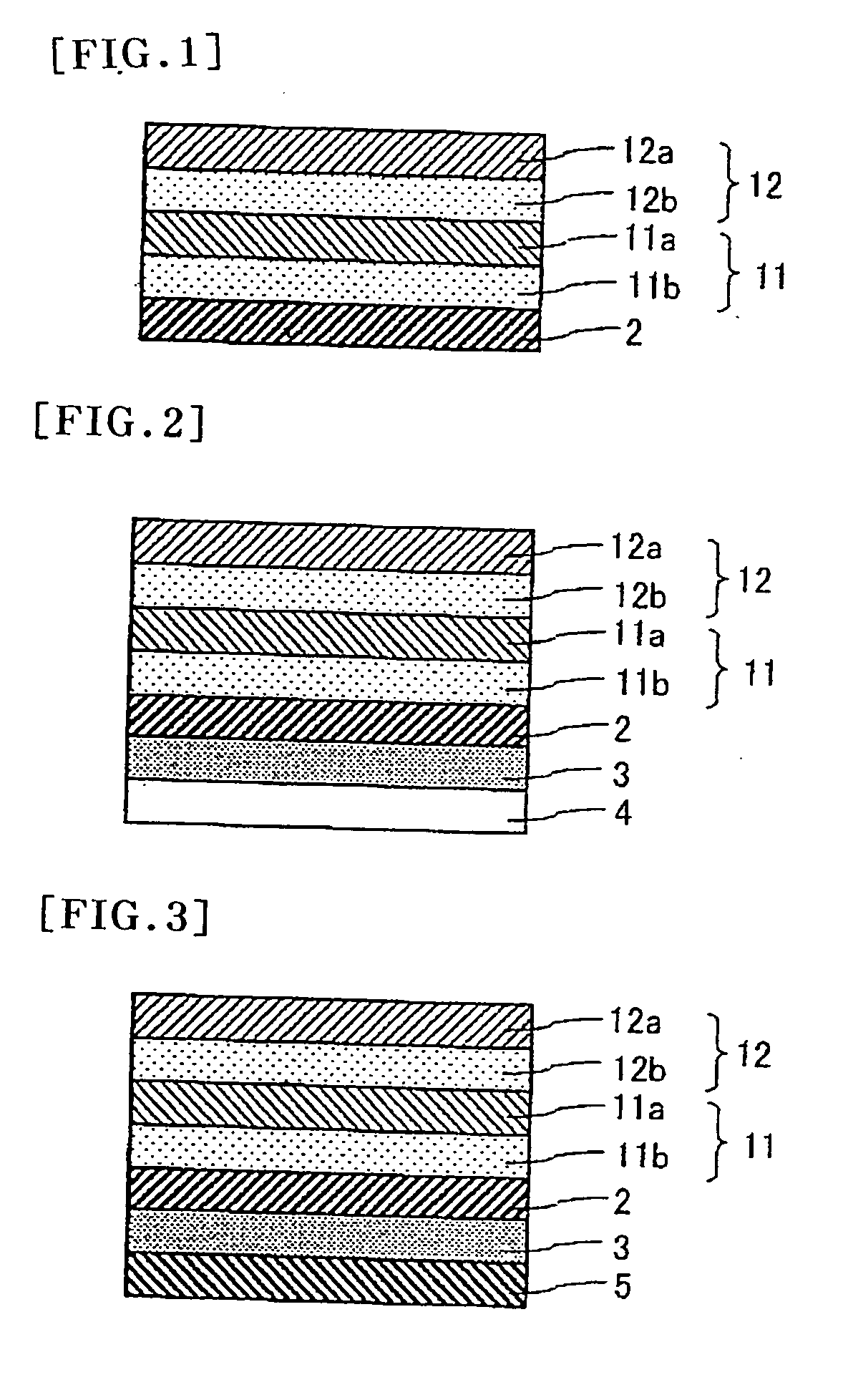

Retardation plate with protective film, method of manufacturing thereof, pressure-sensitive adhesive type retardation plate with protective film, and pressure-sensivie adhesive type optical material with protective film

InactiveUS20070182898A1Curl suppressionImprove machinabilitySynthetic resin layered productsLaminationTectorial membraneEngineering

A retardation plate with protective films of the present invention comprises a retardation plate; and at least two protective films that each comprise a base film and a pressure-sensitive adhesive layer formed on one side of the base film and are sequentially laminated on the retardation plate, wherein the first protective film laminated on the retardation plate differs in adhesive strength to adherend from the protective film or films other than the first protective film, and the first protective film has the lowest adhesive strength. The retardation plate with protective films can suppress curling and has good workability and good peelability even when using a thin retardation plate.

Owner:NITTO DENKO CORP

Two-way warp knitted fabric

A two-way warp knitted fabric of warp knit structure prepared by cross-knitting a polytrimethylene terephthalate fiber as a front yarn and an elastomer fiber as a back yarn, which has a knitted fabric density ratio represented by the following formula (I): knitted fabric density ratio = number of course / 2.54 cm / number of wale / 2.54 cm of 1.55 to 2.35. This knitted fabric is a stretchable ground material of knitted fabric for clothes which is suppressed in curl, has a soft feeling and suffers no yellowing.

Owner:ASAHI KASEI KK

Ink for ink-jet recording

An ink-jet ink comprising at least water and an organic solvent having a boiling point of not less than 150 ° C. in an amount of not less than 50 weight % and not more than 80 weight % based on the total weight of the ink, wherein the organic solvent comprises an alkane diol represented by Formula (1) or (2) in an amount of not less than 45 weight % and not more than 70 weight % based on the total weight of the ink, and a glycol mono-ether represented by Formula (3) in an amount of not less than 5 weight % and not more than 15 weight % based on the total weight of the ink: Formula (1) R1—CH(OH)—CH(OH)—R2; Formula (2) R1—CH(OH)—CH2—CH(OH)—R2; Formula (3) CH3—O—R3—OH.

Owner:KONICA MINOLTA INC

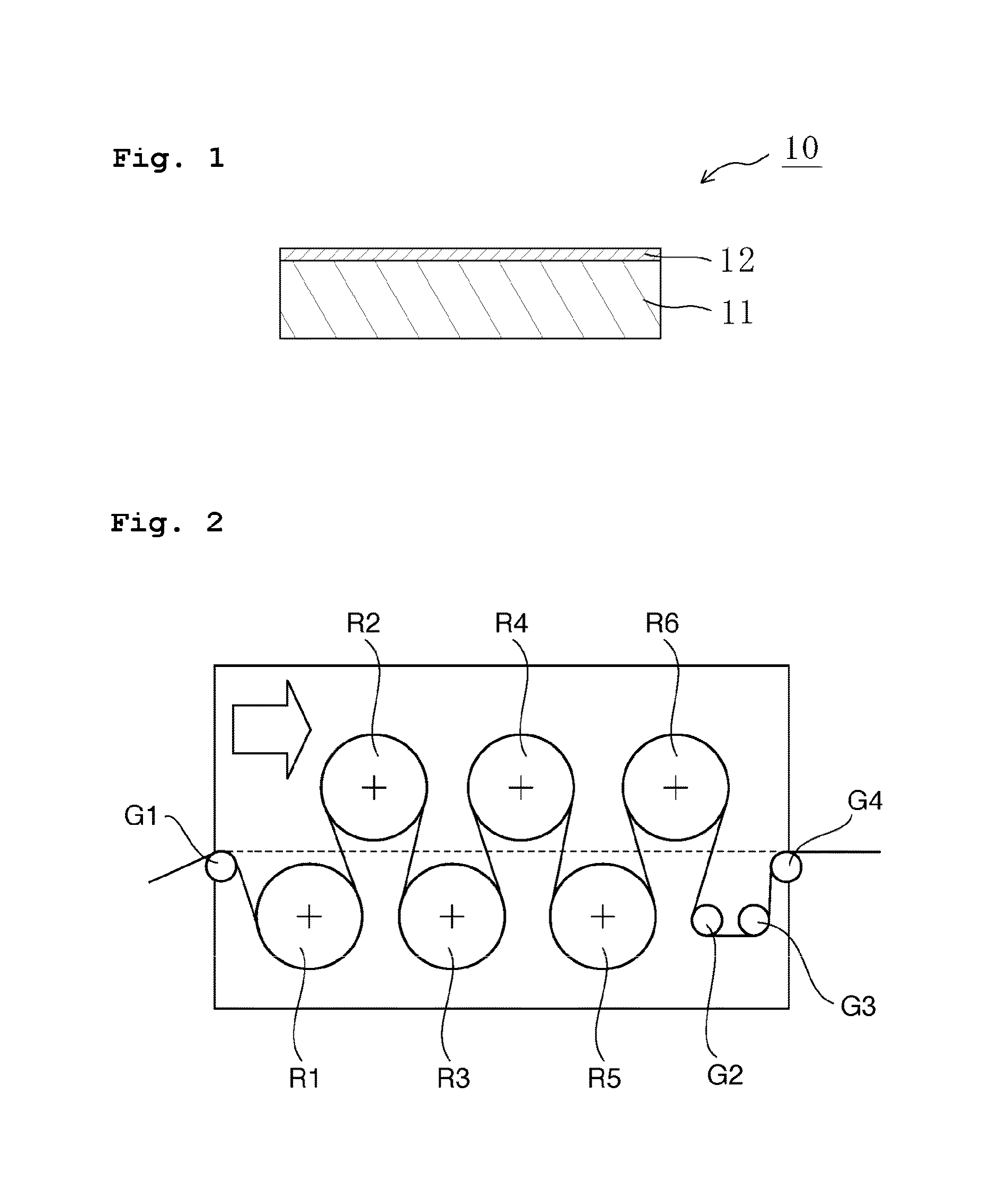

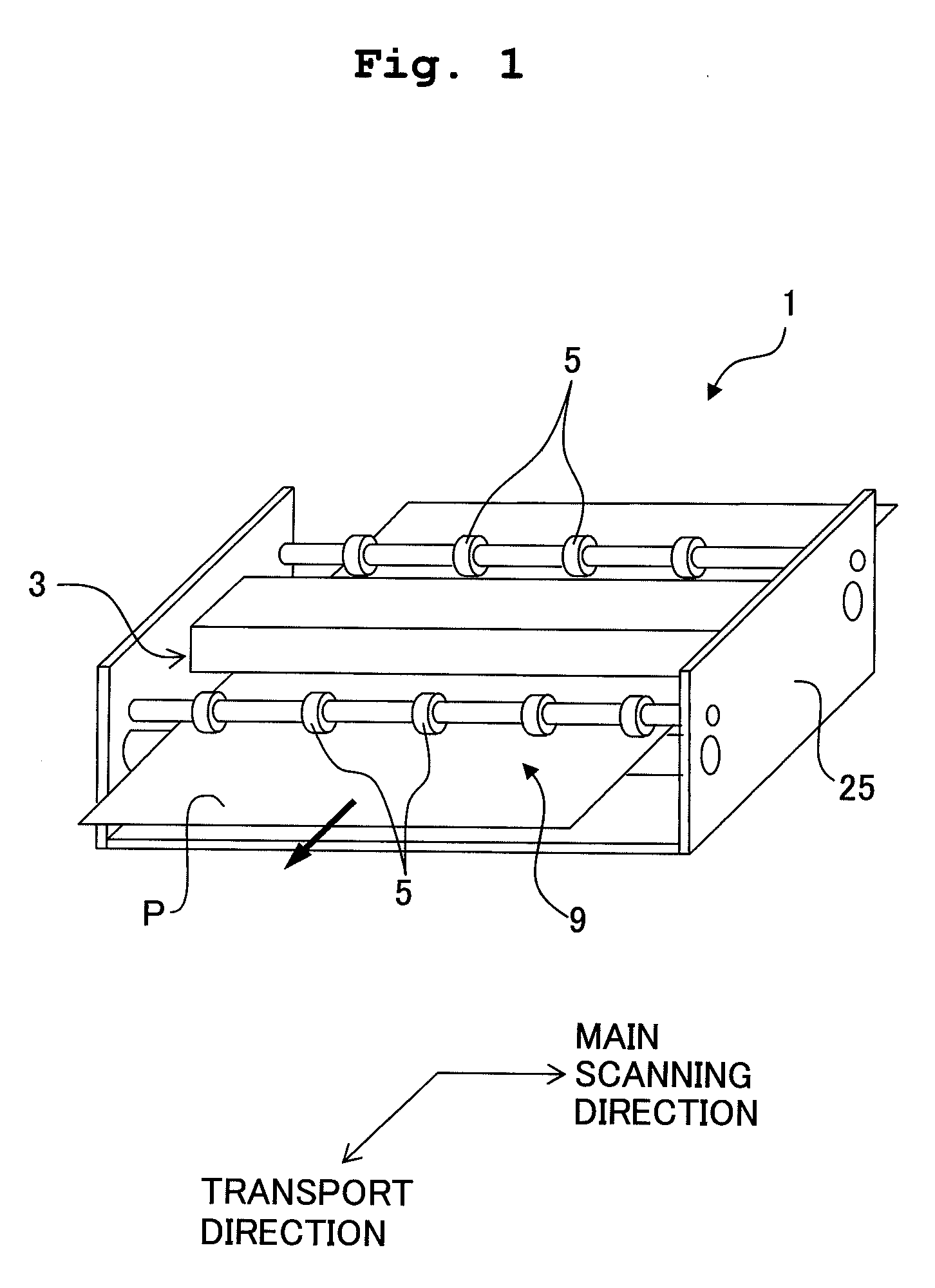

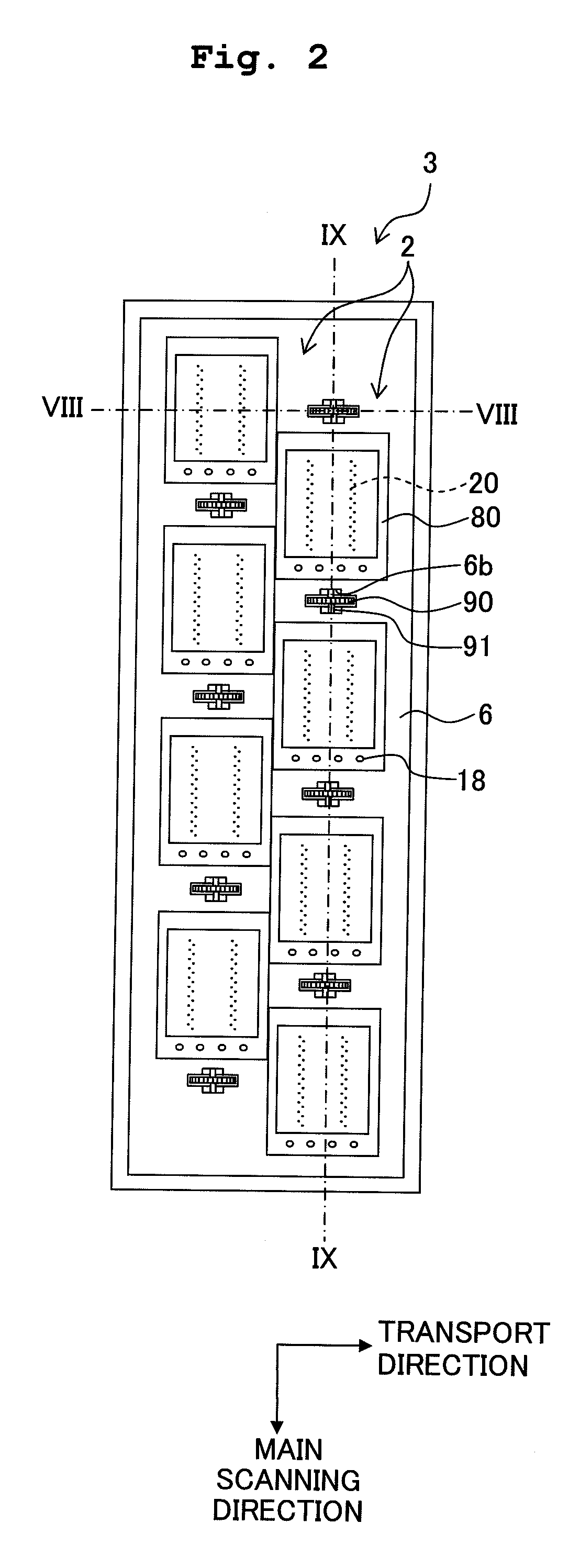

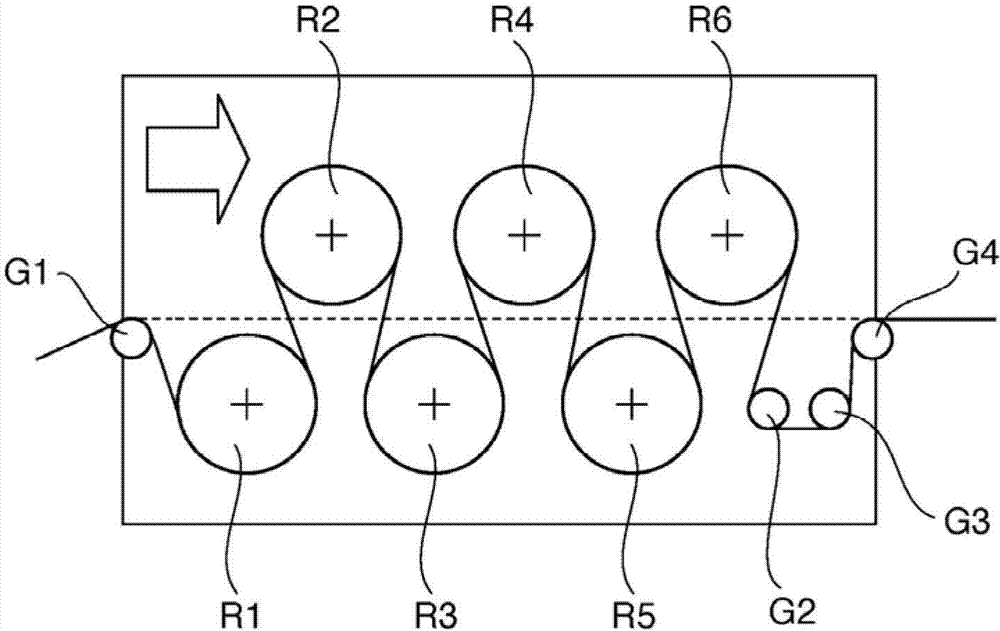

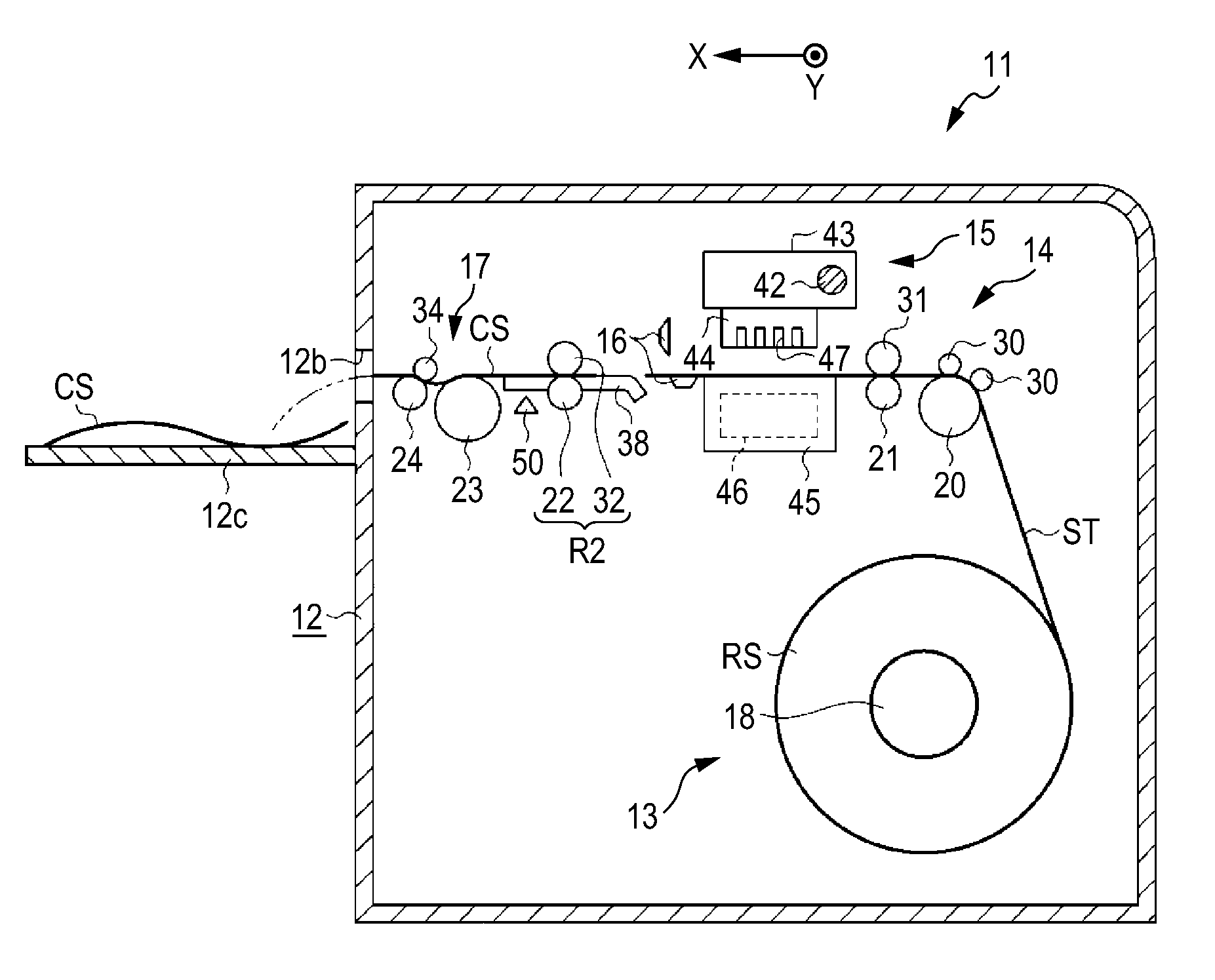

Liquid droplet jetting apparatus

ActiveUS20090244240A1Less frizzCurl suppressionInking apparatusPower drive mechanismsGear wheelEngineering

An ink-jet printer has a line ink-jet head which includes a plurality of heat units arranged in two rows in a zigzag form along a main scanning direction, and a spur which is arranged to be in line in the main scanning direction, with a first head unit belonging to one row, and to overlap a second head unit adjacent to the first head unit, which belongs to the other row, in a direction intersecting the main scanning direction. The spur presses a recording paper from a side of the head unit. Accordingly, it is possible to suppress curling of the recording paper in a direction intersecting a transport direction.

Owner:BROTHER KOGYO KK

Optical layered body, polarizer and image display device

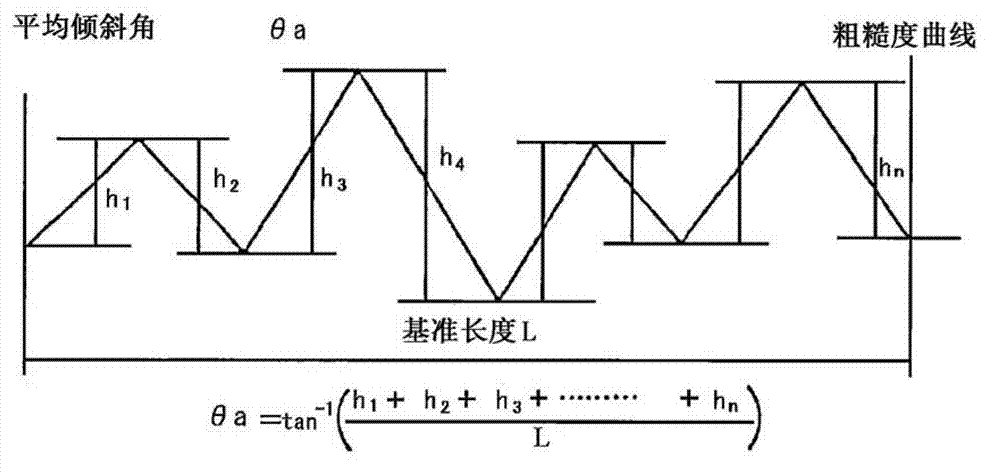

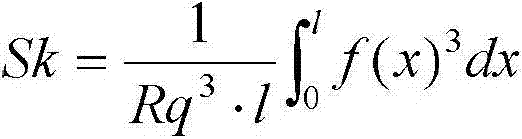

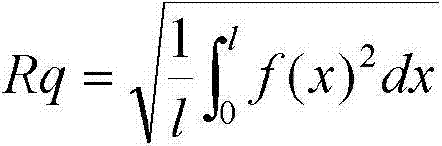

ActiveCN103245982AWide range of choicesReduce the overall heightDiffusing elementsLayered productsSlant angleDisplay device

The present invention provides an optical layered body, a polarizer and an image display device. The optical layered body can fully restrain interference fringe and crimp, realize the thinning of an optical function layer, and prevent the manufacture cost to be increased. The optical layered body of the invention possesses the optical function layer on one surface of a transmission base material, and is characterized in that the surface of the above optical function layer has a convex-concave shape, for the convex-concave shape, when the average slant angle of the convex-concave shape is theta a, and the concave-convex skewness is Sk, the absolute value of the Sk and the theta a satisfy the following formula: 0.01 degree <= theta a<=0.10 degree (absolute value of Sk) <=0.5.

Owner:DAI NIPPON PRINTING CO LTD

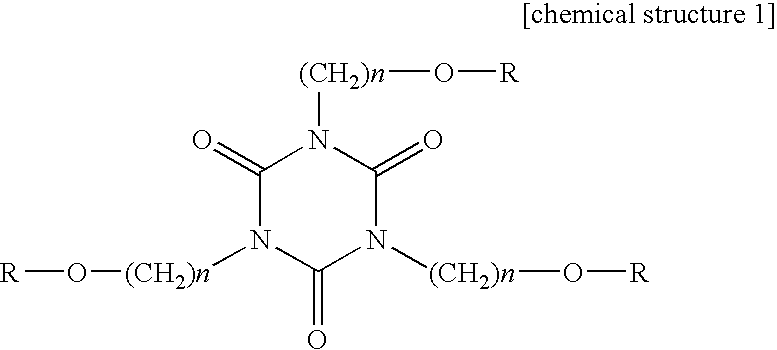

Active energy ray-curable resin composition and article and molded product using the same

InactiveCN101203537ACuring shrinkage is smallCurl suppressionPolyurea/polyurethane coatingsIsocyanateSide chain

An actinic radiation curable resin composition characterized by comprising a urethane acrylate (A) which is a product of addition reaction of a polyisocyanate (a1) with an acrylate (a2) having one hydroxyl group and two or more (meth)acryloyl groups in the molecule and a polymer (B) having a (meth)acryloyl group which is obtained by reacting a (meth)acrylate polymer (b1) having a reactive functional group in the side chain with an a,ss-unsaturated compound (b2) having a functional group reactive with the reactive functional group. The composition can be cured by irradiation with an actinic radiation such as ultraviolet light to give a cured film having high hardness and high mar resistance with little cure shrinkage.

Owner:DAINIPPON INK & CHEM INC

Method of manufacturing polarizing film

ActiveCN103163583APromote crystallizationHigh crystallinityPolarising elementsThin material handlingPolymer sciencePolyvinyl alcohol

A method of manufacturing a polarizing film according to an embodiment of the present invention includes forming a polyvinyl alcohol-based resin layer on a thermoplastic resin substrate having a crystallinity of 7% or less to produce a laminate and subjecting the laminate to a wet treatment followed by a drying treatment with a heat roll.

Owner:NITTO DENKO CORP

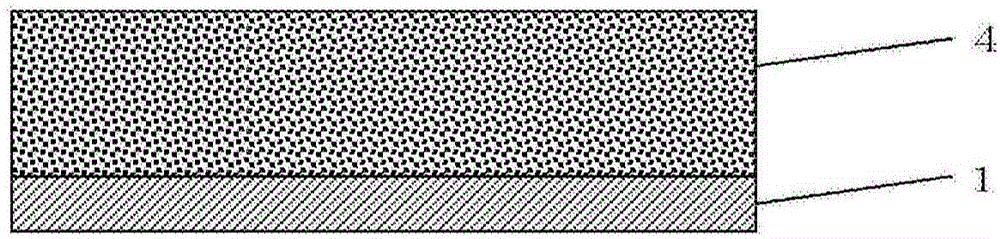

Coating film composition for battery electrodes or separators, battery electrode or separator provided with coating film obtained by using same, and battery provided with battery electrode or separator

ActiveCN105027328AImprove heat resistancePrevent crushingElectrode manufacturing processesActive material electrodesElectrical batteryHeat resistance

The problem of the present invention is to provide a coating film composition for battery electrodes or separators that is capable of forming a coating film which has high heat resistance and for which the occurrence of curling is suppressed. The present invention is a coating film composition for battery electrodes or separators which includes a binding agent, a solvent, and viscoelastic particles.

Owner:KYORITSU KAGAKU SANGYO KK

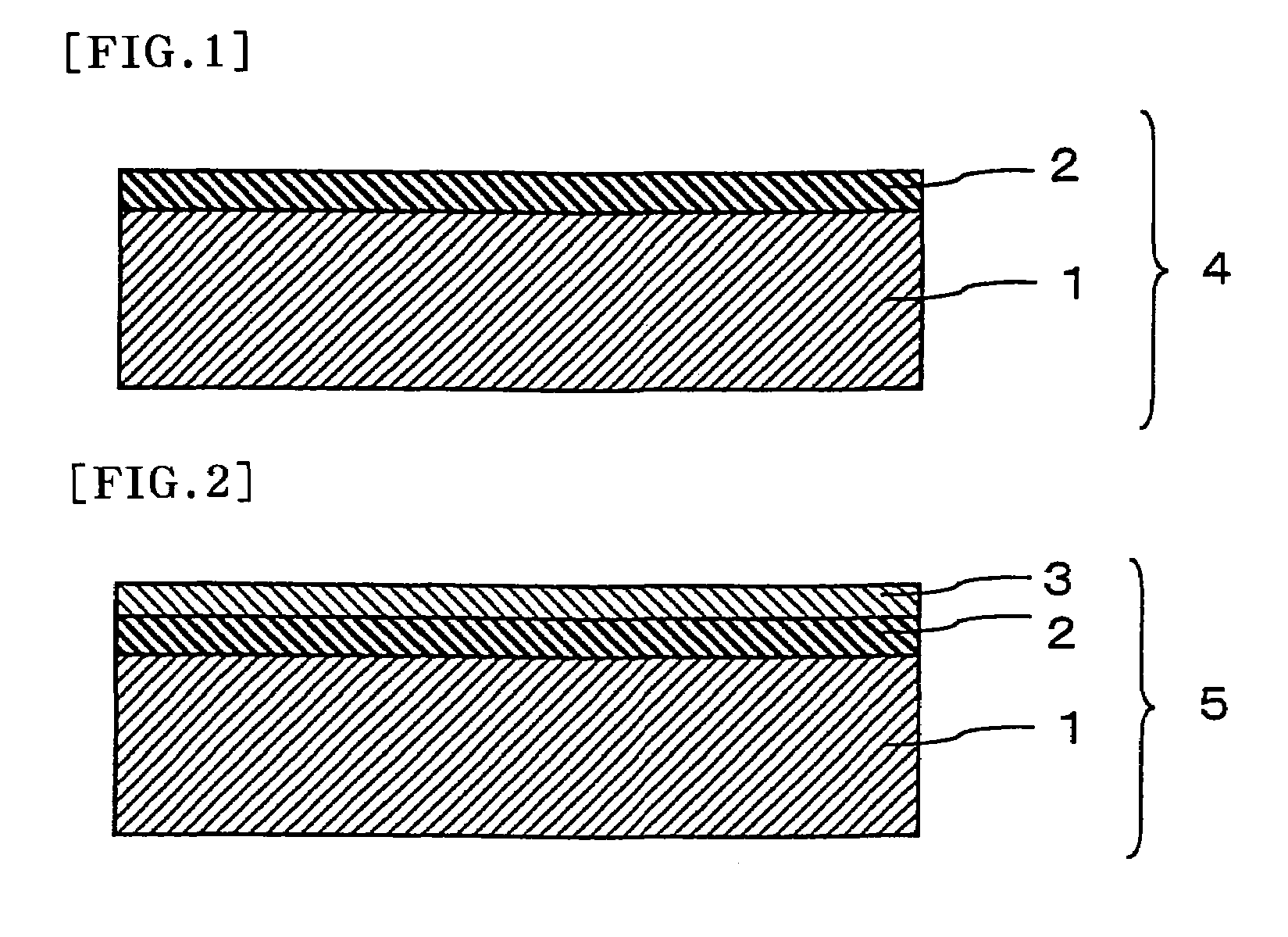

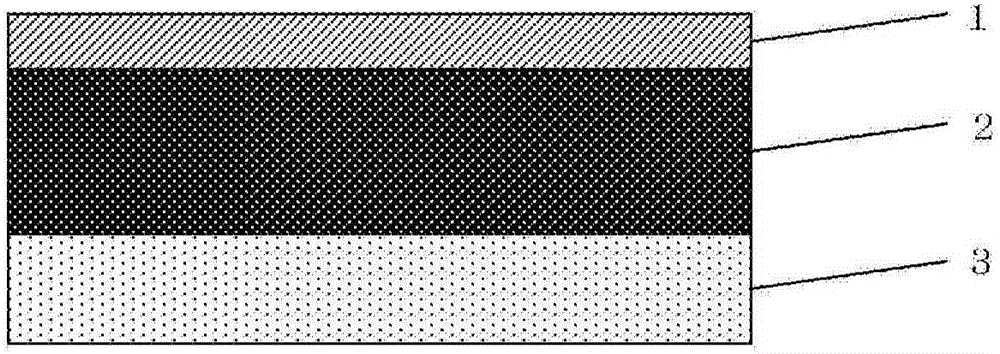

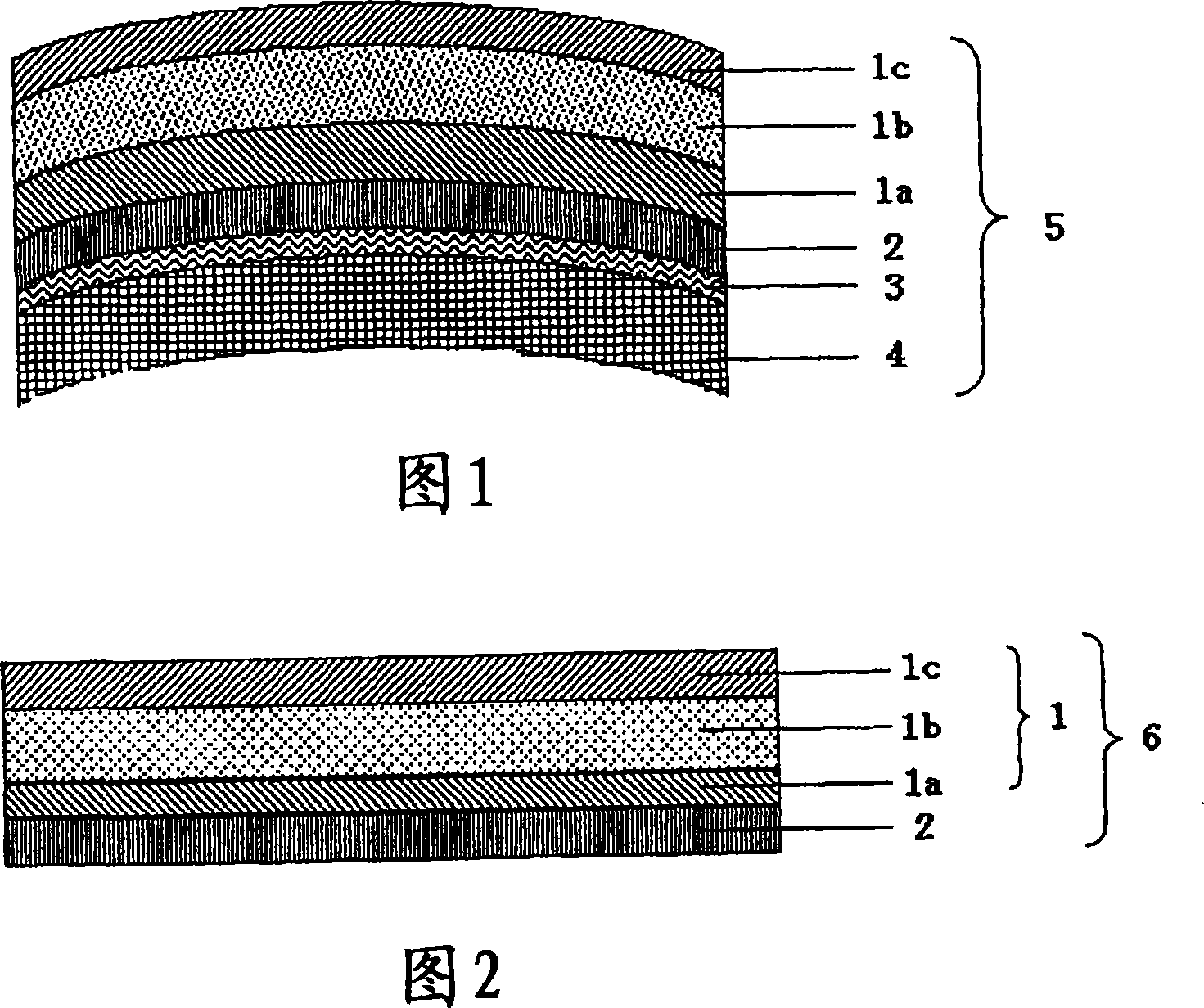

Multi-layer laminate and flexible copper-clad laminated substrate production method

InactiveCN101151946AImprove workabilityImprove adhesionCircuit precursor manufactureCircuit susbtrate materialsHeat resistanceCopper foil

The purpose is to reduce the curling of a flexible cupper-clad laminated substrate which occurs when a resin solution is applied directly on an ultrathin copper foil with a heat-resistant carrier to form a resin layer on the substrate and then the carrier is peeled off. A method for producing a flexible copper-clad laminated substrate (6) having a resin layer (1) and an ultrathin copper foil (2), the method comprising, in an ultrathin copper foil with a heat-resistant carrier in which the ultrathin copper foil (2) is provided on the carrier (4) thorough a releasable layer (3), applying a resin solution onto the ultrathin copper foil, drying and thermally treating the resin solution to form the resin layer (1) which is composed of one or more layers on the ultrathin copper foil with the heat-resistant carrier, thereby producing a multi-layer laminate, and removing the carrier from the laminate. In the multi-layer laminate provided before the removal of the carrier, a force for causing the laminate to curl inwardly on the carrier-side is applied to the laminate and then the carrier is peeled off from the substrate. Thus, a flexible cupper-clad laminated substrate (6) can be produced which is reduced in the degree of curling.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

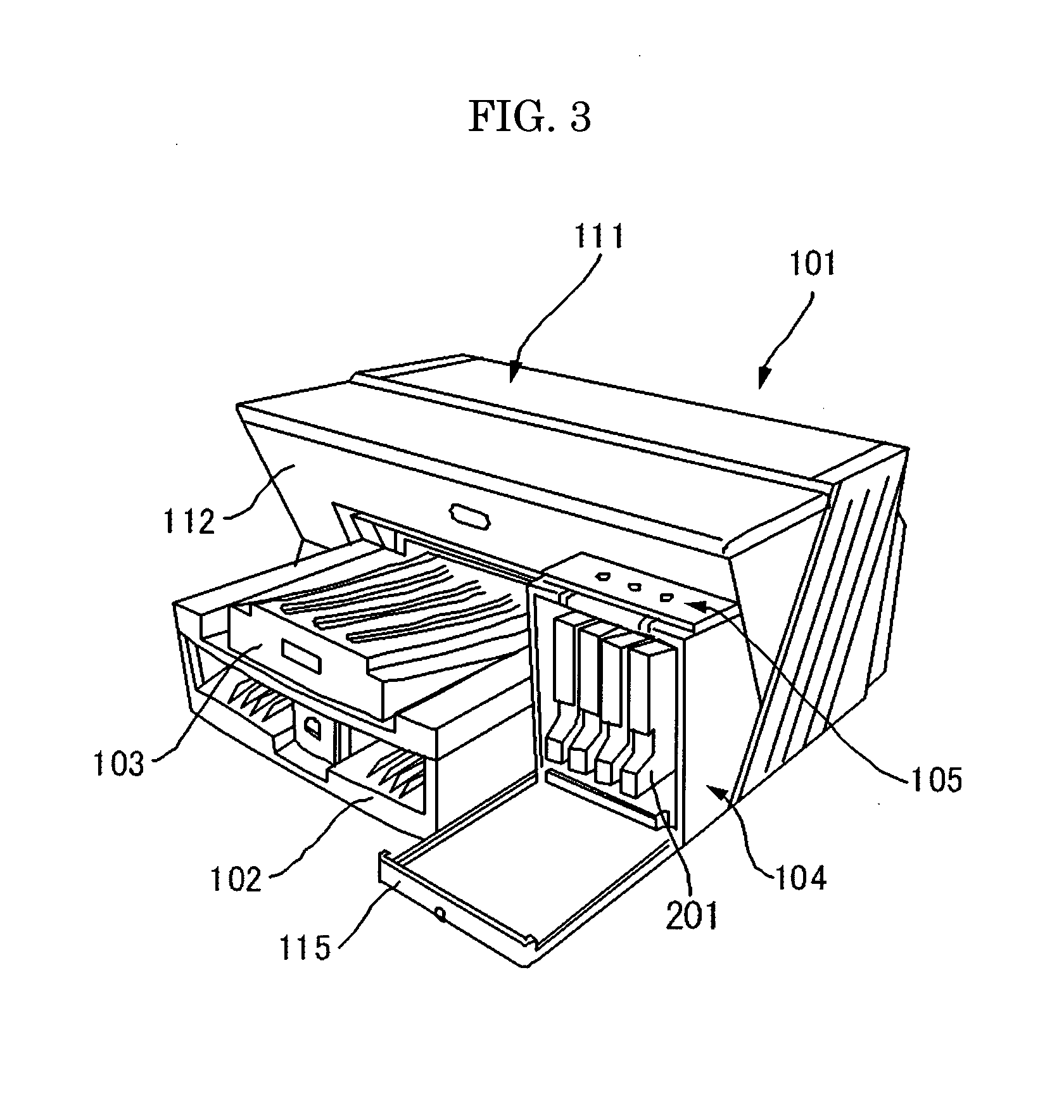

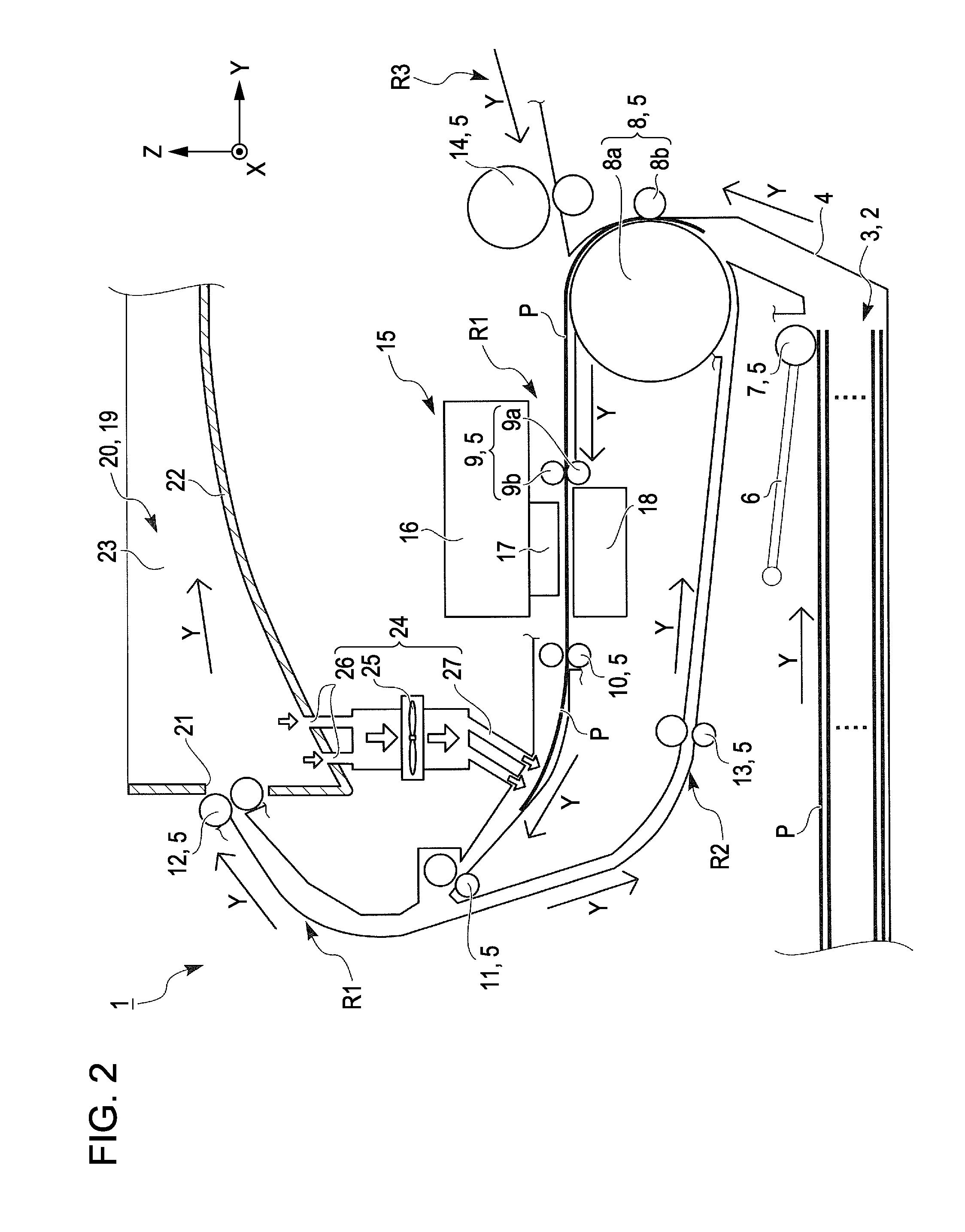

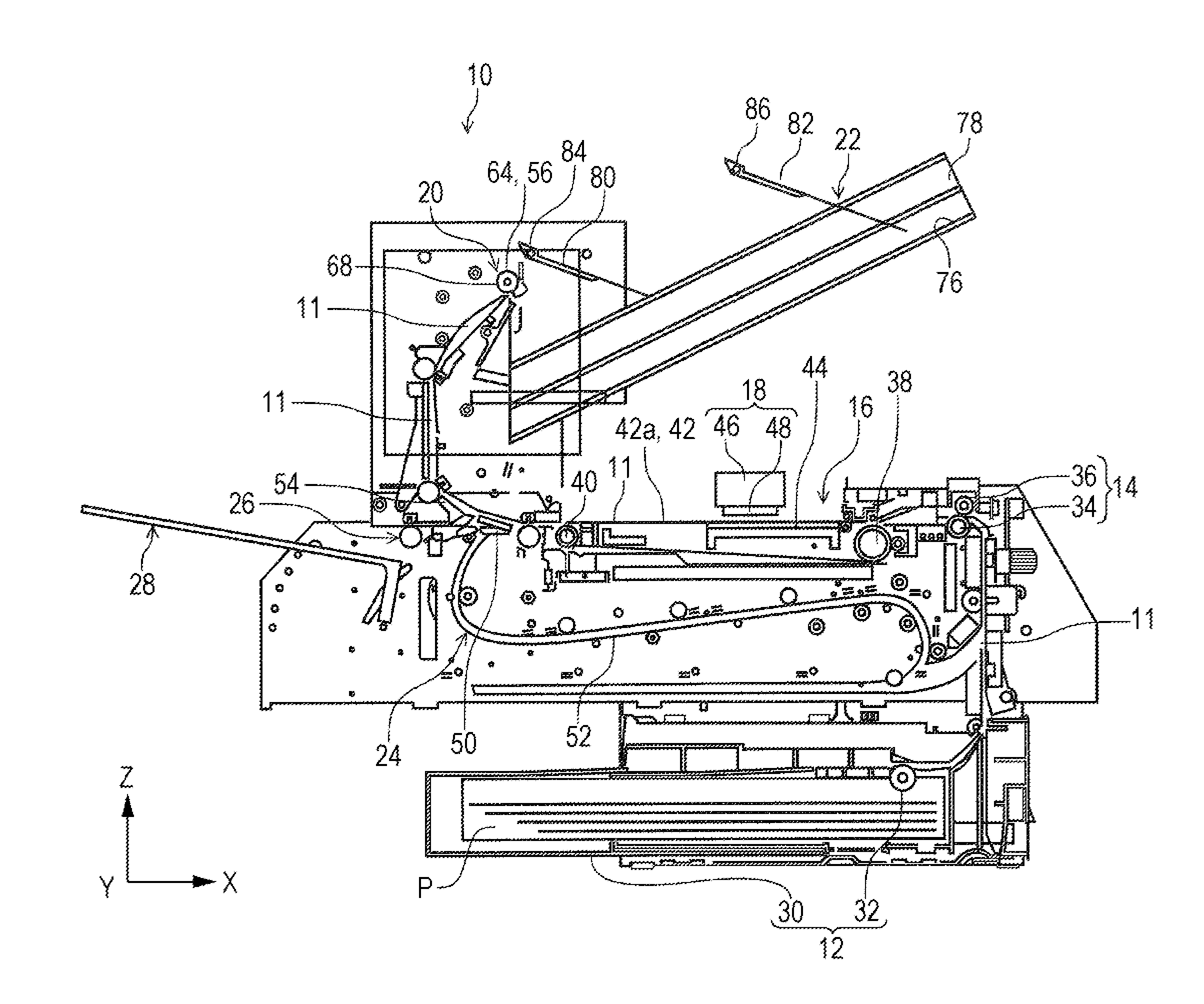

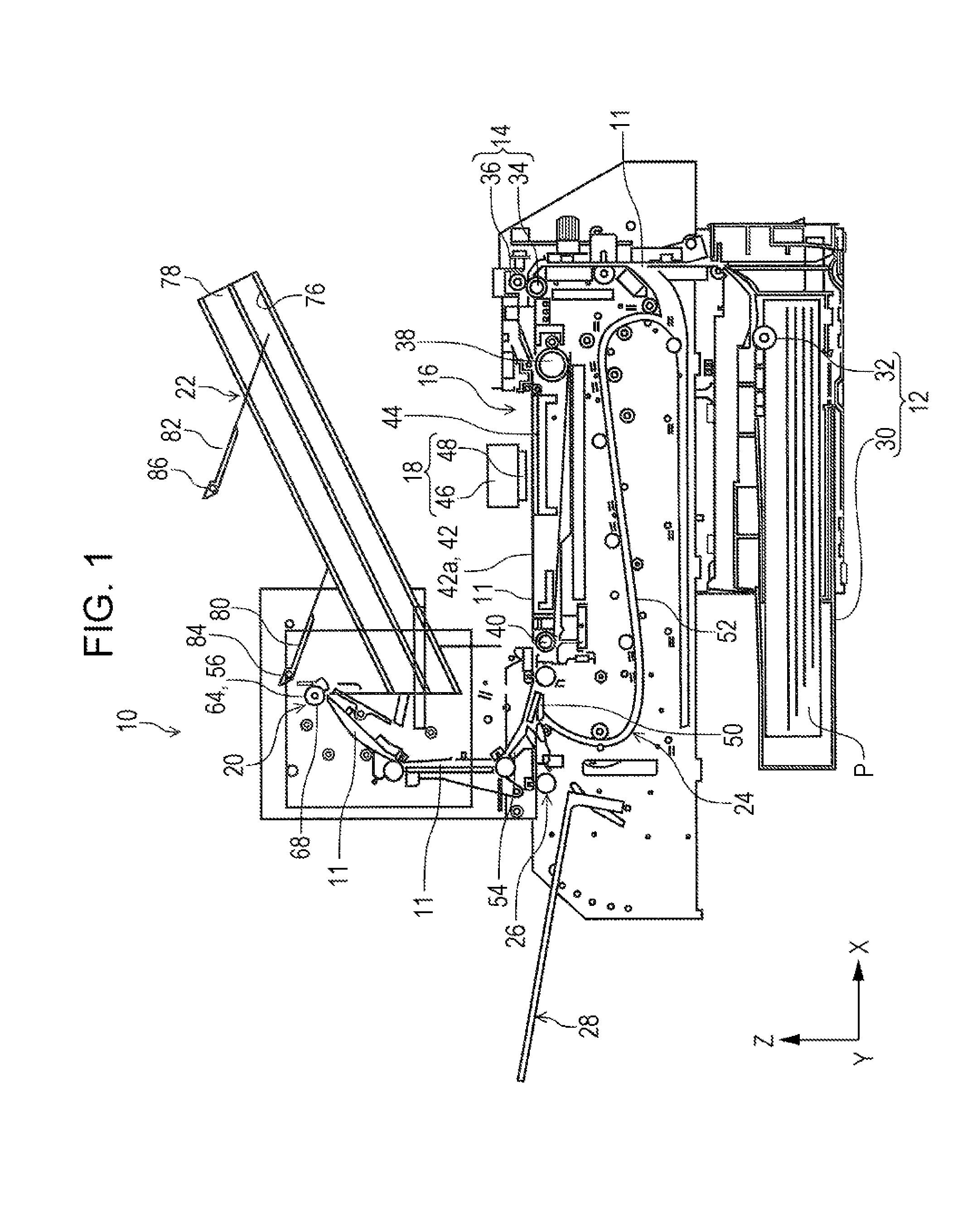

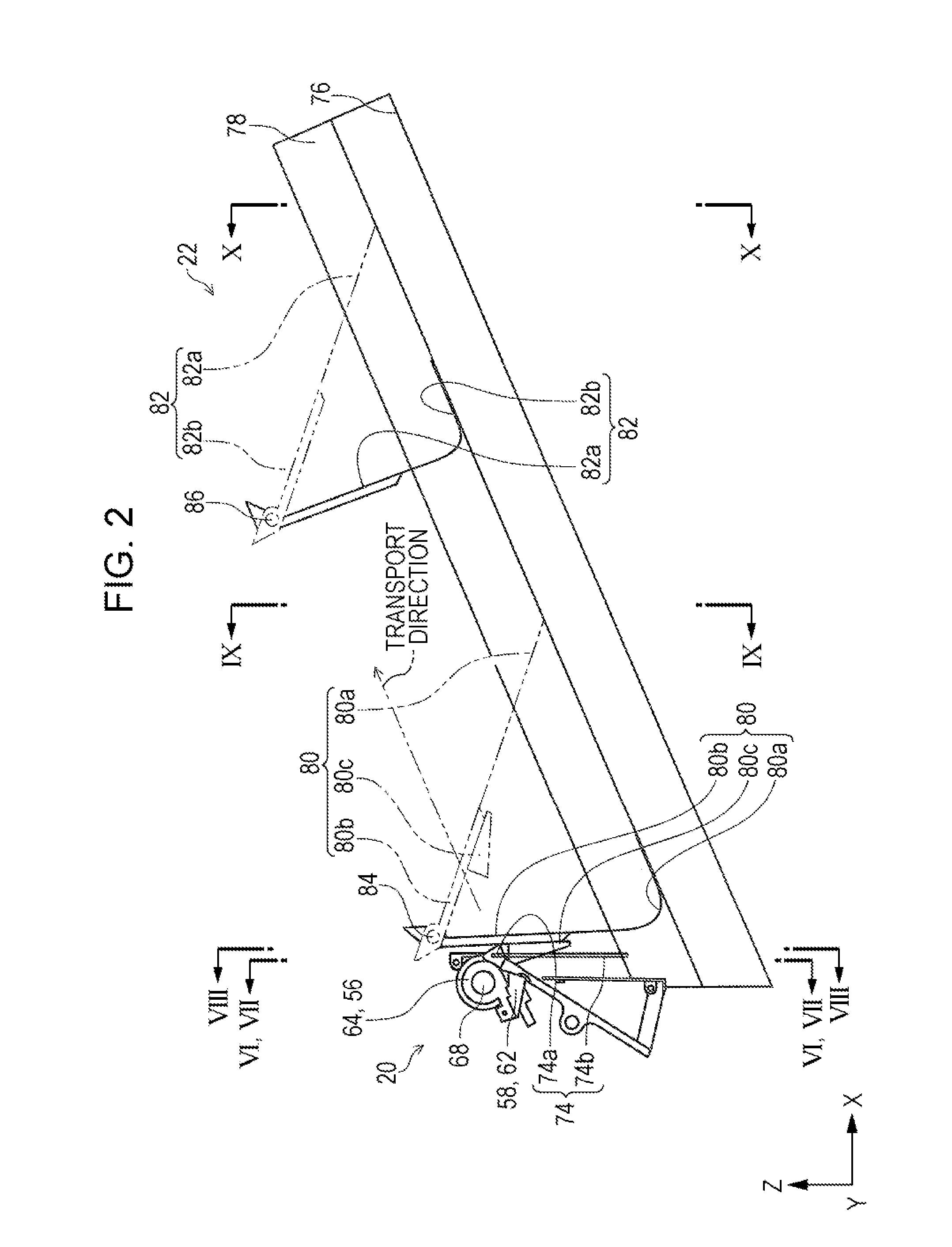

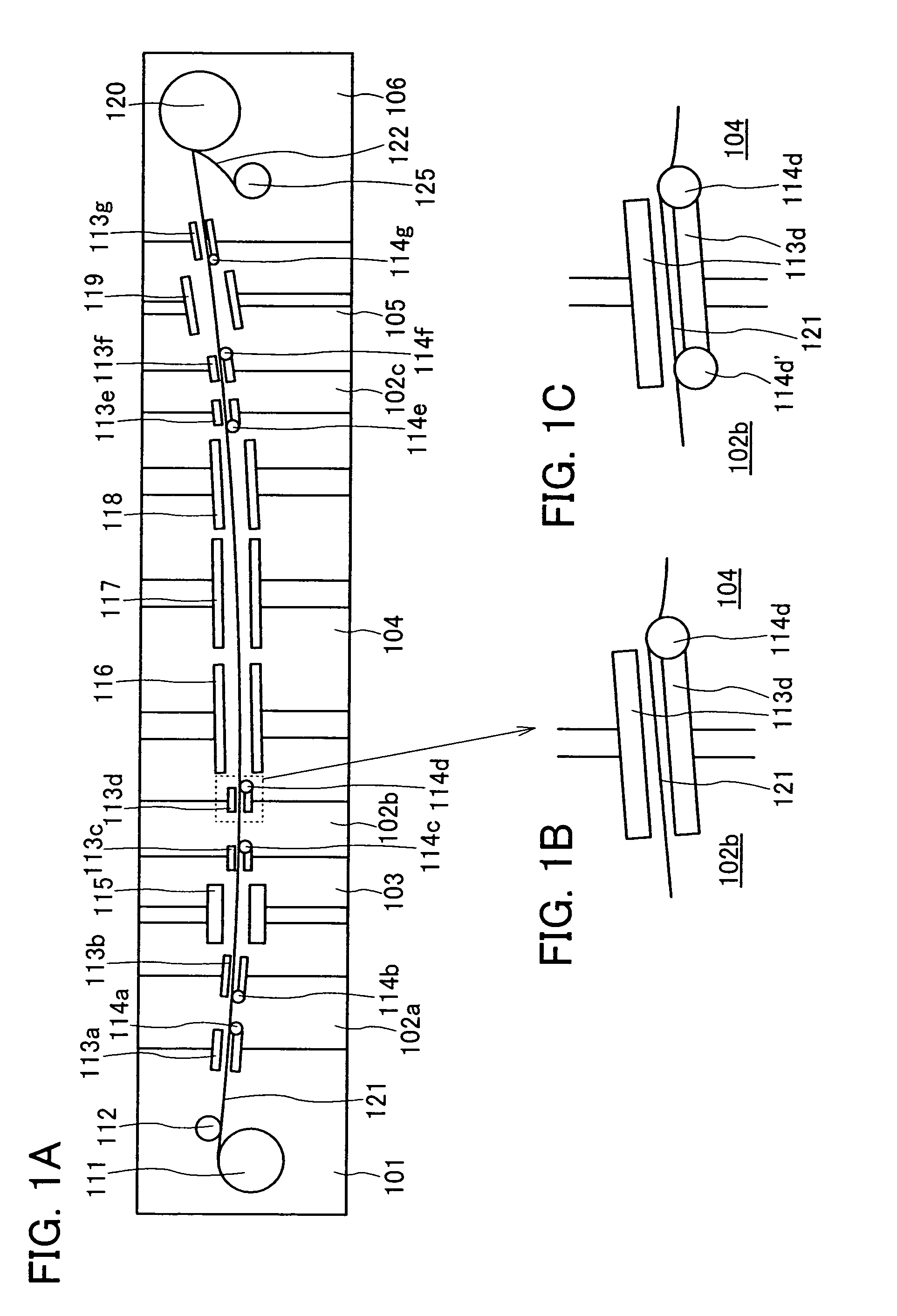

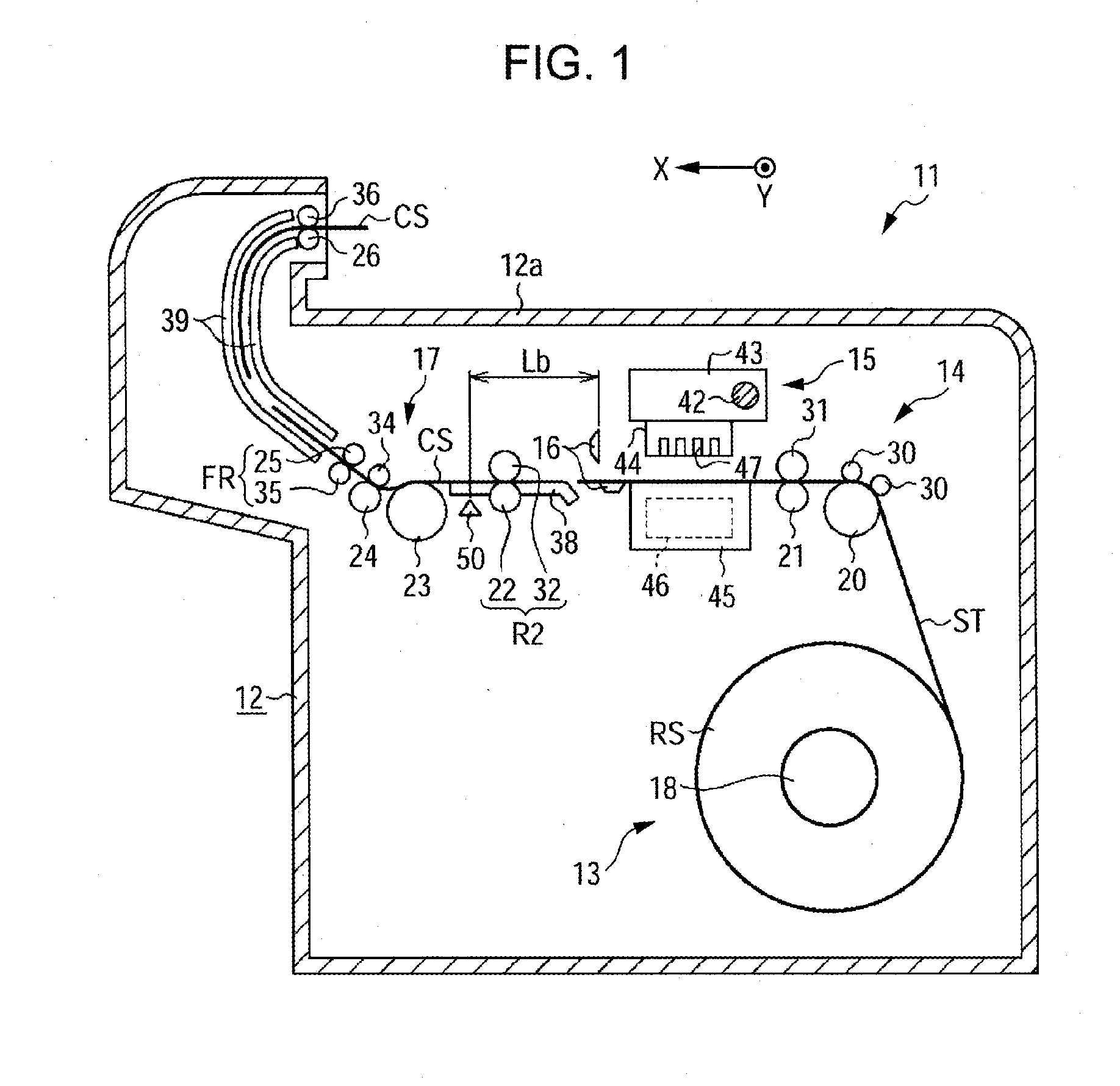

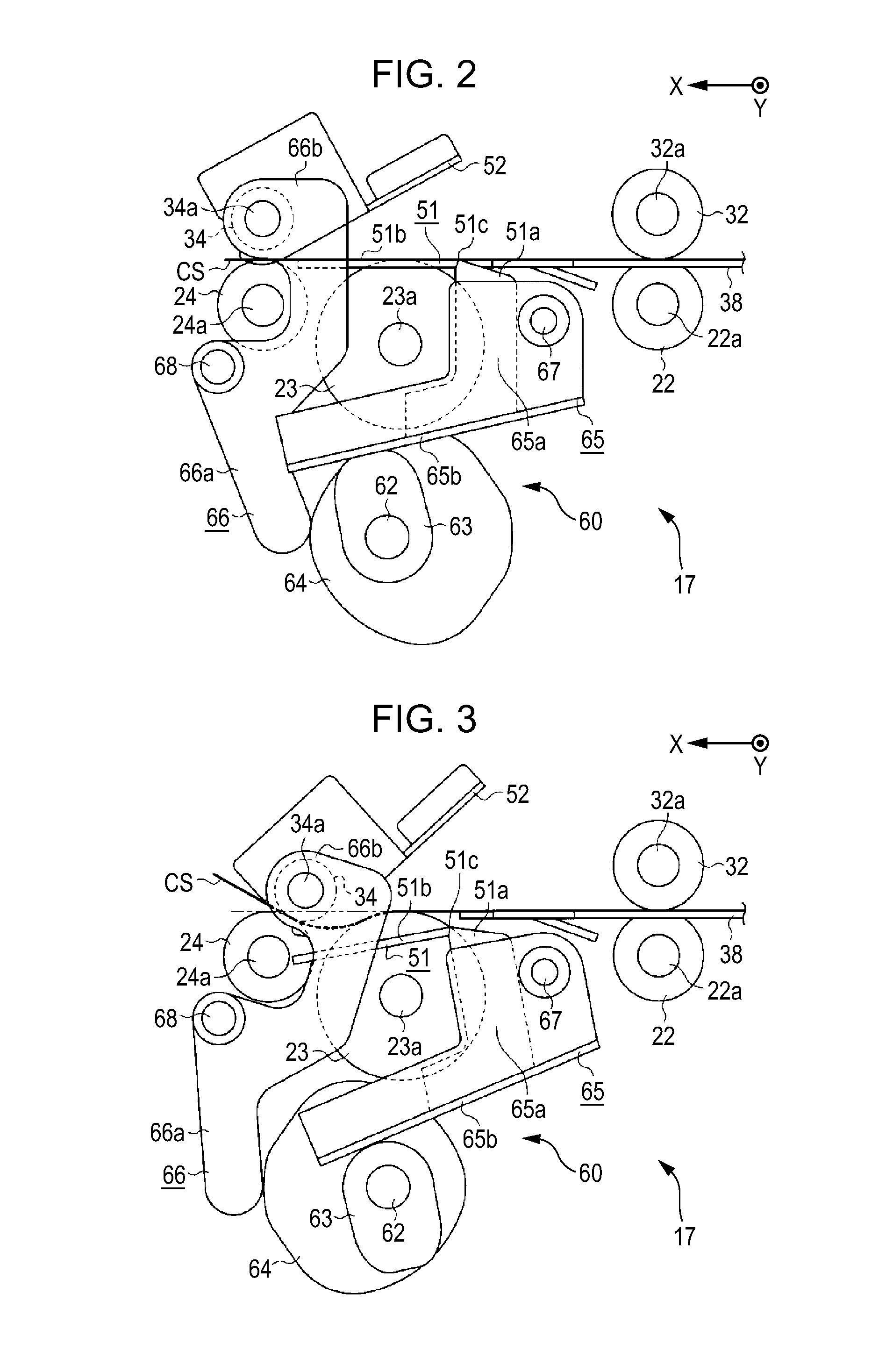

Recording apparatus

ActiveUS20140292979A1Increase flexibilityCurl suppressionOther printing apparatusArticle deliveryFeeding forceEngineering

A recording apparatus includes a recording unit that performs recording on a recording surface of a recording medium, a discharge section that discharges the recording medium, and a first bending member that is in contact with the recording medium which passes through the recording unit in the transport path and is transported toward the discharge section to bend the recording medium, in which the first bending member bends the recording medium in such a manner that the recording surface is directed inside by displacing both side portions of the recording medium in a width direction with respect to a central portion of the recording medium in the width direction of the recording medium at a position on a further upstream side in a direction of the transport than a contact position of the discharge section where a feeding force is applied to the recording medium.

Owner:SEIKO EPSON CORP

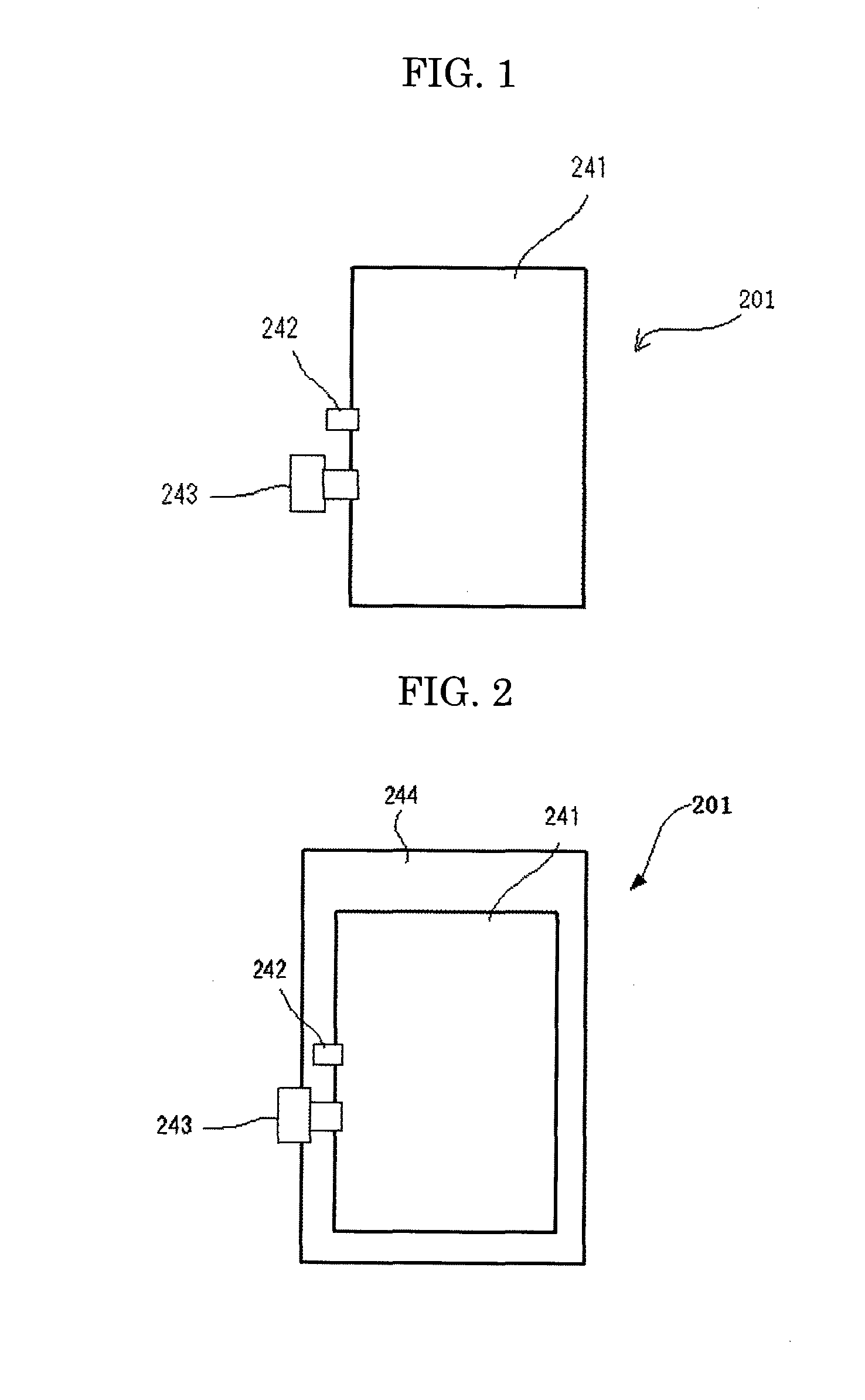

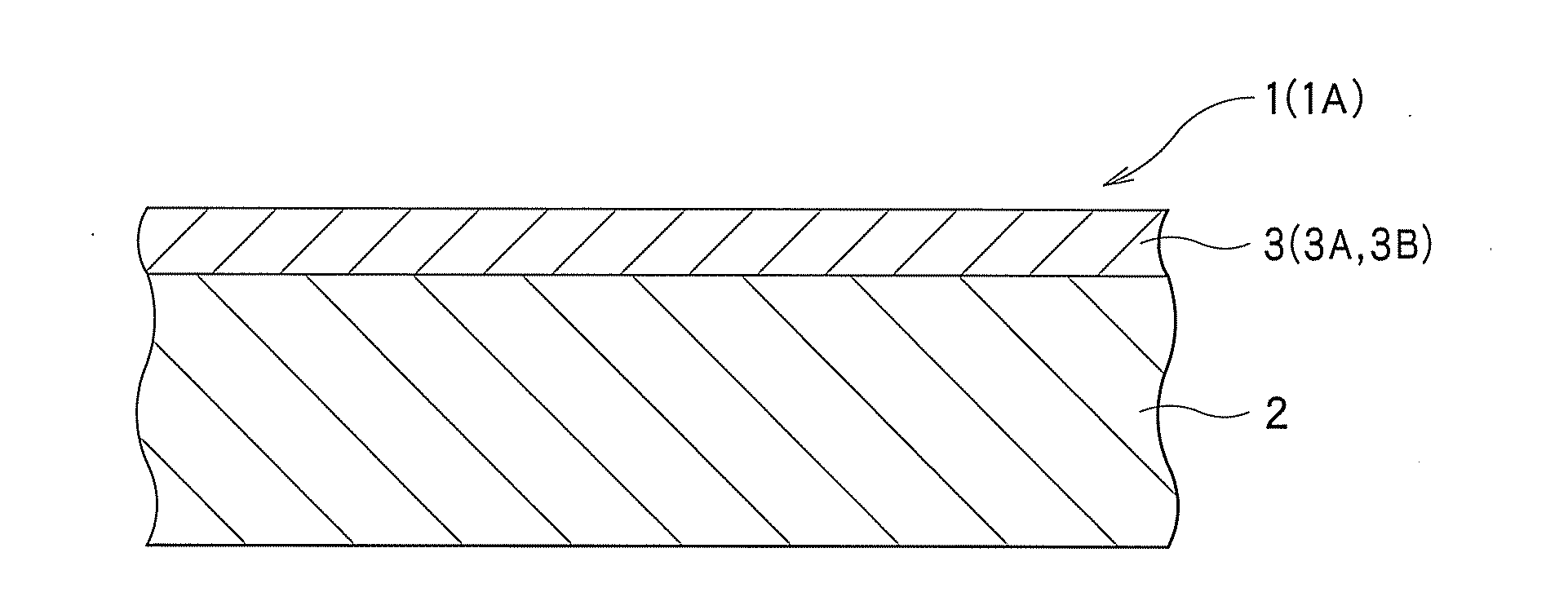

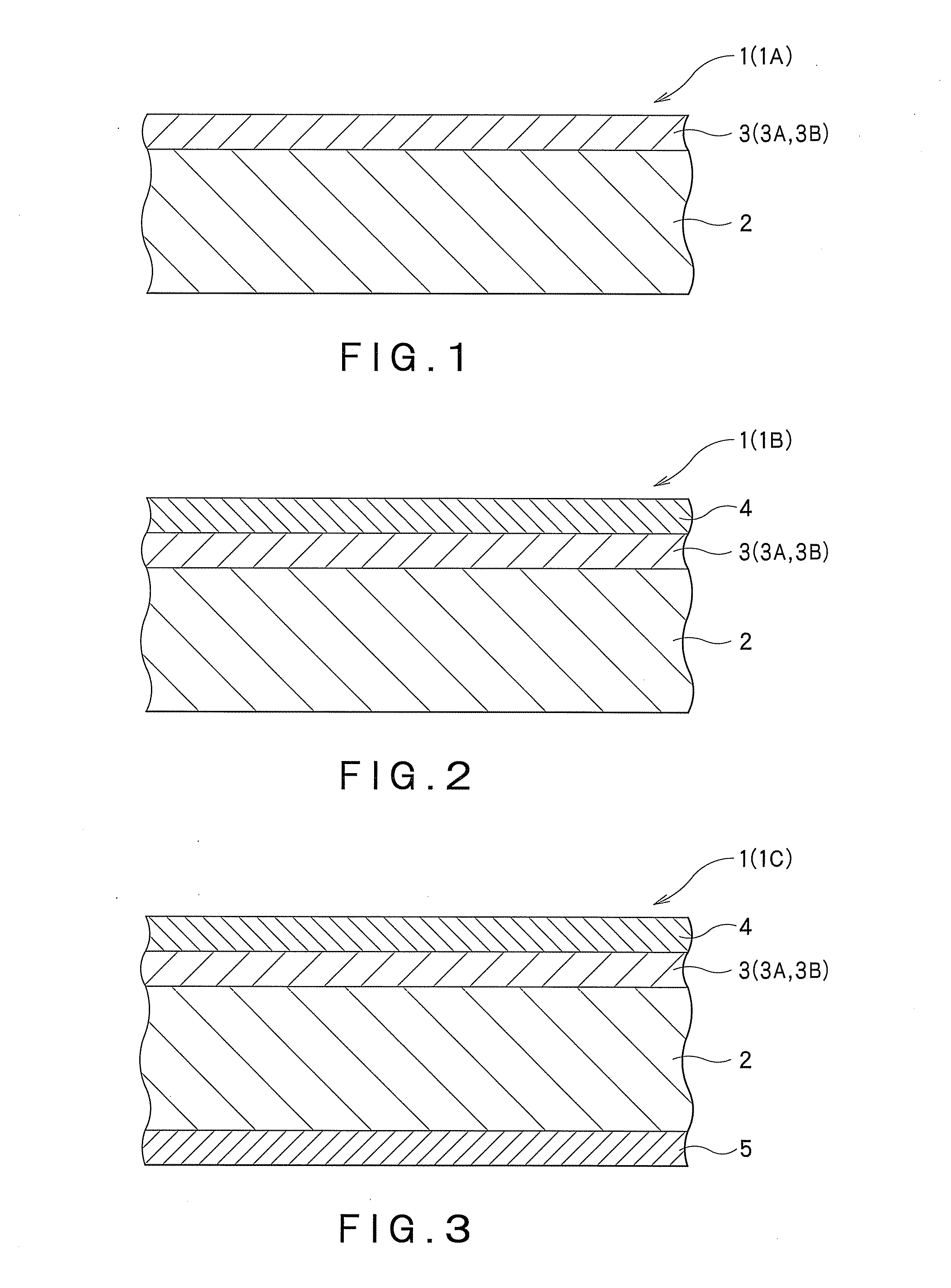

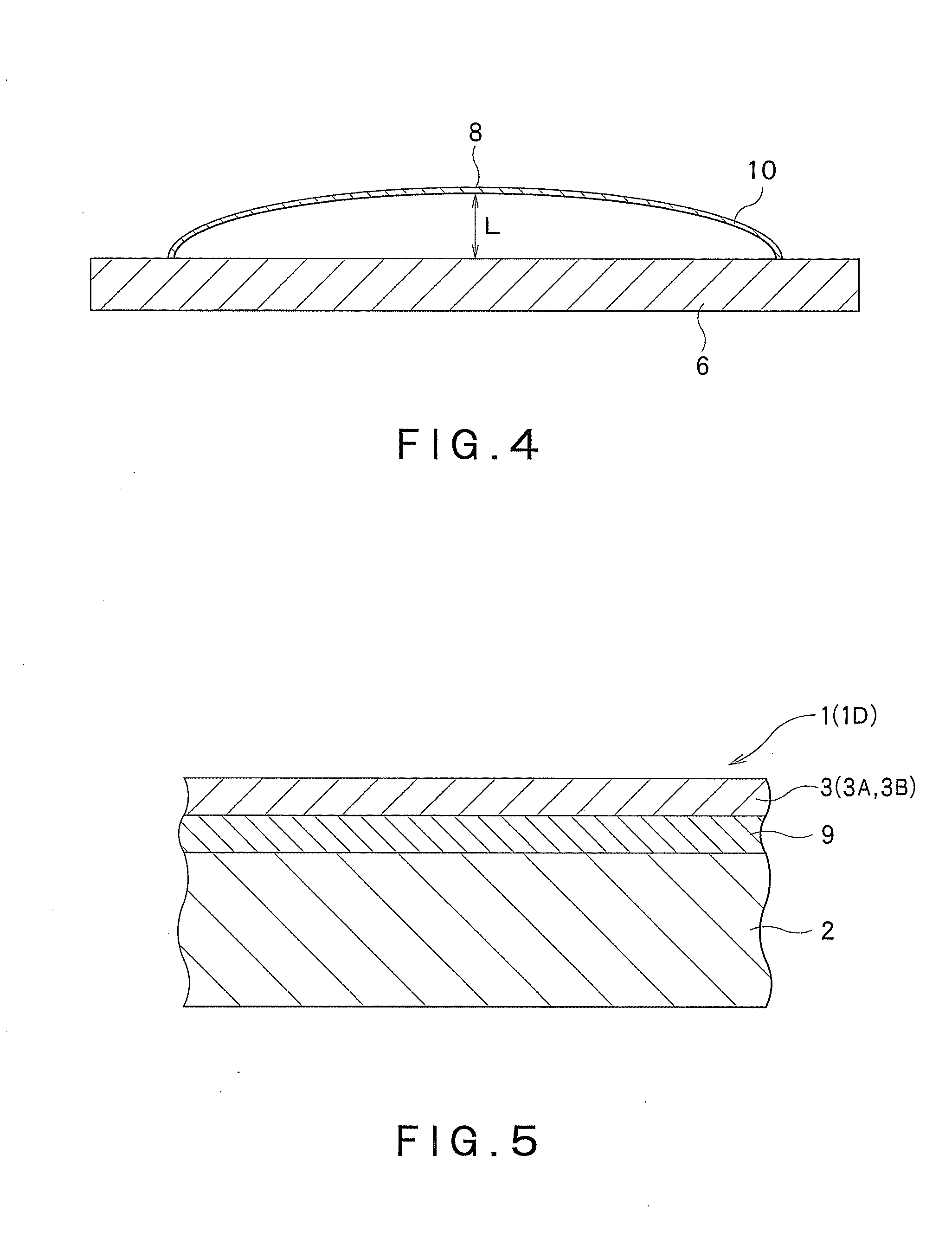

Gas barrier sheet

ActiveUS20100098955A1Improve adhesionImprove productivitySynthetic resin layered productsVacuum evaporation coatingProduction rateRefractive index

There is provided a gas barrier sheet that has high productivity, good gas barrier properties, and anticurling properties. In particular, a gas barrier sheet is provided that, even after a heat cycle test which is performed as a durability test for organic EL displays and the like, can suppress the occurrence of curling and can maintain gas barrier properties. The gas barrier sheet comprises a gas barrier film 3 provided on a base material 2. The gas barrier film 3 is an SiNxOy film, wherein x=0.5 to 1.5 and y=0.25 to 1, has an absorption intensity of IR absorption (830 cm−1 to 840 cm−1), corresponding to an Si—N bond, per unit thickness of 0.5×10−3 / nm to 1.8×10−3 / nm and has a refractive index of 1.7 to 2.1.

Owner:DAI NIPPON PRINTING CO LTD

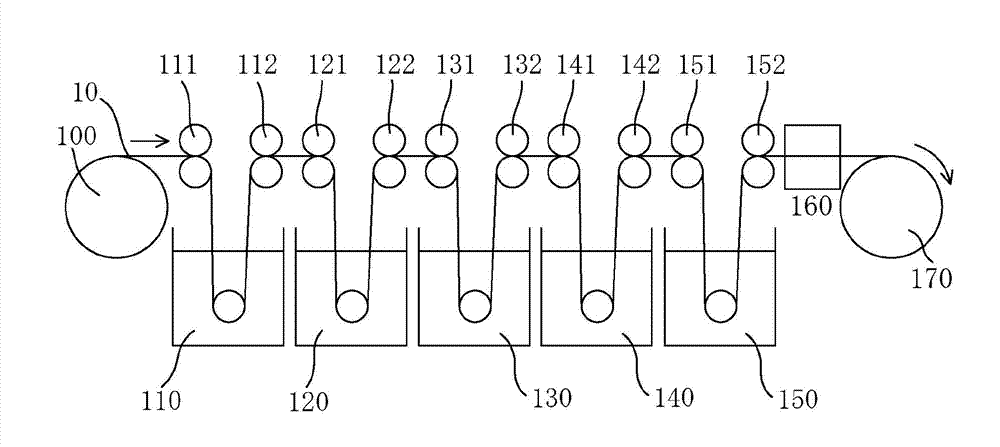

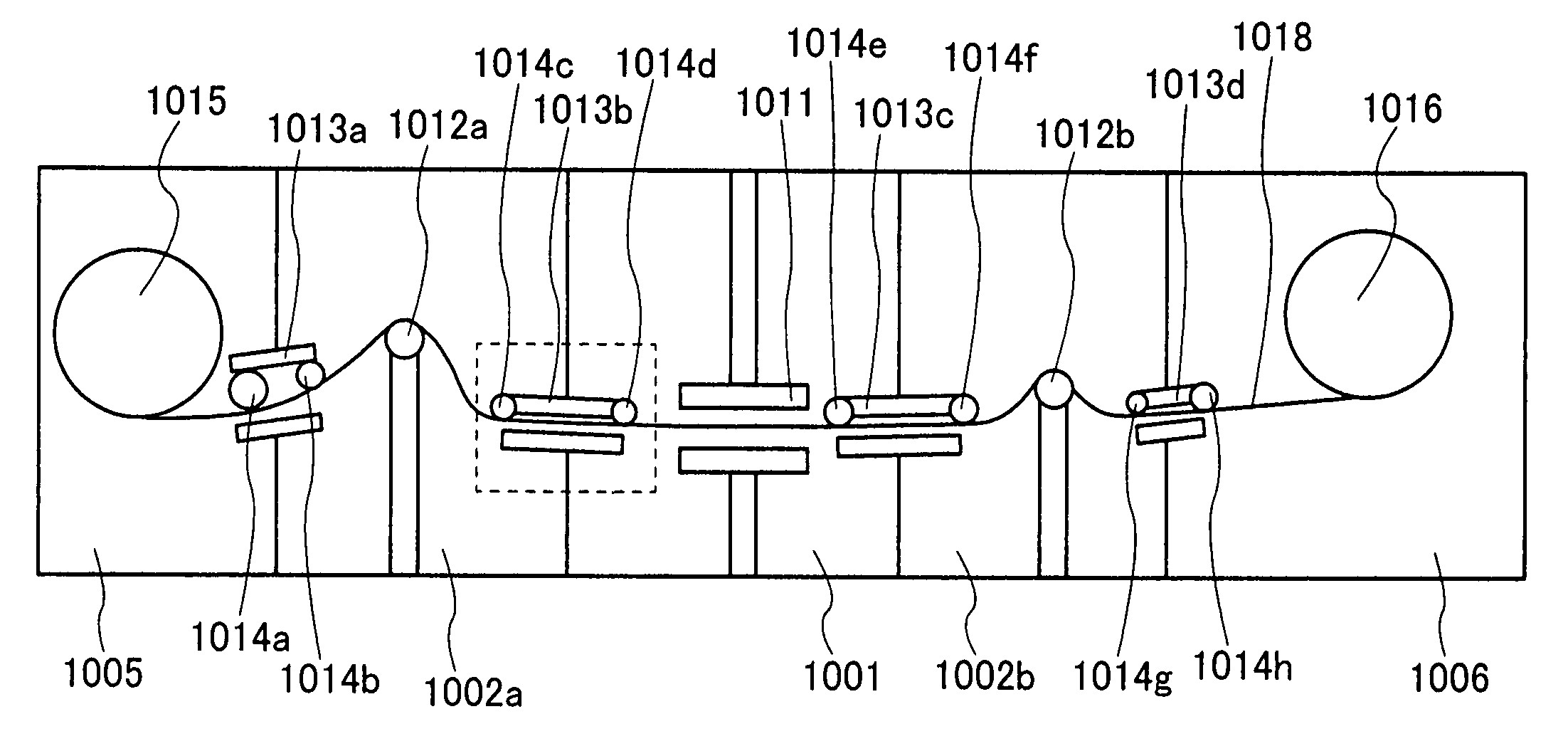

Film formation apparatus, method for forming film, and method for manufacturing photoelectric conversion device

InactiveUS7666766B2InhibitionAvoid damageFinal product manufactureSemiconductor/solid-state device manufacturingPhotoelectric conversionEngineering

The present invention relates to a film formation apparatus including a first transfer chamber having a roller for sending a substrate, a film formation chamber having a discharging electrode, a buffer chamber provided between the transfer chamber and the film formation chamber or between the film formation chambers, a slit provided in a portion where the substrate comes in and out in the buffer chamber, and a second transfer chamber having a roller for rewinding the substrate. The slit is provided with at least one touch roller, and the touch roller is in contact with a film formation surface of the substrate. In addition, the present invention also relates to a method for forming a film and a method for manufacturing a photoelectric conversion device that are performed by using such a film formation apparatus.

Owner:SEMICON ENERGY LAB CO LTD

Ink jet printing apparatus, data generation apparatus and printed product

InactiveUS20070291071A1Reduce curlingHigh-quality image printingTypewritersInkjet printingEngineering

Without newly providing a curling inhibition apparatus or a curling inhibitor and without placing excessive restrictions on a composition of an ink or a printing properties enhancing liquid, curling after printing is suppressed. In an ink jet printing apparatus which performs printing on a printing medium by ejecting from a printing head an ink and a reaction liquid which reacts with the ink, said apparatus comprising; means for on the basis of ink ejection data for ejecting the ink onto an one side of the printing medium, generating reaction liquid ejection data for ejecting the reaction liquid onto an other side of the printing medium.

Owner:CANON KK

Inkjet ink, inkjet recording method, and inkjet recording device

An inkjet ink, which contains water, an organic solvent, a surfactant, and a colorant, wherein the organic solvent contains at least one polyhydric alcohol having an equilibrium moisture content of 30% by mass or higher at a temperature of 23° C. and humidity of 80% RH, at least an amide compound represented by the general formula (I), and at least one selected from the group consisting of compounds represented by the following general formulae (II) to (IV):

Owner:RICOH KK

Transportation device and recording apparatus

ActiveUS20120037680A1Suppress failureSuppress generationArc welding apparatusOther printing apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com