Waterproof panel and manufacturing method thereof

A manufacturing method and board technology, applied in chemical instruments and methods, building structure, lamination, etc., can solve the problems of delamination, insufficient environmental protection, poor stability of wood-plastic floors, etc., and achieve light weight, comfortable foot feel, reduce The effect of material and shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

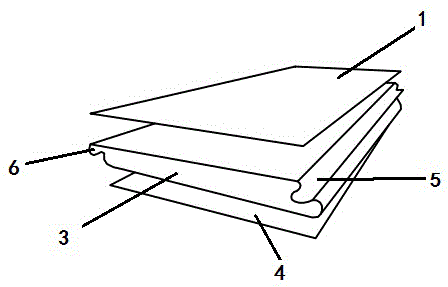

[0038] Such as figure 1 , The waterproof board of the present invention includes a wear-resistant layer 1, a waterproof layer 3, a bottom layer 4, and grooves 5 and tenons 6 arranged on both sides of the board. The waterproof layer 3 is arranged between the wear-resistant layer 1 and the bottom layer 4, the wear-resistant layer 1 is adhered to the waterproof layer 3 by bonding methods such as hot melt adhesive, and the waterproof layer 3 passes through Adhesive means such as hot melt adhesive is adhered on the bottom layer 4 . The decorative layer 2 can be tile veneer or stone laminate or rubber or decorative plastic or linoleum or decorative vinyl, which is not only a beautiful board but also waterproof. The bottom layer 4 can be selected from cork or rubber. The molding structure of the groove 5 and the tenon 6 can cooperate to form a fastening connection of a plurality of adjacent plates. The clamping method is mechanically clamped in the form of a lock or chemically cla...

Embodiment 2

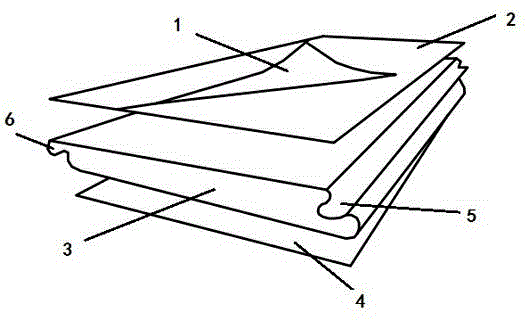

[0056] Such as figure 2 , the present invention includes a wear-resistant layer 1, a decorative layer 2, a waterproof layer 3, a bottom layer 4, and grooves 5 and tenons 6 arranged on both sides of the board. The decoration layer 2 is arranged between the wear-resistant layer 1 and the waterproof layer 3, and the bottom layer 4 is arranged below the waterproof layer. The wear-resistant layer 1 and the decorative layer 2 are heat-pressed together, and then adhered to the waterproof layer 3 by bonding means such as hot-melt adhesive. The wear-resistant layer 1, the decorative layer 2 and the The waterproof layer 3 is bonded into one body and then adhered to the bottom layer 4 by means of bonding such as hot melt adhesive. The decorative layer 2 can be tile veneer or stone laminate or rubber or decorative plastic or linoleum or decorative vinyl, which is not only a beautiful board but also waterproof. The bottom layer 4 can be selected from cork or rubber. The molding structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com