Device and process for forming double-layer brick

A molding device and double-layer technology, which is applied to supply devices, ceramic molding machines, manufacturing tools, etc., can solve problems such as being unsuitable for the production and processing of double-layer bricks, unable to form a continuous operation form, and low production and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

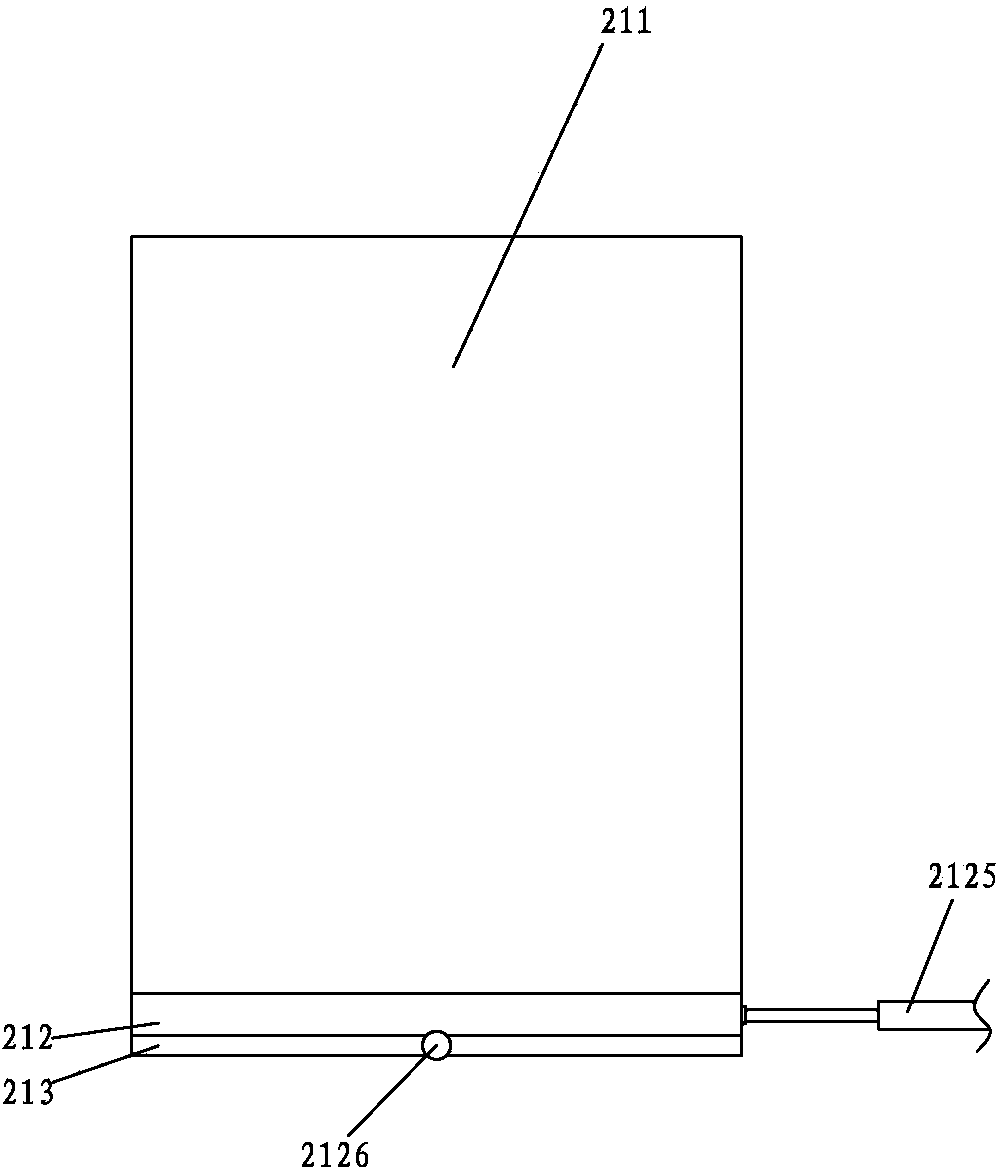

[0096] In order to specifically realize the brick surface material blanking mechanism 21 and the brick bottom material blanking mechanism 22, the preferred first embodiment is that the brick surface quantitative blanking gate 212 is equipped with a drive brick surface quantitative blanking gate 212 relative to the brick. The fabric baffle 213 and the brick fabric barrel 211 slide the first brick fabric driving device 2122, the brick fabric baffle 213 is fixedly connected with the brick fabric barrel 211, and the first brick fabric driving device 2122 can specifically be an oil cylinder.

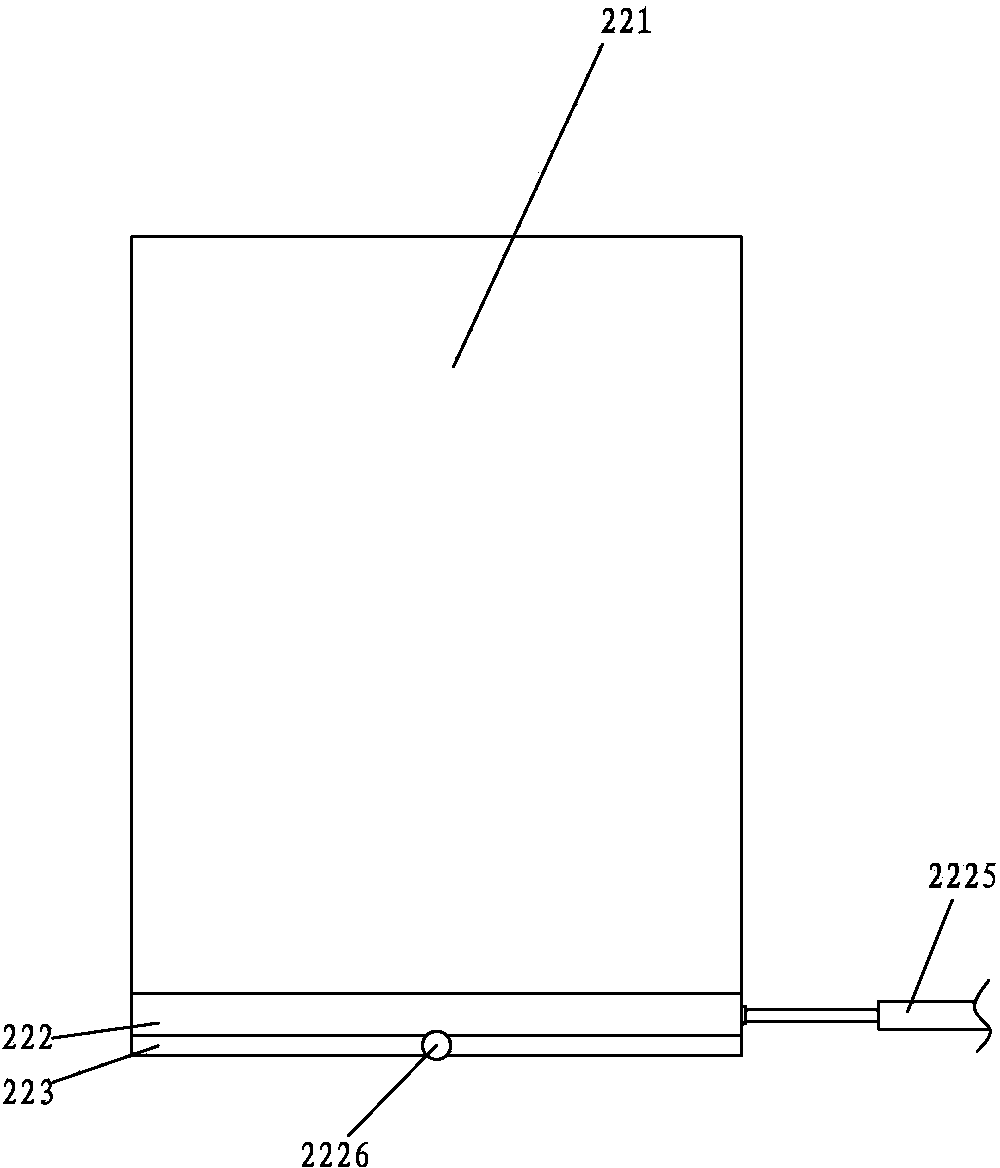

[0097] The brick bottom material quantitative blanking gate 222 is equipped with a first brick bottom material driving device 2222 that drives the brick bottom material quantitative blanking gate 222 to slide relative to the brick bottom material baffle plate 223 and the brick bottom material barrel 221. The bottom material baffle plate 223 is fixedly connected with the brick bottom material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com