Composite honeycomb sandwich board and preparation method thereof

A composite honeycomb and sandwich panel technology, which is applied in the field of composite materials, can solve the problems of non-environmental protection, easy delamination, and low bonding strength of adhesives, and achieve the effects of not easy delamination, improved bonding strength, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] At the same time, the present invention also provides a method for preparing the above-mentioned composite honeycomb sandwich panel, which includes the following steps: S1, preparing a hot-melt epoxy resin prepreg, the hot-melt epoxy resin prepreg The impregnating material comprises reinforcing material and epoxy resin composition, and described epoxy resin composition contains epoxy resin, latent curing agent, accelerator, coupling agent and optional toughening agent and optional filler; S2 . Laminating the epoxy resin prepreg on one or both sides of the aluminum honeycomb sandwich to obtain a laminated sheet, and heat-pressing the laminated sheet to obtain the composite honeycomb sandwich panel. For the requirements of "epoxy resin prepreg" and "epoxy resin composition", please refer to the previous description, and will not repeat them here.

[0038] According to the preparation method of the composite honeycomb sandwich panel of the present invention, the S1 include...

Embodiment 1

[0042] Used to illustrate the composite honeycomb sandwich panel of the present invention and its preparation method

[0043] Epoxy resin composition: 40 parts by weight of bisphenol A type epoxy resin (NPEL-128 commercially available from South Asia epoxy resin, epoxy value 0.51), novolak type epoxy resin (631 commercially available from South Asia, ring Oxygen value is 0.57) 20 weight parts, polyurethane modified epoxy resin (commercially available from the HypoxUA10 of CVC, epoxy value 0.46,) 6 parts by weight, dicyandiamide (commercially available from the 3636AS of Adidas) 5 parts by weight, 1.5 parts by weight of phenyldimethylurea (commercially available from CVC u405), aluminum hydroxide (particle size D 50 8 microns) 15 parts by weight, aluminum powder (particle size D 50 5 microns) 8 parts by weight, amino group-containing silane coupling agent N-(6-aminohexyl) aminomethyltriethoxysilane (commercially available from Gelest company's SIA0592.6) 1 part by weight, epox...

Embodiment 2-9

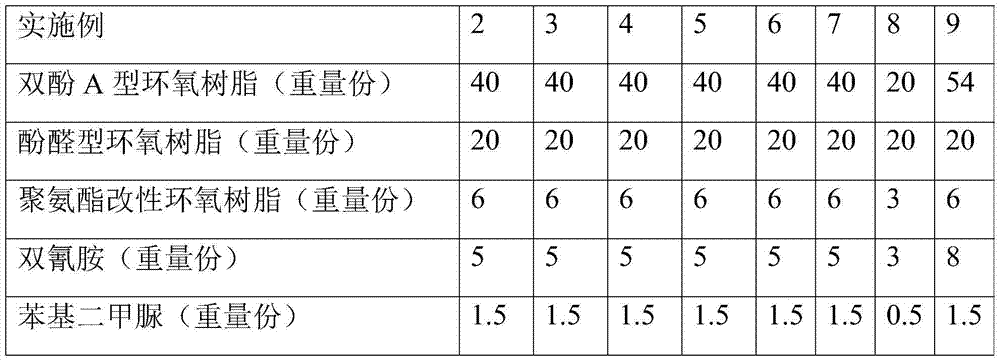

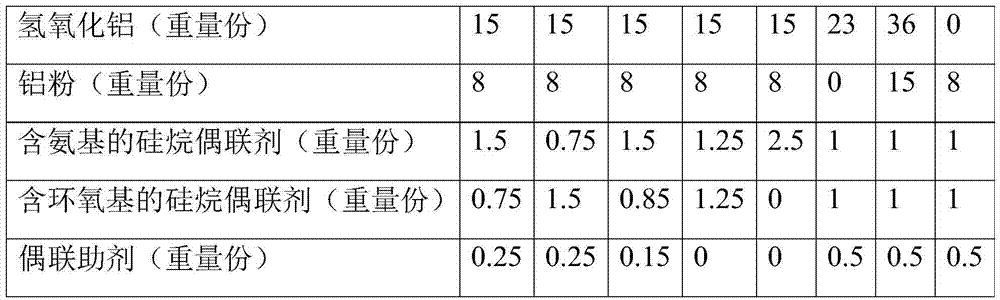

[0047] Used to illustrate the composite honeycomb sandwich panel of the present invention and its preparation method

[0048] Epoxy resin composition: with reference to the epoxy resin composition in Example 1, the difference is that the consumption of each raw material is as shown in Table 1.

[0049] Table 1.

[0050]

[0051]

[0052] Preparation of hot-melt epoxy resin prepreg: same as embodiment 1.

[0053] Preparation of the composite honeycomb sandwich panel: the same as in the examples to obtain the composite honeycomb sandwich panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com