Semiconductor chip set

A semiconductor and chip set technology, applied in the field of semiconductor chip sets and their manufacturing, and high-power semiconductor components, can solve the problems of limited routing capability, excessive volume, and limited heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

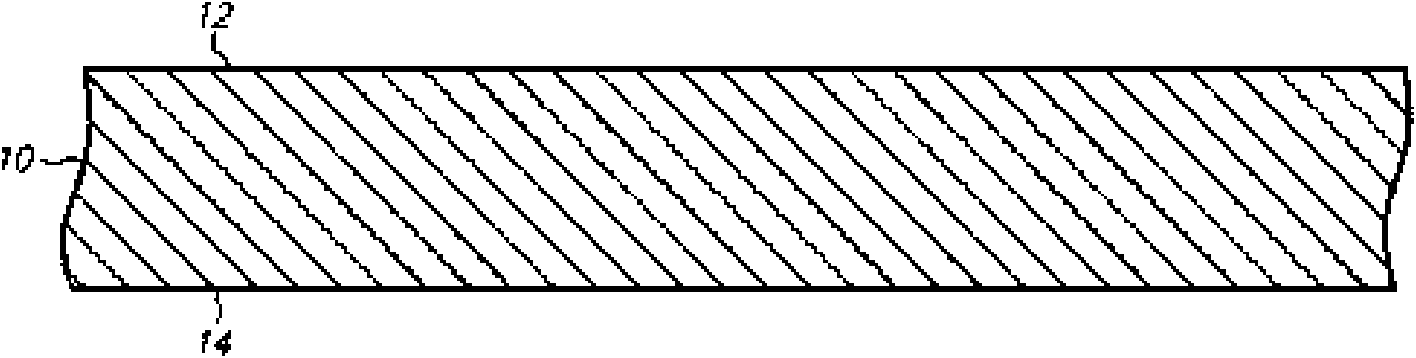

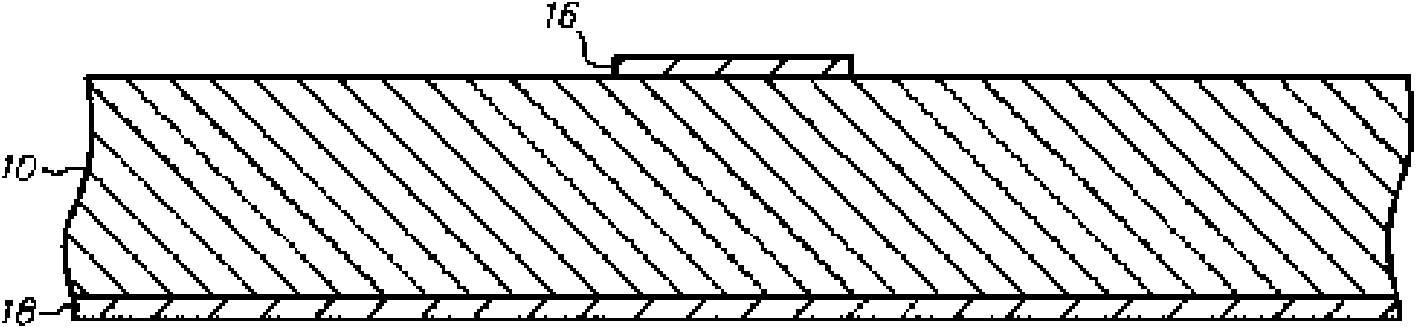

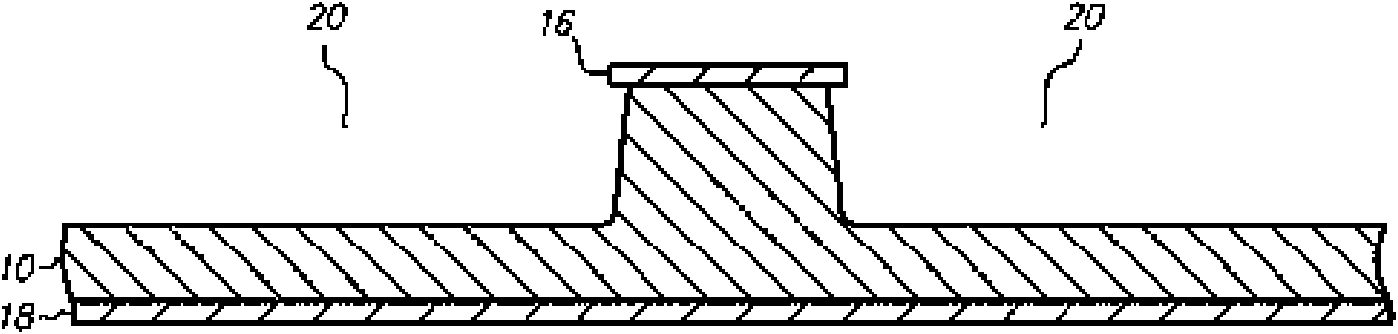

[0110] The invention is a semiconductor chip assembly body, which at least includes a semiconductor component, a heat dissipation seat, a substrate and an adhesive layer. The semiconductor component is electrically connected to the substrate and thermally connected to the heat dissipation seat, and the heat dissipation seat at least includes a protrusion and a base. wherein the protrusion extends upward through an opening of the adhesive layer and enters a through hole of the substrate, the base extends laterally from the protrusion, and the adhesive layer extends between the protrusion and the substrate and between the base and the substrate. The substrate at least includes first and second conductive layers and a dielectric layer therebetween. Thereby, the substrate can provide a pad and a terminal on the first conductive layer by using a routing line on the second conductive layer and the first and second conductive holes passing through the dielectric layer between the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com