Molding preparation method of fuel cell bipolar plate

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of long production cycle, uneven particle size and irregular shape of expanded graphite, achieve short molding time and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

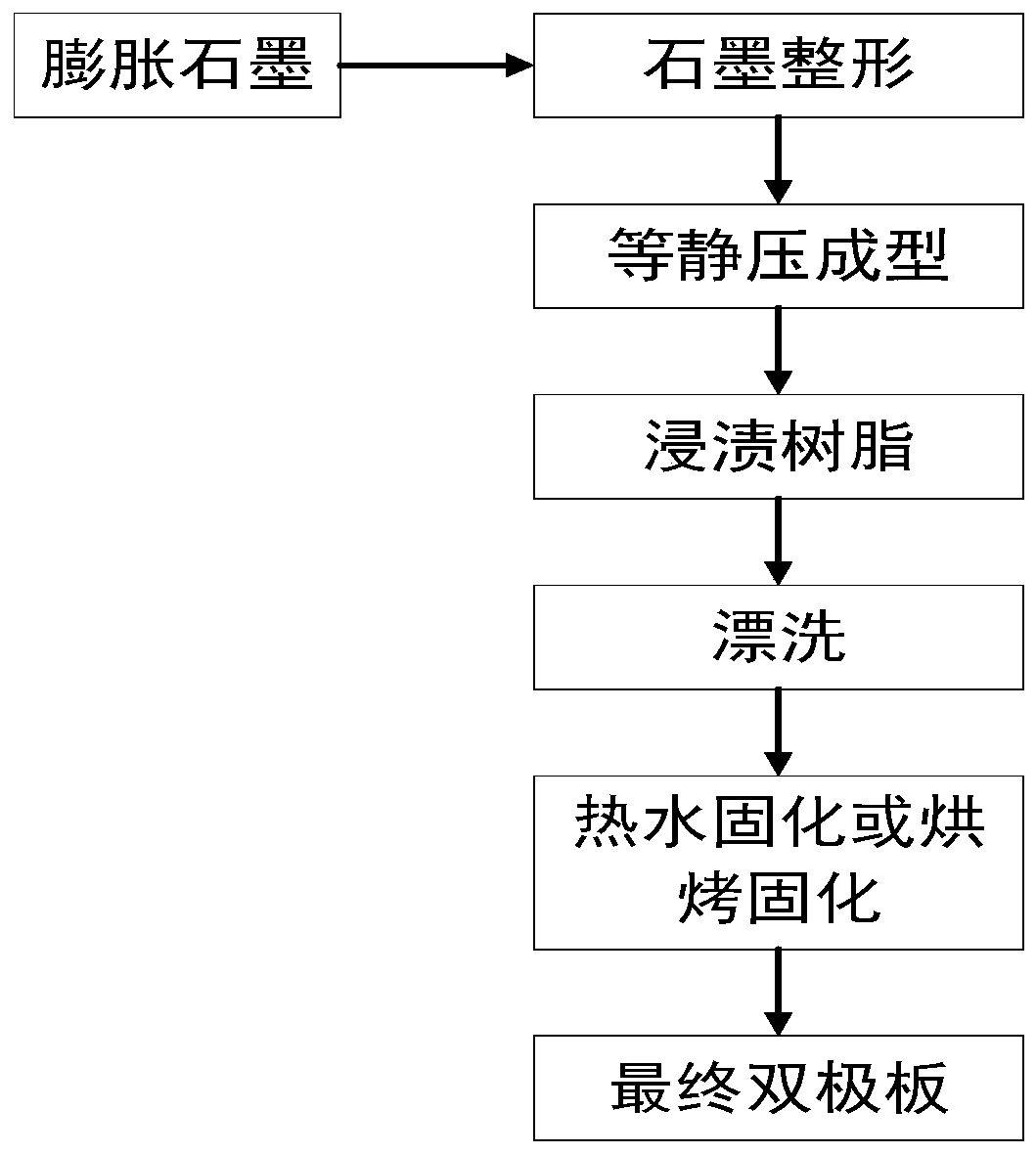

Image

Examples

Embodiment 1

[0029] 1) Take 2000g of expanded graphite, and use a graphite shaping machine to carry out shaping treatment on it. The shaping time is 10 minutes. After shaping, the long diameter of the expanded graphite is reduced by about 40%;

[0030] 2) Take 150g of shaped expanded graphite and place it in the mold of the isostatic pressing equipment. Under the pressure of 200MPa and normal temperature, the pressing process is completed within 2 minutes to obtain a 0.9mm thick bipolar plate with a flow field;

[0031] 3) Take out the pressed bipolar plate and place it in the dipping device, then vacuumize the dipping device, and then inject a certain amount of polyimide resin into it, and the resin completely immerses the bipolar plate, Under these conditions, soak the glue for 12h. During this process, vacuuming is repeated 2-3 times to ensure that the vacuum degree of the dipping process is less than 1 atmosphere.

[0032] 4) Take out the dipped bipolar plate, and then rinse it with a...

Embodiment 2

[0035]1) Take 1000g of expanded graphite, and use a graphite shaping machine to shape it. The shaping time is 5 minutes. After shaping, the long diameter of the expanded graphite is reduced by about 40%.

[0036] 2) Take 100g of reshaped expanded graphite and place it in the mold of the isostatic pressing equipment. Under the pressure of 100MPa and normal temperature, within 1min, the pressing process is completed to obtain a 0.6mm thick bipolar plate with a flow field.

[0037] 3) Take out the pressed bipolar plate and place it in the dipping device. Then, the dipping device is evacuated, and then a certain amount of acrylic resin is injected into it. The resin completely immerses the bipolar plate. Under this condition Next, dipping for 8h. During this process, vacuuming is repeated 2-3 times to ensure that the vacuum degree of the dipping process is less than 1 atmosphere.

[0038] 4) Take out the dipped bipolar plate, and then rinse it with deionized water.

[0039] 5) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com