Vertical carbon fiber template and production method thereof

A production method and carbon fiber technology, applied in the field of vertical carbon fiber formwork and production, can solve the problems of low turnover times, easy expansion, and low strength, and achieve the effect of high reuse rate, small expansion coefficient, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

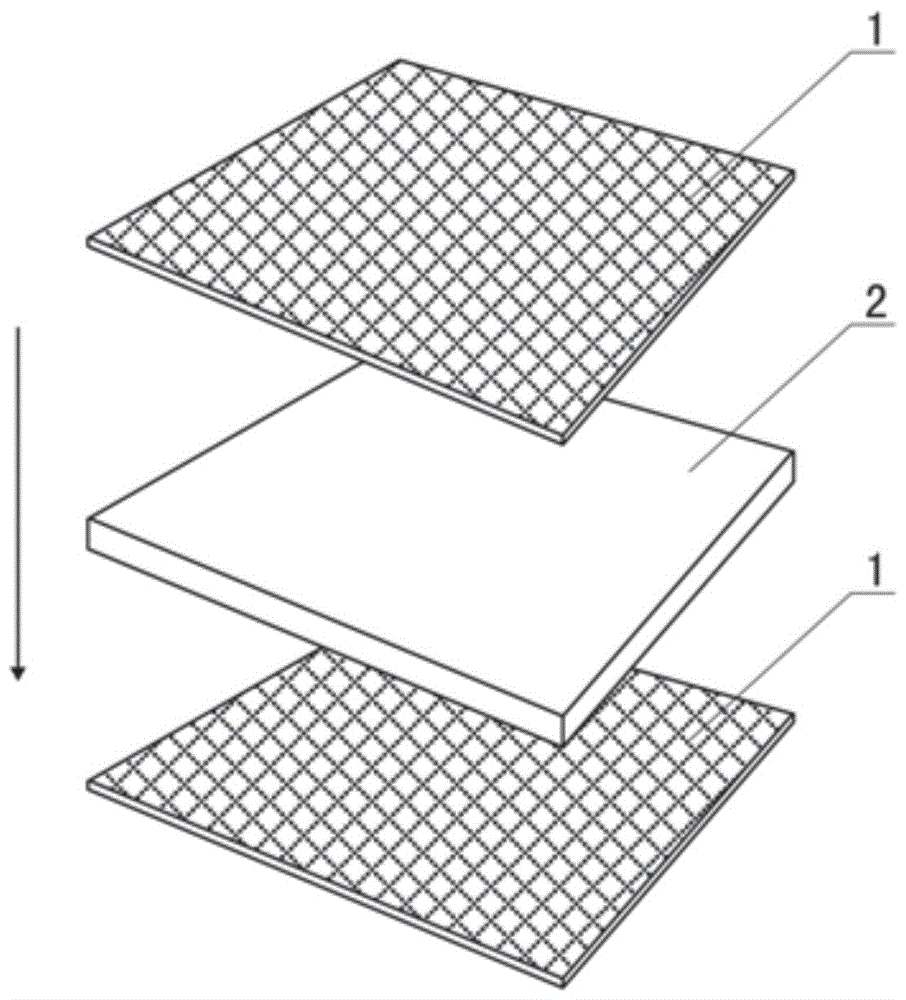

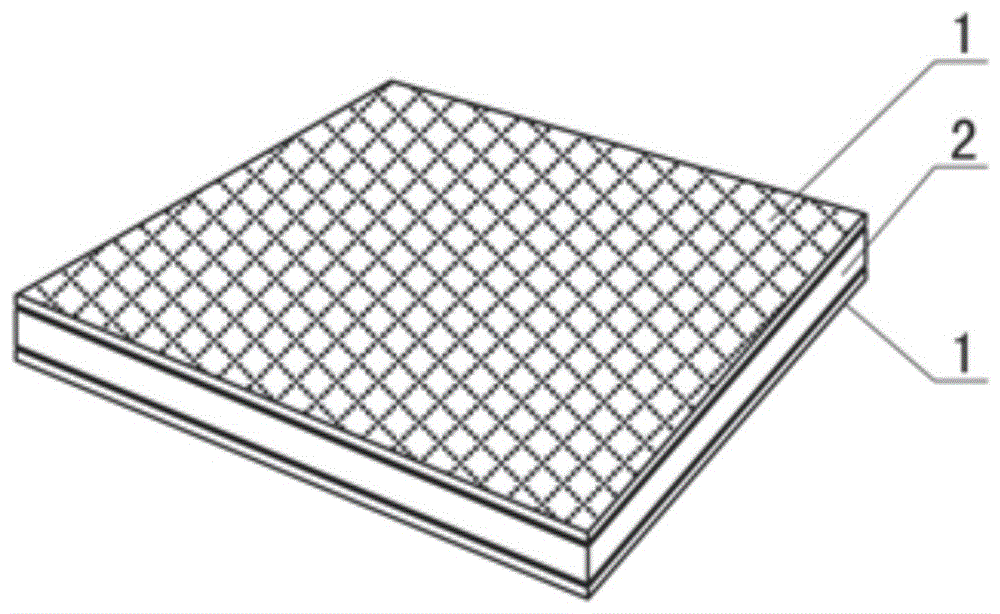

[0042] Such as figure 1 and figure 2 As shown, the vertical carbon fiber template of the present invention includes a carbon fiber composite skin 1 and a core plate 2, the carbon fiber composite skin 1 is made of carbon fiber cloth, spunlace non-woven fabric, random copolymerized polypropylene and a binder, and the core plate 2 is formed by splicing and solidifying a plurality of wooden strips, and two carbon fiber composite skins 1 are pasted and connected to the large planes on both sides of the core board 2 respectively.

[0043] combine figure 1 and figure 2 , the production method of vertical carbon fiber template of the present invention, comprises the following steps:

[0044] (1) Processing core board: including the following steps:

[0045] (1.1) Recycling and treatment of waste building formwork: recycle waste building formwork that is free from mildew, rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com