Simple creep test device of rocks and test method thereof

A creep test and rock technology, applied in the field of simple rock creep test device, can solve the problems of complex test device system, high cost and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

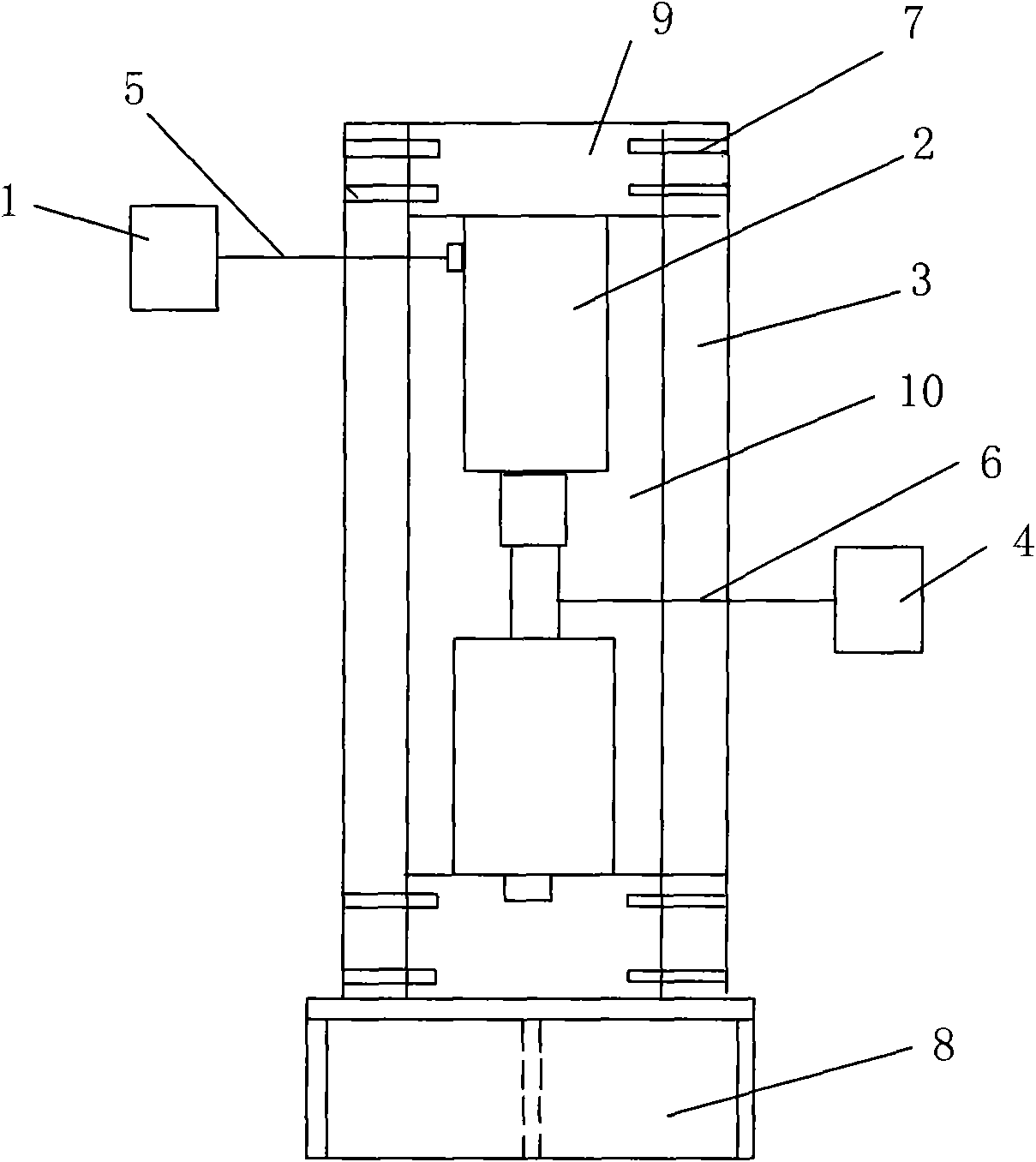

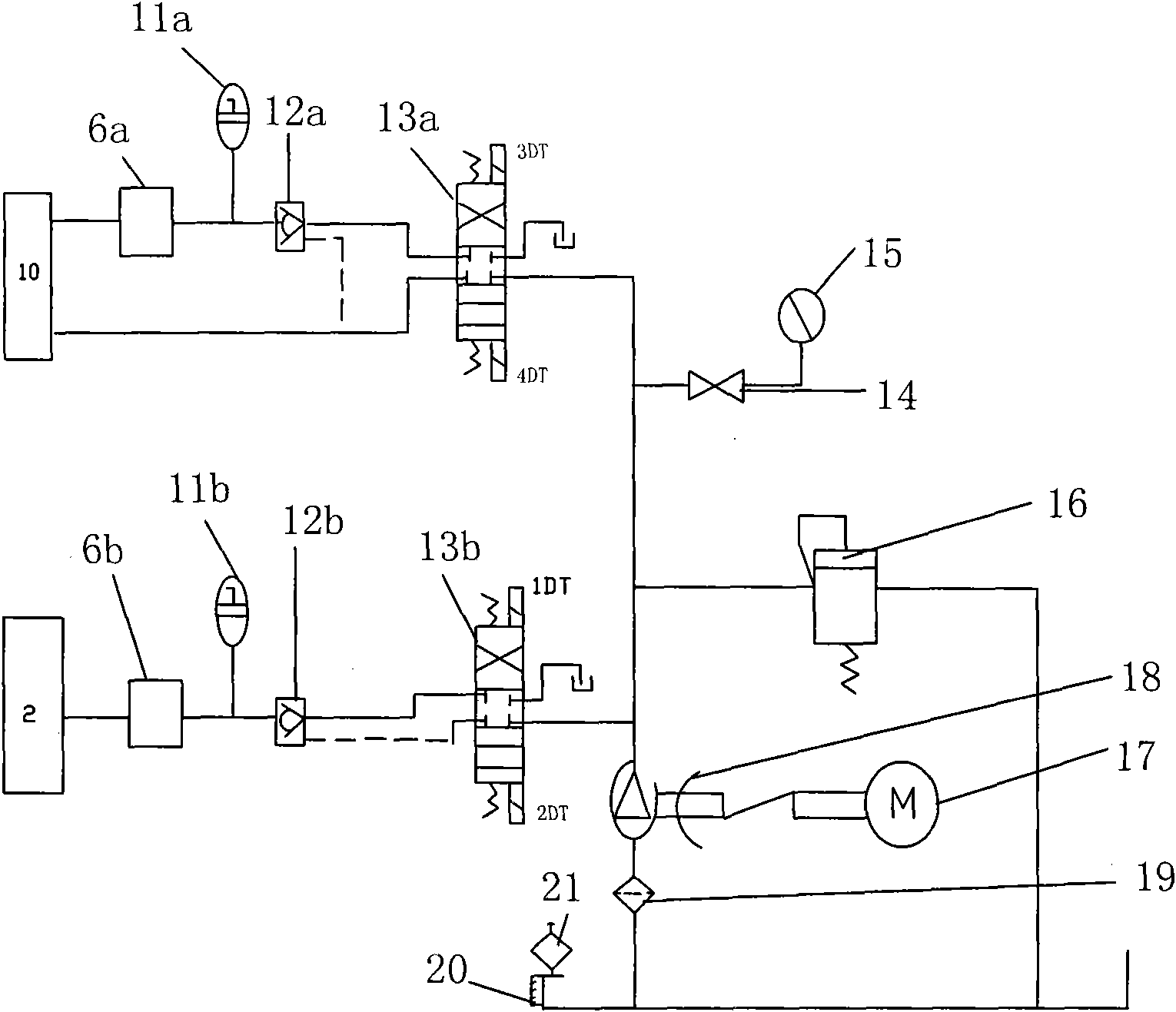

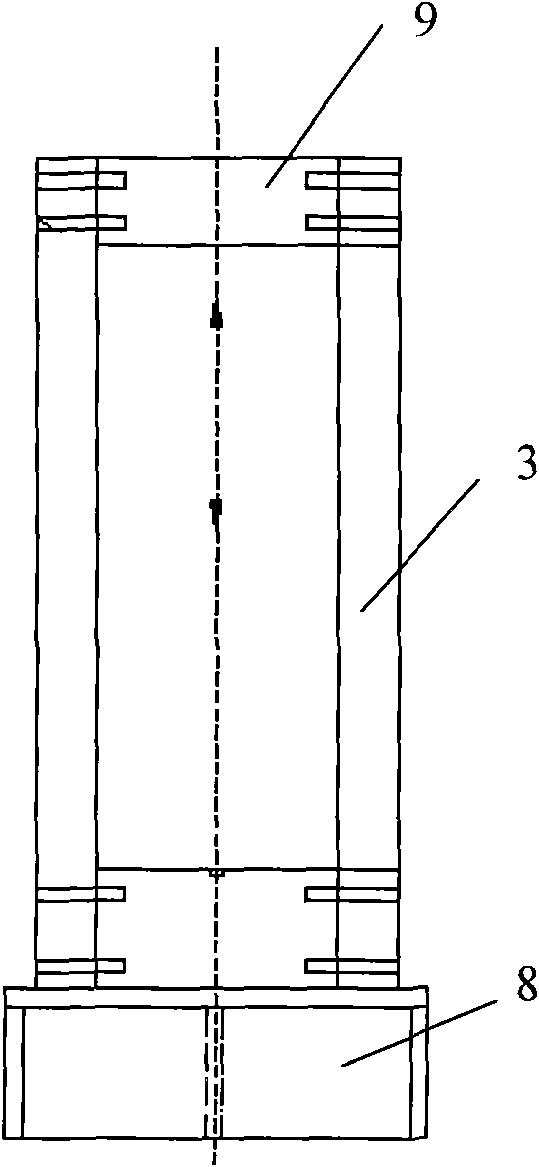

[0011] Depend on Figure 1-5 As shown, the present invention includes a test platform reaction frame, a test piece axial pressure actuation system and a test piece confining pressure actuation system. The test platform reaction force frame is composed of a base 8 and a counter pressure support 3 on the base. The counter pressure support 3. The top beam 9 is installed on the upper part, and the top beam 9 is fixed together with the counter pressure pillar 3 (for the convenience of maintenance, the rivet 7 can be used for fixed connection). The actuating system 2 is connected to the external hydraulic control system 1 through the oil pipeline 5, and a pressure sensor 6 is installed at the lower part of the axial pressure actuating system 2 of the specimen. There is a test piece confining pressure actuation system 10 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com