Aluminum alloy corrosion-resistant surface treatment method

A surface treatment, anti-corrosion technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of poor interface adhesion, poor corrosion resistance, easy delamination, etc., to achieve good interface adhesion, interface The effect of the bonding force is not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

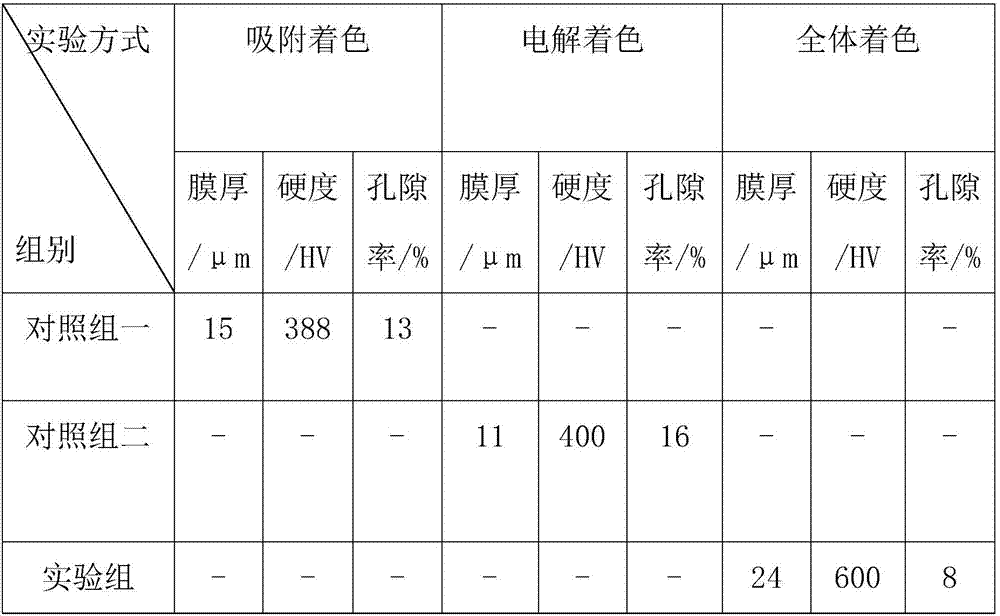

Embodiment 1

[0013] A method for treating an anti-corrosion surface of an aluminum alloy, comprising the following steps:

[0014] 1) Degreasing and alkali etching treatment, the specific steps are: A. Take the concentrated sodium hydroxide solution and hot water at a temperature of 40°C in a ratio of 1:5 and add them to the blender for mixing, and pass through the blender at a rate of 35r / pm Stir at a rotating speed evenly to prepare a hot alkaline solution with a concentration of 18% for later use; B. Pour the hot alkaline solution prepared in the specific step A into the cleaning tank, then put the aluminum alloy plate into the cleaning tank, and use a brush to clean the aluminum alloy. The surface of the alloy plate is scrubbed and degreased, the grease on the surface of the aluminum alloy plate is cleaned, and it is set aside; D. Take ionized water to carry out alkaline cleaning of the residual alkaline solution on the surface of the aluminum alloy plate, and then use the ionized water...

Embodiment 2

[0021] A method for treating an anti-corrosion surface of an aluminum alloy, comprising the following steps:

[0022] 1) Degreasing and alkali etching treatment, the specific steps are: A. Take the concentrated sodium hydroxide solution and hot water at a temperature of 60°C in a ratio of 1:5 and add them to the mixer for mixing, and pass them through the mixer at a rate of 35r / pm Stir at a rotating speed evenly to prepare a hot alkaline solution with a concentration of 20% for later use; B. Pour the hot alkaline solution prepared in the specific step A into the cleaning tank, then put the aluminum alloy plate into the cleaning tank, and use a brush to clean the aluminum The surface of the alloy plate is scrubbed and degreased, the grease on the surface of the aluminum alloy plate is cleaned, and it is set aside; D. Take ionized water to carry out alkaline cleaning of the residual alkaline solution on the surface of the aluminum alloy plate, and then use the ionized water to al...

Embodiment 3

[0029] A method for treating an anti-corrosion surface of an aluminum alloy, comprising the following steps:

[0030] 1) Degreasing and alkali etching treatment, the specific steps are: A. Take the concentrated sodium hydroxide solution and hot water at a temperature of 50°C in a ratio of 1:5 and add them to the blender for mixing, and pass through the blender at a rate of 35r / pm Stir at a rotating speed evenly to prepare a hot alkaline solution with a concentration of 19% for subsequent use; B. Pour the hot alkaline solution prepared in the specific step A into the cleaning tank, then put the aluminum alloy plate into the cleaning tank, and use a brush to clean the aluminum alloy. The surface of the alloy plate is scrubbed and degreased, the grease on the surface of the aluminum alloy plate is cleaned, and it is set aside; D. Take ionized water to carry out alkaline cleaning of the residual alkaline solution on the surface of the aluminum alloy plate, and obtain Clean aluminu...

PUM

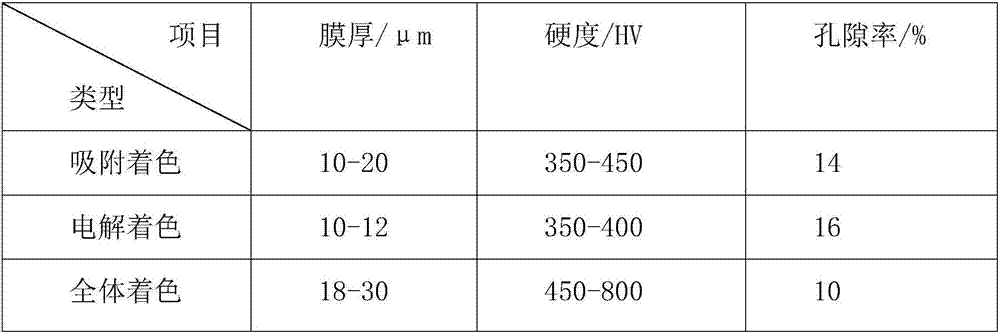

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com