Waterproof self-cleaning GRC (glass fiber reinforced concrete) product and preparation method thereof

A self-cleaning, water-permeable technology, applied to ceramic products, household utensils, and other household utensils, can solve the problems of reducing the service life of protective coatings, damaging the appearance of GRC, and not easily receiving light, so as to improve photocatalytic efficiency and increase Durability and aesthetics, the effect of preventing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

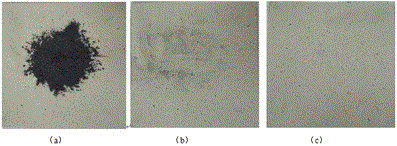

Image

Examples

Embodiment 1

[0056] (1) Preparation of waterproof decorative surface layer mixed with GRC

[0057] 20kg of cement, 3kg of siloxane, 60kg of sand, 2kg of PVA fiber, 5kg of powdered pigment, 0.5kg of redispersible latex powder, 0.2kg of water reducing agent naphthalenesulfonate formaldehyde condensate, 0.2kg of antifreeze calcium chloride, Mix 0.1kg of early-strength agent sulfate, 1kg of metakaolin and 8kg of water, mix well, and make a surface layer mortar, use the spray method to prepare a GRC-doped waterproof decorative surface layer, and naturally cure for 10 minutes;

[0058] (2) GRC structural layer composite

[0059]Cement 50kg, water 10kg, quartz sand 25kg, metakaolin 4kg, glass fiber 3kg, PVA fiber 2kg, redispersible latex powder 4kg, water reducing agent naphthalenesulfonate formaldehyde condensate 1kg, antifreeze agent calcium chloride 0.5kg and Mix 0.5kg of early strength agent sulfate, stir evenly to make GRC structural layer slurry, spray it into the prepared GRC internal wat...

Embodiment 2

[0065] (1) Preparation of waterproof decorative surface layer mixed with GRC

[0066] Cement 45kg, epoxy resin 1kg, fine stone 25kg, PU fiber 0.5kg, liquid pigment 0.5kg, polypropylene emulsion 3kg, water reducer sulfonated melamine formaldehyde condensate 1kg, early strength agent nitrite 0.5kg, thickener Mix 0.5kg of hydroxypropyl methylcellulose, 6kg of fly ash and 17kg of water, stir evenly to make a surface layer mortar, use the brushing method to prepare a GRC-doped waterproof decorative surface layer, and naturally cure for 20 minutes;

[0067] (2) GRC structural layer composite

[0068] Cement 23kg, water 18kg, quartz sand 48kg, fly ash 5kg, PP fiber 2kg, PU fiber 1kg, polypropylene emulsion 2kg, water reducer sulfonated melamine formaldehyde condensate 0.5kg, early strength agent nitrite 0.2kg, Thickener hydroxypropyl methylcellulose 0.3kg mixed, stirred evenly to make GRC structural layer slurry, vibrating poured into the prepared GRC waterproof decorative surface l...

Embodiment 3

[0074] (1) Preparation of waterproof decorative surface layer mixed with GRC

[0075] Mix 28kg of cement, 2kg of acrylic polymer, 40kg of glass crumbs, 1kg of PP fiber, 2kg of powdered pigment, 2kg of styrene-acrylic emulsion, 0.5kg of water-reducing agent polycarboxylic acid, 0.3kg of early strength agent triethanolamine, thickener hydroxyl Mix 0.2kg of ethyl cellulose, 4kg of mineral powder and 20kg of water, stir evenly to make a surface layer mortar, use the laying vibration method to prepare a GRC-doped waterproof decorative surface layer, and naturally cure for 40 minutes;

[0076] (2) GRC structural layer composite

[0077] 38kg of cement, 15.5kg of water, 35kg of quartz sand, 10kg of mineral powder, 0.5kg of steel fiber, 0.5kg of styrene-acrylic emulsion, 0.2kg of water reducing agent polycarboxylic acid, 0.2kg of early strength agent triethanolamine, thickener hydroxyethyl Mix 0.1kg of cellulose, stir evenly to make a slurry for the GRC structural layer, spray it int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com