Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176 results about "Decorative product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carefully check the label of any decorative product you’re considering for use in foods. Companies that make edible glitters and dusts are required by law to include a list of ingredients on the ...

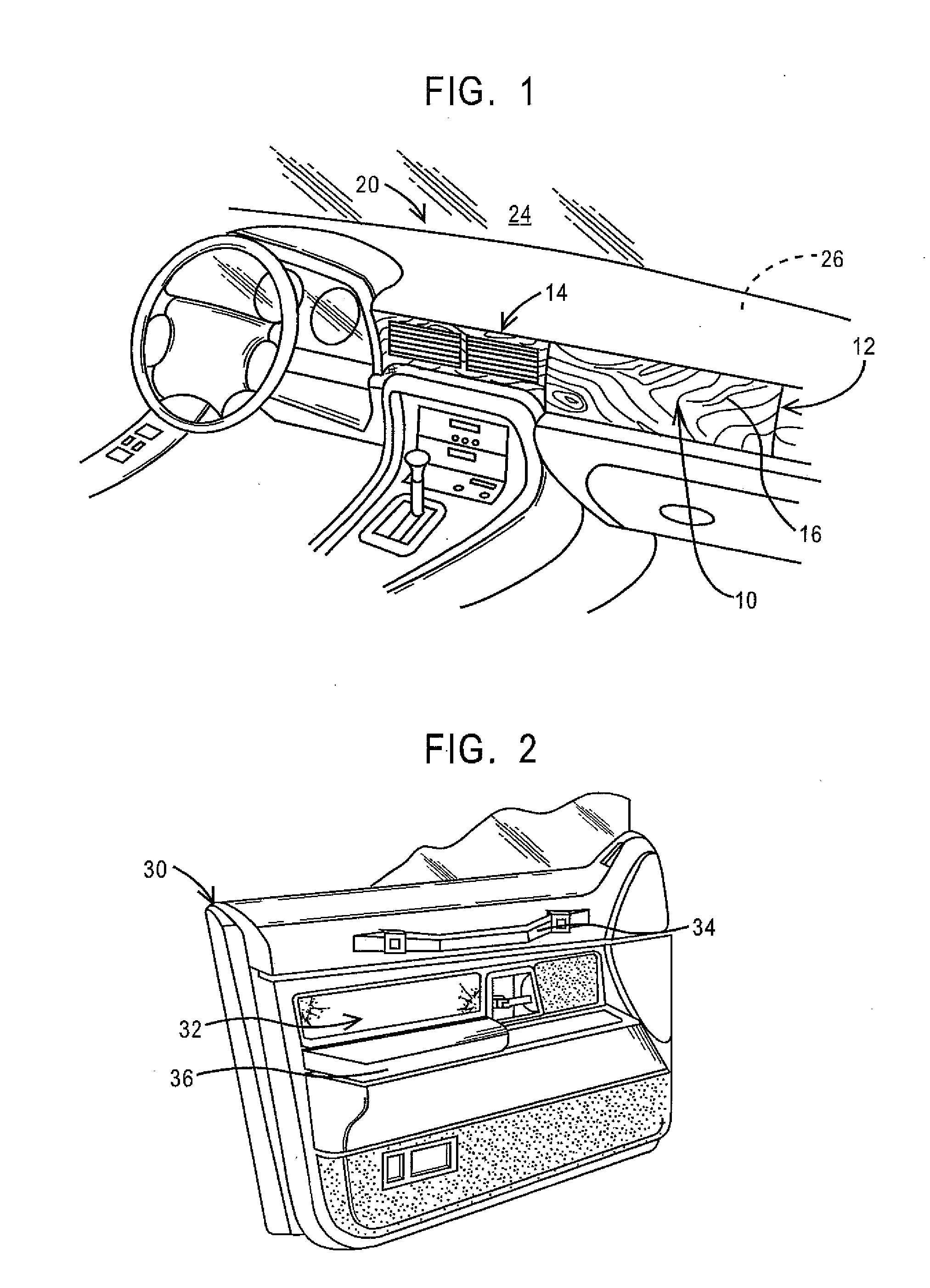

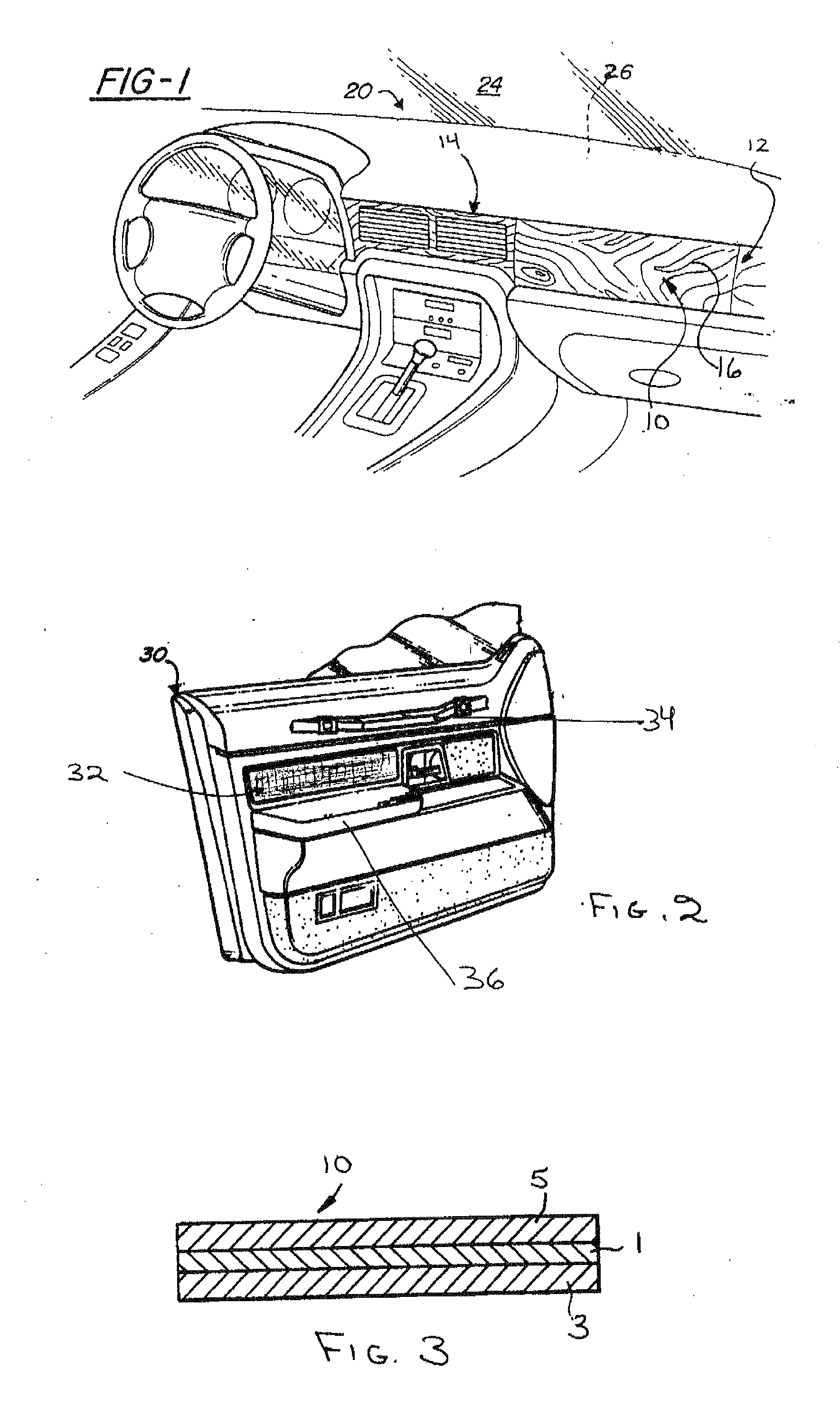

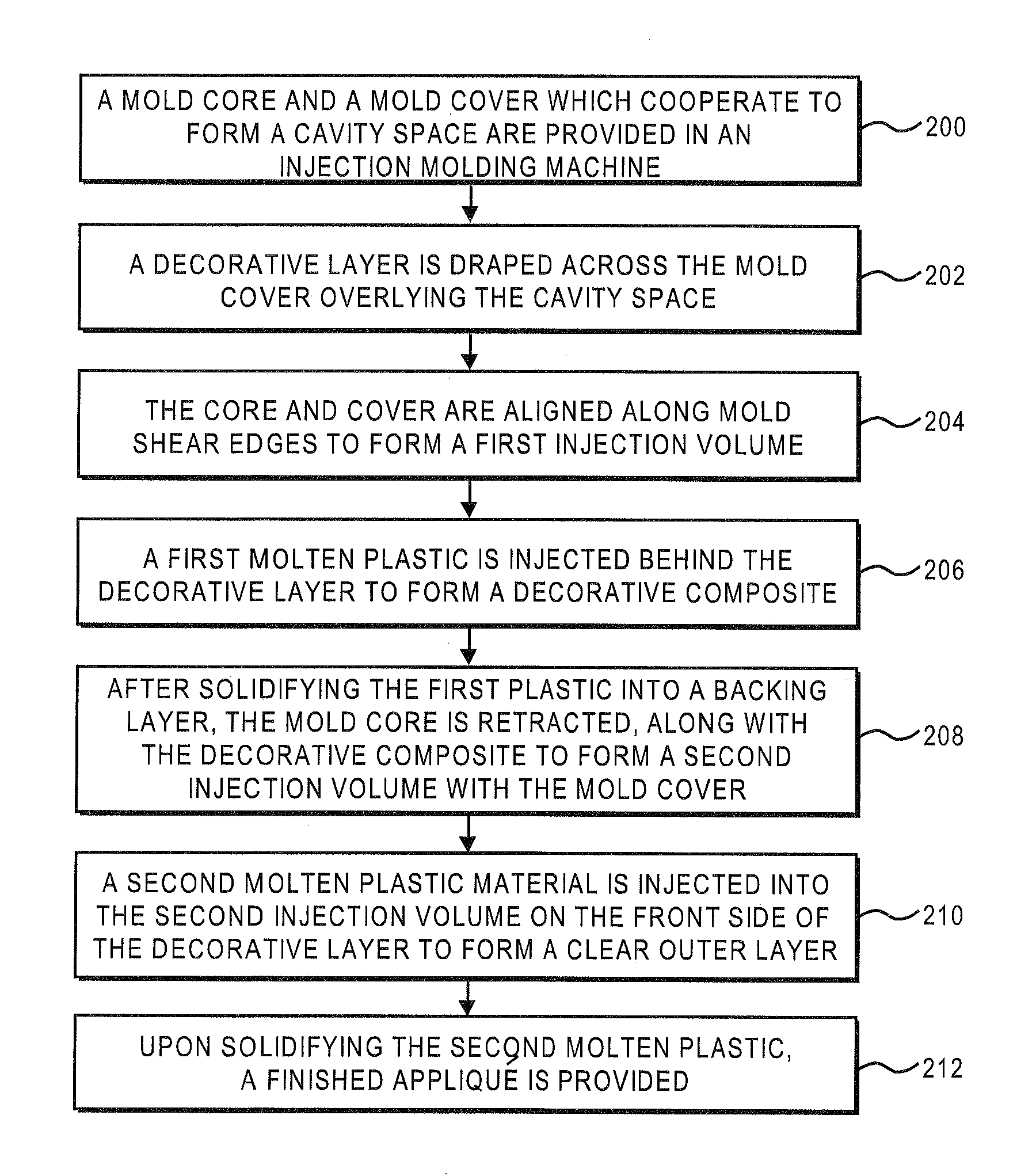

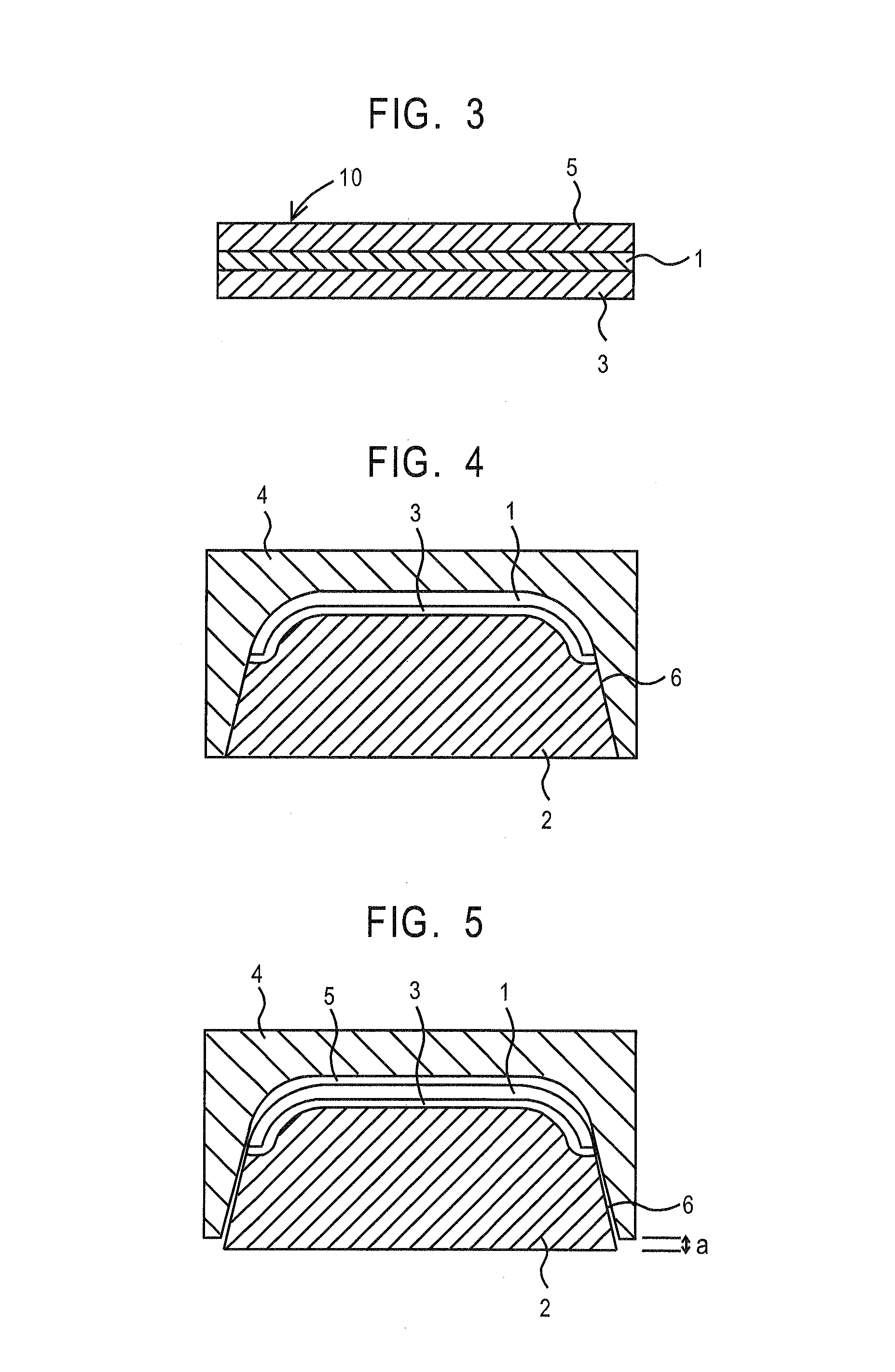

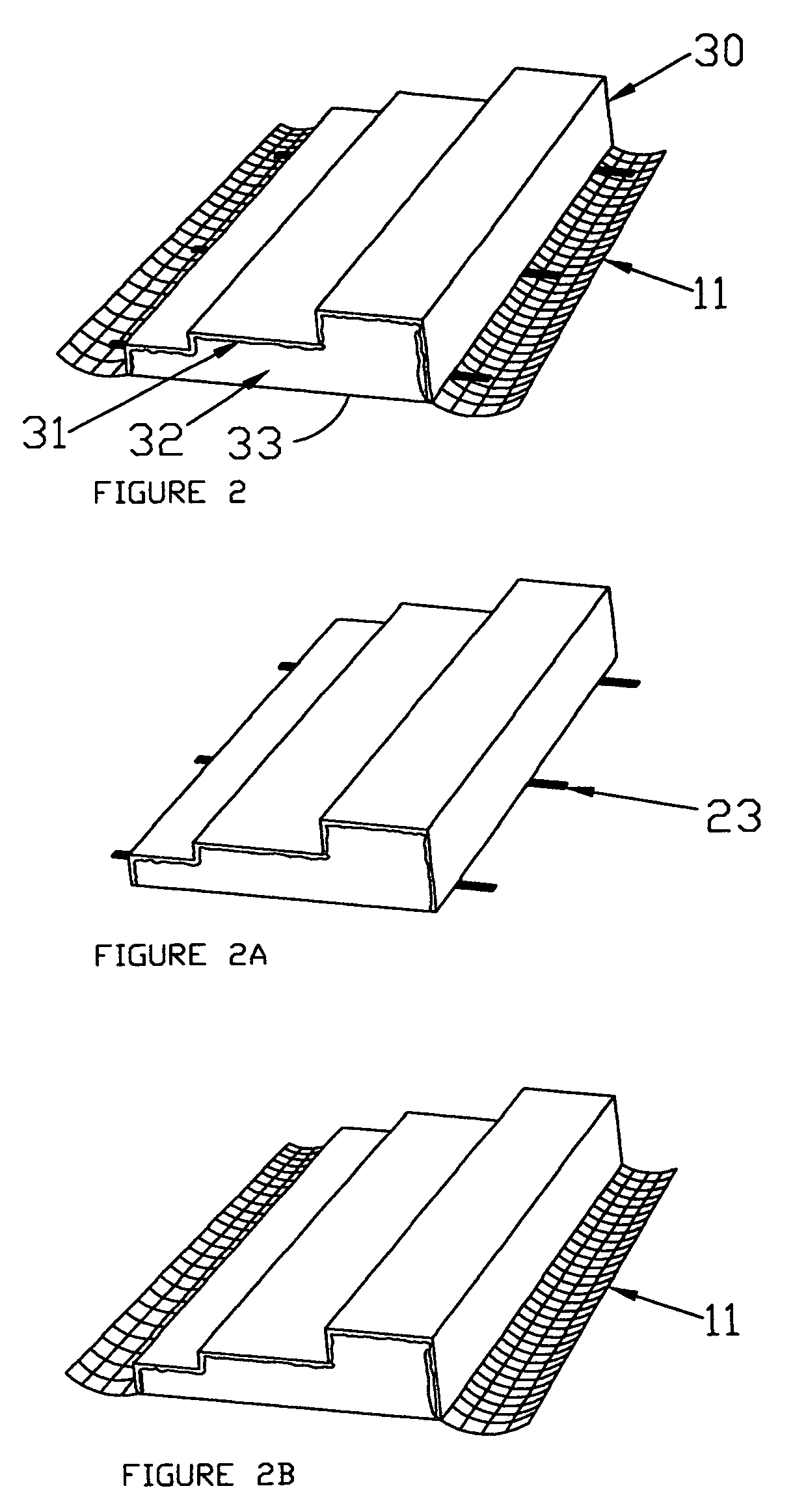

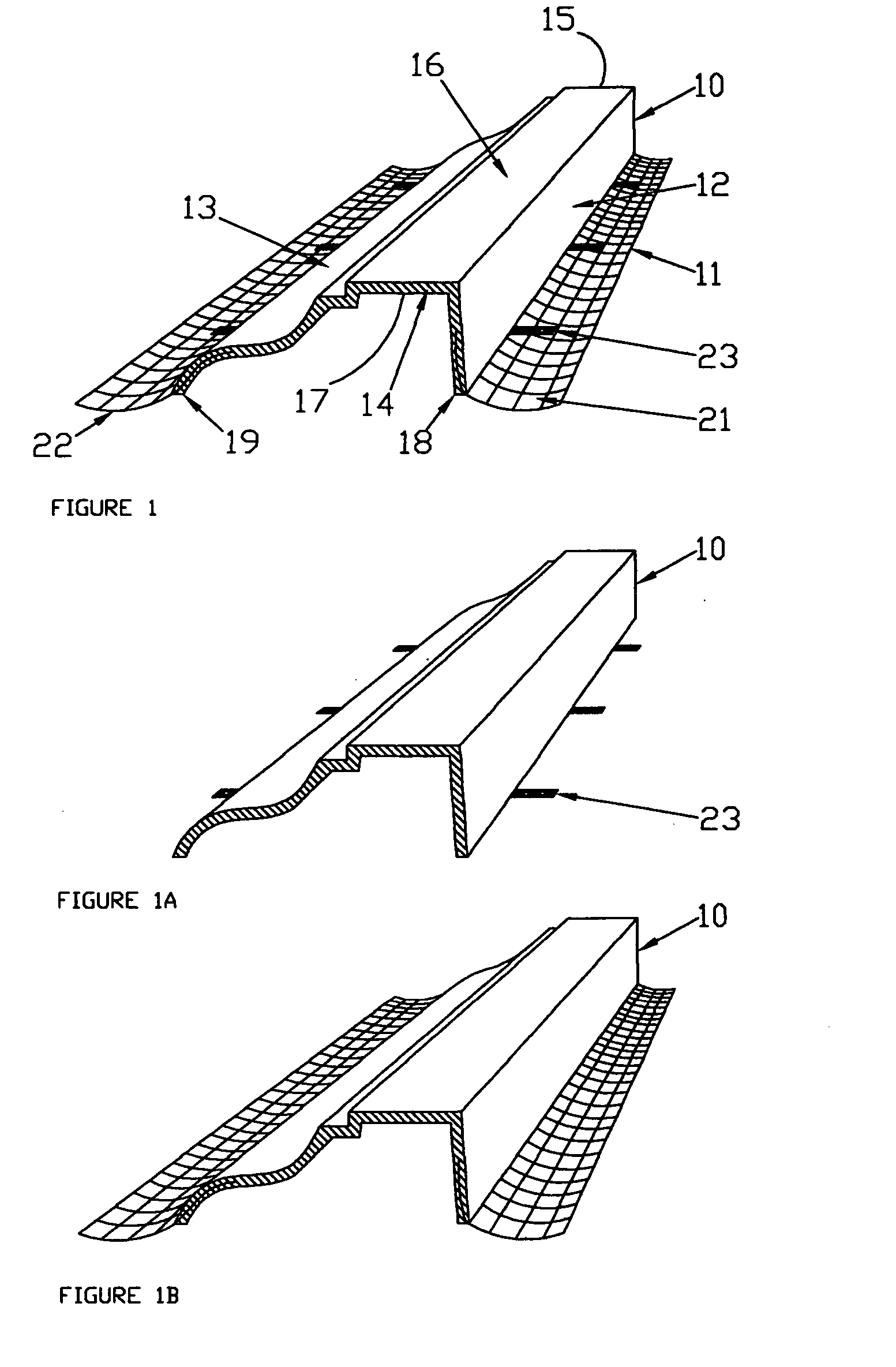

In-Mold Lamination Of Decorative Products

InactiveUS20090174121A1Luxurious appearanceExceptional depth of imageMouldsSynthetic resin layered productsEngineeringDecorative product

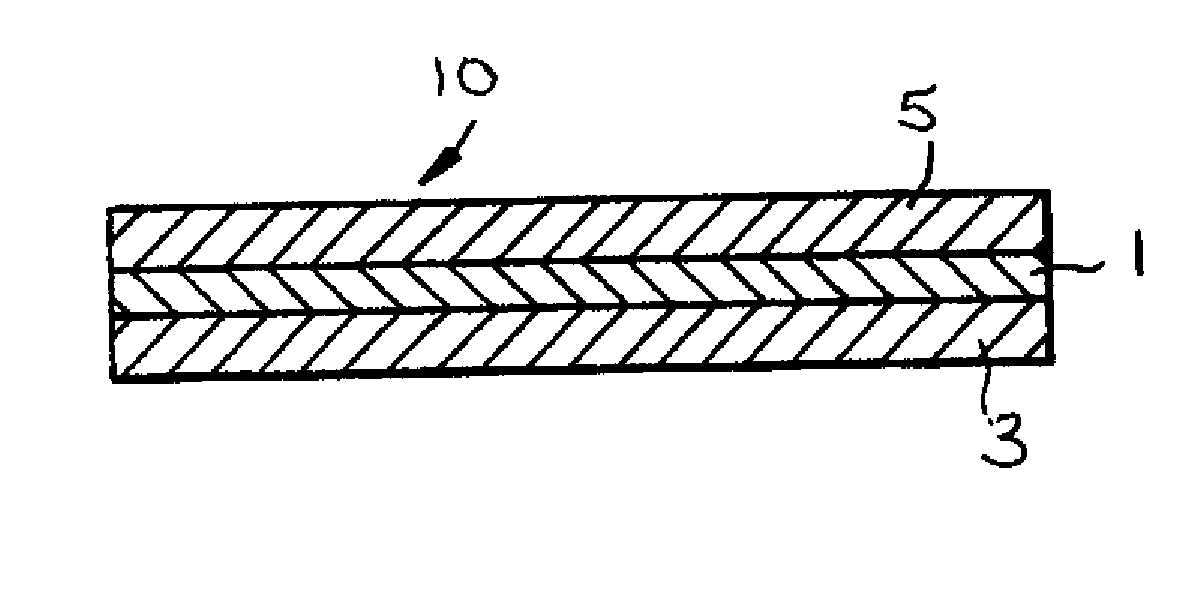

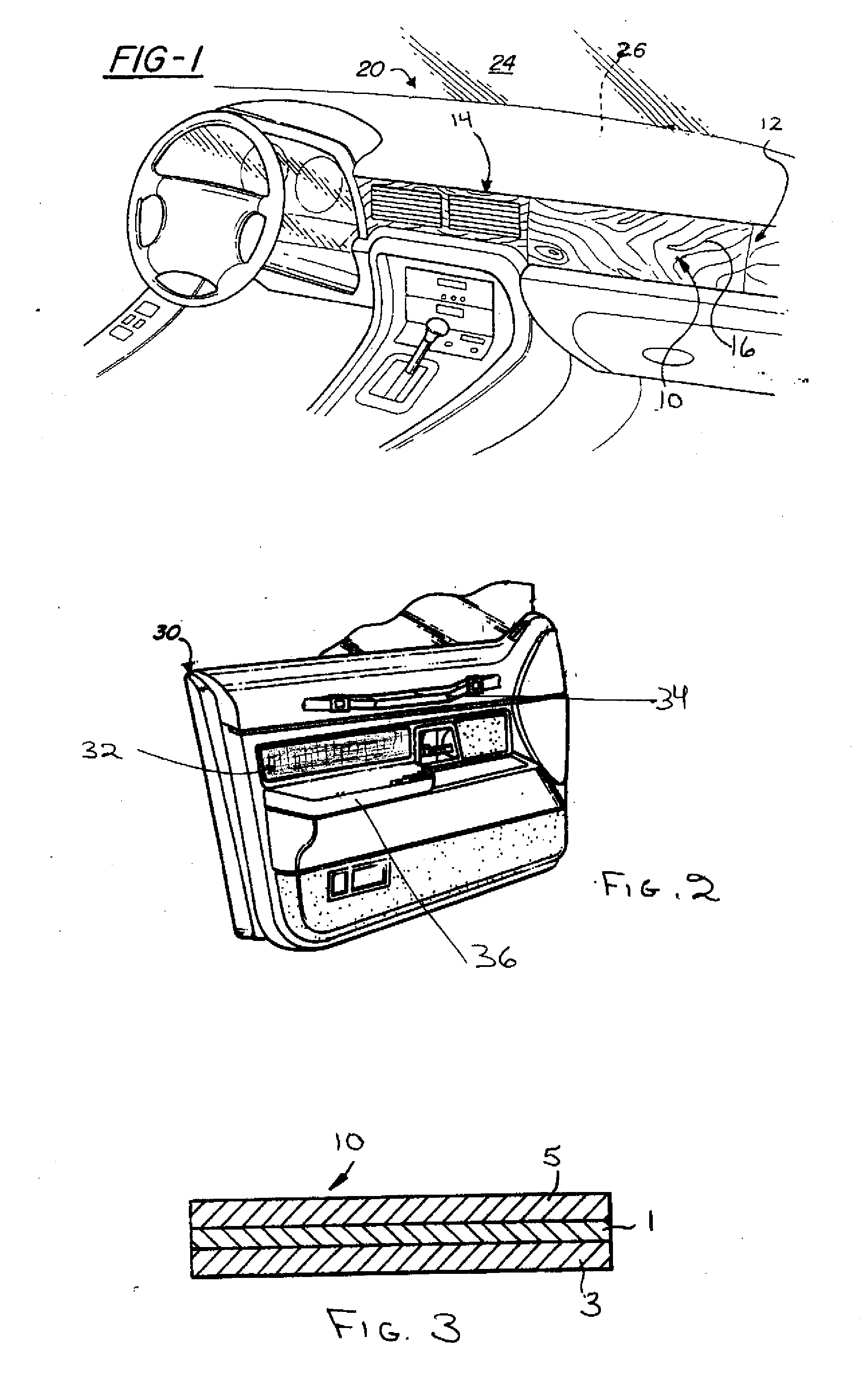

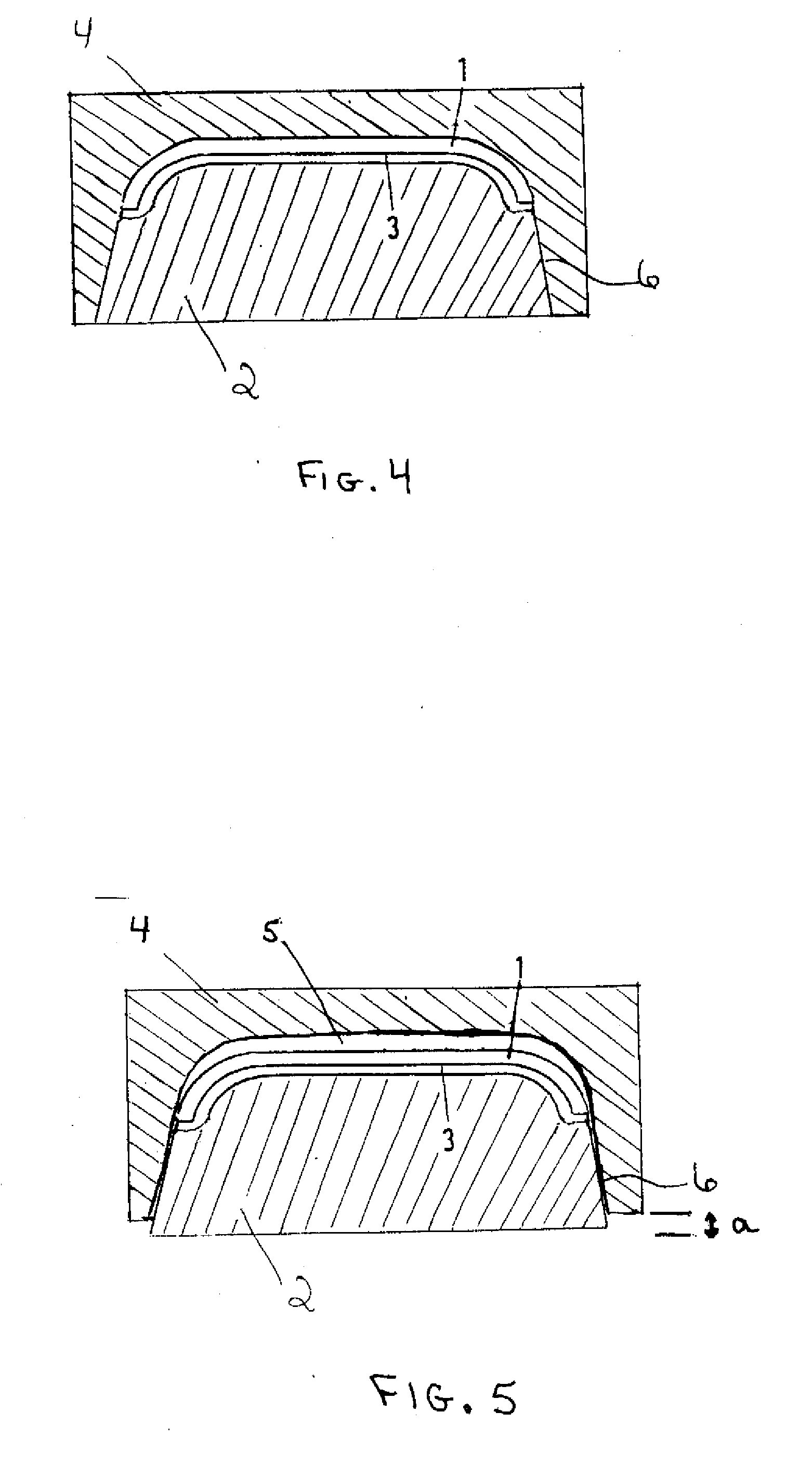

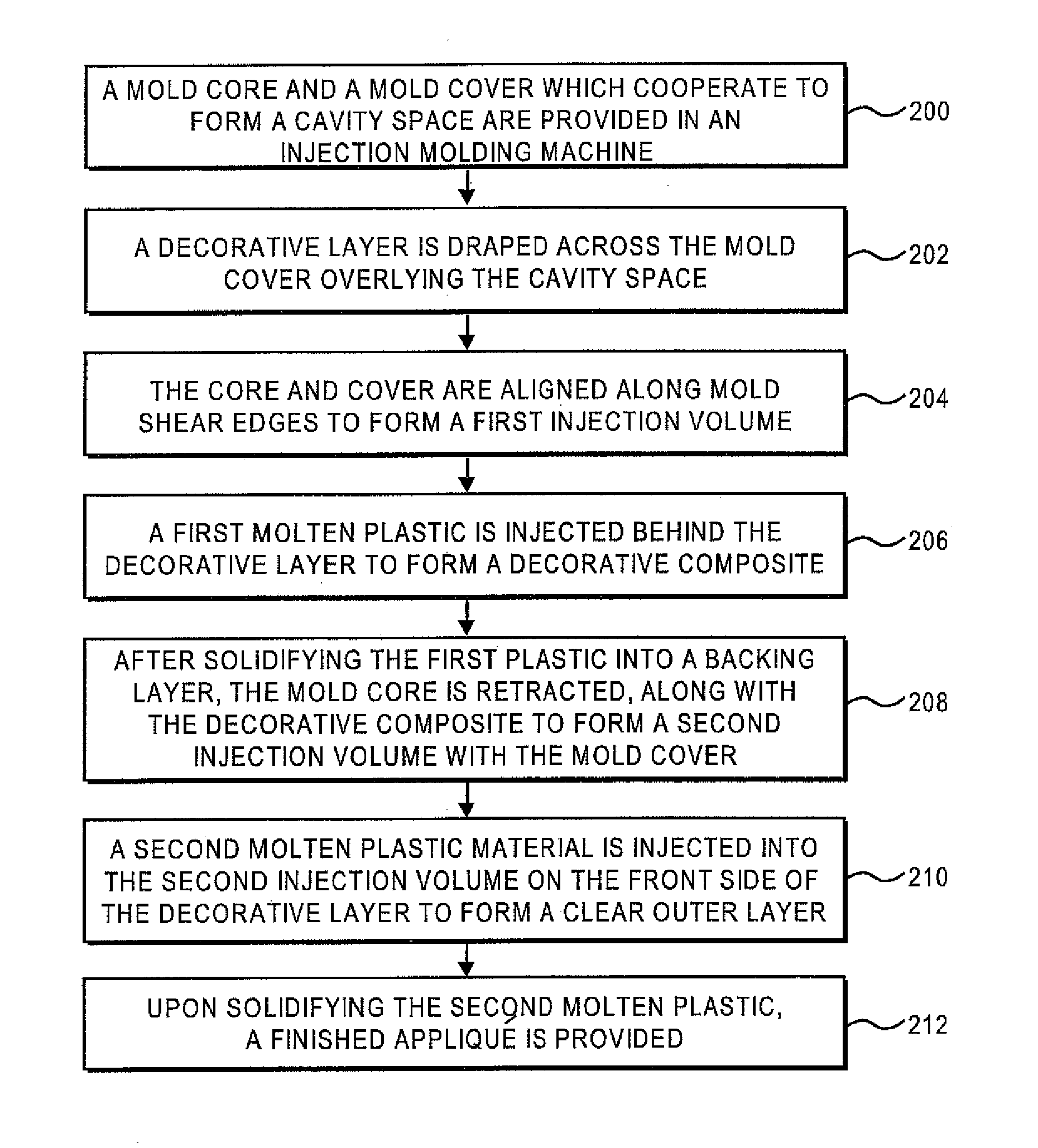

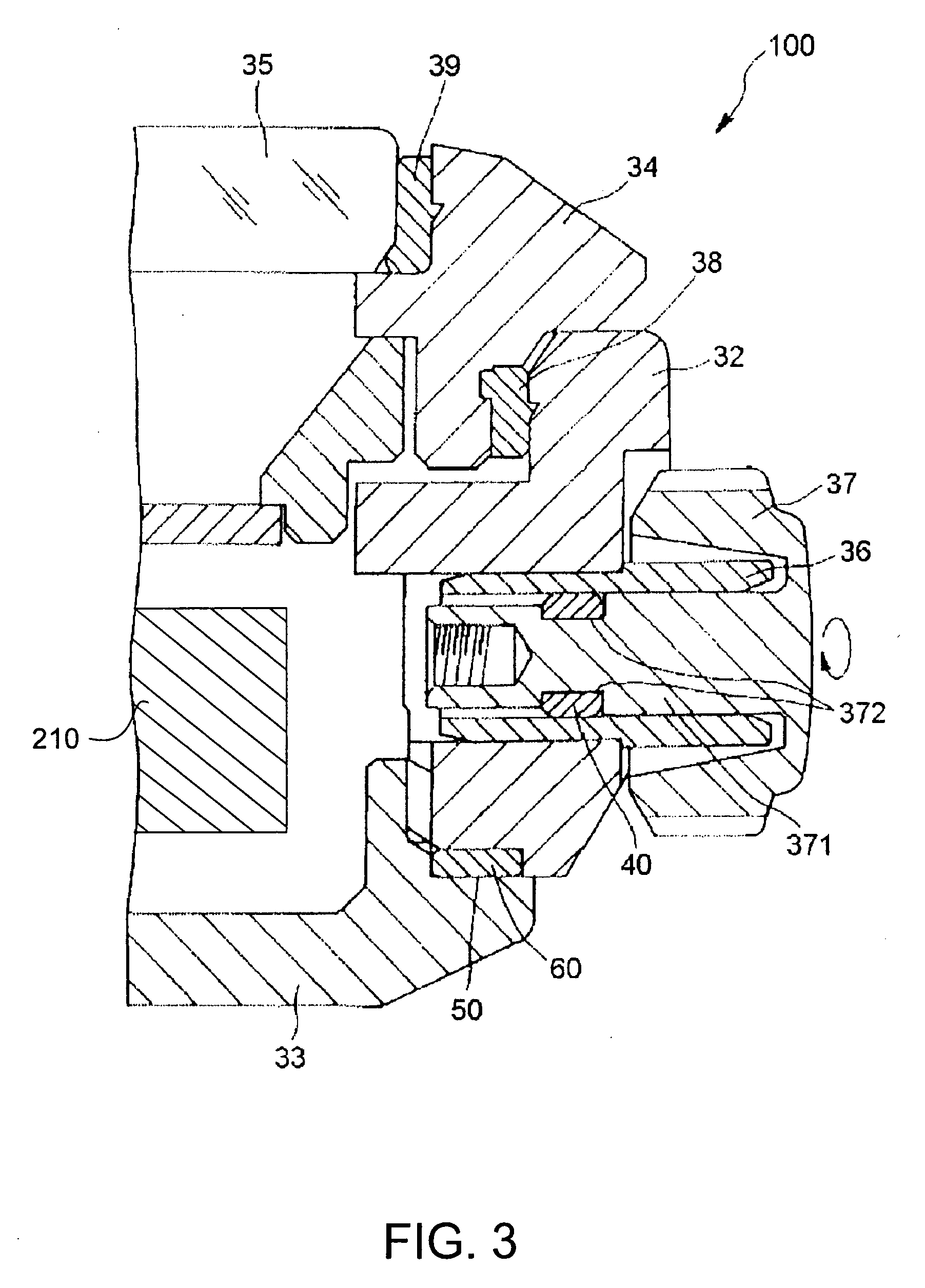

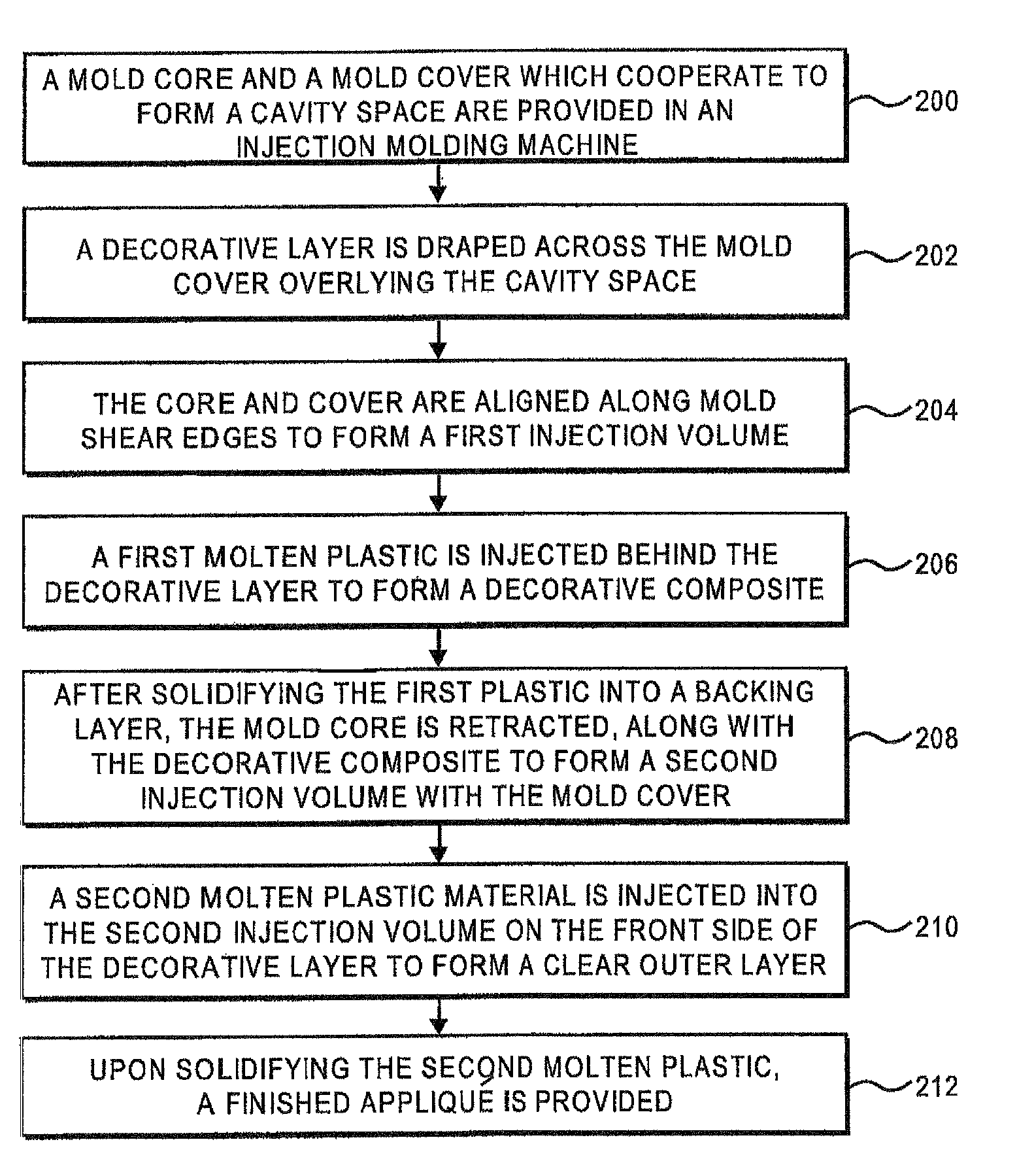

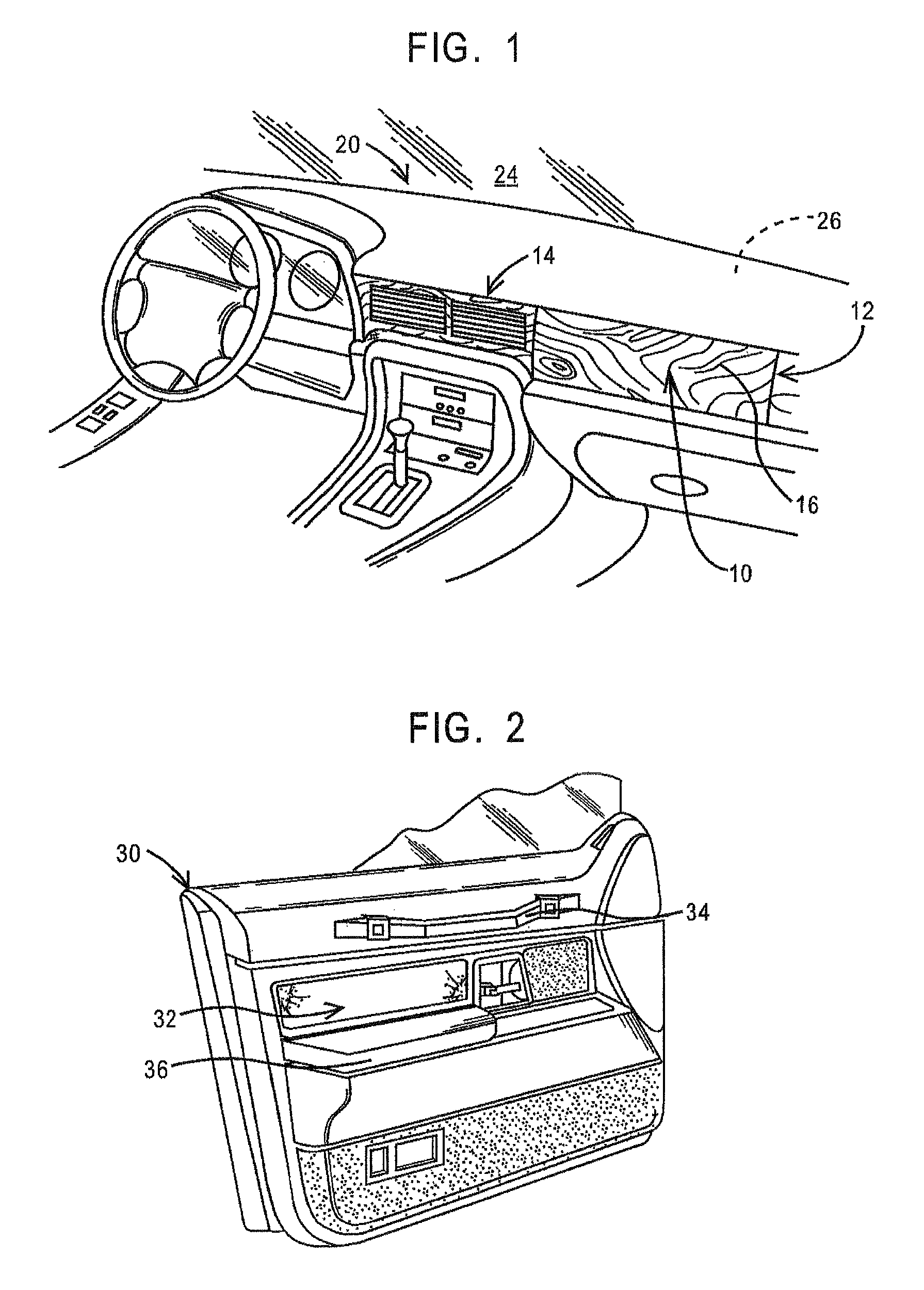

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer. A method is also disclosed for coating the exposed surface of the decorative layer between injection of the backing and outer layers to impart a desired visual effect or repair the surface. Use of multiple layers of decorative film, clear plastic and colored / opaque plastic is also disclosed to provide distinguishing visual effects.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Composition for application to a surface

The present disclosure provides compositions, methods, apparatuses, kits, and combinations thereof for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The décor product is formulated to be applied and affixed to a surface, and may be substantially removed from the surface before being affixed thereto. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, methods such as heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemicals may be used. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

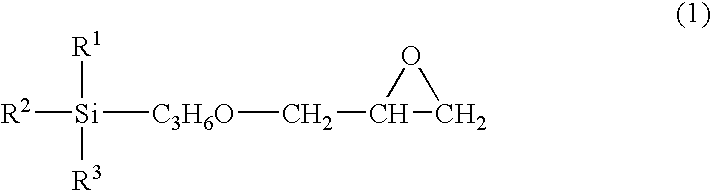

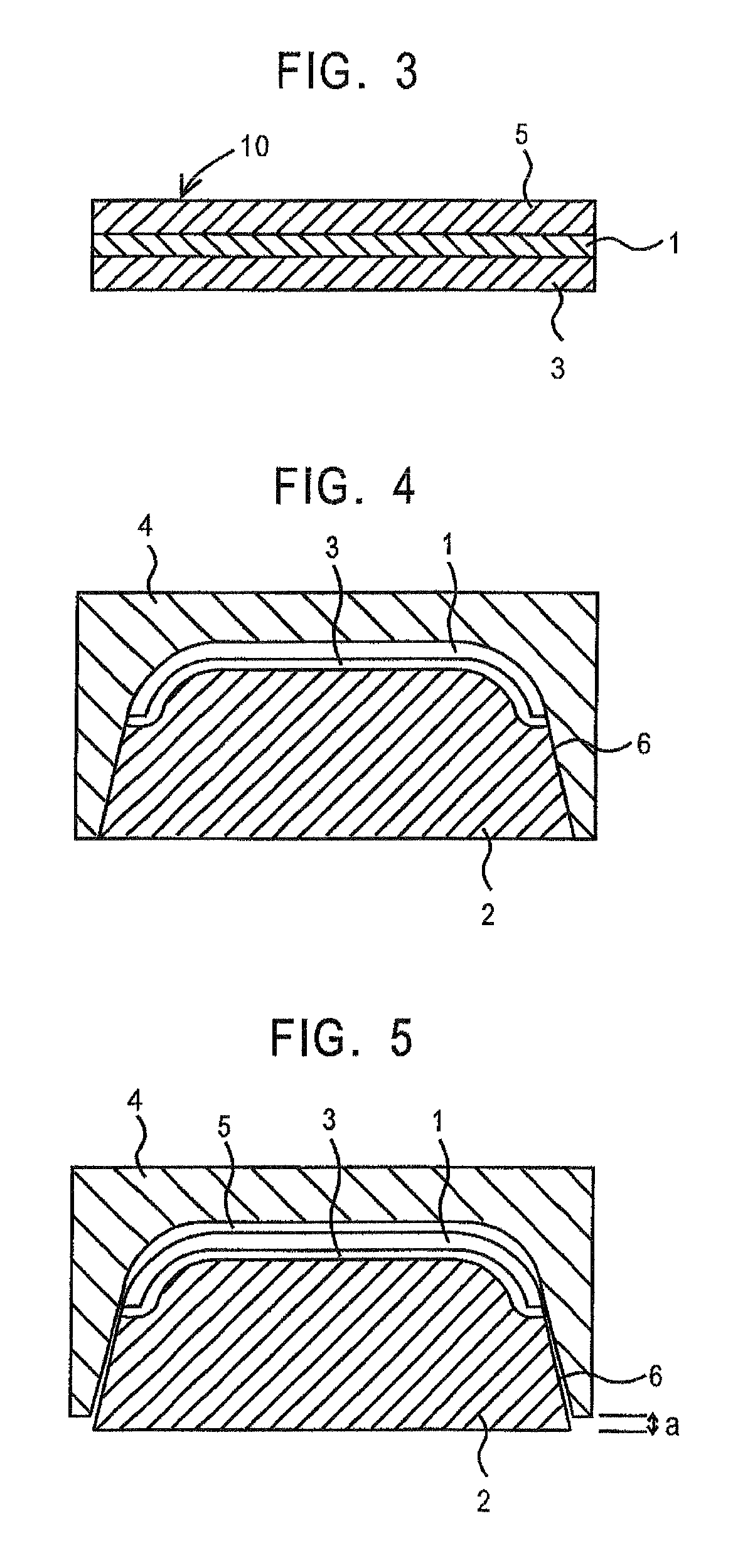

Clear coating composition, method of forming multilayer coating film and inmold decoration product

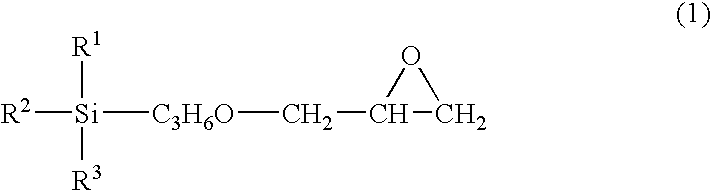

InactiveUS20060014024A1Design value is deterioratedBeautiful designSynthetic resin layered productsPolyurea/polyurethane coatingsClear LayerCorrosion reaction

It is an object of the present invention to provide a clear coating composition which inhibits a corrosion reaction by containing a rust preventive agent in a clear layer on a silver-plating layer and preventing a corrosive substance such as chlorine ion from contacting with the surface of the silver-plating layer, and develops beautiful silver-plating design for a long time, and an inmold decoration product comprising a silver-plating layer. A clear coating composition used in forming a multilayer coating film comprising a silver-plating layer, said multilayer coating film being obtainable by forming a base coating film layer, a silver-plating layer and a clear coating film layer in succession on a plastic substrate, wherein said clear coating composition is a two-package polyurethane coating composition comprising a main material containing acrylic polyol and a curing agent containing a polyisocyanate compound, the equivalence ratio of an NCO group in said polyisocyanate compound to an OH group in said acrylic polyol (NCO / OH) ranges from 0.8 / 1 to 1.2 / 1, and the clear coating composition contains a rust preventive agent in the proportions of 1.0 to 13.0 parts (on a basis of solids weight) with respect to 100 parts by weight of the total of the acrylic polyol and the rust preventive agent.

Owner:HONDA MOTOR CO LTD +1

Composition For Application To A Surface

The present disclosure provides compositions, methods, apparatuses, kits, and combinations thereof for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The décor product is formulated to be applied and affixed to a surface, and may be substantially removed from the surface before being affixed thereto. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, methods such as heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemicals may be used. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Composition for application to a surface

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product that is formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed to the surface by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

In Mold Lamination Of Decorative Products

InactiveUS20070141353A1Exceptional depth of imageThinner cross-sectionMouldsSynthetic resin layered productsDecorative productElectrical and Electronics engineering

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

In-Mold Lamination Of Decorative Products

InactiveUS20070194487A1Exceptional depth of imageThinner cross-sectionMouldsSynthetic resin layered productsDecorative productElectrical and Electronics engineering

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer. A method is also disclosed for coating the exposed surface of the decorative layer between injection of the backing and outer layers to impart a desired visual effect or repair the surface.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

In mold lamination of decorative products

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a decorative layer, the decorative layer comprising a relatively thin metal foil, film, fabric, veneer or sheet of paper having a digital image from an inkjet printer deposited on a front surface thereof. In one exemplary embodiment, the appearance of a wood veneer may be modified by digitally printing a burl pattern over the wood grain surface of the veneer prior to injection molding.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

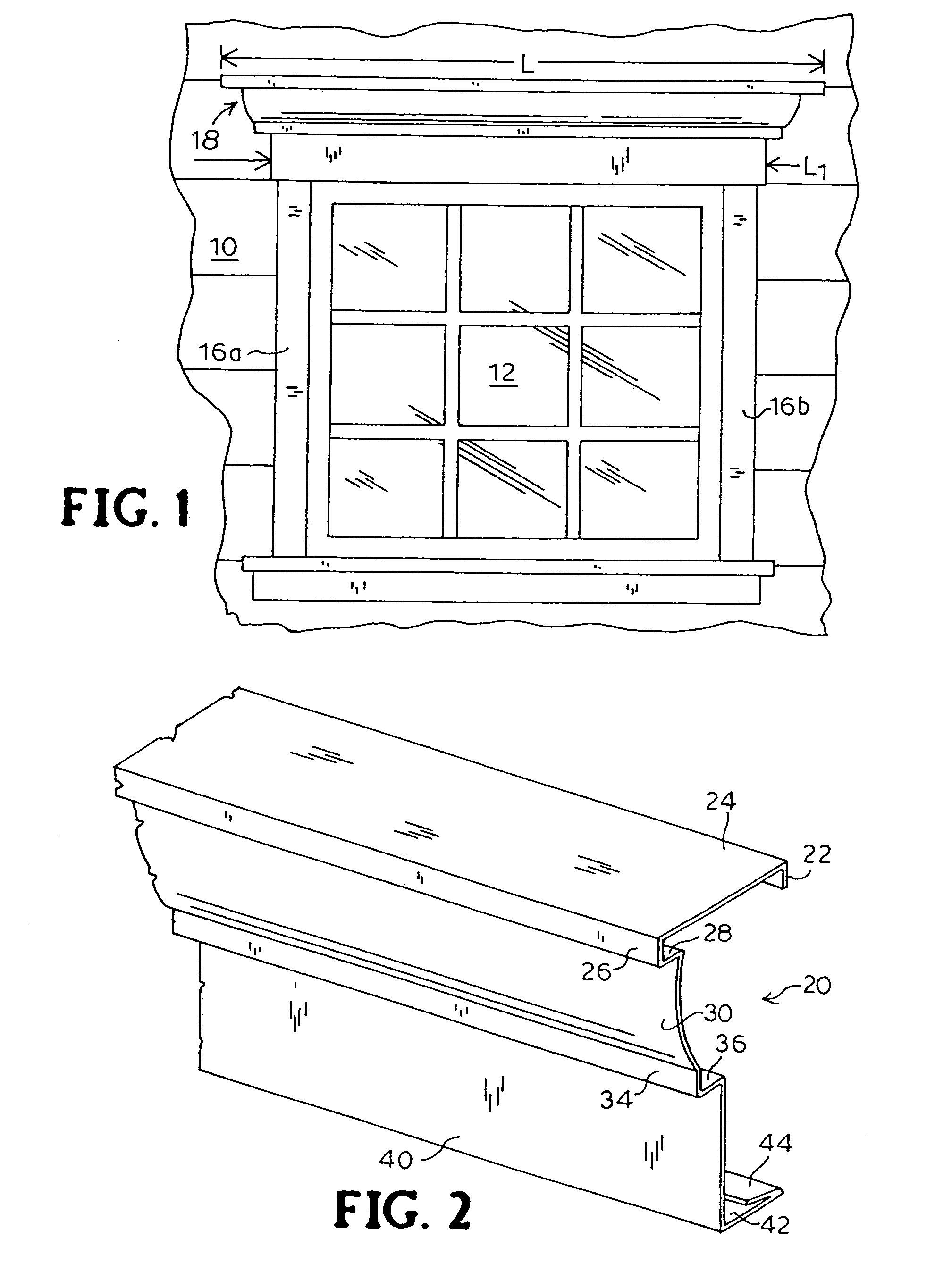

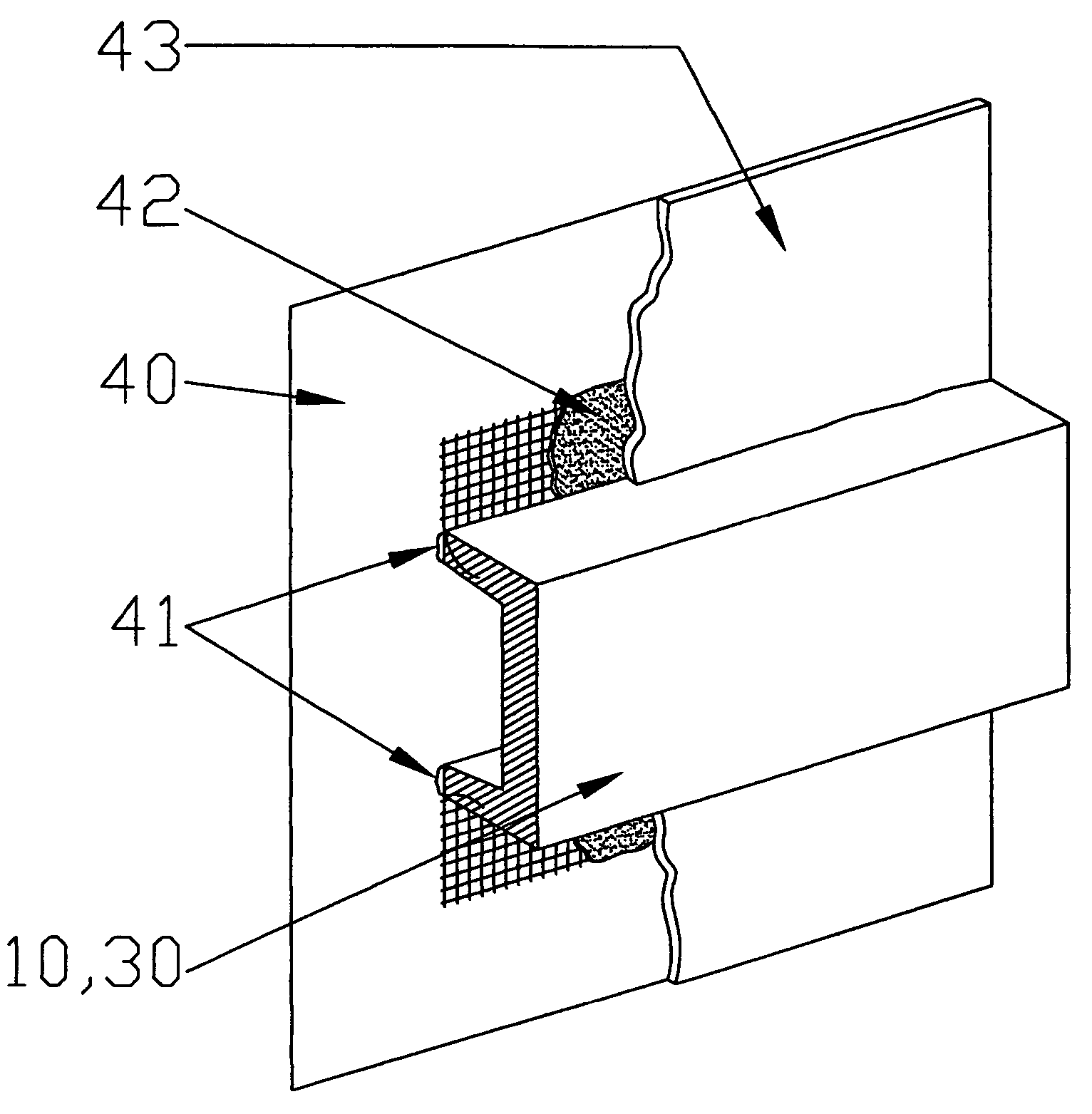

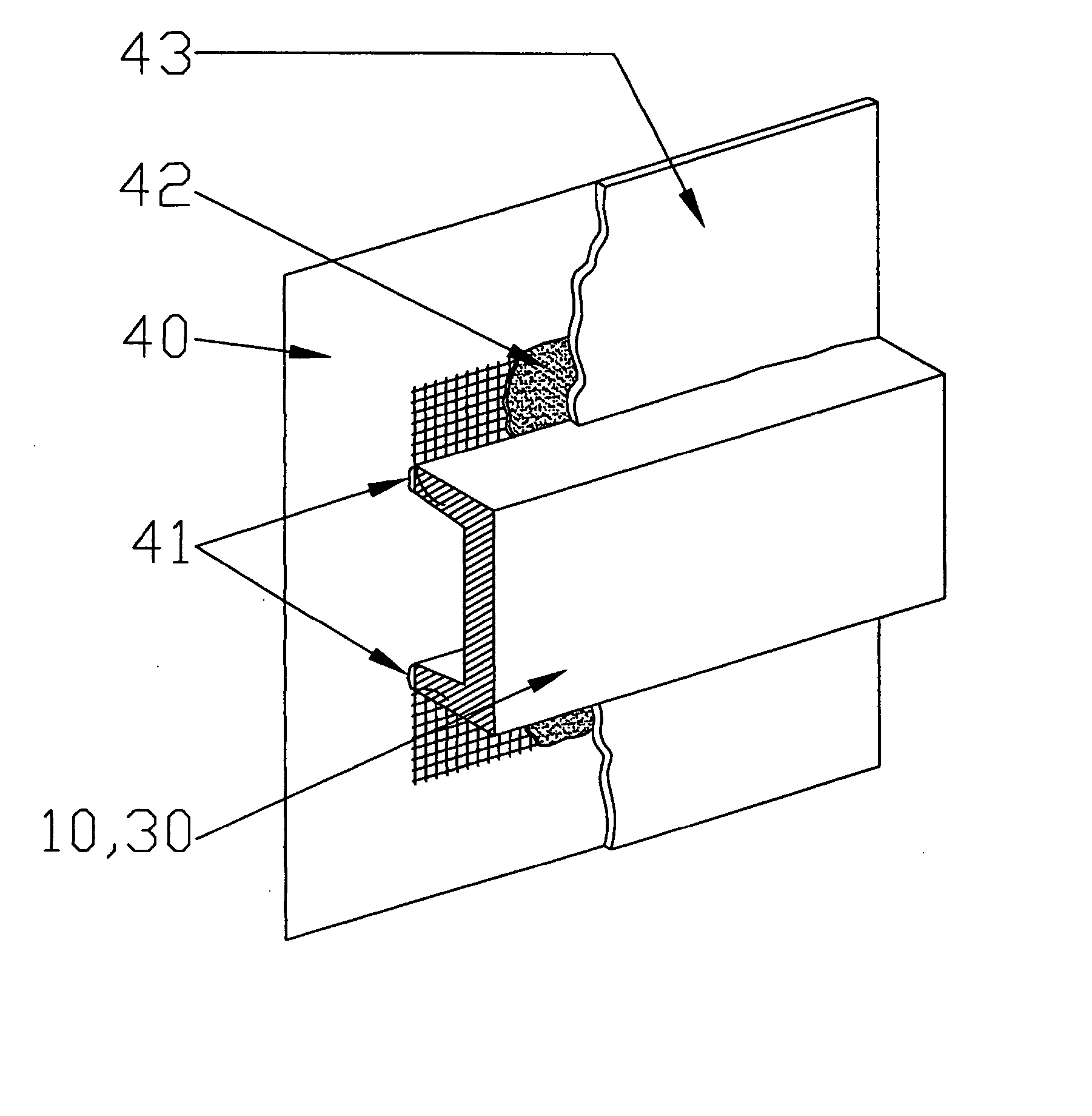

Architectural trim product

InactiveUS7036282B1Minimizing any tendencyCovering/liningsNatural patternsEngineeringDecorative product

An elongated horizontal transitional trim product includes an elongated, molded, horizontally-positionable stiffening block. The block has a flat, vertical back surface; a flat, horizontal top surface; a flat, horizontal bottom surface; and a front surface. The front surface extends between an outer edge proximate to the top surface and an outer edge proximate to the bottom surface, and has a cross-sectional profile that includes a plurality of interconnected curved and vertical and horizontal flat surfaces. The stiffening block is capable of being secured directly to a flat, vertical surface of a building. The trim product further includes an elongated deformable metallic sheet terminating in respective upper and lower end sections located above and below a central section. The central section of the metallic sheet includes a plurality of interconnected, continuous surfaces in its cross-sectional profile which mate and snugly fit with the cross-sectional profile of the stiffening block. The metallic sheet is capable of being mounted onto the stiffening block by utilizing the shape of the central, upper, and lower end sections of the sheet to support and maintain the sheet on the stiffening block prior to installing other support means.

Owner:ALSCO METALS CORP

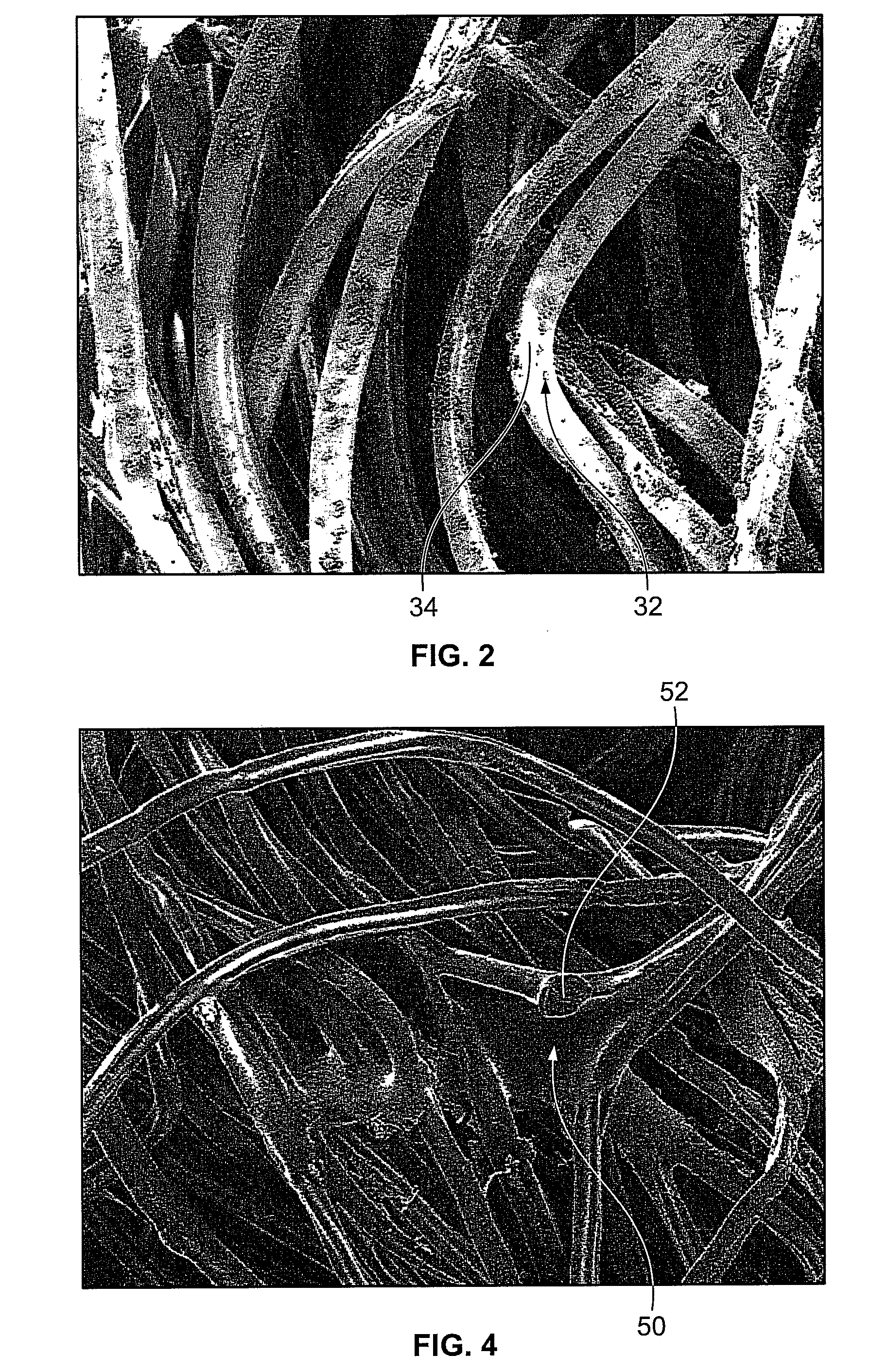

Method for manufacturing high-strength viscose-based active carbon fiber fabrics

ActiveCN101864635AHigh mechanical strengthWell-developed microporous structureLiquid/gas/vapor removal by squeezing rollersWoven fabricsCarbonizationHigh intensity

The invention discloses a method for manufacturing high-strength viscose-based active carbon fiber fabrics. In the method, viscose fiber fabrics woven by using long viscose fibers as a precursor are used as raw materials; according to the composition and structural characteristics of the viscose fiber fabrics, a phosphorus-free chemical reagent is used as a fire retardant and graphitizer which can improve the mechanical strength of the active carbon fiber fabric is added, and thus the high-strength viscose-based active carbon fiber fabrics with a developed microporous structure are manufactured by continuous low-and high-temperature carbonization, activation, drawing and other processes. In the invention, the production process, which is simple and easy to control, allows for continuous production and can be optimized according to actual application requirements, is adopted to manufacture the high-strength viscose-based active carbon fiber fabric products of different specifications. The method can be widely used for manufacturing products including protective products, such as fireproof, antitoxin and antichemical products, decorative products and the like.

Owner:DALIAN UNIV OF TECH +1

In mold lamination of decorative products

InactiveUS7674414B2Exceptional depth of imageLuxurious appearanceMouldsSynthetic resin layered productsEngineeringDecorative product

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Composition for application to a surface

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product that is formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed to the surface by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

Composition for application to a surface

InactiveUS20060288499A1Organic detergent compounding agentsLiquid surface applicatorsEngineeringMaterials science

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product that is formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed to the surface by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

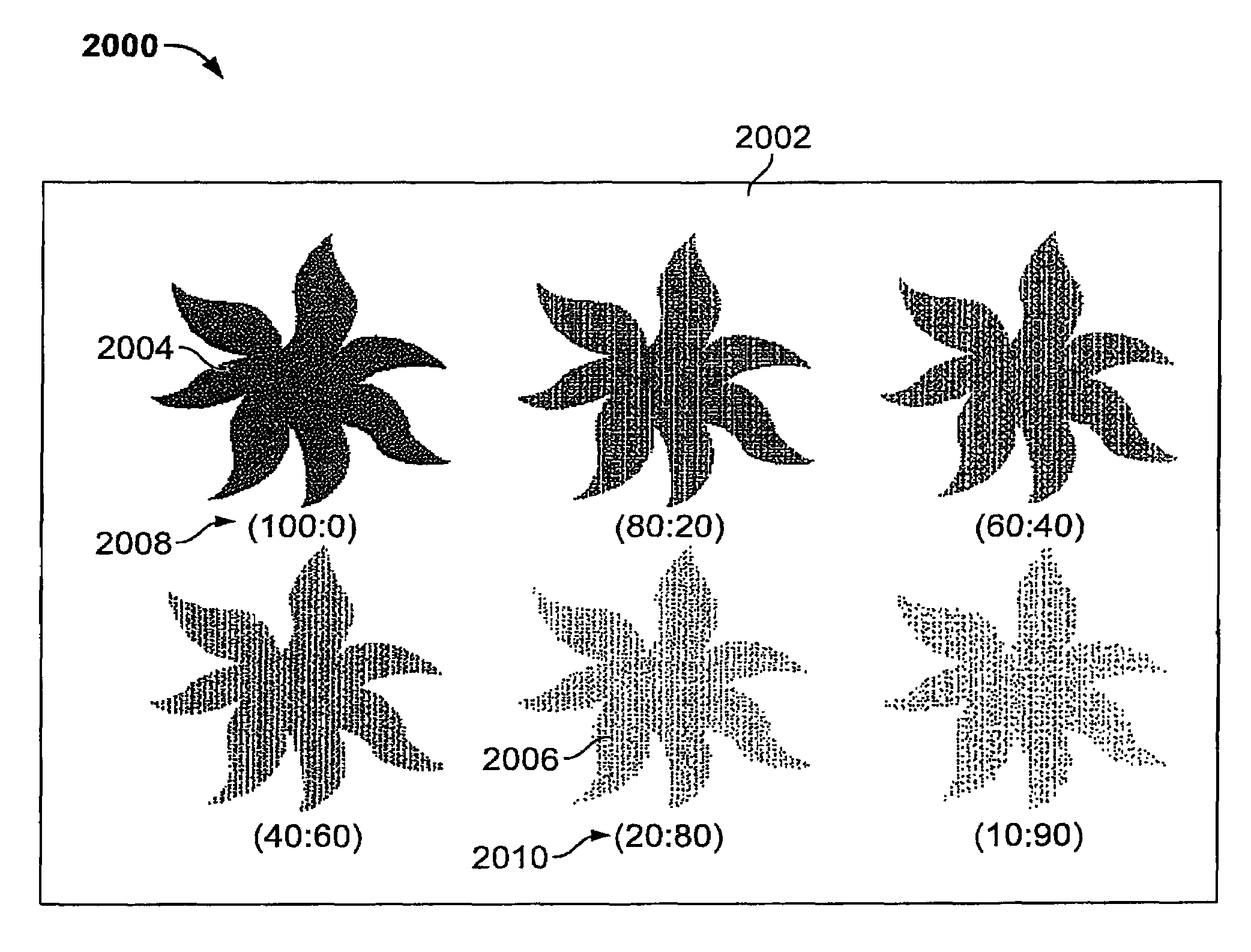

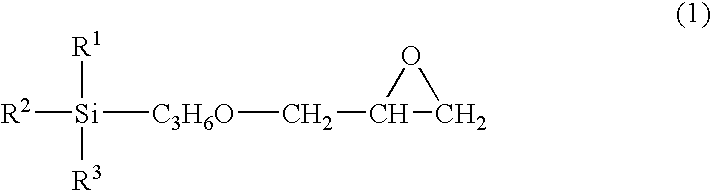

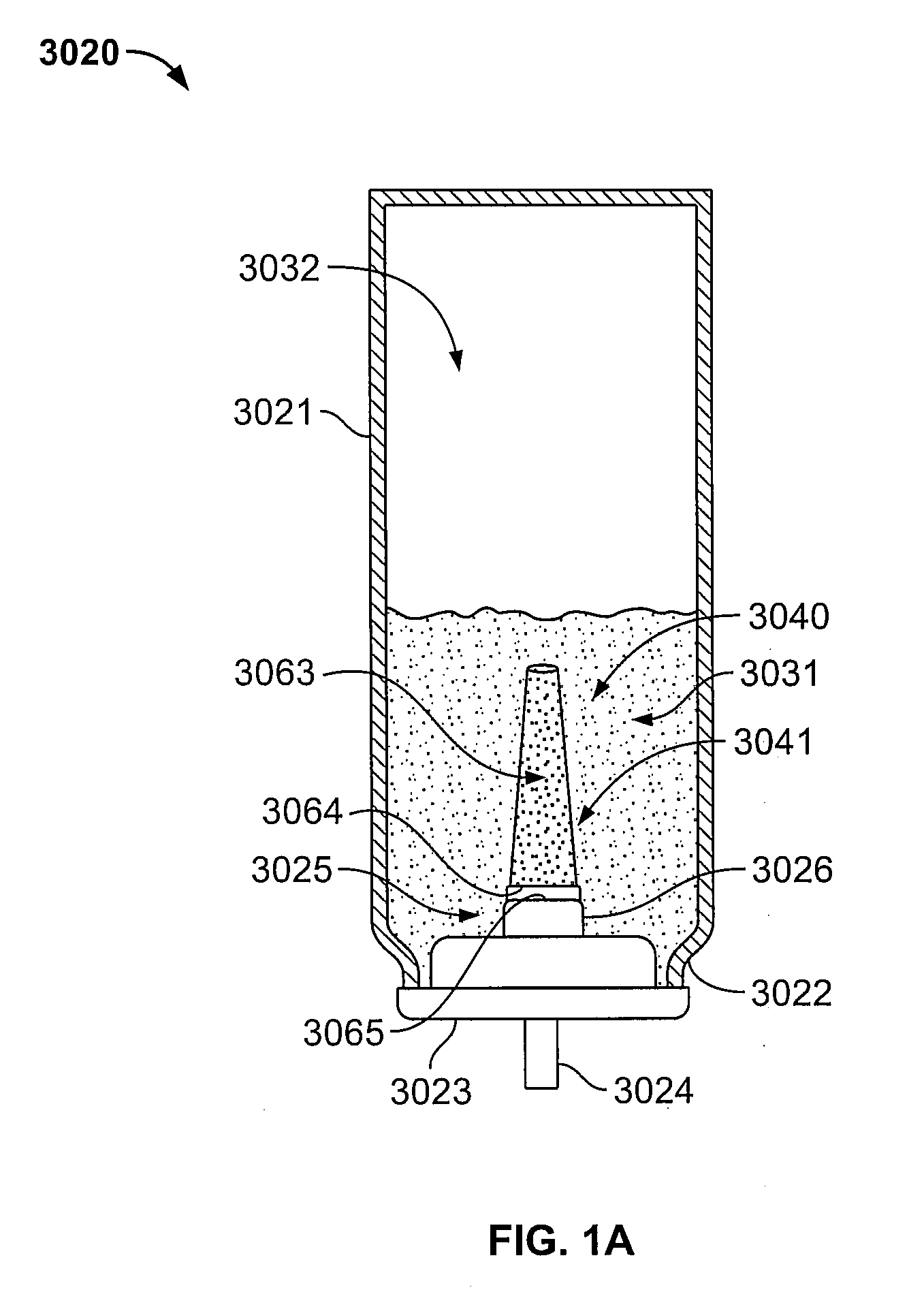

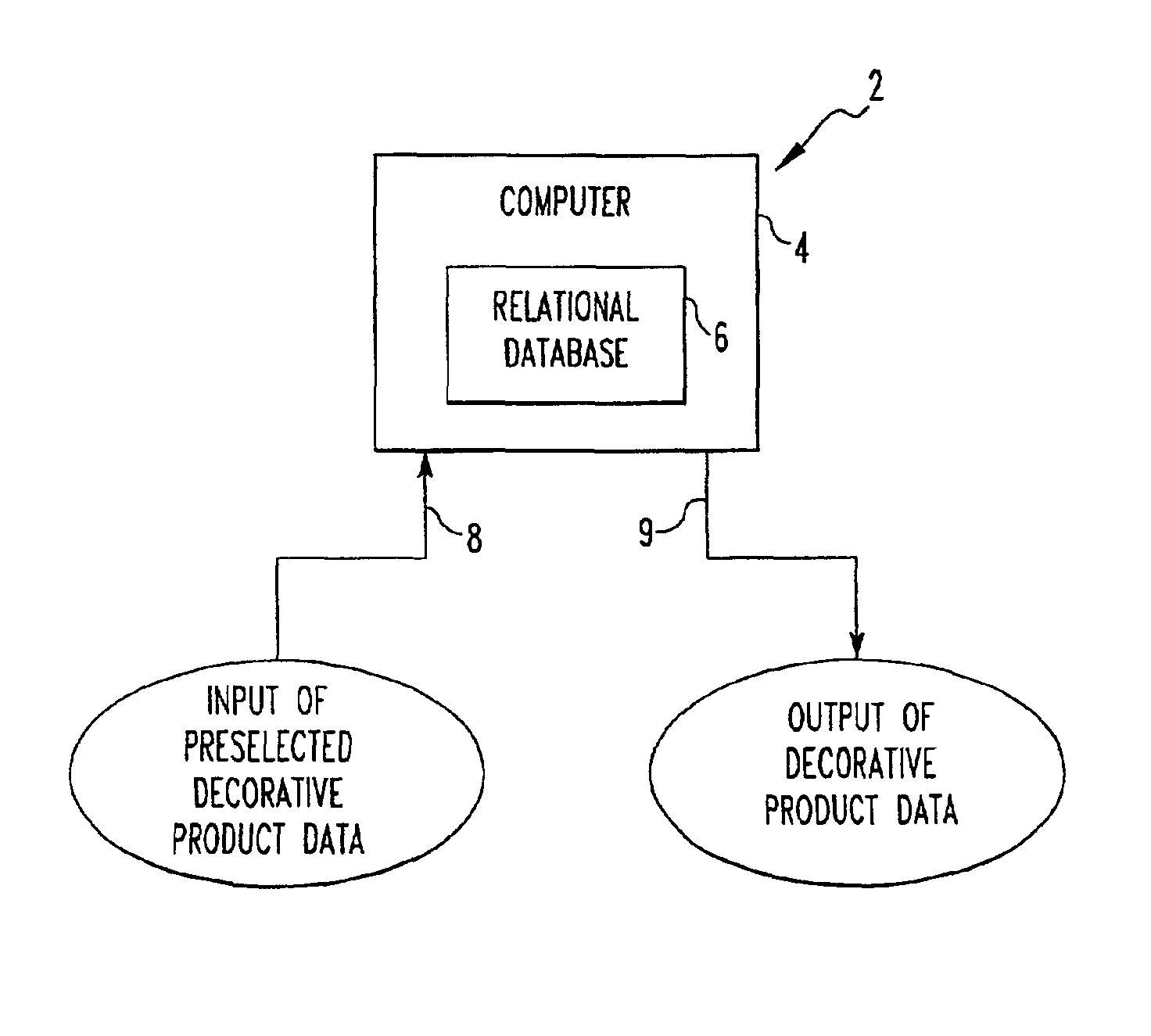

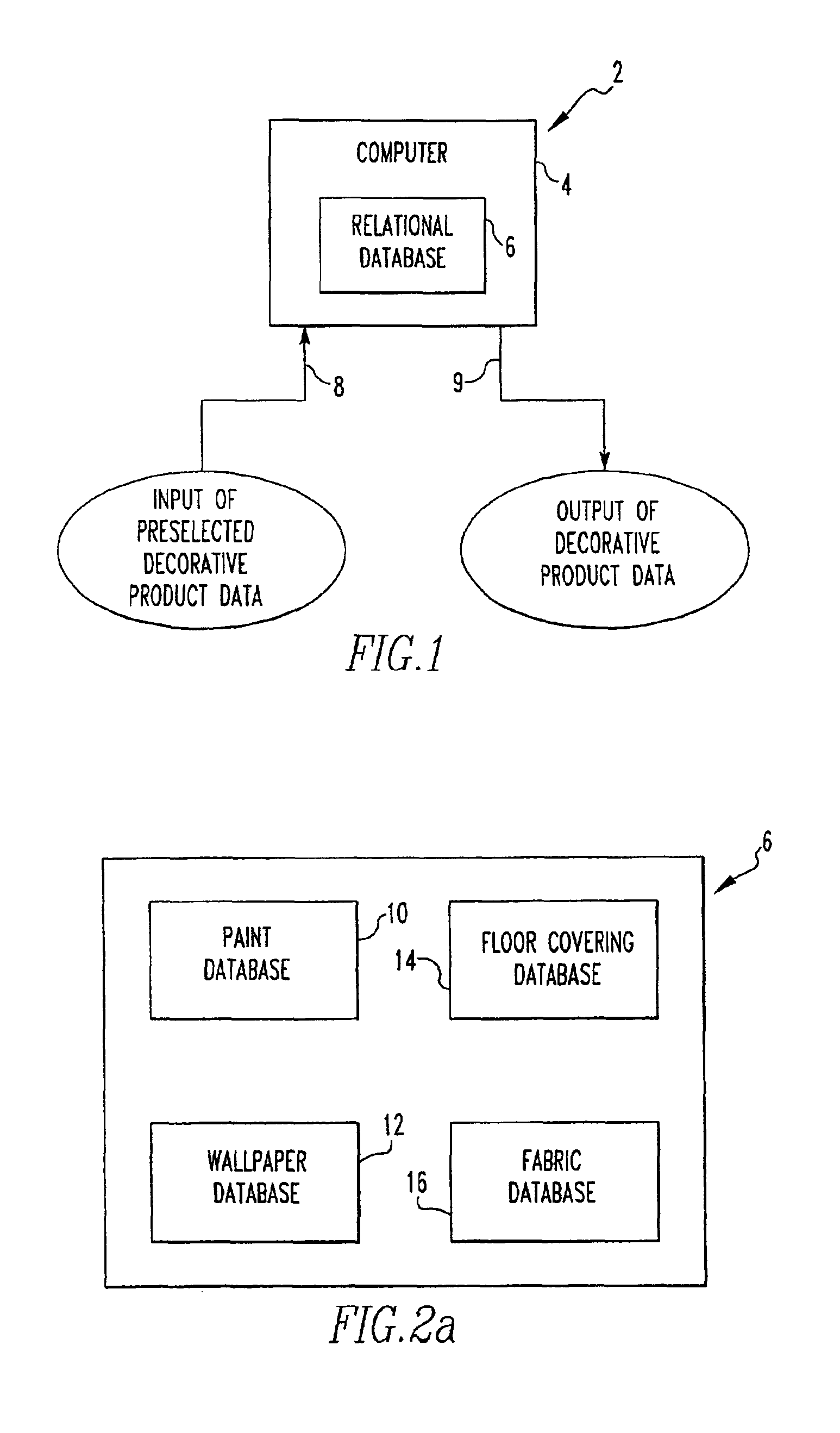

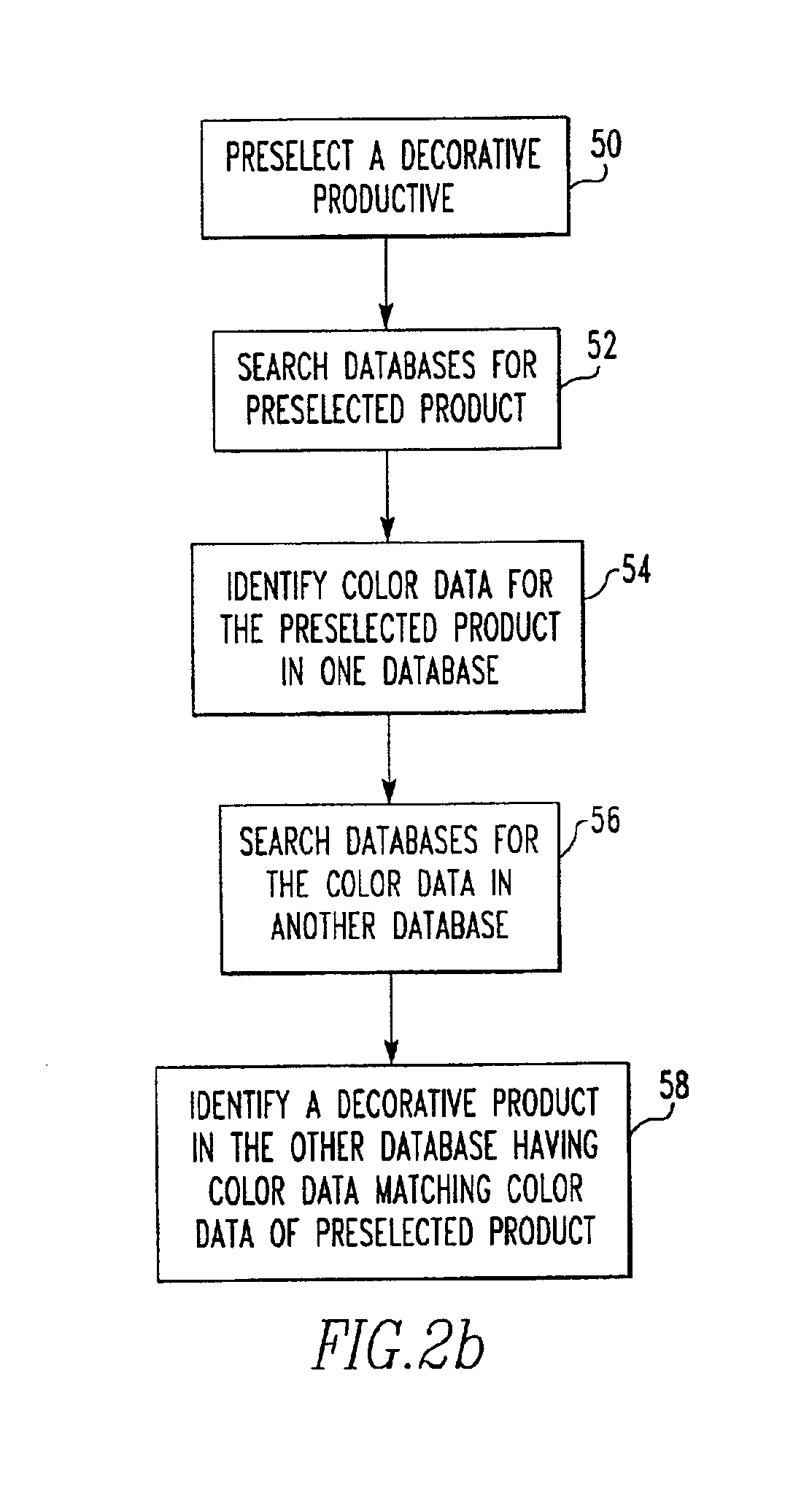

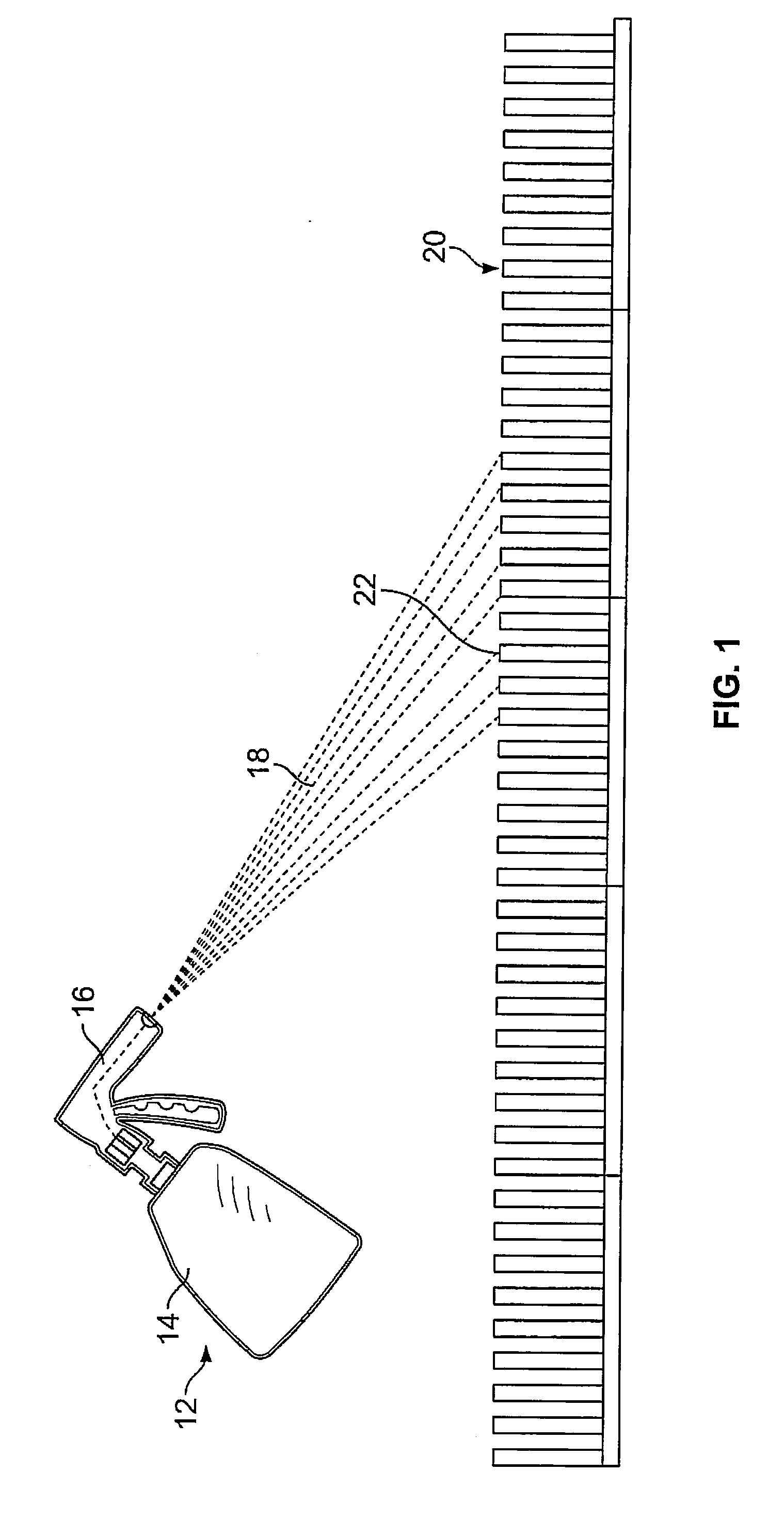

Method and system for color matching decorative products

InactiveUS6928454B2Cathode-ray tube indicatorsSpecial data processing applicationsComputer graphics (images)Relational database

A method of identifying decorative products based on matching with paint colors. The method includes the use of a relational database having data on various decorative product types which are cross-referenced to each other via color values.

Owner:PPG IND OHIO INC

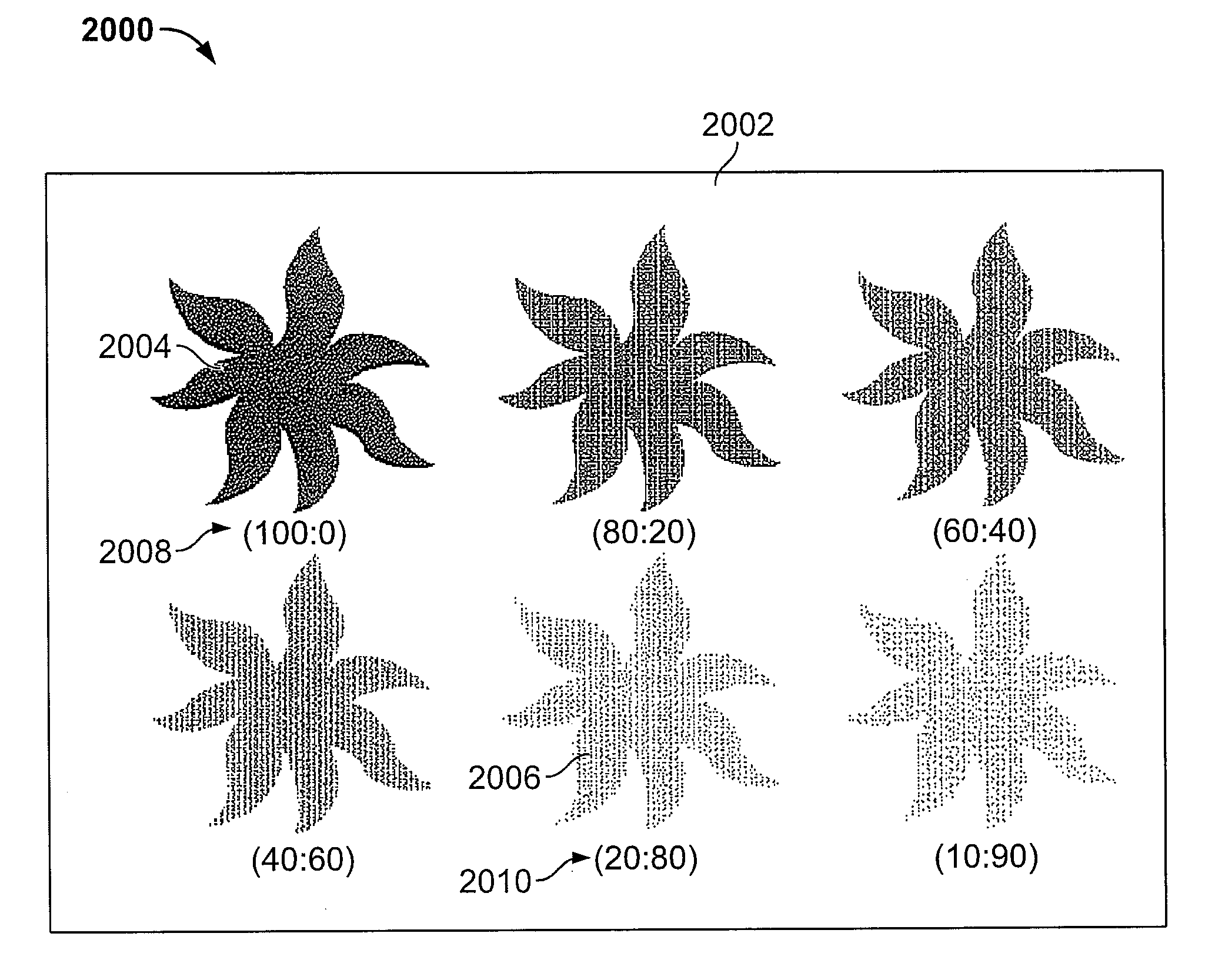

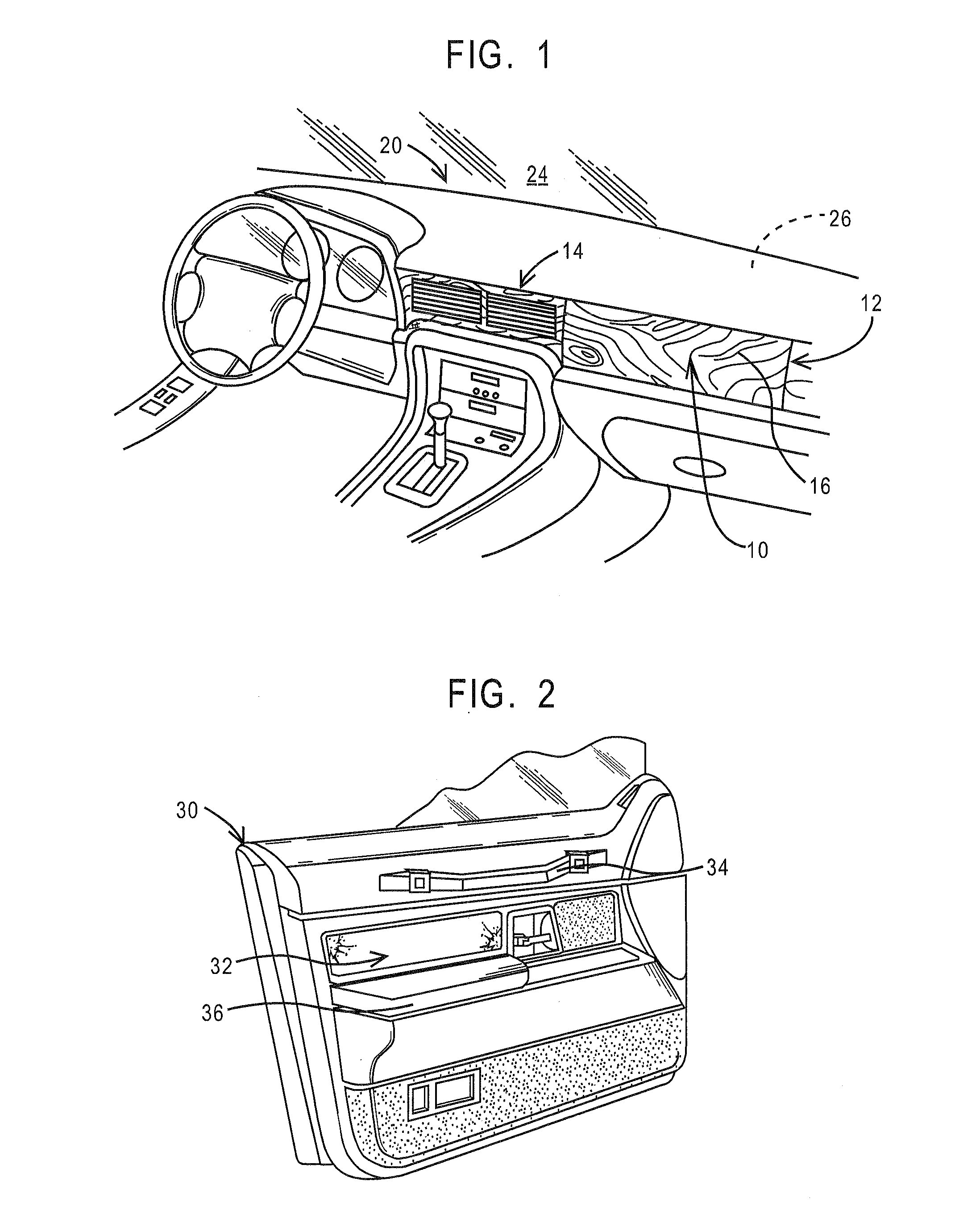

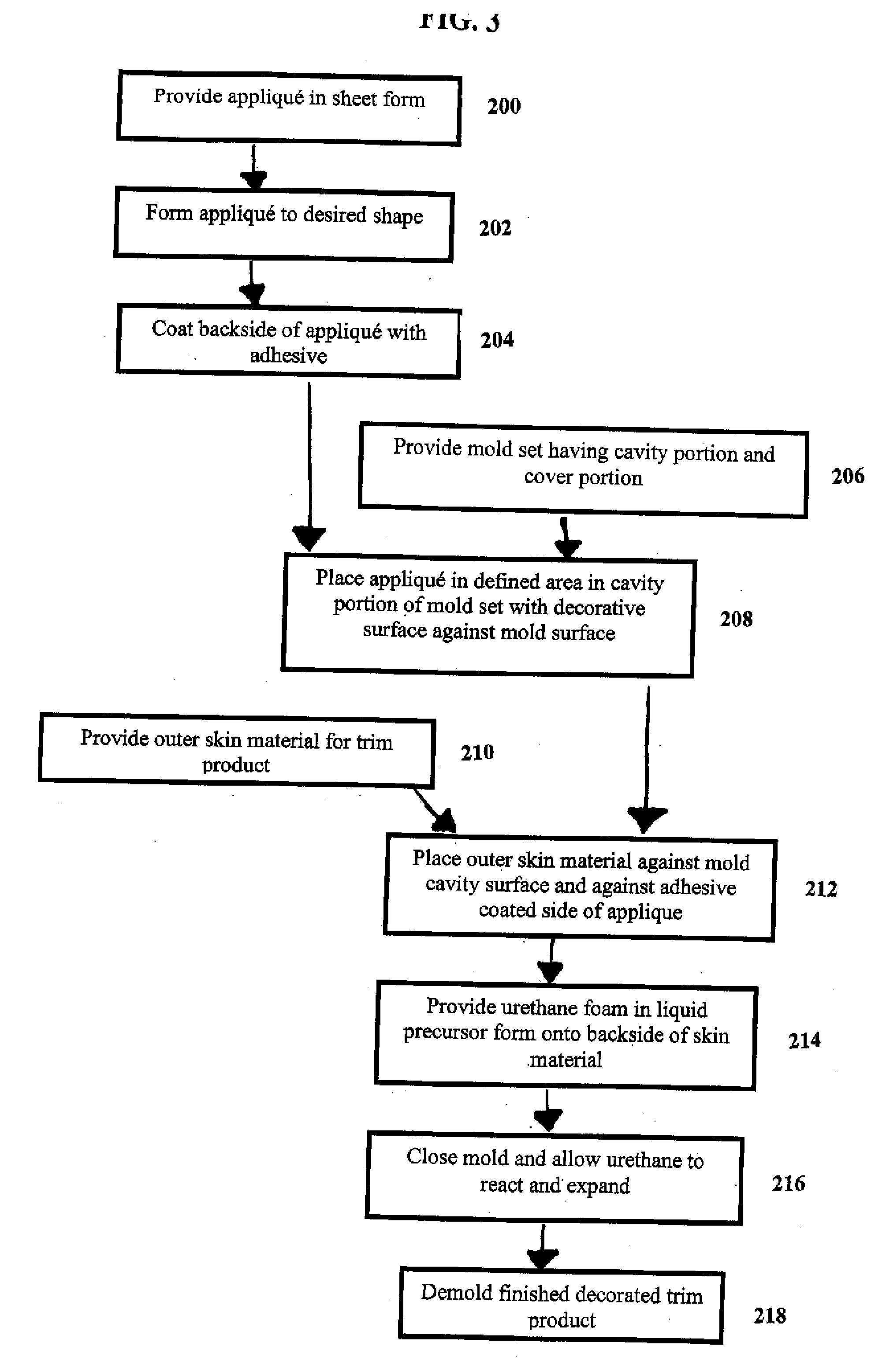

In-Mold Lamination Of A Decorative Product To A Primary Substrate

InactiveUS20070054116A1Effective meanEfficient preparationVehicle componentsThin material handlingAdhesiveEngineering

A decorative trim panel which includes a shell of, preferably, flexible plastic having a front exposed surface and a back surface, a foam layer formed and adhered to the back surface of said shell, and an appliqué having a front surface and a back surface. The appliqué is formed to compliment the shape of a portion of the front exposed surface of the outer shell, and the appliqué further includes an adhesive layer between the back surface and the front surface of the skin, wherein the adhesive is activated during formation of the foam layer to adhere the appliqué′ to the shell. A corresponding method for production of the decorative trim panel is disclosed.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Architectural building products and methods therefore

Owner:MILU GREGORY C

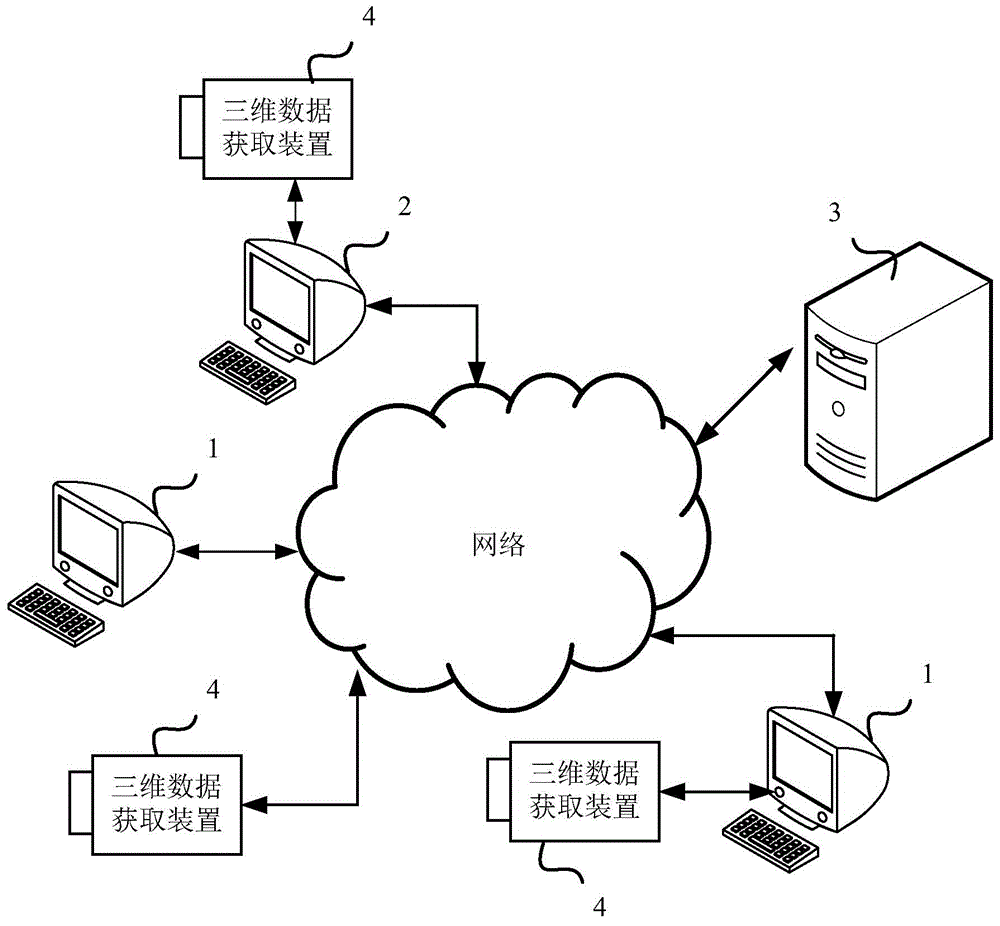

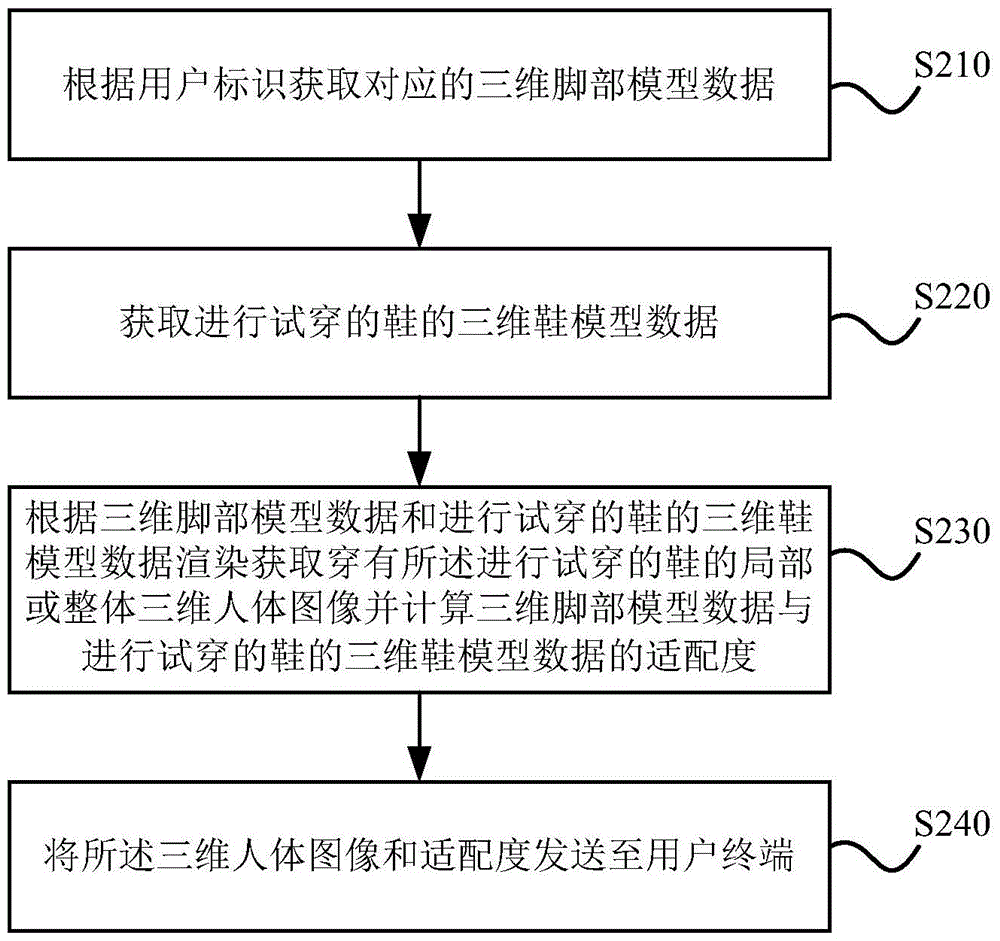

3D virtual shoe fitting method and system

InactiveCN105788002AAchieve integrationAvoid wastingBuying/selling/leasing transactionsImage generationSimulationHigh effectiveness

The invention discloses a 3D virtual shoe fitting method and system which combine foot model of a user with shoe model, which realizes fusion of virtual shoes and actual foot shapes of an actual customer. Through dynamic exhibition of fitting effects, the customer can rapidly browse fitting effects of various shoe patterns within a short time period, and can watch fitting effects of various decorative products under different backgrounds. The method and system can provide corresponding suggestions and recommendations to customers, help customers to select satisfying shoes, and realize shoe selection in an efficient manner. Therefore, the method and system can prevent waste of logistic resources and time waste caused by goods return and exchanging, thus improving user experience of network shoe shopping.

Owner:HUNAN VISUALTOURING INFORMATION TECH CO LTD

Colored glazed glass and production method thereof

The invention belongs to the technical field of deep processing of glass, in particular to colored glazed glass and a production method thereof. The colored glazed glass is prepared by the following method: cleaning a glass substrate, then drying, roll-coating a layer of high-temperature inorganic glass glaze or screen-printing the glass glaze on the surface of the glass, and they drying; and further heating the glass to a softening point, and then slowly reducing the temperature for annealing, thereby preparing a finished product. The color glazed glass produced by the method does not contain volatile harmful substances and can be any color and translucent or opaque; and the secondary processing can be carried out, and the glass has no deformation or color change, thereby being an environment-friendly high-grade glass decorative product which can meet the needs of customers to the maximum extent; in addition, the glass substrate can be any dimension, and the maximum dimension of the glass which can be produced is 1.83 multiplied by 2.44M.

Owner:ZHENGZHOU HENGHAO GLASS TECH

Architectural building products and methods therefore

Owner:MILU GREGORY C

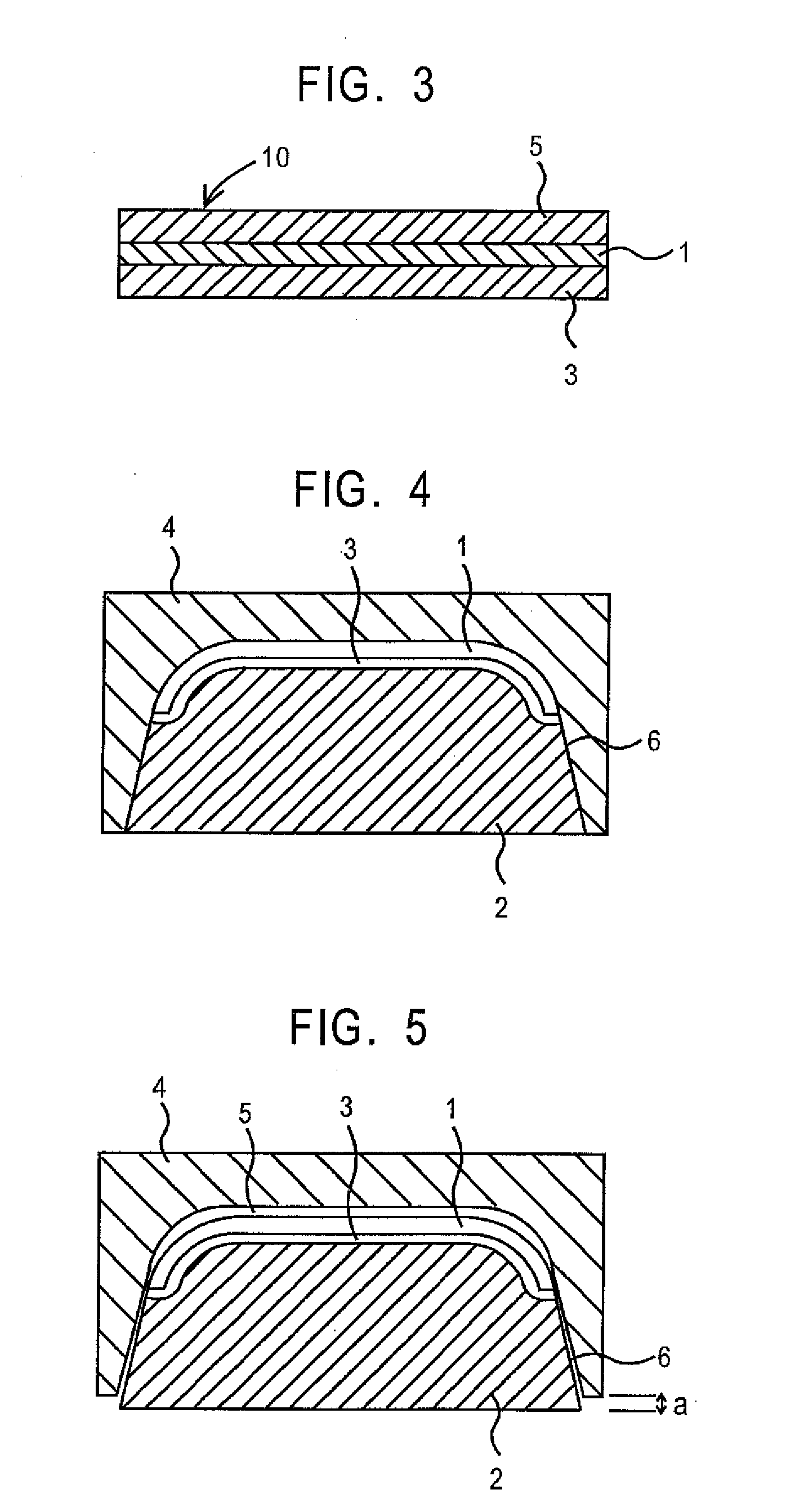

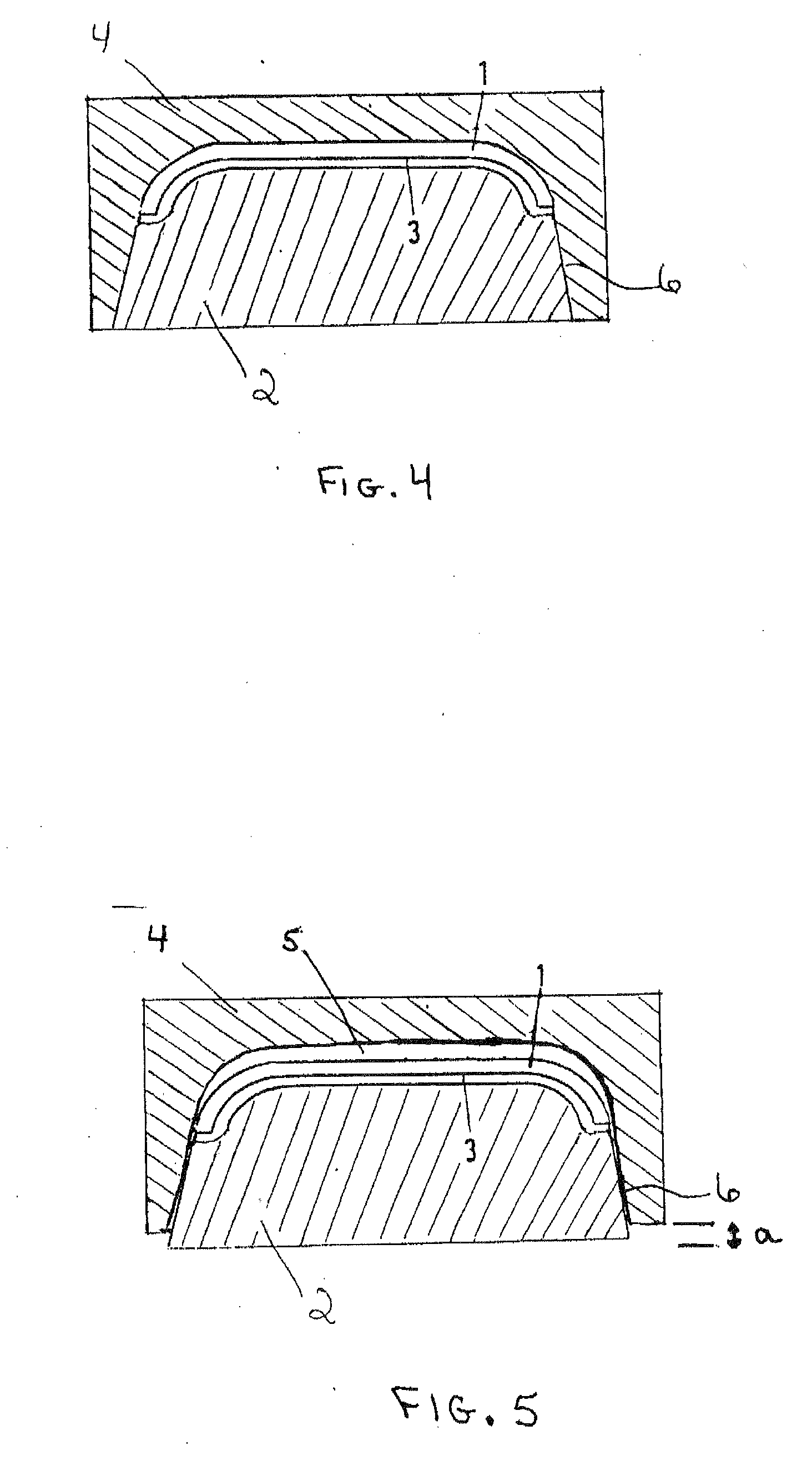

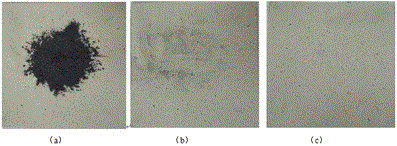

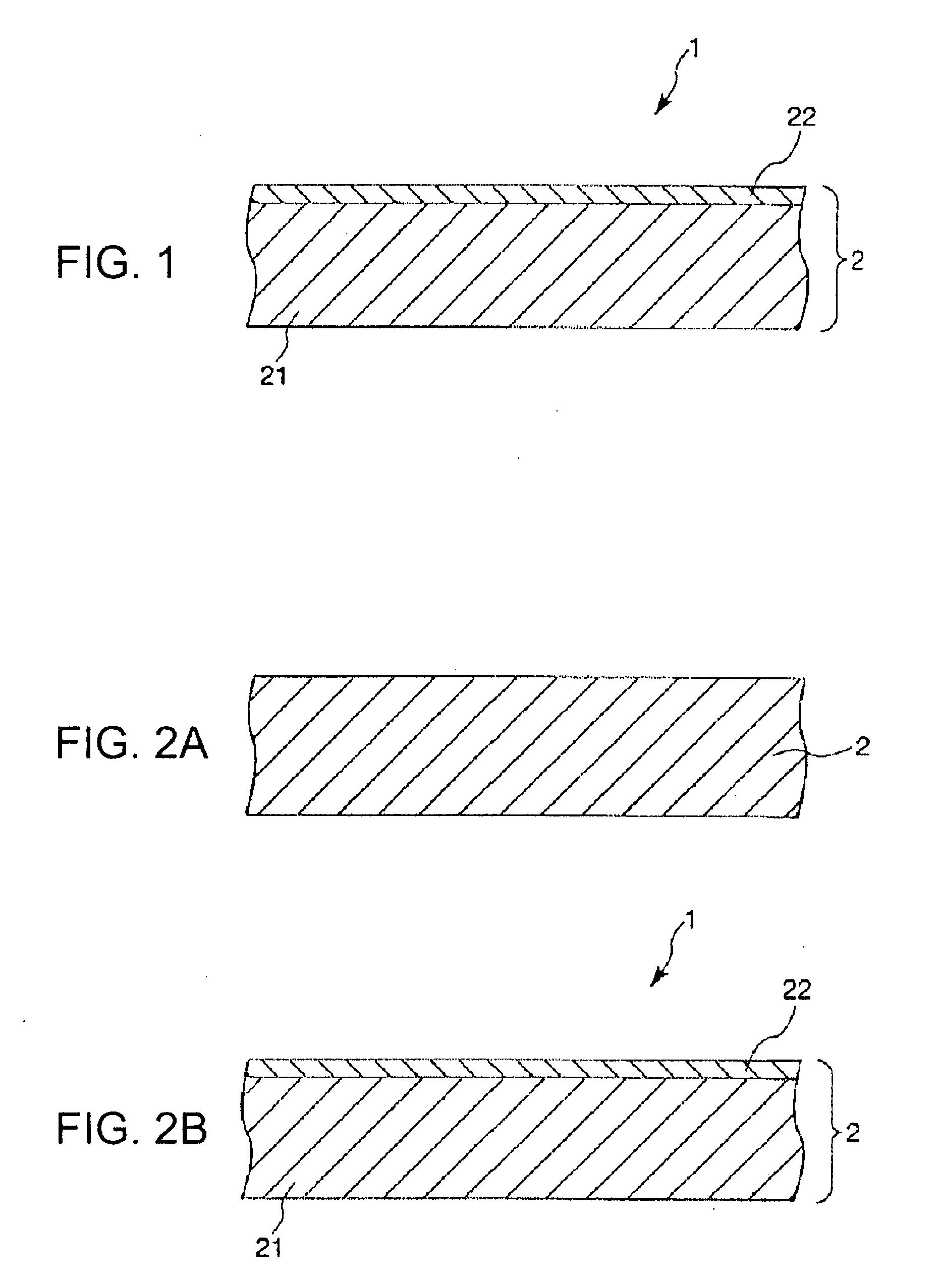

Waterproof self-cleaning GRC (glass fiber reinforced concrete) product and preparation method thereof

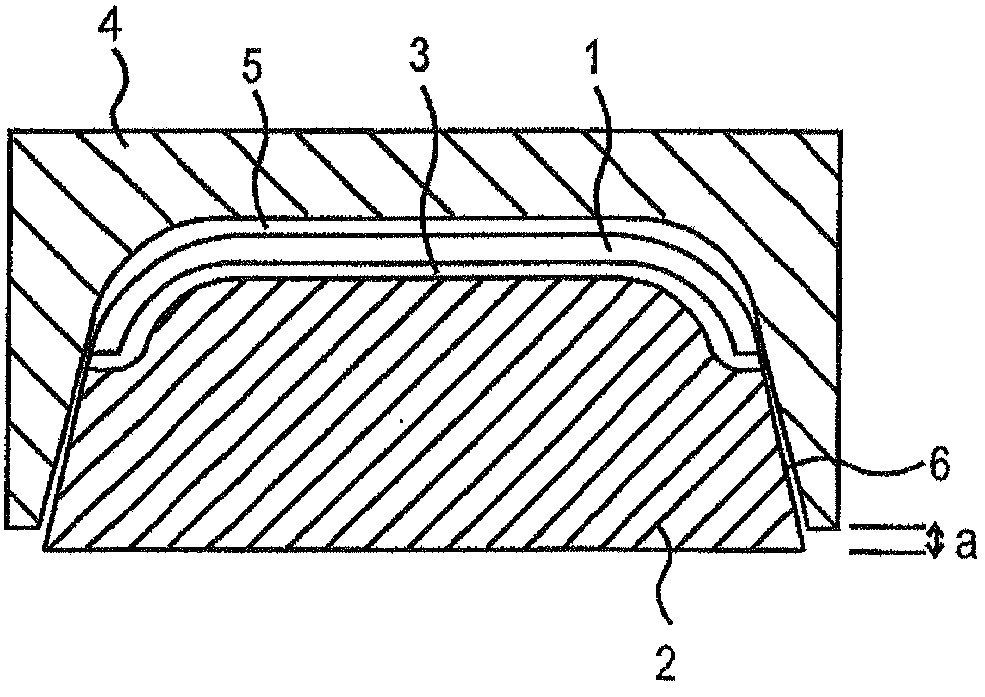

The invention relates to a building external wall decorative product, in particular to a waterproof self-cleaning GRC (glass fiber reinforced concrete) product.The waterproof self-cleaning GRC product comprises a self-cleaning coating (1), a GRC internally-doped waterproof decoration finish layer (2) and a GRC structural layer (3).The waterproof self-cleaning GRC product has the advantages that a hydrophobic protective agent is added into a GRC finish material and is distributed in voids produced after cement hydration reaction, so that moisture entering is prevented effectively; since the finish layer is applied with the contamination-resistant self-cleaning coating based on a waterborne inorganic binder, GRC has the waterproof, contamination-resistant and self-cleaning functions, the organic coating is prevented from being decomposed by a photocatalyst, and service life of the GRC is prolonged; the waterproof self-cleaning GRC product is simple in technology and high in economic and environmental benefits, thereby achieving high added-value resource utilization.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

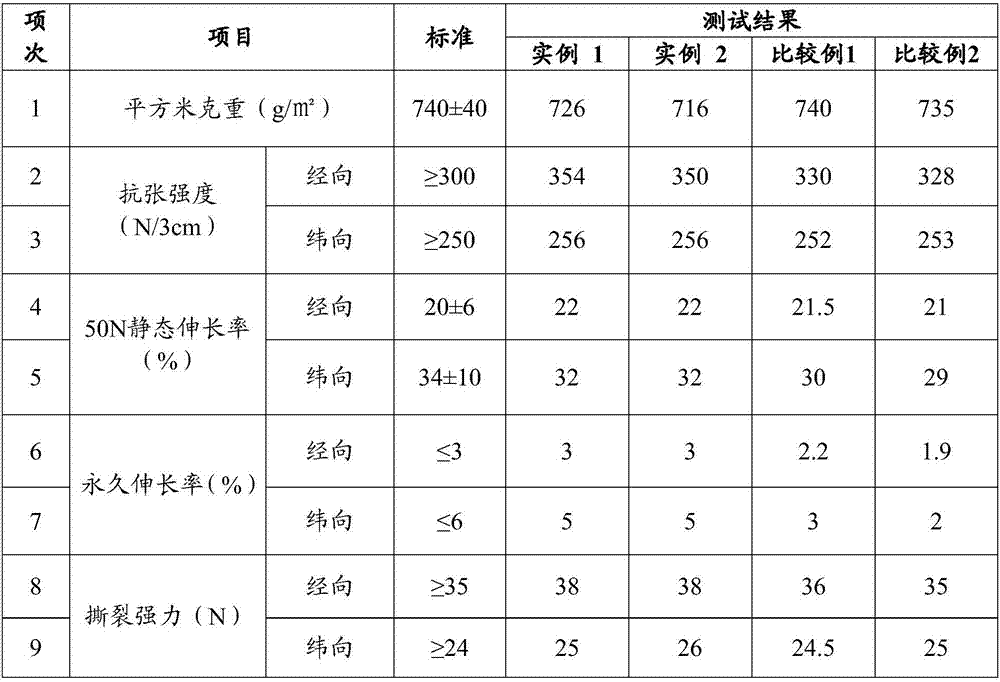

Artificial leather treating agent, polyvinyl chloride artificial leather, preparation method and application thereof

InactiveCN107011788ASolve dim lightGood low temperature bending performancePolyurea/polyurethane coatingsTextiles and paperMedicinePolyvinyl chloride

The invention relates to the field of auto interior decoration and in particular relates to an artificial leather treating agent, polyvinyl chloride artificial leather, a preparation method and an application thereof. According to the artificial leather treating agent, acrylic acid modified waterborne polyurethane per 100 parts by weight contains 5-10 parts by weight of an auxiliary agent, wherein the auxiliary agent comprises the following components in parts by weight: 3-8 parts of a curing agent, 0.01-0.2 part of a defoamer, 0.5-1.5 parts of a flatting agent and 8-15 parts of a feeling agent. The viscosity of the artificial leather treating agent is that the time of the artificial leather treating agent flowing out through a bottom hole of a #3 Ford cup is 30-40s. The artificial leather treating agent is coated to the surface of a base layer to form a treatment layer, wherein the coating amount is 45-70g / m<2>; and a semiproduct forming the treatment layer is foamed and knurled to obtain the polyvinyl chloride artificial leather. The polyvinyl chloride artificial leather applied to an automobile interior decorative material has the characteristic of reducing the frictional noise and meets the requirement of frictional noise of an interior decorative product.

Owner:BAIC GRP ORV CO LTD

Decorative product and timepiece

InactiveUS20070217293A1High hardnessAttractive appearanceSolid state diffusion coatingClockwork casesNitrogenEngineering

A decorative product having a base member composed of primarily an Fe—Cr alloy, and an austenite layer that is austenitized by adding nitrogen atoms near the surface of the base member.

Owner:SEIKO EPSON CORP

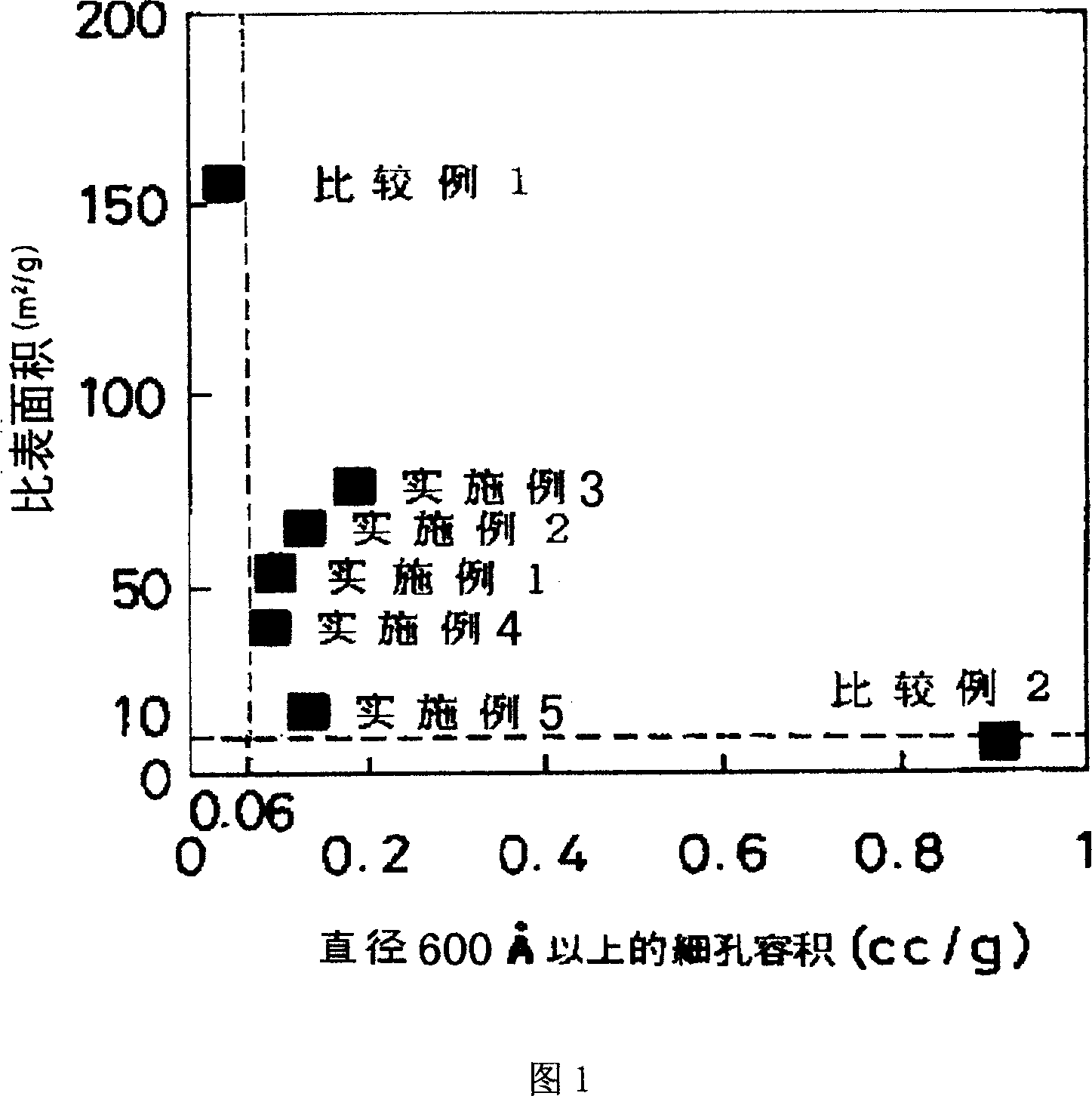

Architecture decorative product capable of regulating indoor air humidity and its preparation method

InactiveCN101007742AHas adsorption capacityAvoid condensationCeramicwareIndoor air qualityHazardous substance

The invention discloses a architectural decoration product of adjusting indoor air humidity, which is characterized by the following: possessing pore structure with specific surface area at 10-900m2 / g; setting pore bulk accumulation greater-than 0.06ml / g of diameter greater-than 600; setting the product possess adsorption capacity through inner eyelet of capillary force; The preparing method including the following steps: bruising; balling; prilling; modeling; glazing; burning with low temperature; setting glazing quantity at 100-150g / m2 and burnt temperature below 1000 deg.c.

Owner:ICOT GUANGDONG CERAMICS

In-mold lamination of decorative products

InactiveUS7981342B2Exceptional depth of imageLuxurious appearanceMouldsSynthetic resin layered productsDecorative laminateMultiple layer

A method of manufacturing decorative plastic composites having a decorative layer, a backing layer and a clear outer layer which provides exceptional “depth of image” is disclosed. Decorative or protective appliqués' having a wide range of decorative patterns may be formed by injection molding a backing layer behind and a clear outer layer on the top surface of a thin foil, film, fabric or veneer. A method is also disclosed for coating the exposed surface of the decorative layer between injection of the backing and outer layers to impart a desired visual effect or repair the surface. Use of multiple layers of decorative film, clear plastic and colored / opaque plastic is also disclosed to provide distinguishing visual effects.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Electronic product outer shell and manufacturing method thereof

InactiveCN103379760AImprove shielding effectPlay a decorative roleCeramic shaping apparatusElectrical apparatus casings/cabinets/drawersAdditional valuesHigh intensity

The invention provides an electronic product outer shell which comprises an amorphous substrate and ceramic patterns embedded in the substrate. The invention further provides a manufacturing method for the electronic product outer shell. According to the electronic product outer shell, the ceramic patterns are embedded in a specified portion in amorphous materials, the function of decoration is performed, and the shielding of signals by the outer shell made of the amorphous materials can be further improved. Further, due to the fact that ceramic is a high-end decorative product and is brittle and fragile, the ceramic is mixed with the amorphous materials, the advantages of both the ceramic and the amorphous materials can be achieved, and additional value of the overall product is improved.

Owner:BYD CO LTD

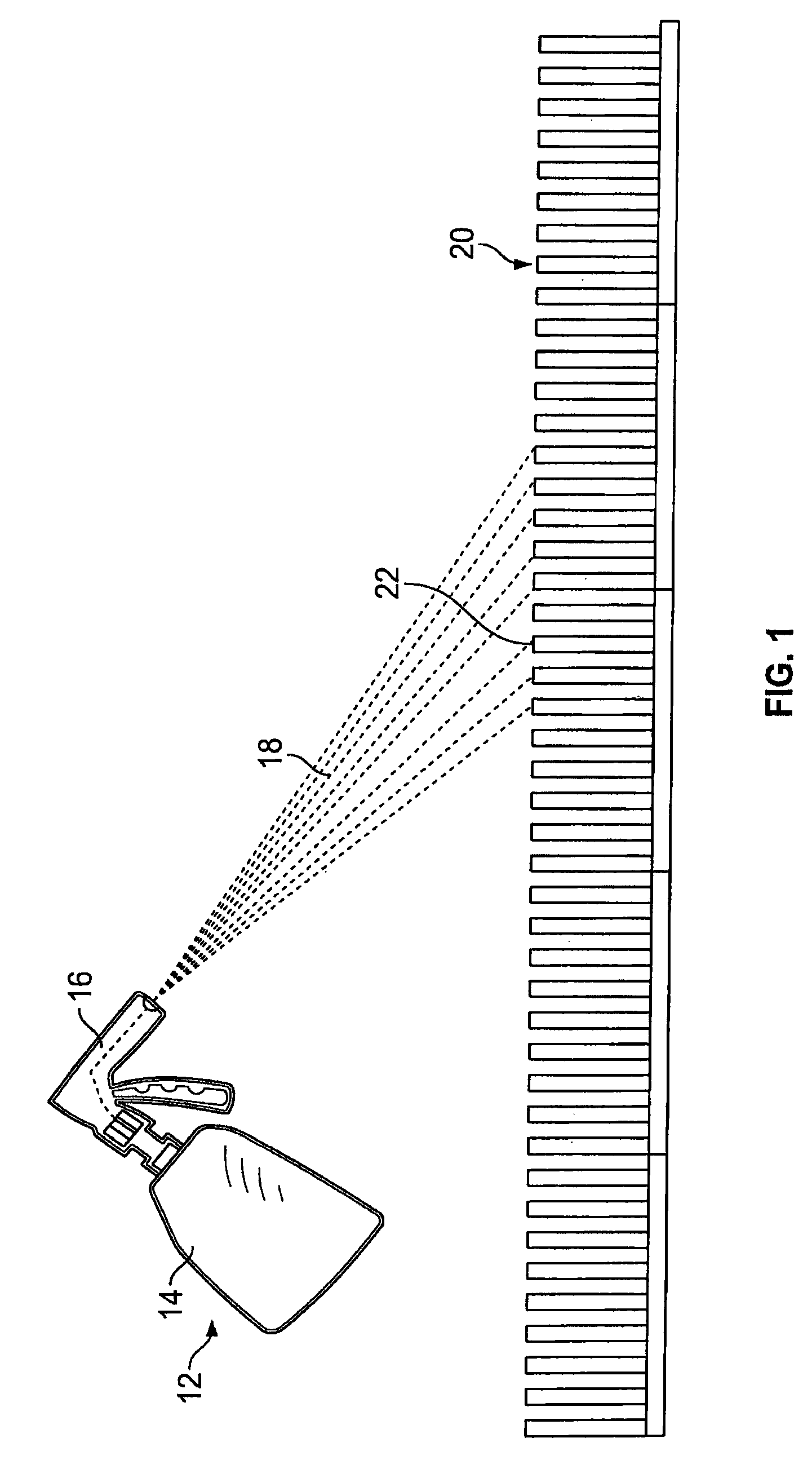

Carpet decor and setting solution compositions

Compositions, methods, apparatuses, kits, and combinations are described for permanently or temporarily re-designing, decorating, and / or re-coloring a surface. The compositions useful in the present disclosure include a décor product that is formulated to be applied and affixed to a surface. If desired, the décor product may be substantially removed from the surface before being affixed thereto. If a user desires to remove the décor product, the décor product is formulated to be removed by a number of methods including, for example, vacuuming, wet extraction, chemical application, and the like. If the user desires to affix the décor product to the surface in a permanent or semi-permanent manner, the décor product may be affixed to the surface by applying energy thereto in the form of, for example, heat, pressure, emitted waves, an emitted electrical field, a magnetic field, and / or a chemical. The décor product may also be utilized in the form of a kit or in conjunction with a design device, such as a stencil, to control the application of the décor product to create, for example, a pattern on the surface.

Owner:SC JOHNSON & SON INC

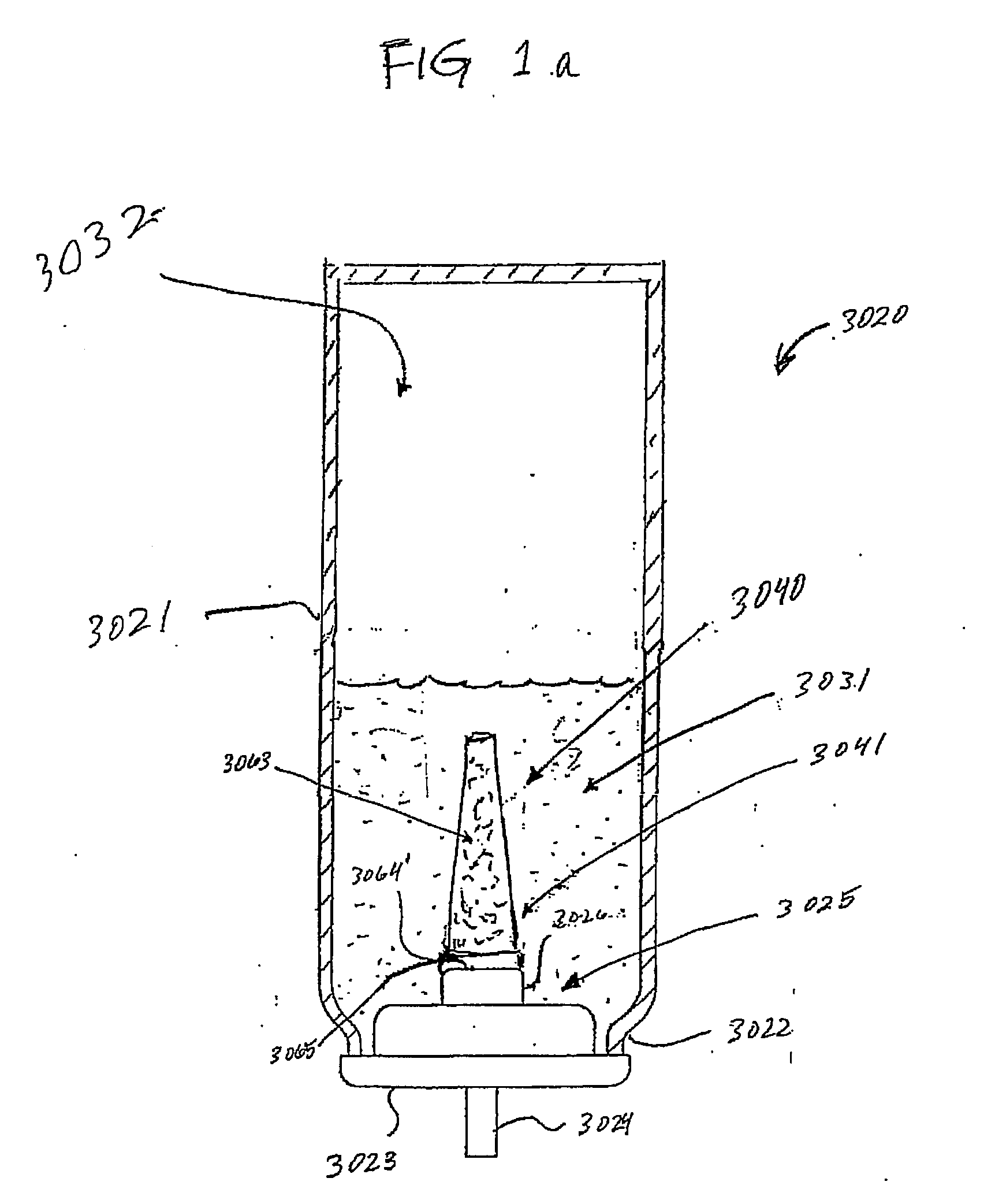

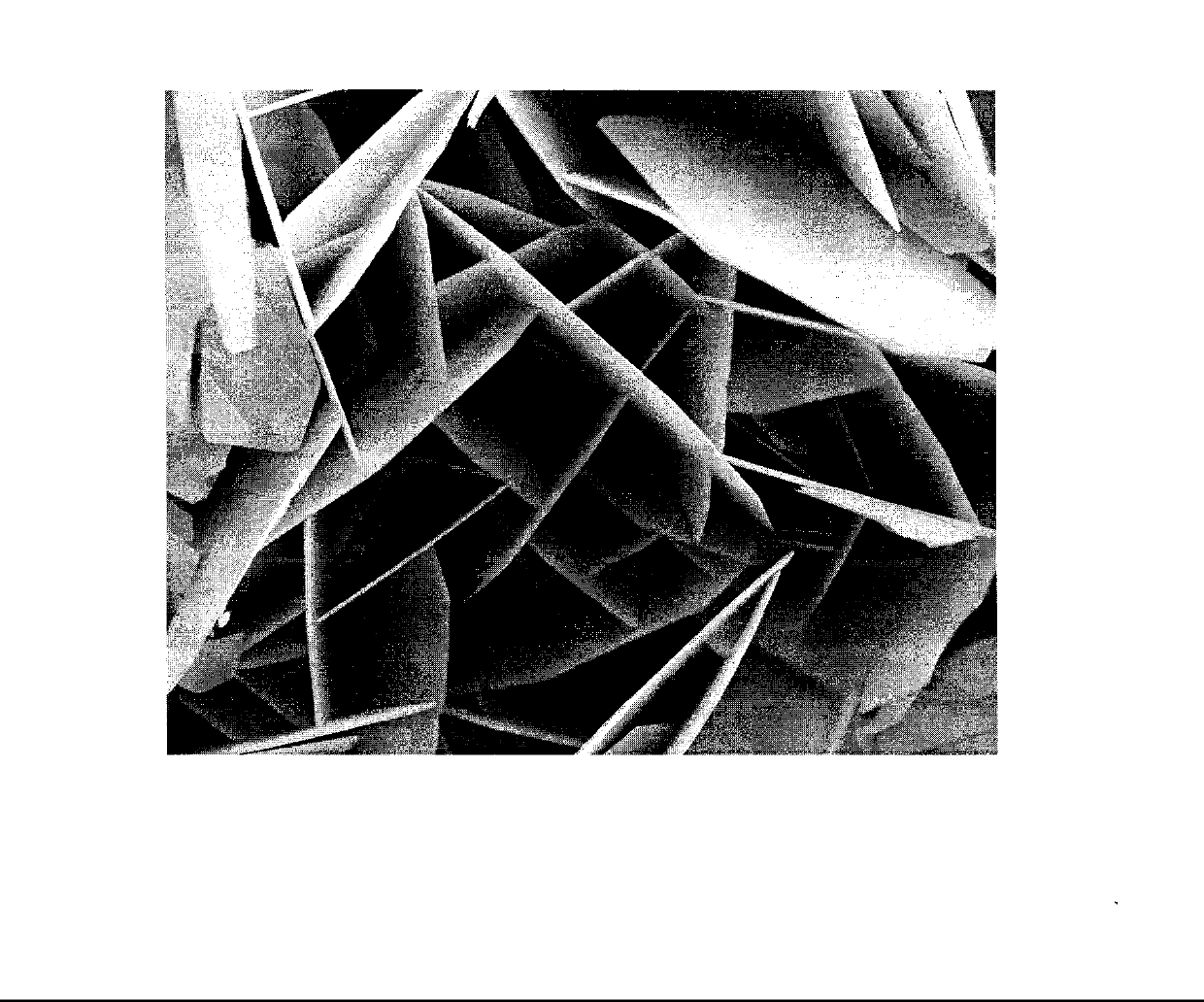

Preparation method of laminar pearl bismuth oxychloride

InactiveCN103130275AIncrease brightnessIncrease coverageBismuth compoundsBuffering agentInorganic pigments

The invention provides a preparation method of laminar pearl bismuth oxychloride. The preparation method comprises the following steps: controlling nucleation and growth processes of a bismuth oxychloride crystal seed through the synergy of an anionic surfactant, a non-ionic surfactant and a buffering agent, and finally getting the bismuth oxychloride, wherein the microscopic appearance of the bismuth oxychloride is of a honeycomb structure constituted by three-dimensional intersection of single-layer slices or a multi-layer thin plate structure formed by parallel overlapping. The product obtained through the method has good brightness, bright effect and covering force, and owns broad market prospects in the fields of coatings, inorganic pigments, high-quality cosmetics, pearl decorative products, optoelectronic functional materials and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

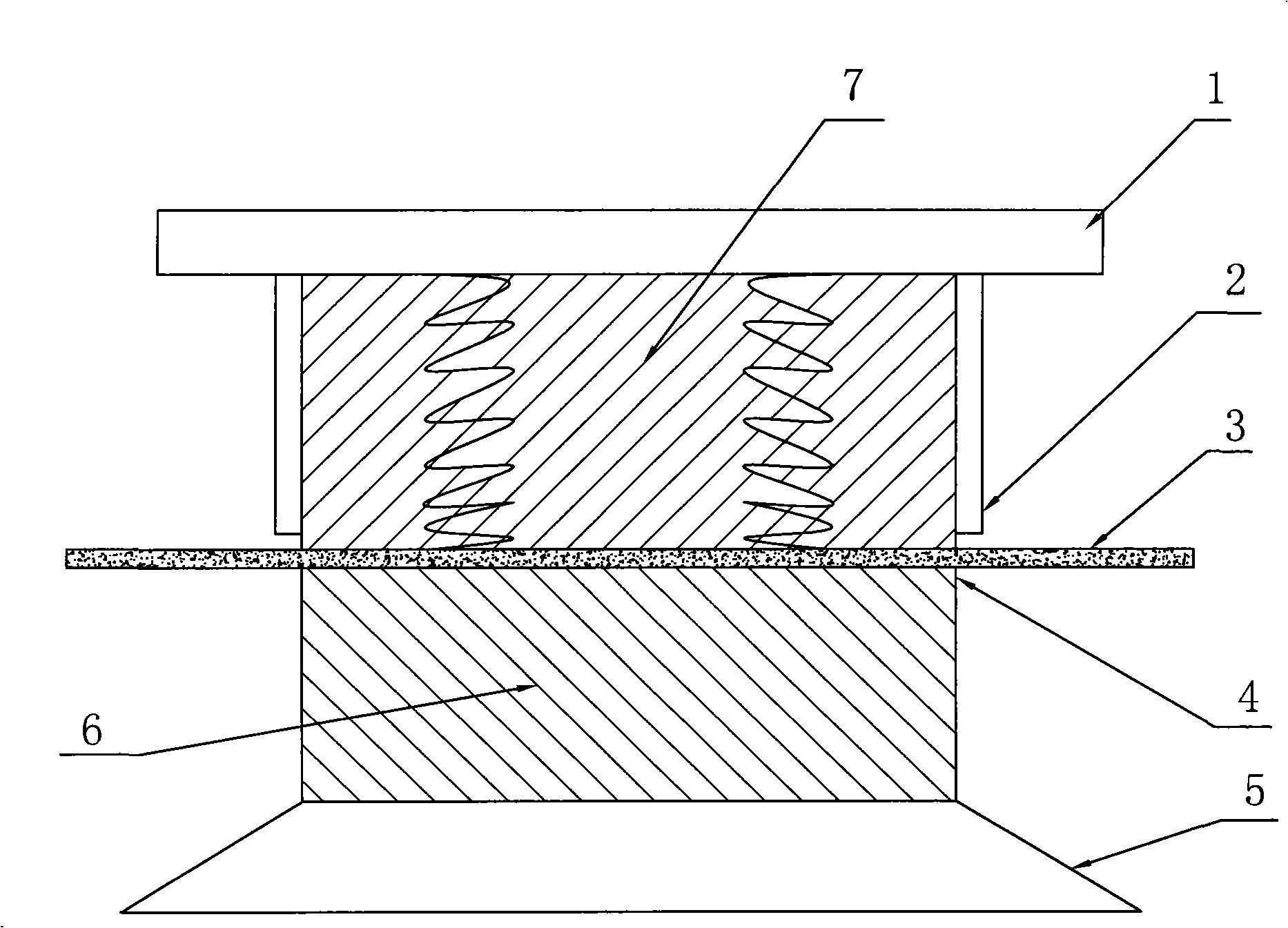

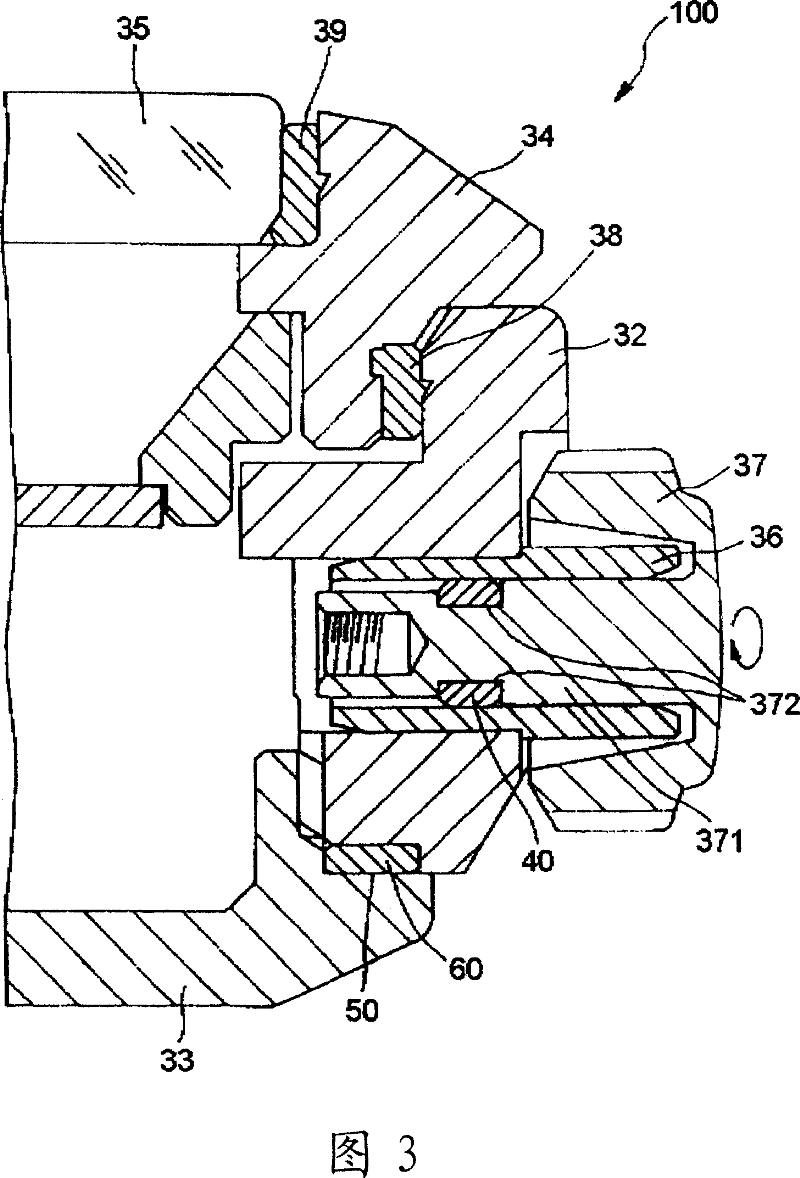

Process method for punching inside of automobile inner decorative mould

The invention provides a process method for punching the inside of an automobile inner decorative mould. The inside of a compression moulding mould is provided with a cavity punching device for an automobile inner decorative, and the outer edge of the compression moulding mould is provided with a floating type shear trimming device. The moulding production process flows comprise the following steps: (1) heating base materials of automobile inner decorative products to soften the base materials; (2) compounding non-woven fabrics on the softened base materials; and (3) arranging the compression moulding mould on a press, placing the base materials compounded with the non-woven fabrics on a working plane of the compression moulding mould, starting the mould to complete forming, punching, cavity punching and trimming of the automobile inner decorative for one time, completing mould pressing of the automobile inner decorative, and directly entering the assembly working procedure. The process method combines the prior compression moulding, cavity punching and trimming into a set of mould, and realizes completion of the compression moulding, the cavity punching and the trimming for one time to save working procedures, reduce equipment investment and production cost of products, and improve production efficiency.

Owner:DONGFENG VISTEON WUHAN AUTOMOTIVE TRIM SYST

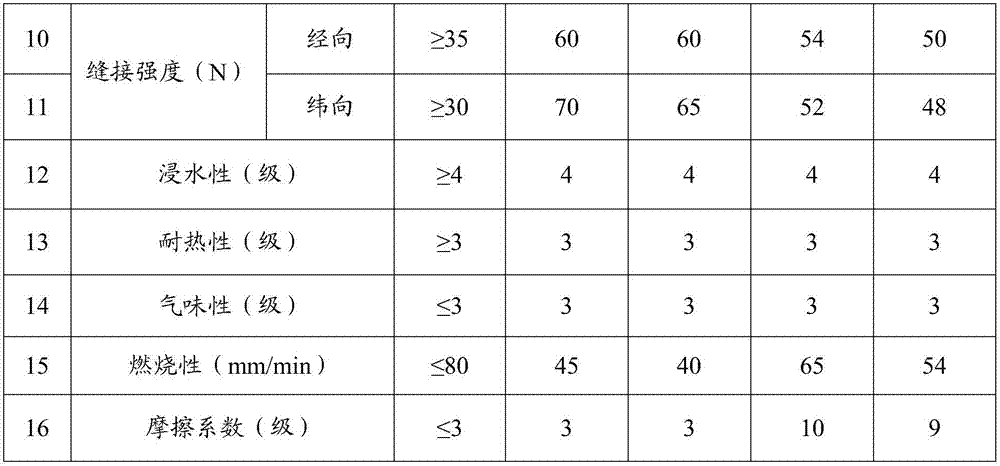

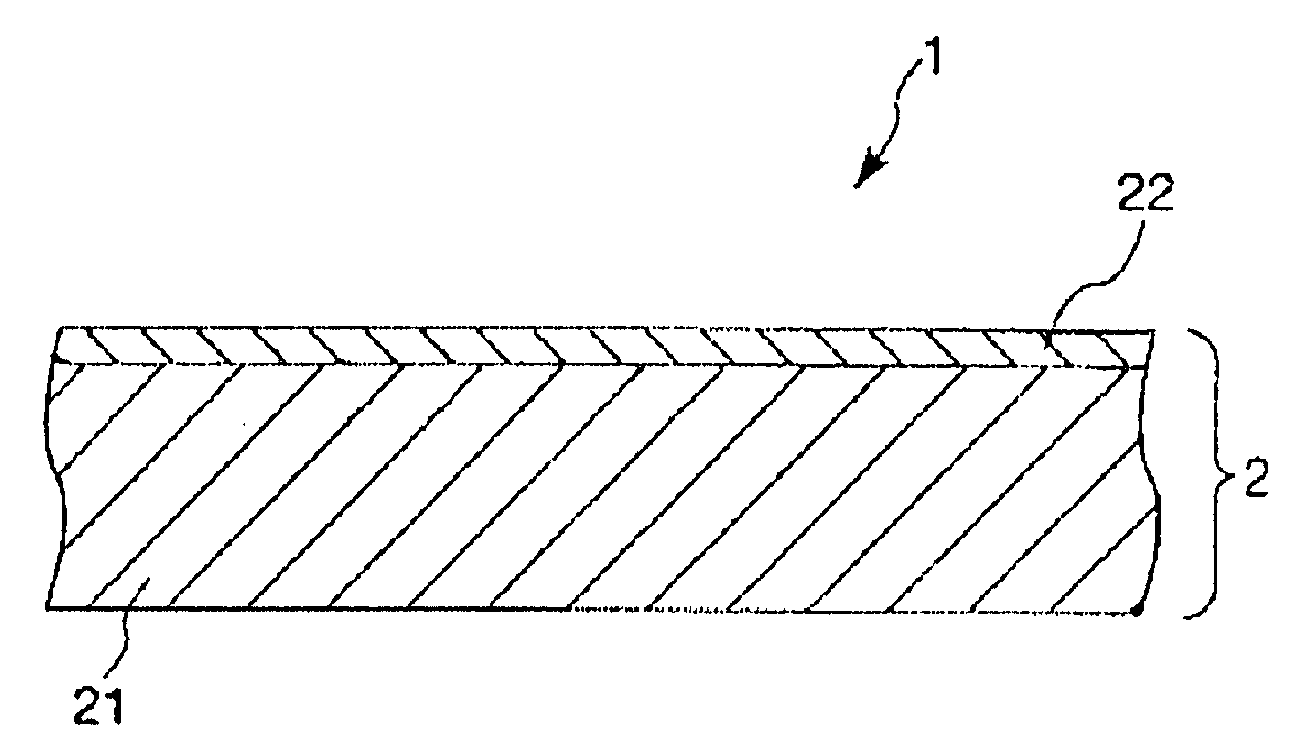

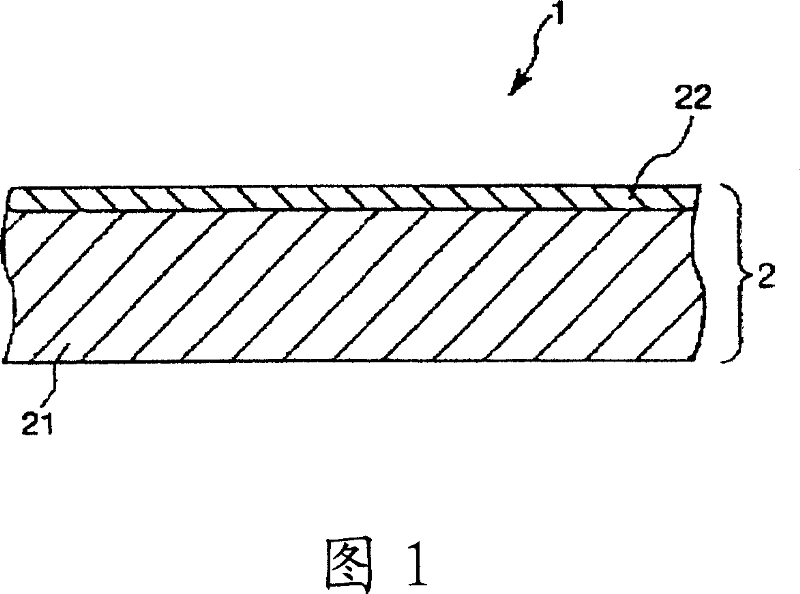

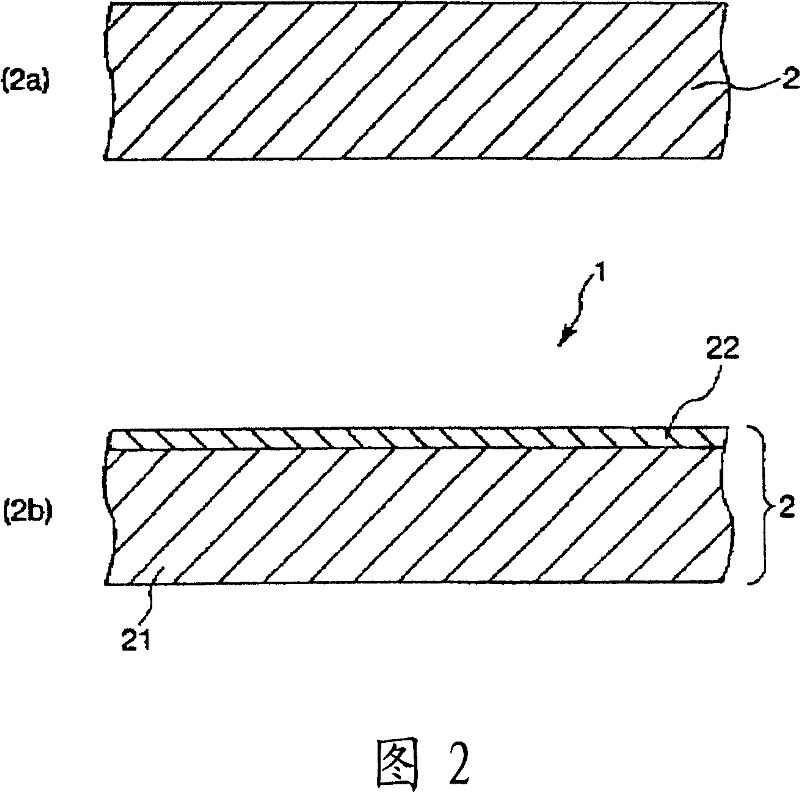

Decorative product and timepiece

InactiveCN101037773AHigh hardnessGood lookingSolid state diffusion coatingFurnace typesNitrogenAlloy

The decoration 1 includes a base material 2 mainly composed of Fe-Cr alloy. The base material 2 includes a base part 21 and an austenite layer 22 which is made into austenite by addition of nitrogen atoms. The thickness of the austenite layer 22 is preferably 5-500 [mu]m. The content of the nitrogen in the austenite layer 22 is preferably 0.3-1.2 wt.%. The content of Ni in the base material 2 is preferably <=0.05 wt.%.

Owner:SEIKO EPSON CORP

Method for making stone-imitation material and products thereof

InactiveCN1371800ANo pollution in the processSimple preparation processGlass fiberMaterials processing

At the normal temp. the unsaturated polyester resin and talcum powder are mixed according to a certain ratio, coloured and coated on the glass fibre fabrics, and can be made into various imitation stone material products of artificial white marble and artificial marble with various patterns. It possesses extensive application range, after it is powered on at night, it can transmit bright light, so that it not only can be used as decorative product, but also can be used as lighting fixture.

Owner:李德元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com