Embedded surface ornament and its making process

A decorative product and manufacturing process technology, applied in the field of inlaid surface material decorative products and its manufacturing process, can solve the problems of lack of flexibility in living room space, inability to adapt to high-grade consumer demand, and inability to better reflect indoor effects, etc., to achieve Flexibly embodies and shapes indoor effects, combined with solid bonding, and various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings.

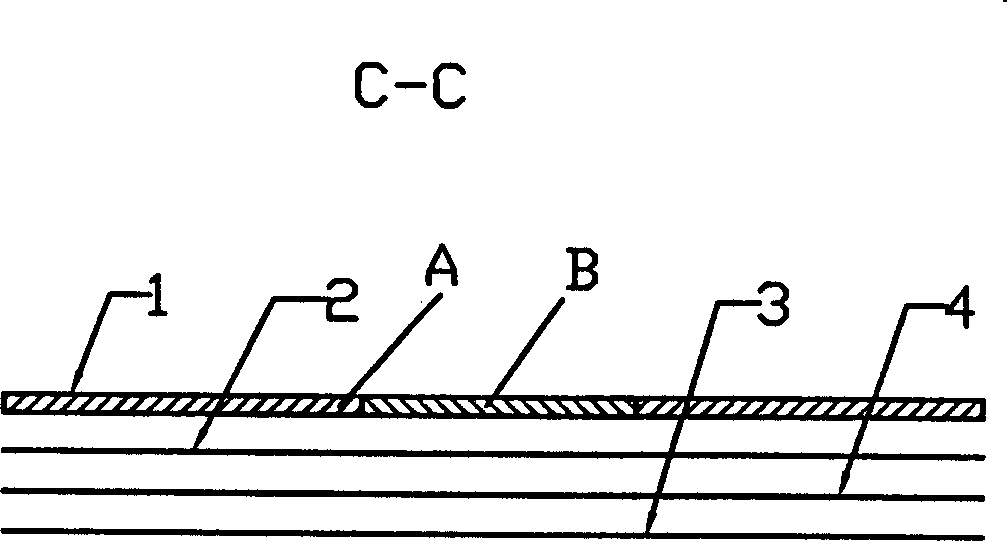

[0015] The inlaid face material decorative product and the manufacturing process thereof of the present invention include a substrate, which is characterized in that: the surface decorative layer 1 on the substrate is composed of a decorative surface material A with a hollow pattern and another decorative surface material inlaid in the hollow pattern. Composition of a decorative surface material B.

[0016] The substrate of the present invention can be a fireproof board or a composite board.

[0017] The substrate of the present invention is composed of a base cloth 3, a plastic film 4 and a long fiber paper 2 which are sequentially stacked from bottom to top. The base fabric is non-woven fabric or fireproof paper.

[0018] The manufacturing process of the present invention is realized as follows:

[0019] (1) Selected or prefabricated substrate;

[0020] (2) Prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com