A wet transfer printing process of polyester-cotton blended fabric

A technology of wet transfer printing and polyester-cotton blending, which is applied in the field of printing and dyeing to achieve fine patterns, reduce production costs and environmental protection pressure, and reduce adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

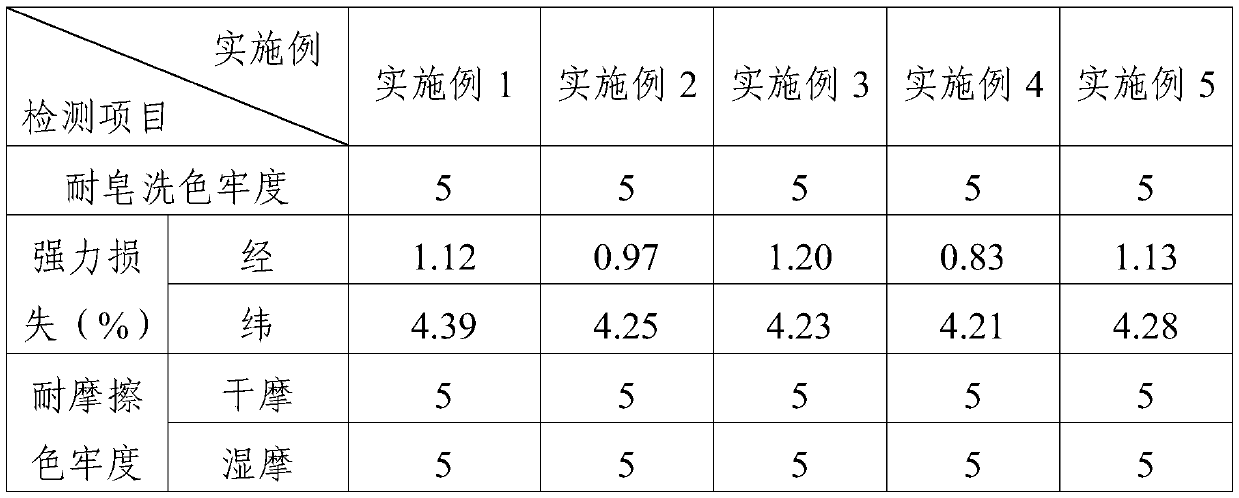

Examples

Embodiment 1

[0028] A wet transfer printing process for polyester-cotton blended fabrics, comprising the following steps:

[0029] (1) 25 parts of hydroxypropyl methylcellulose, 25 parts of sodium alginate and 15 parts of nano-scale SiO 2 Add it into 45 parts of clear water, stir for 25 minutes, and get the modifier. Spread the modifier evenly on the surface of the decal paper with a coating thickness of 0.2 mm. Then put the decal paper into an oven to dry, and control the oven temperature to 60°C. , drying time 50min;

[0030] (2) Apply acrylic acid-styrene copolymer system release agent to the printed paper surface after drying, and the coating surface density of release agent is 5g / m 2 After smearing, the release agent is cured, the curing temperature is 105°C, the curing time is 20s, and finally calendering is carried out;

[0031] (3) printing paper with disperse dyes to make transfer printing paper;

[0032] (4) After evenly spraying lye with a pH of 12 on the polyester-cotton ble...

Embodiment 2

[0035] A wet transfer printing process for polyester-cotton blended fabrics, comprising the following steps:

[0036] (1) 20 parts of hydroxypropyl methylcellulose, 20 parts of sodium alginate and 10 parts of nano-scale SiO 2 Add it into 40 parts of clear water, stir for 20 minutes, and get the modifier. Spread the modifier evenly on the surface of the decal paper with a coating thickness of 0.25mm. Then put the decal paper into an oven to dry, and control the oven temperature to 50°C. , drying time 40min;

[0037] (2) smear acrylic acid-styrene copolymer system release agent to the printed paper surface after drying, the coating surface density of release agent is 3g / m 2 After smearing, the release agent is cured, the curing temperature is 100°C, the curing time is 25s, and finally calendering is carried out;

[0038] (3) printing paper with disperse dyes to make transfer printing paper;

[0039] (4) On the polyester-cotton blended fabric, evenly spray the lye with a pH of...

Embodiment 3

[0042] A wet transfer printing process for polyester-cotton blended fabrics, comprising the following steps:

[0043] (1) 30 parts of hydroxypropyl methylcellulose, 30 parts of sodium alginate and 10 parts of nano-scale SiO 2 Add it into 50 parts of clean water, stir for 40 minutes, and get the modifier. Spread the modifier evenly on the surface of the decal paper with a coating thickness of 0.15 mm. Then put the decal paper into an oven to dry, and control the oven temperature to 70°C. , drying time 60min;

[0044] (2) smear acrylic acid-styrene copolymer system release agent to the decal paper surface after drying, and the coating surface density of release agent is 6g / m 2 After smearing, the release agent is cured, the curing temperature is 110°C, the curing time is 25s, and finally calendering is carried out;

[0045] (3) printing paper with disperse dyes to make transfer printing paper;

[0046] (4) After evenly spraying lye with a pH of 13 on the polyester-cotton blen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com