Deck clip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

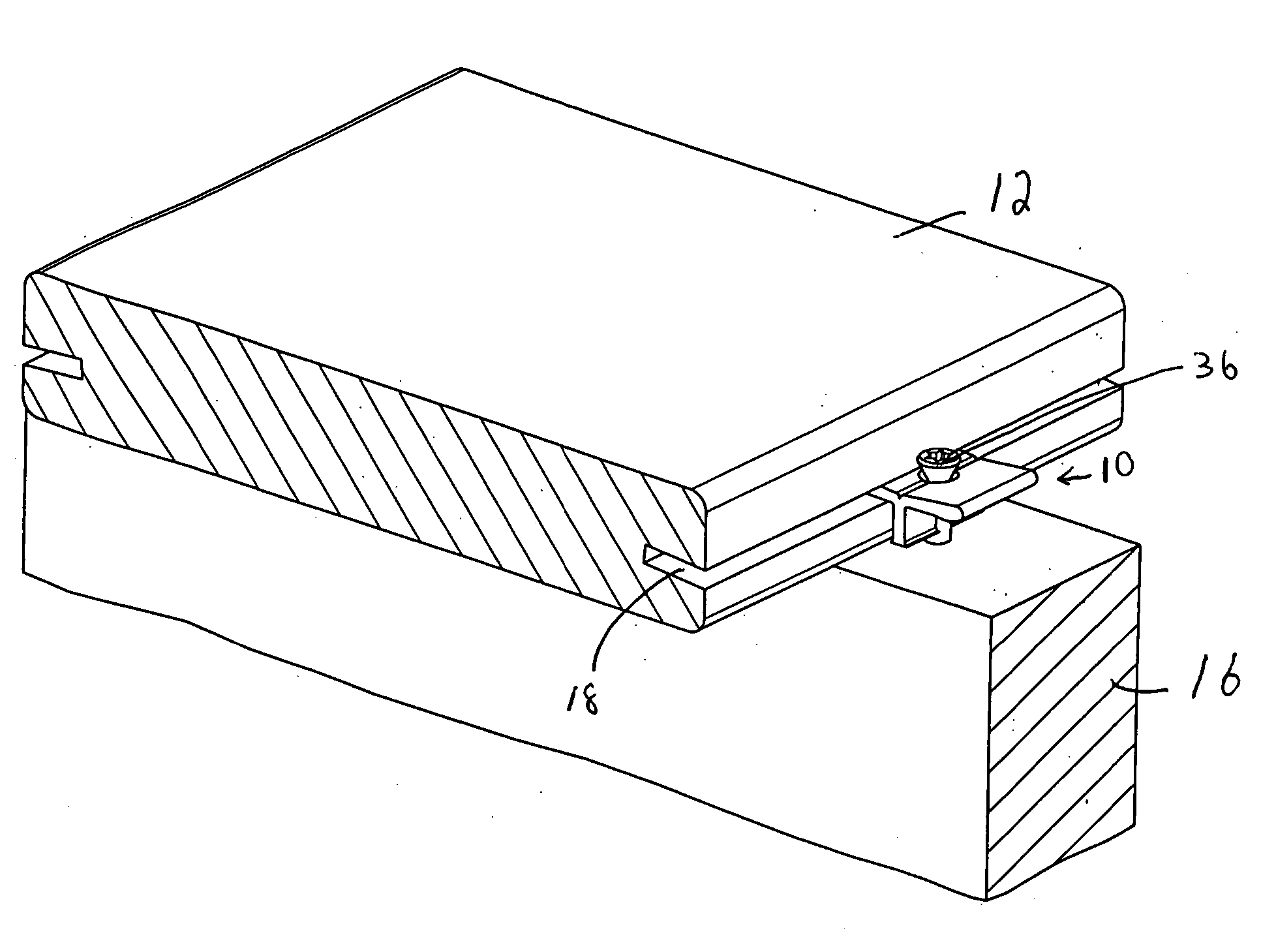

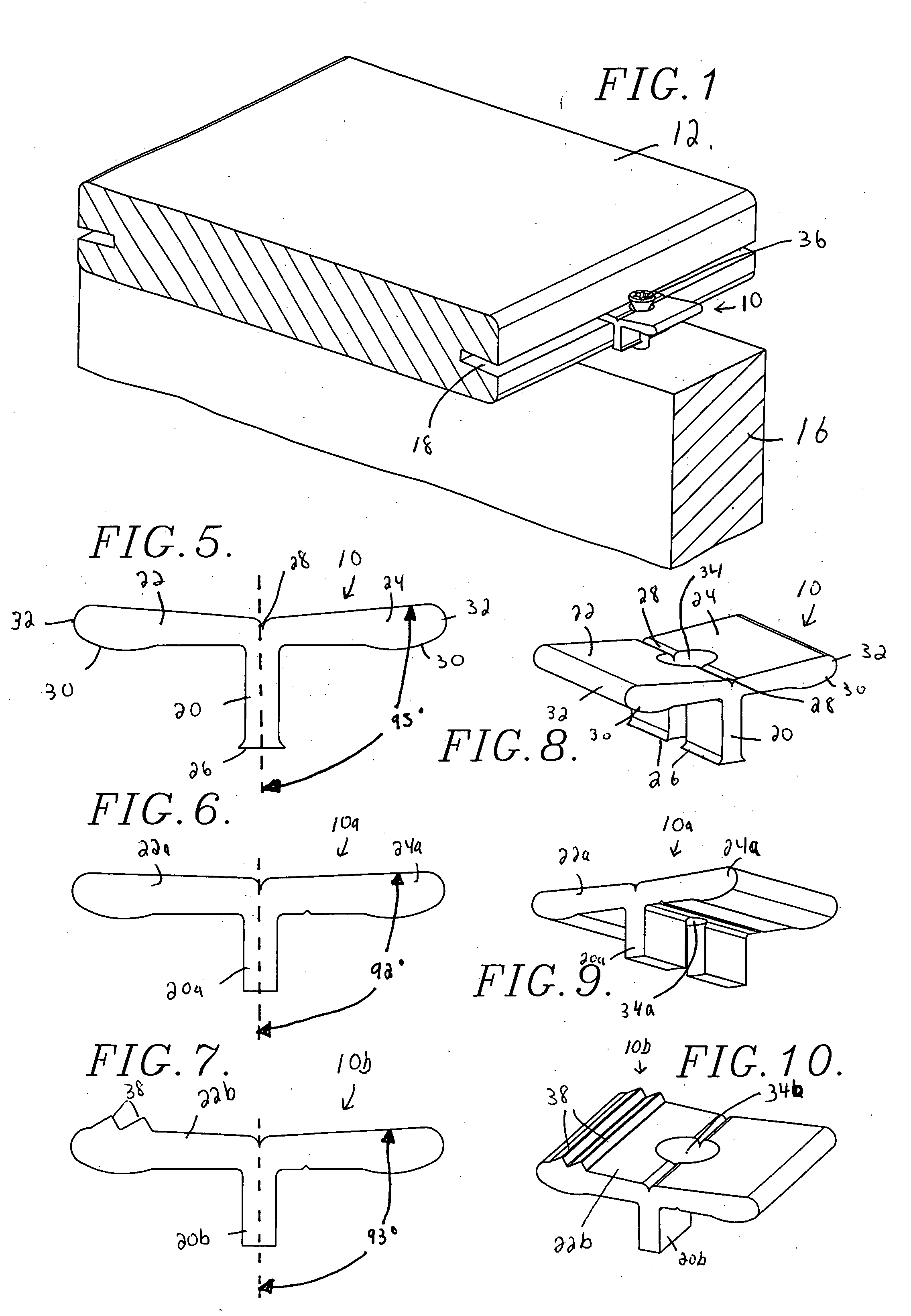

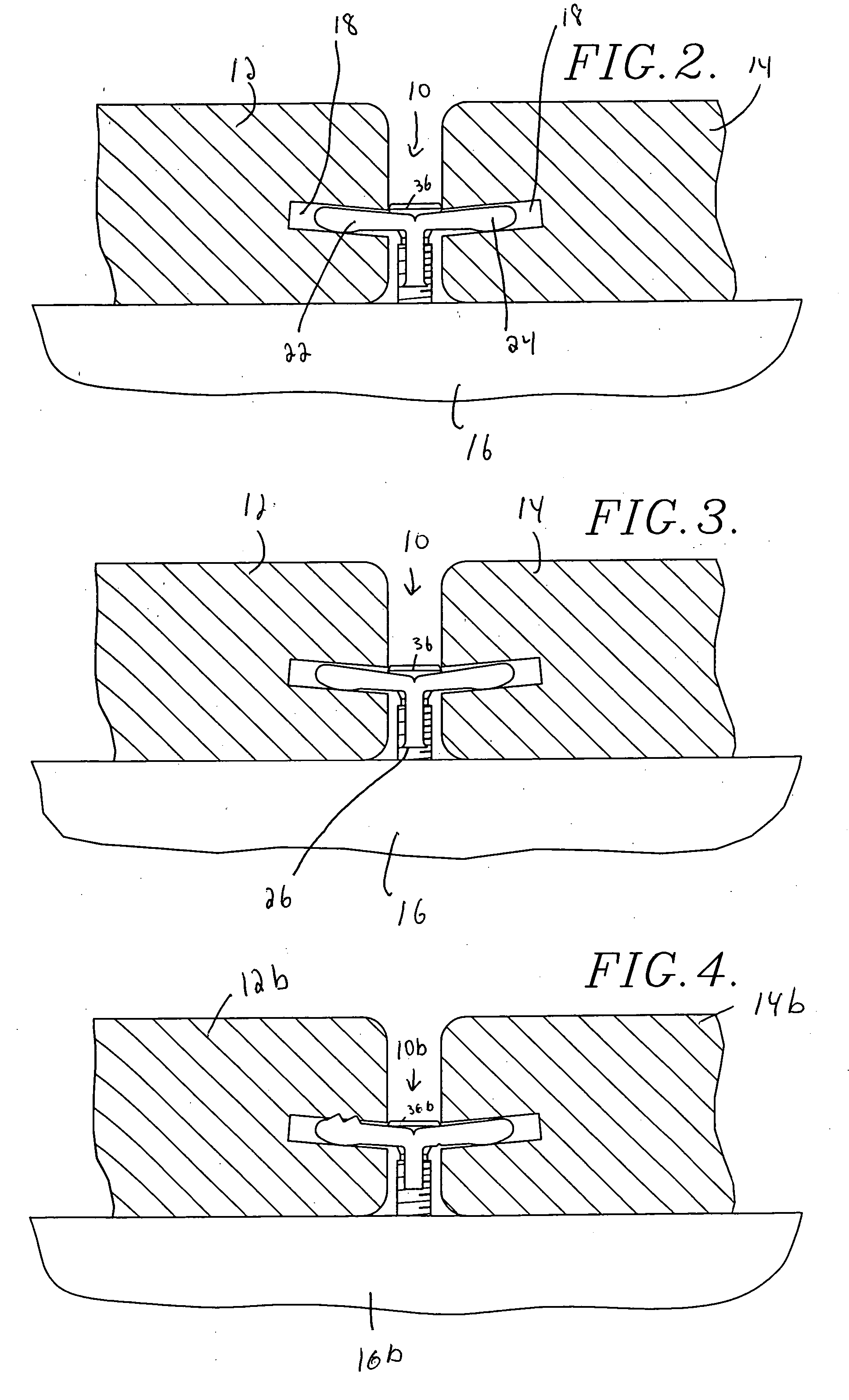

[0027] Turning now to the drawing figures, and particularly FIGS. 1, 2, 3, 5 and 8, a deck clip 10 constructed in accordance with a first preferred embodiment of the invention is shown securing deck boards 12,14 to an underlying support 16. The deck boards 12,14 are conventional and are preferably formed of a hard wood material such as cumaru, ipe, or tauari; however, they may be formed of other types of wood, composite materials, synthetic resins, or any other materials commonly used for decking.

[0028] As shown, each deck board 12,14 has at least one elongated, pre-grooved or biscuitjointer slot 18 formed therein. The slots 18 are preferably formed between 3 / 8″-5 / 16″ from the bottom of the boards, the exact positioning depending on the thickness of the boards. The slots 18 are preferably approximately ⅛″ to ¼″ tall (from top to bottom) and approximately ½″ deep (from left to right). As best illustrated in FIGS. 2-4, the slots 18 are preferably slightly angled relative to horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com