Workpiece stamping intelligent control process and intelligent control manipulator

An intelligent control and manipulator technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of hand crush, disability and insecurity, and achieve the effect of enhancing stability, convenient operation and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

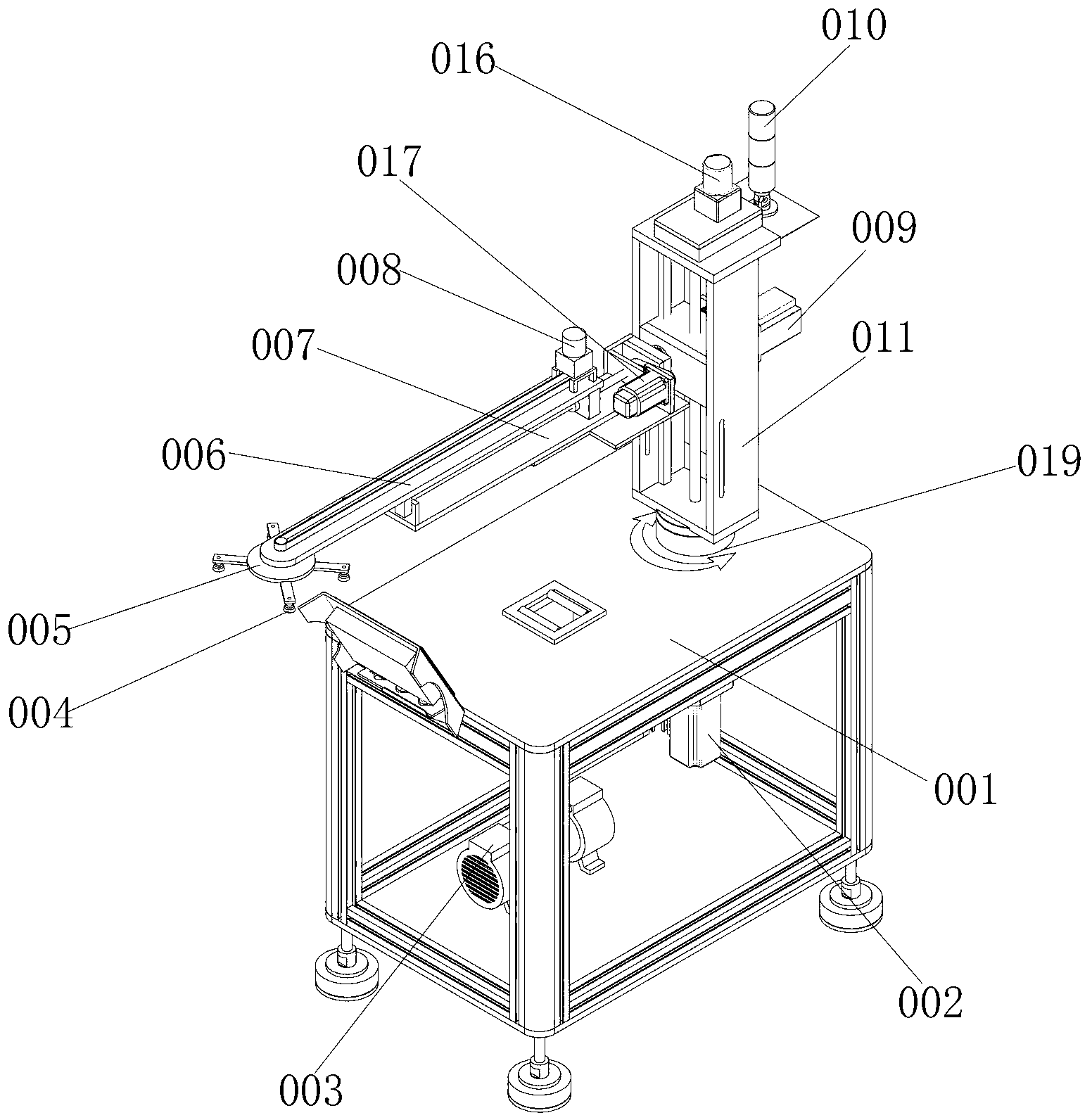

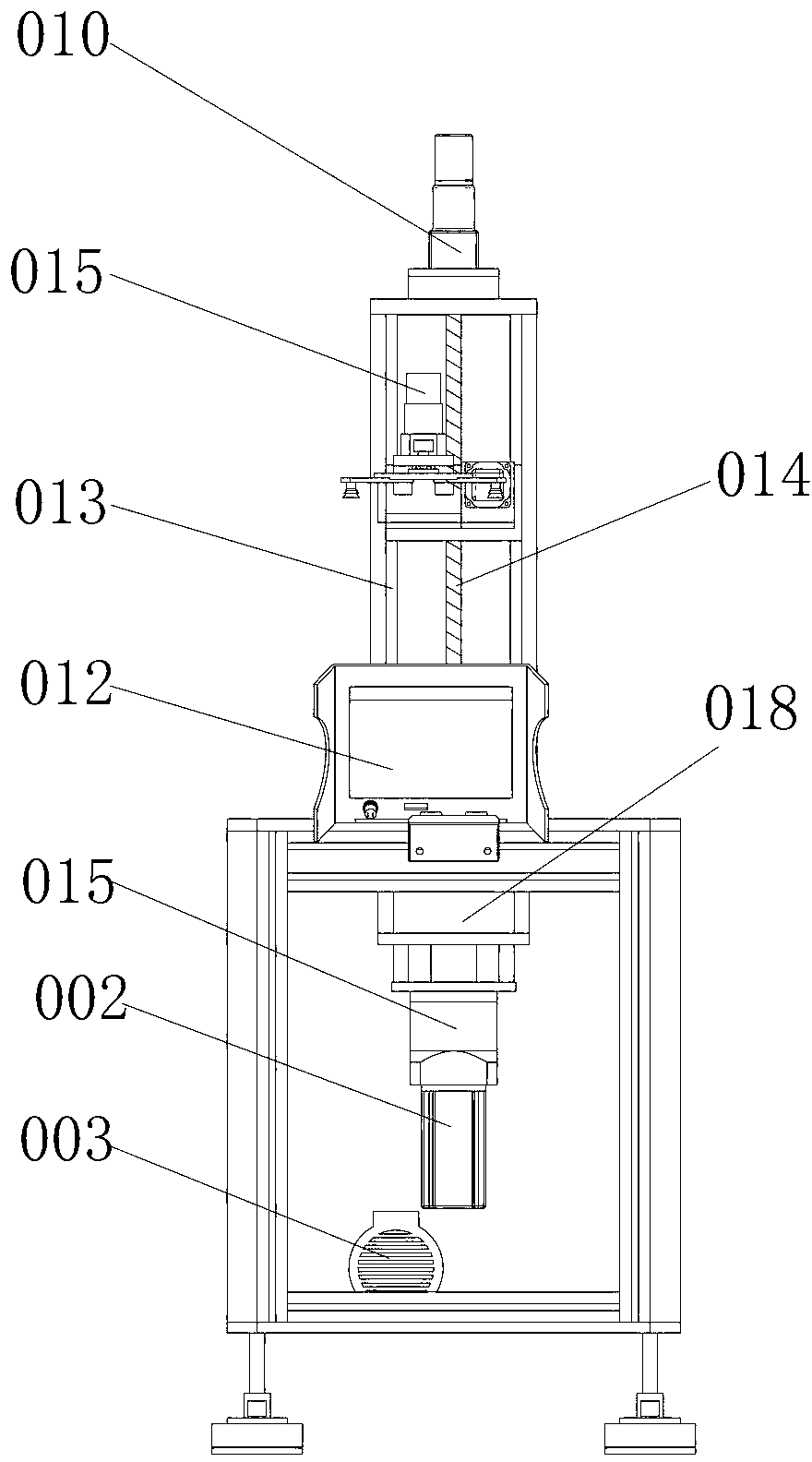

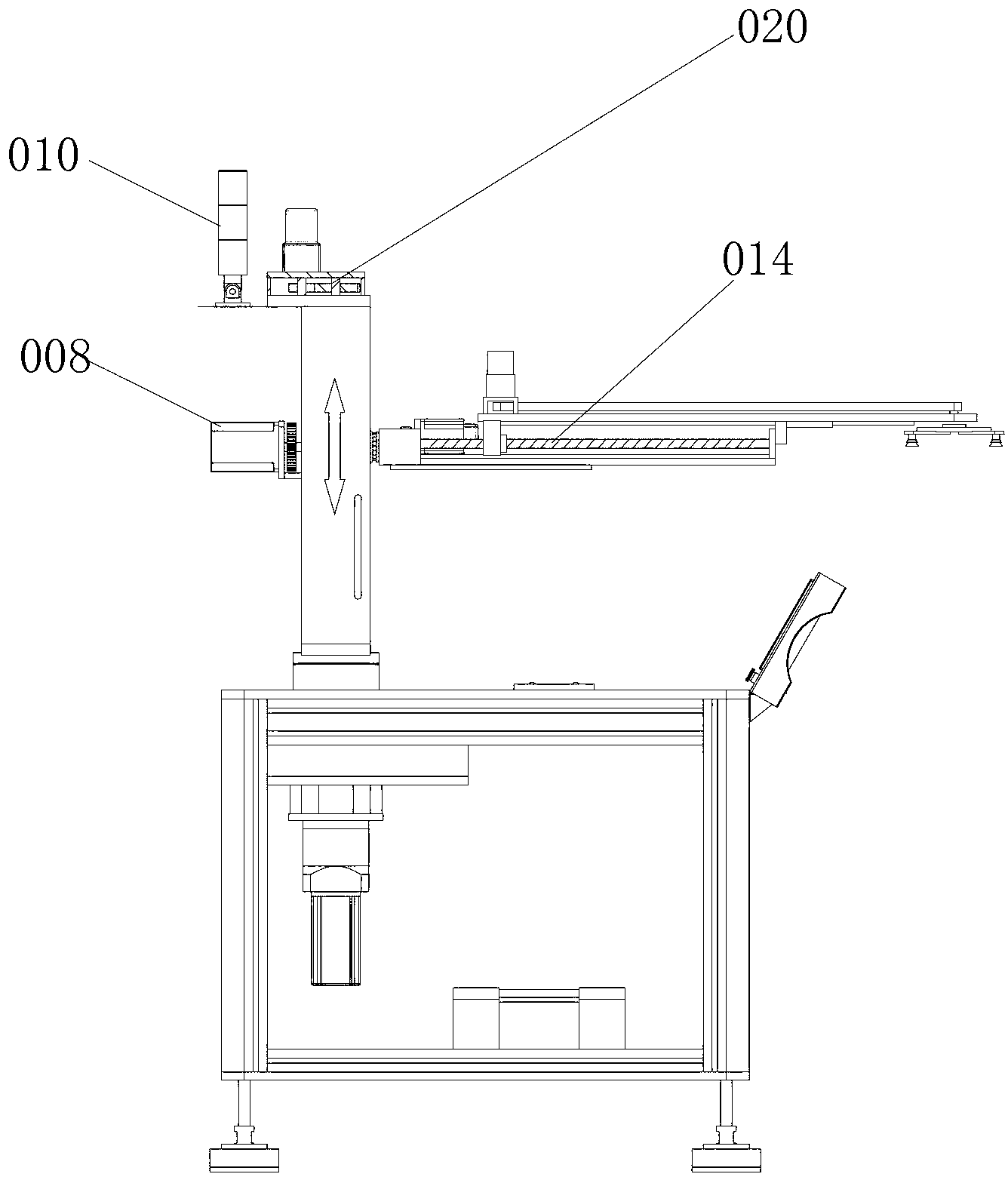

[0034] Such as figure 1 , 2 and image 3 As shown, the workpiece stamping intelligent control process provided in this embodiment includes the following steps:

[0035] (1) Set up an intelligent control manipulator, which is composed of a control device 012, an executive mechanism and a driving device; The interface control device 012 and the control system consist of a thrust bearing 019 for increasing stability at the connection and fixation of the supporting machine platform and the arm column 011.

[0036] (2) The actuator is composed of an arm column 011, a mechanical arm and a correction plate 005 arranged on the arm column 011; the correction plate 005 is arranged at the front end of the mechanical arm, and the correction plate 005 is provided Multiple sets of suction cups 004, a vacuum pump 003 is provided in the control machine 001, the vacuum pump 003 is connected to the suction cup 004 and completes the vacuum conversion of the suction cup 004, and the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com