Jeans frosting apparatus and method

A technology for jeans and whitening, which is applied in textiles and papermaking, fiber treatment, fabric surface trimming, etc. It can solve the problems that cannot meet the requirements, and achieve the effect of increasing layering and naturalness, strong operability, and realistic patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

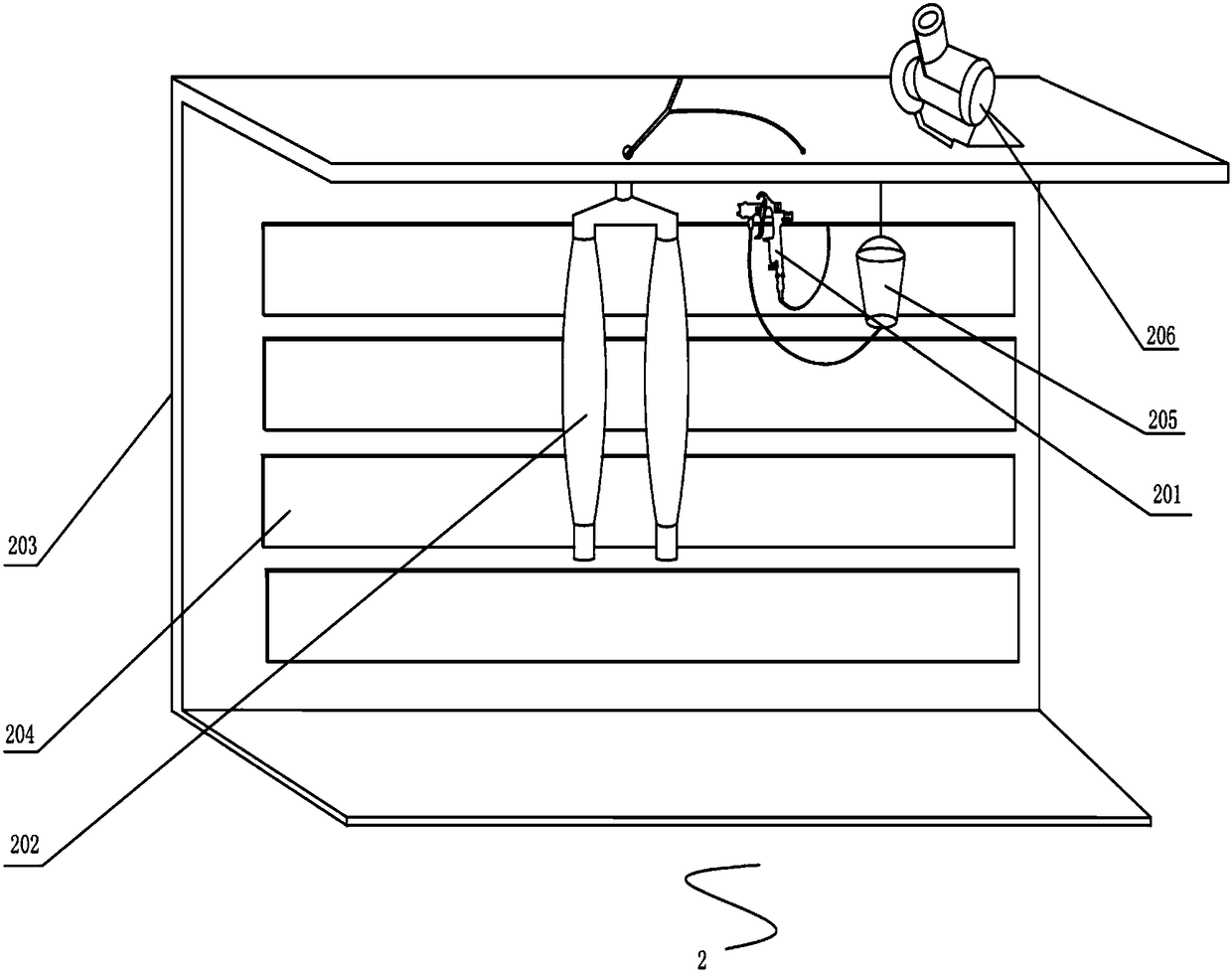

[0032] refer to figure 1 with figure 2 , a device for whitening jeans, comprising a grinding device 1 and a spraying device 2, the grinding device 1 comprising a trouser-shaped soft bag 101, a control pedal 102 and an electric grinder 103, the top of the trouser-shaped soft bag 101 Bearings are provided and rotated through the bearings, so that when grinding is convenient, the front and back of the jeans can be polished by rotating the trouser-shaped soft bag 101; Tighten the straps to prevent air leakage. The shape of the pants-shaped soft bag 101 corresponds to the shape of jeans. The pants-shaped soft bag is connected with high-pressure air through a control valve (not shown in the figure), and the control pedal 102 includes a circuit connection. The air intake ped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com