Preparation method of laminar pearl bismuth oxychloride

A bismuth oxychloride and pearlescent technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., to achieve good brightness and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Heat deionized water to a temperature of 80°C, add bismuth nitrate at a rate of 40 g / L, add concentrated hydrochloric acid with a mass fraction of 37% at a rate of 80 ml / L, stir and dissolve to obtain a bismuth salt solution;

[0016] Heat deionized water to a temperature of 90°C, add buffer ammonium chloride at 1 g / L, add nonionic surfactant polyethylene glycol with a molecular weight of 200 at 0.25 ml / L, and add anionic surface active agent at 0.1 g / L The active agent sodium dodecylbenzenesulfonate is stirred and dissolved, and the pH is adjusted to be less than 2 with hydrochloric acid and ammonia water to obtain a hydrolyzate;

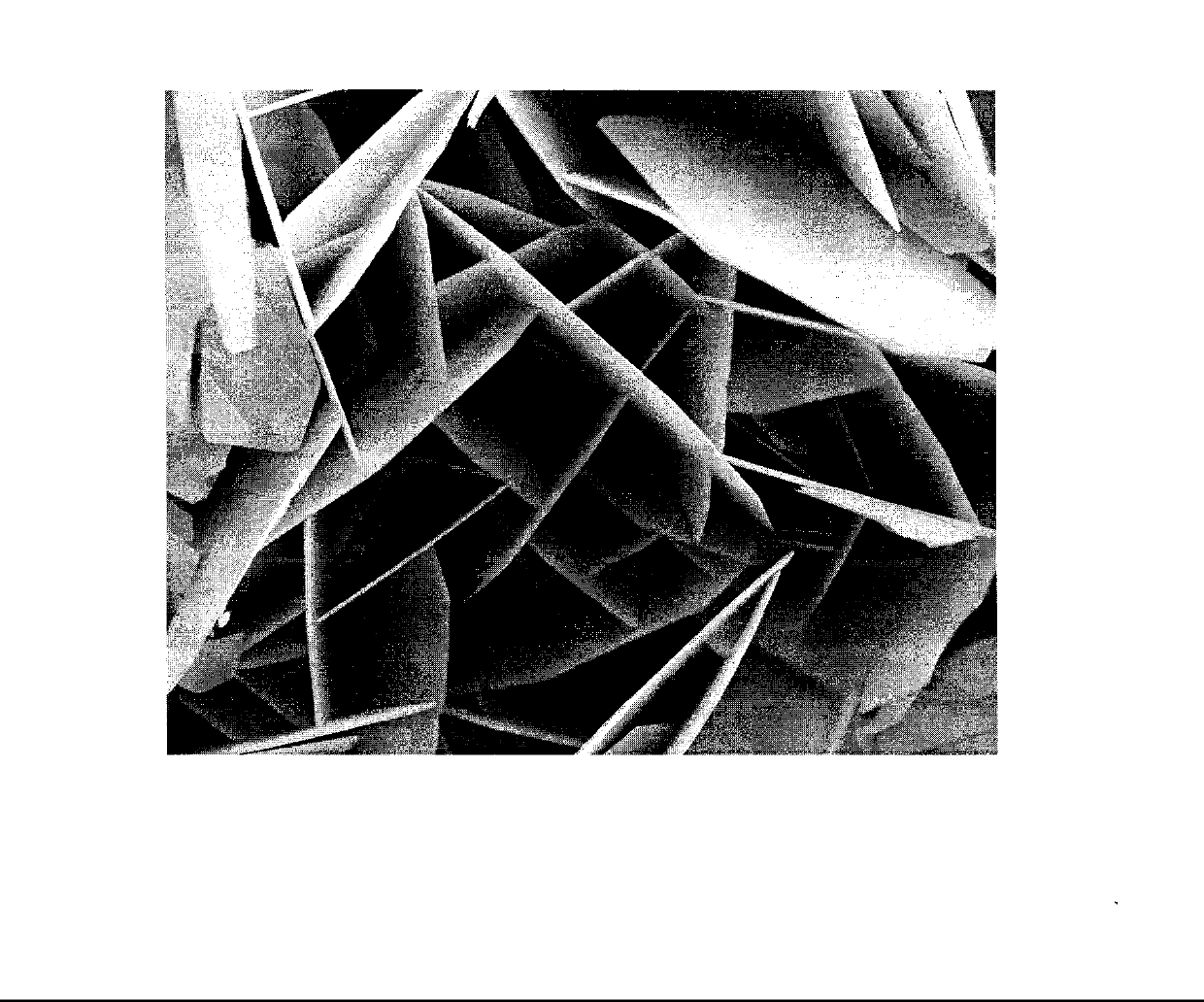

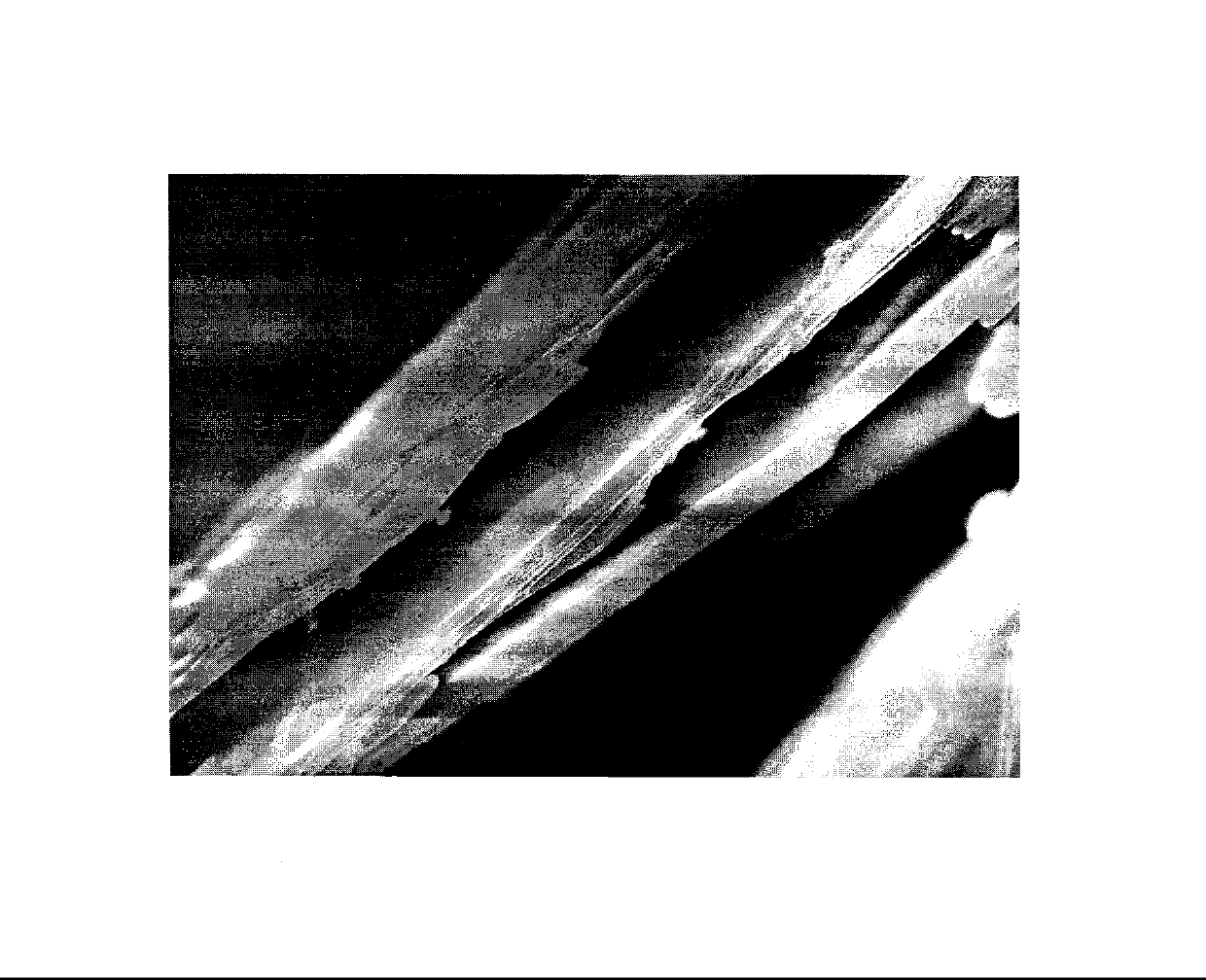

[0017] Control the temperature of the hydrolyzed solution at 85°C, add the bismuth salt solution to the hydrolyzed solution at a volume ratio of 1:5, continue to insulate and stir for 1 hour, remove the supernatant, wash the precipitate with distilled water, and obtain a single-layer flake three-dimensional cross composition after drying The...

Embodiment 2

[0019] Heat deionized water to a temperature of 80°C, add bismuth nitrate at a rate of 60 g / L, add concentrated hydrochloric acid with a mass fraction of 37% at a rate of 100 ml / L, stir and dissolve to obtain a bismuth salt solution;

[0020] Heat deionized water to a temperature of 90°C, add buffer ammonium chloride at 2 g / L, add nonionic surfactant polyethylene glycol with a molecular weight of 300 at 0.5 ml / L, and add anionic surface active agent at 0.2 g / L The active agent sodium dodecylbenzenesulfonate is stirred and dissolved, and the pH is adjusted to be less than 2 with hydrochloric acid and ammonia water to obtain a hydrolyzate;

[0021] Control the temperature of the hydrolyzed solution at 95°C, add the bismuth salt solution to the hydrolyzed solution at a volume ratio of 1:10, continue to insulate and stir for 1 hour, remove the supernatant, wash the precipitate with distilled water, and obtain a single-layer flake three-dimensional cross composition after drying Th...

Embodiment 3

[0023] Heat deionized water to a temperature of 80°C, add bismuth nitrate at 50 g / L, add concentrated hydrochloric acid with a mass fraction of 37% at 90 ml / L, stir and dissolve to obtain a bismuth salt solution;

[0024] Heat deionized water to a temperature of 90°C, add buffer ammonium chloride at 1.5 g / L, add nonionic surfactant polyethylene glycol with a molecular weight of 400 at 0.4 ml / L, and add anion at 0.15 g / L Surfactant sodium dodecylbenzene sulfonate is stirred and dissolved, and the pH is adjusted to be less than 2 with hydrochloric acid and ammonia water to obtain a hydrolyzate;

[0025] Control the temperature of the hydrolyzate at 90°C, add the bismuth salt solution to the hydrolyzate at a volume ratio of 1:7, continue to insulate and stir for 1 hour, remove the supernatant, wash the precipitate with distilled water, and obtain a single-layer flake three-dimensional cross composition after drying The pearlescent bismuth oxychloride with a honeycomb structure ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com