Preparation method of rubber vulcanization accelerator n-tert-butyl-2-benzothiazole sulfenamide (ns)

A technology of benzothiazole sulfenamide and dibenzothiazole disulfide is applied in the field of preparation of rubber vulcanization accelerators, and can solve the problems of large discharge of organic waste water, low product yield and quality, reduced reaction selectivity and the like, To achieve the effect of reducing the amount of wastewater treatment, less variety of materials, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

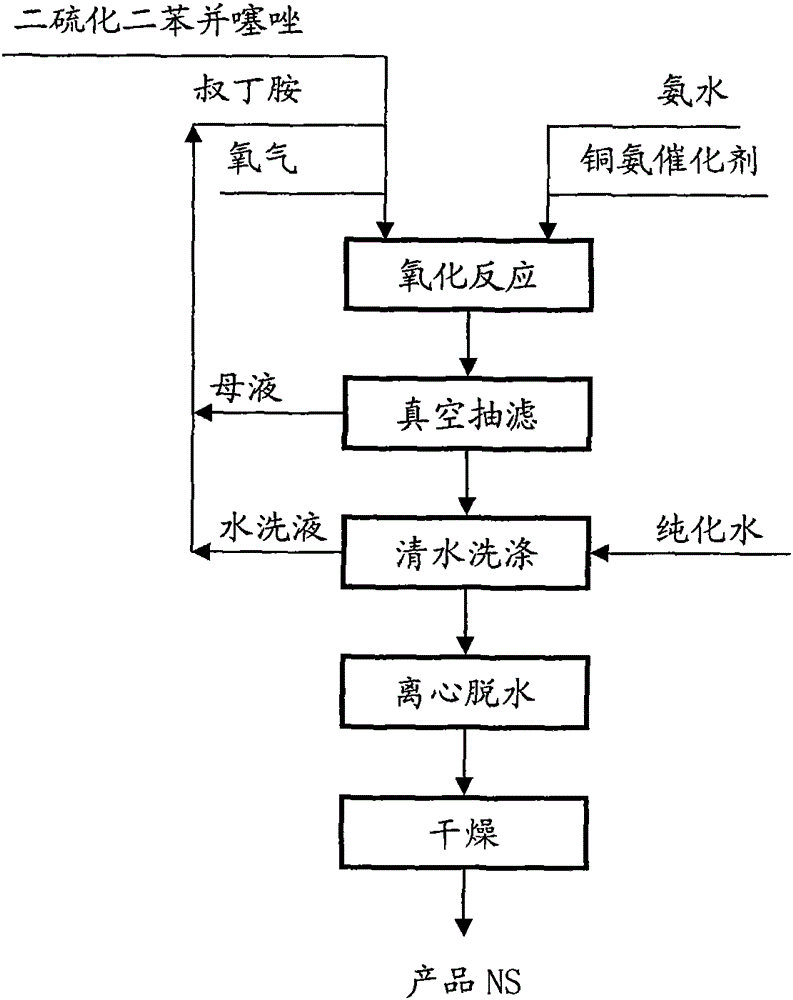

Method used

Image

Examples

Embodiment 1

[0040] Add 35ml of ammonia water in a 1L high-pressure reactor equipped with a temperature and pressure detection device and a permanent magnetic stirrer, and put in the reactant dibenzothiazole disulfide 33.25g (0.1mol), copper ammonia catalyst 0.12g and surfactant under strong stirring TW-20 0.005g, control the temperature to 20°C, feed oxygen to make the pressure 0.4MPa, add 16.09g of tert-butylamine within 2.5h, at this time, the temperature in the kettle rises, control the temperature to 40°C, react for 1.5h, absorb oxygen When it is rare, the reaction reaches the end and the stirring is stopped. The white precipitate is washed with water, dehydrated and dried to obtain the product. Its appearance is off-white. It is determined that the reaction yield is 96.2%. The product obtained after the reaction has an initial melting point of 106.3° C. and a purity of 98.6%.

Embodiment 2

[0042] Add 42ml of ammonia water in a 1L high-pressure reactor equipped with a temperature and pressure detection device and a permanent magnetic stirrer, and put in reactant dibenzothiazole disulfide 33.25g (0.1mol), copper ammonia catalyst 0.18g and surfactant under strong stirring TW-20 0.006g, control the temperature to 16°C, feed oxygen to make the pressure 0.6MPa, add 15.36g of tert-butylamine within 2h, at this time, the temperature in the kettle rises, control the temperature to 38°C, react for 1.5h, oxygen absorption is very When it is small, the reaction will reach the end, so stop stirring. The white precipitate is washed with water, dehydrated and dried to obtain the product. Its appearance is off-white. It is determined that the reaction yield is 95.8%. The product obtained after the reaction has a melting point of 106.8° C. and a purity of 98.9%.

Embodiment 3

[0044] Add 50ml of ammonia water to a 1L high-pressure reactor equipped with a temperature and pressure detection device and a permanent magnetic stirrer, and add 33.25g (0.1mol) of dibenzothiazole disulfide, 0.20g of cuproammonia catalyst and surfactant under strong stirring. TW-20 0.008g, control the temperature to 10°C, feed oxygen to make the pressure 0.5MPa, add 17.55g of tert-butylamine within 3.0h, at this time, the temperature in the kettle rises, control the temperature to 35°C, react for 2h, and absorb oxygen very quickly When it is small, the reaction will reach the end, so stop stirring. The white precipitate is washed with water, dehydrated and dried to obtain the product. Its appearance is white. It is determined that the reaction yield is 97.4%. The product obtained after the reaction has a melting point of 107.2° C. and a purity of 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com