Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about "Stereotype printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

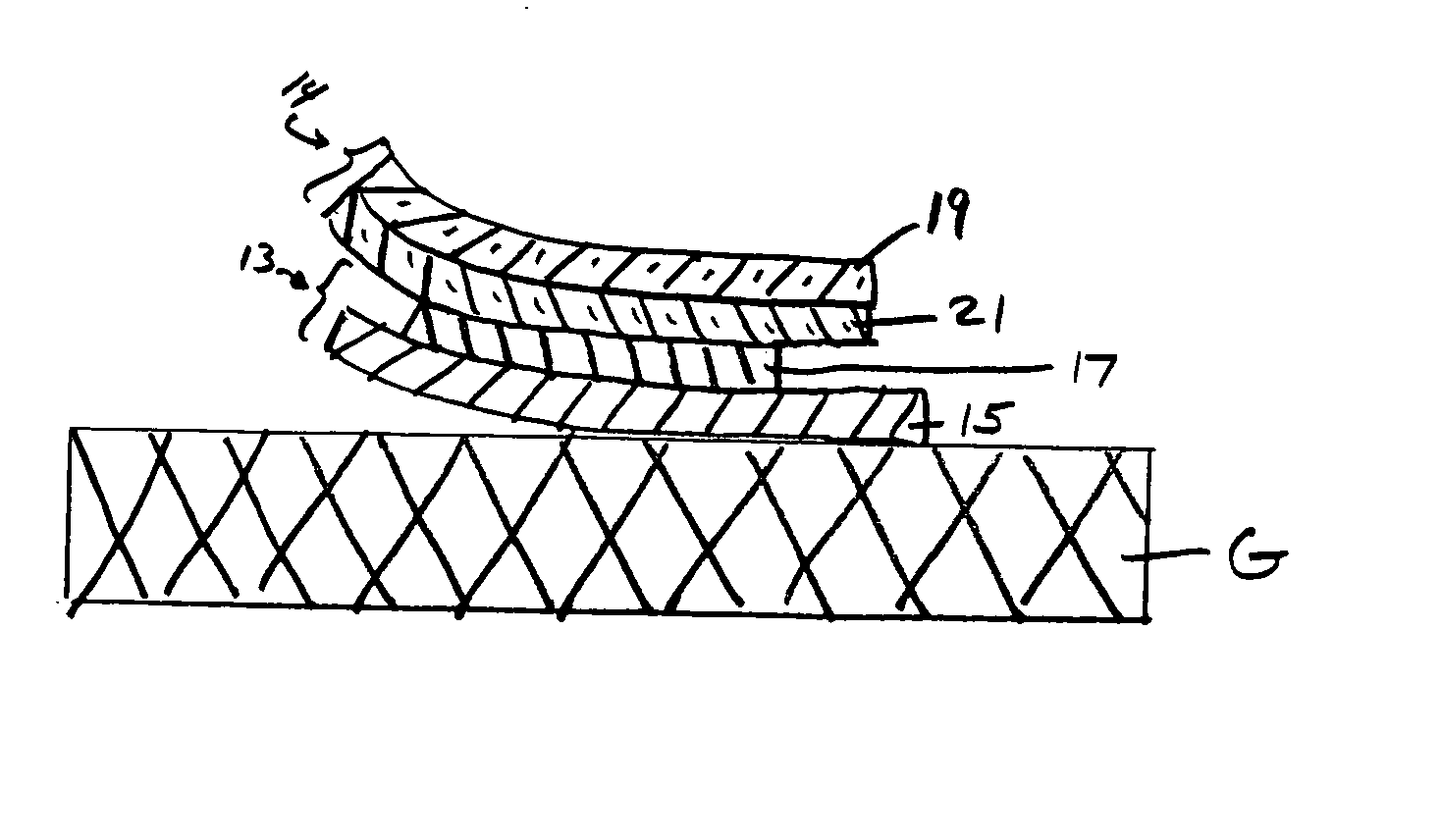

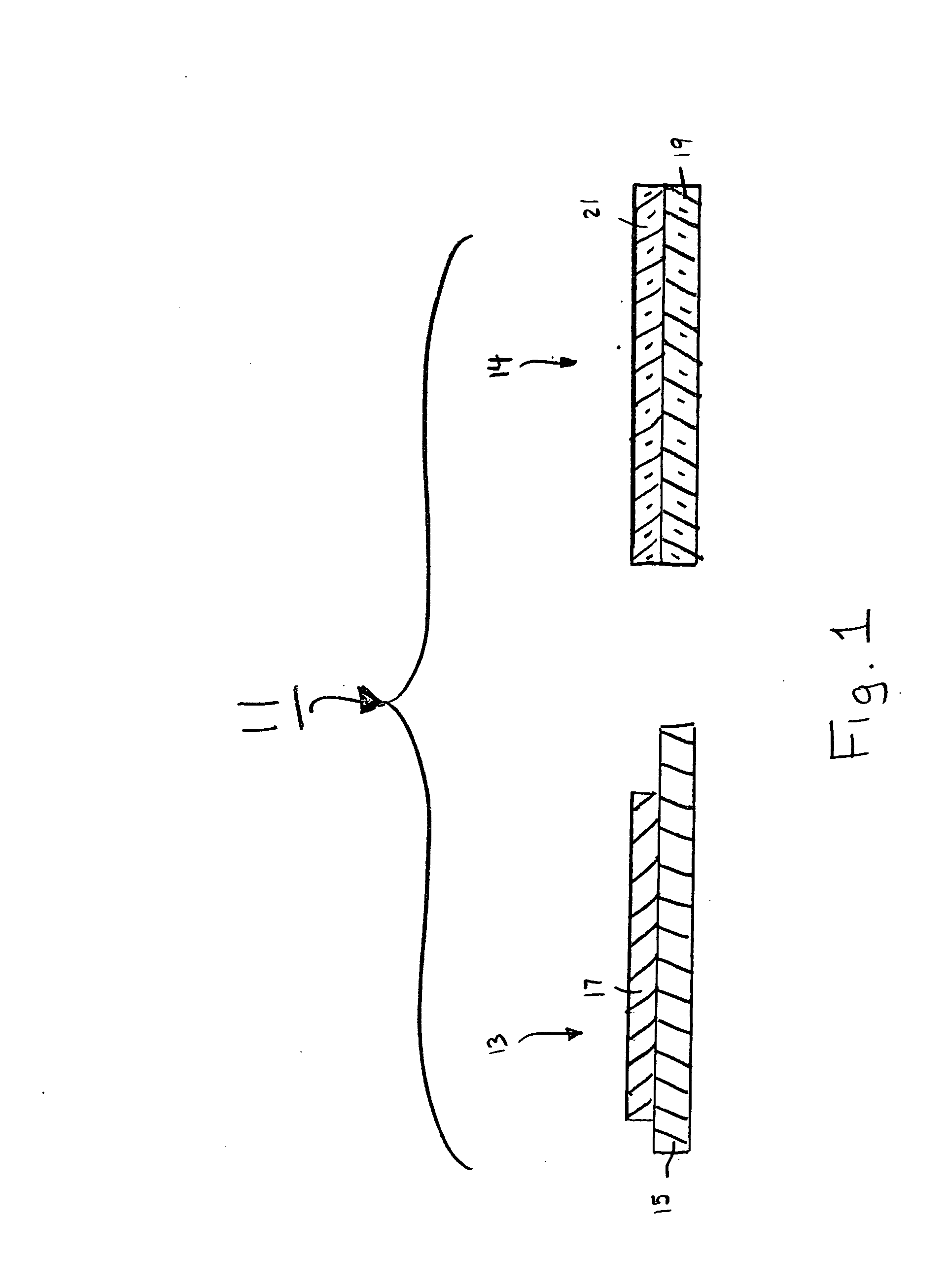

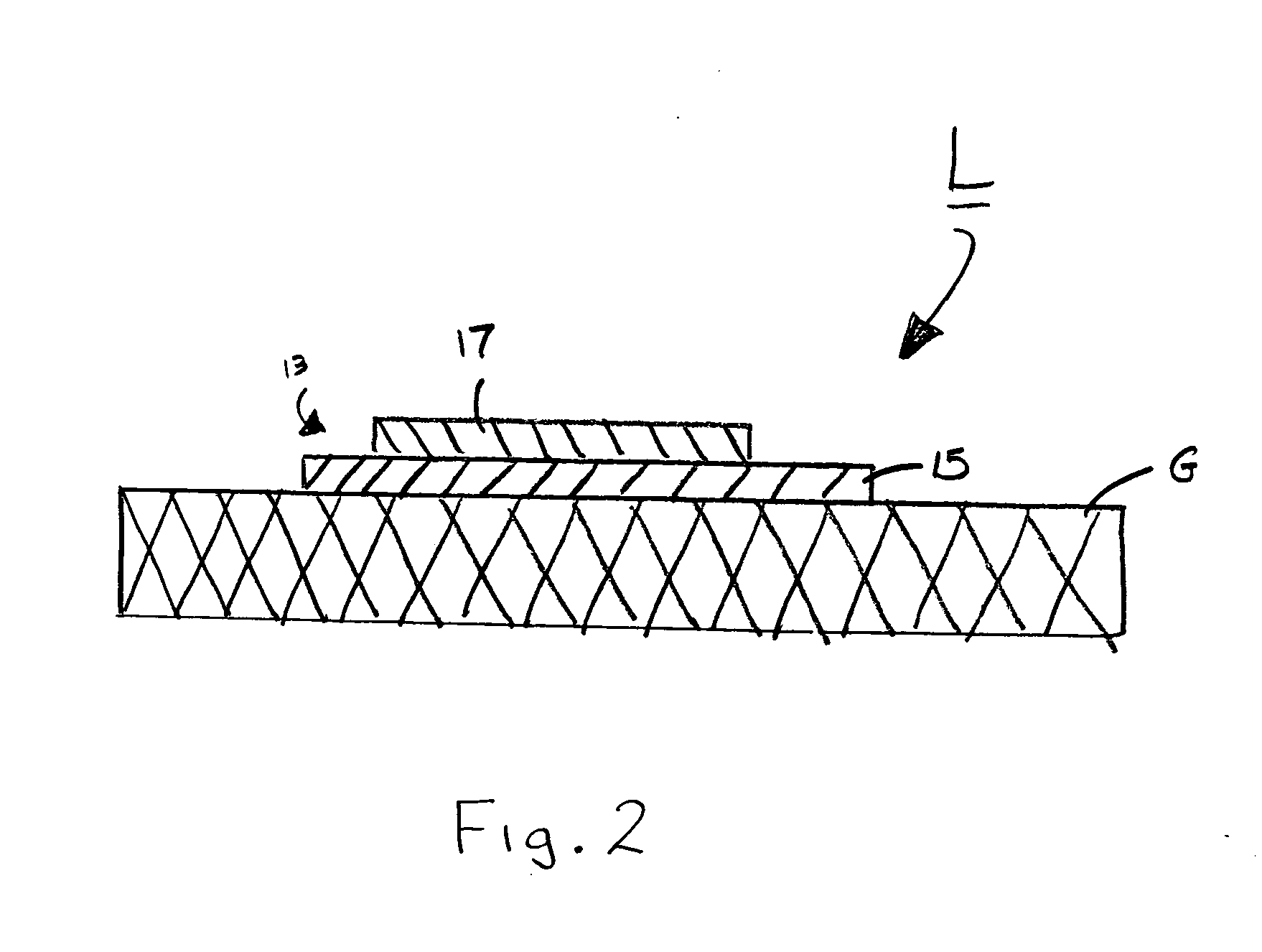

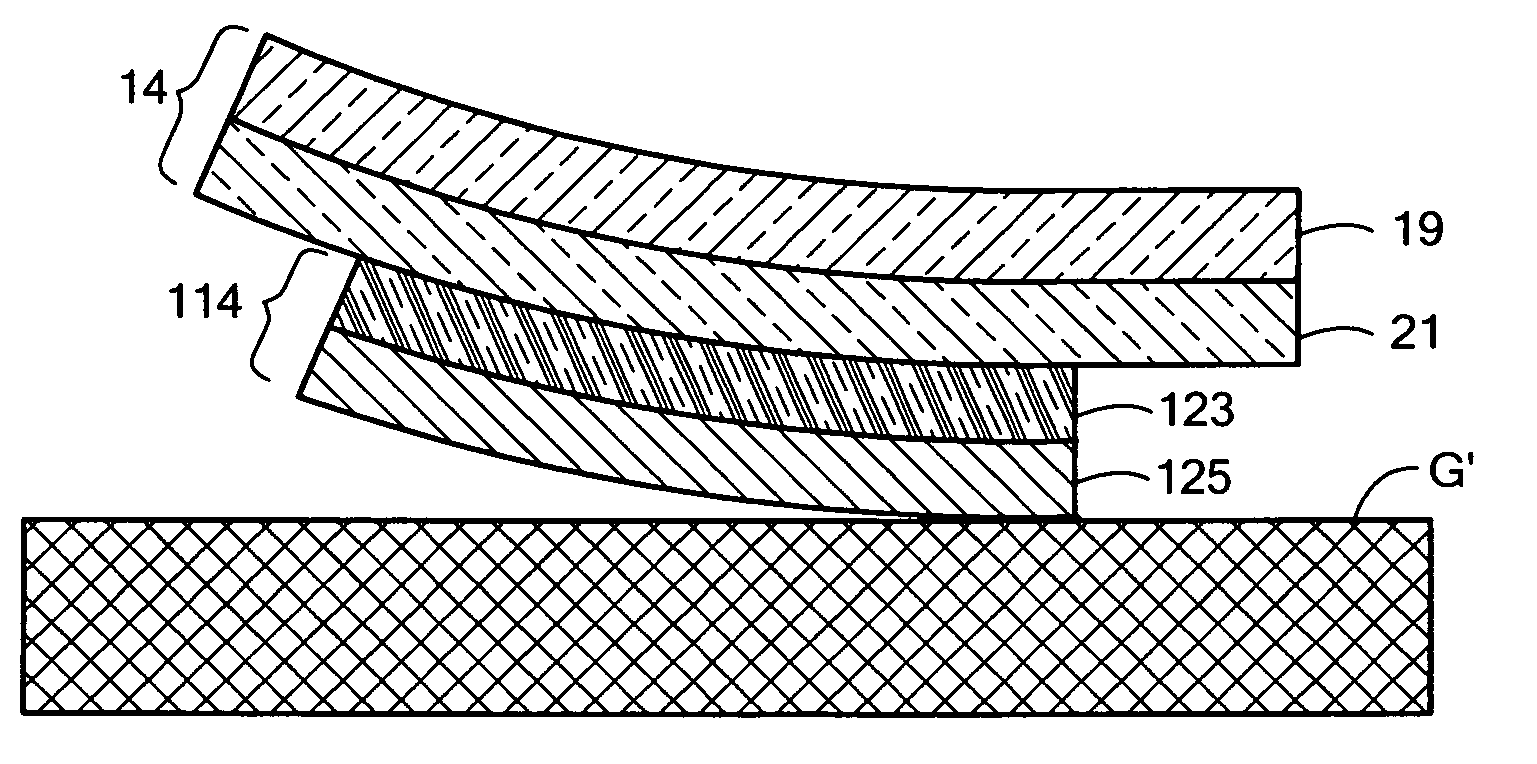

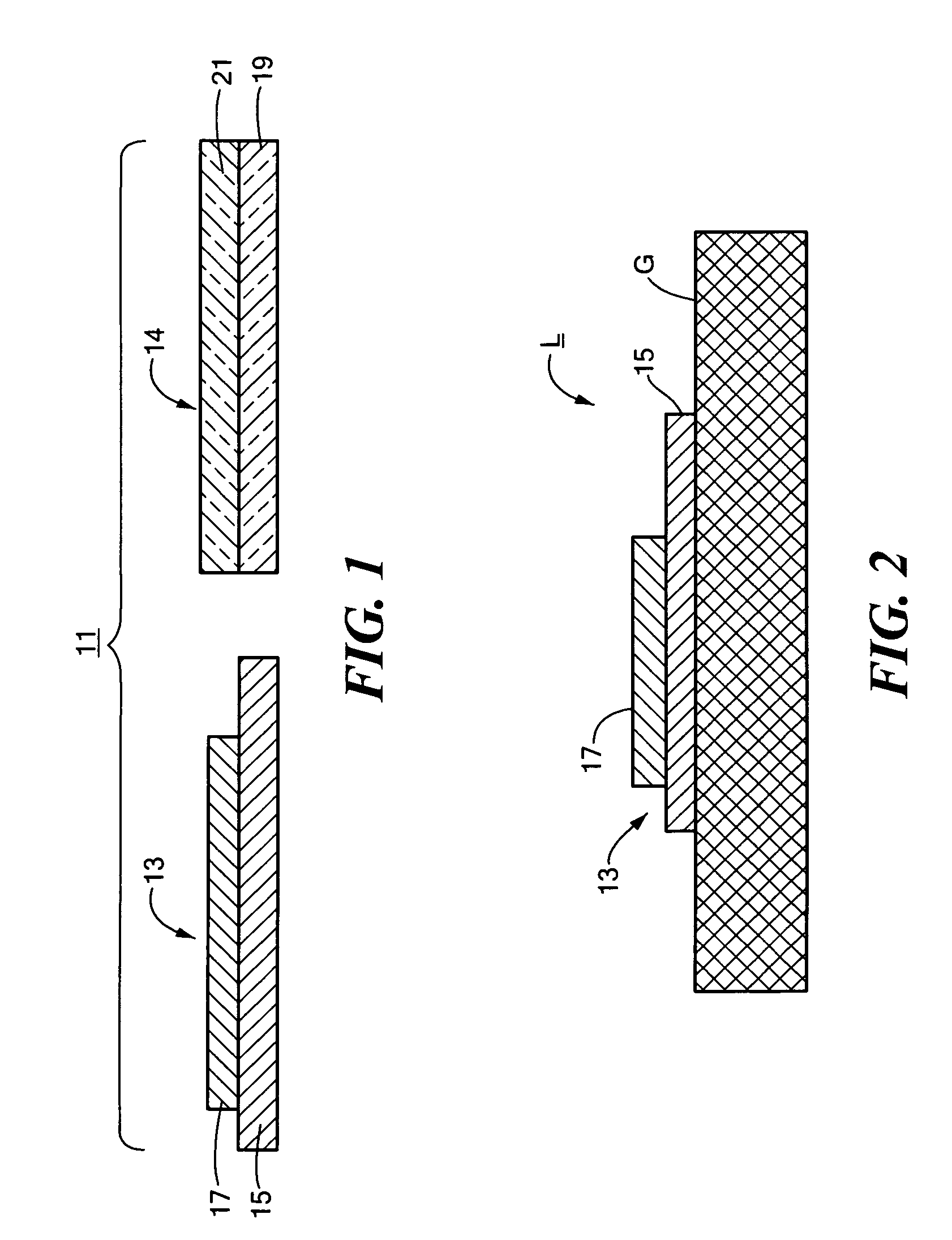

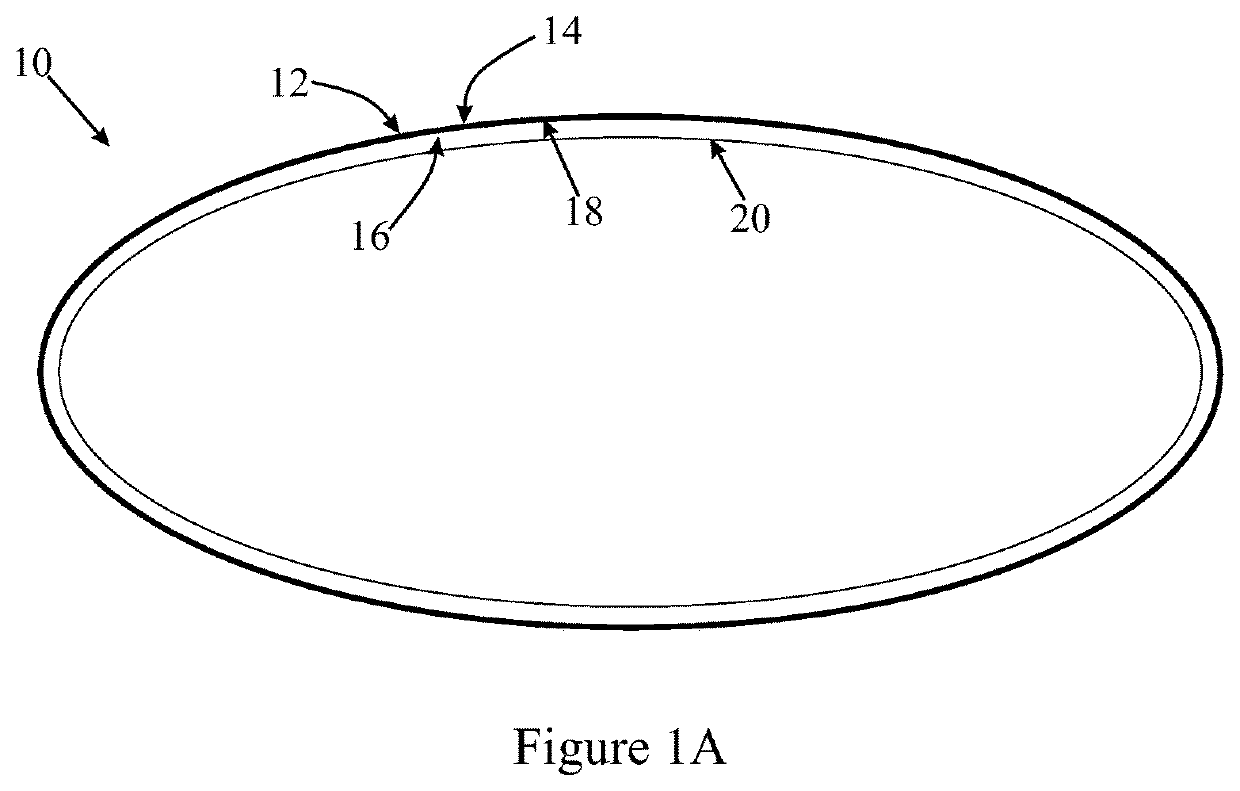

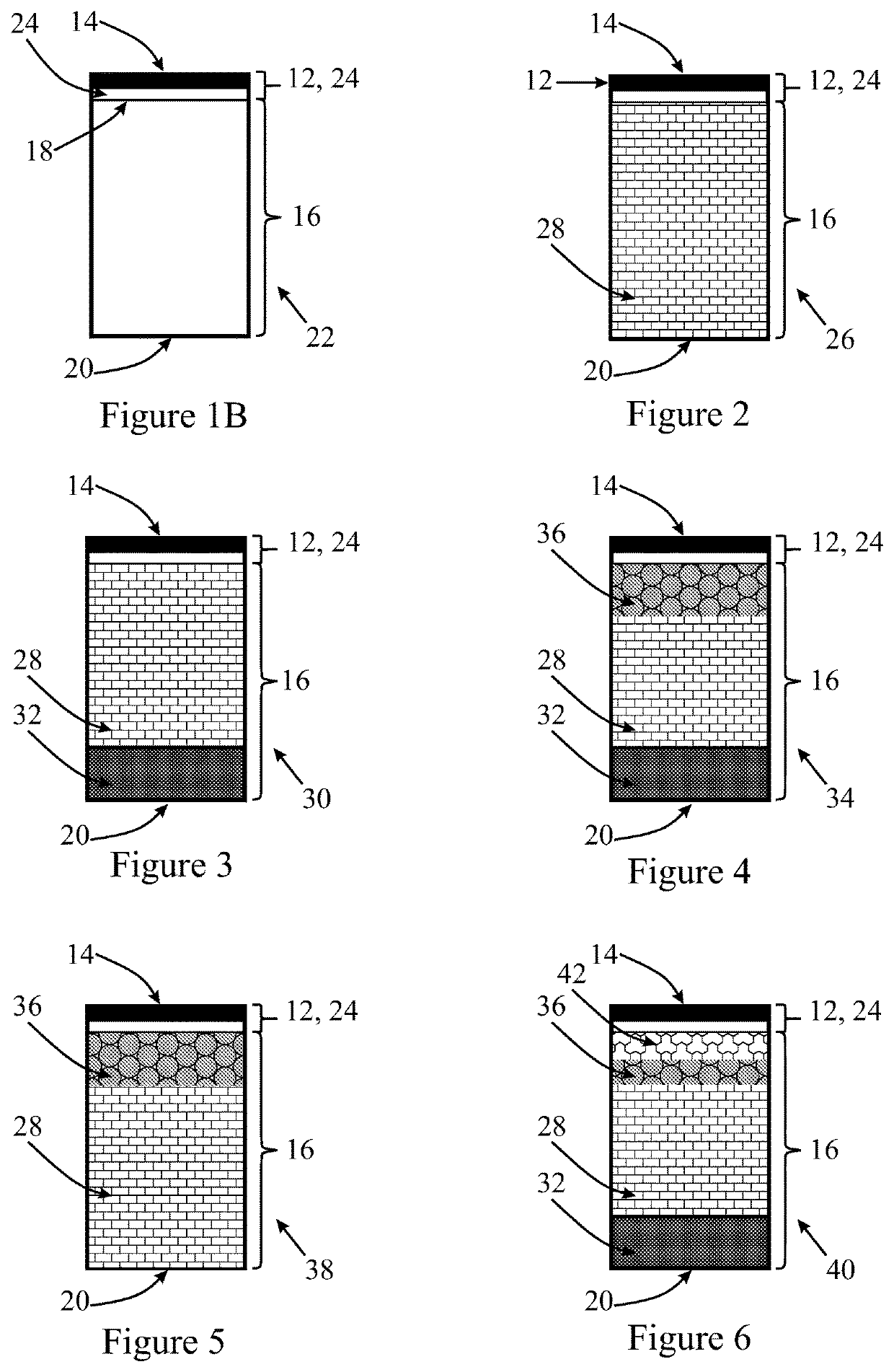

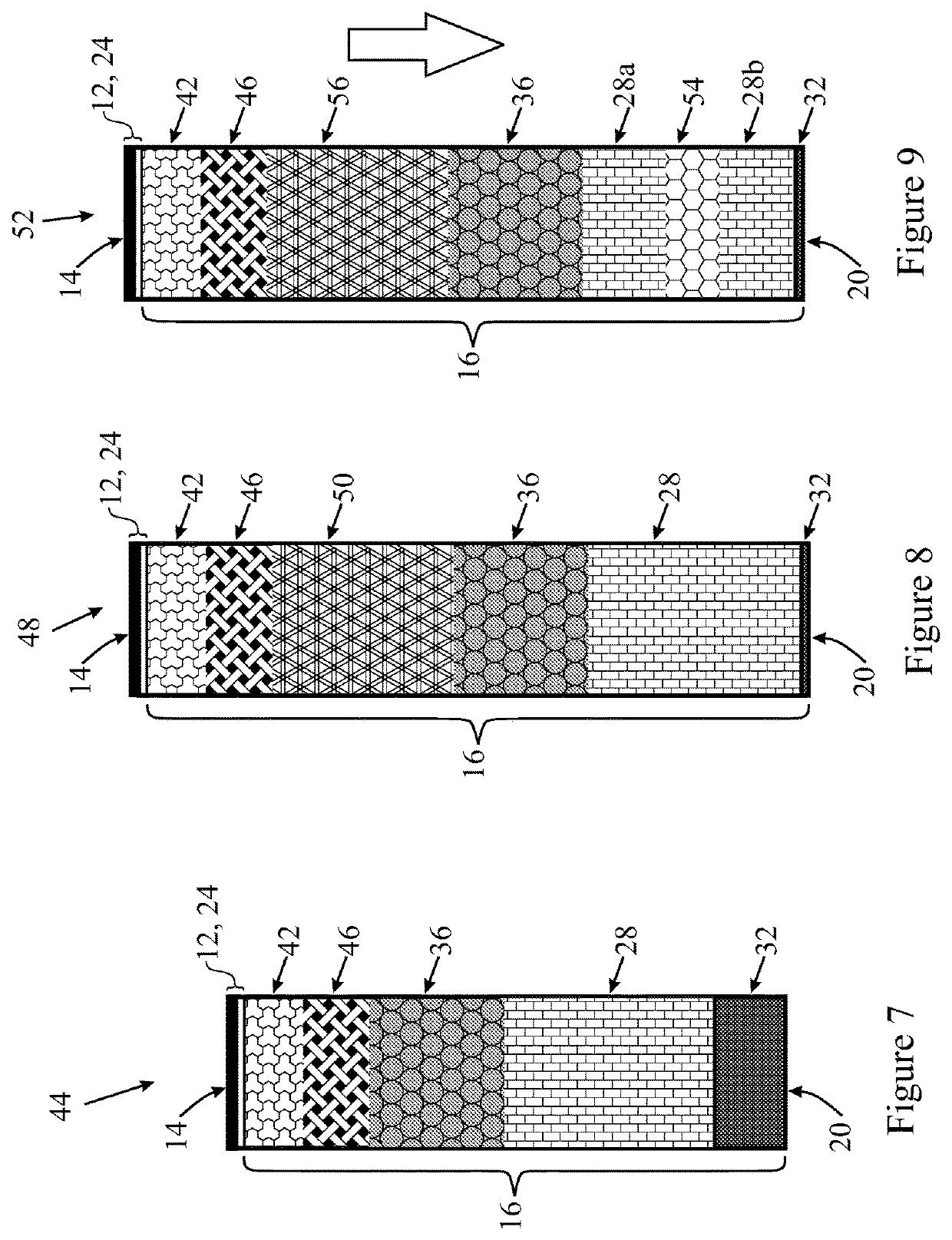

Label assembly and method of using the same to label articles durably yet removably

A label assembly and method of using the same to label articles durably, yet removably. In one embodiment, the label assembly is used to label fabric articles, such as clothing, and comprises (a) an image forming laminate for forming an image on the fabric article, the image forming laminate comprising an ink layer, the ink layer being bondable to the fabric article; and (b) an image removing laminate for removing the image from the fabric article, the image removing laminate comprising a remover layer, the remover layer, upon being activated by heat and / or light, being bondable to the ink layer of the image forming laminate; (c) whereby, upon bonding of the image removing laminate to the ink layer, the bonding between the image removing laminate and the ink layer is stronger than the bonding between the ink layer and the fabric article.

Owner:AVERY DENNISON CORP

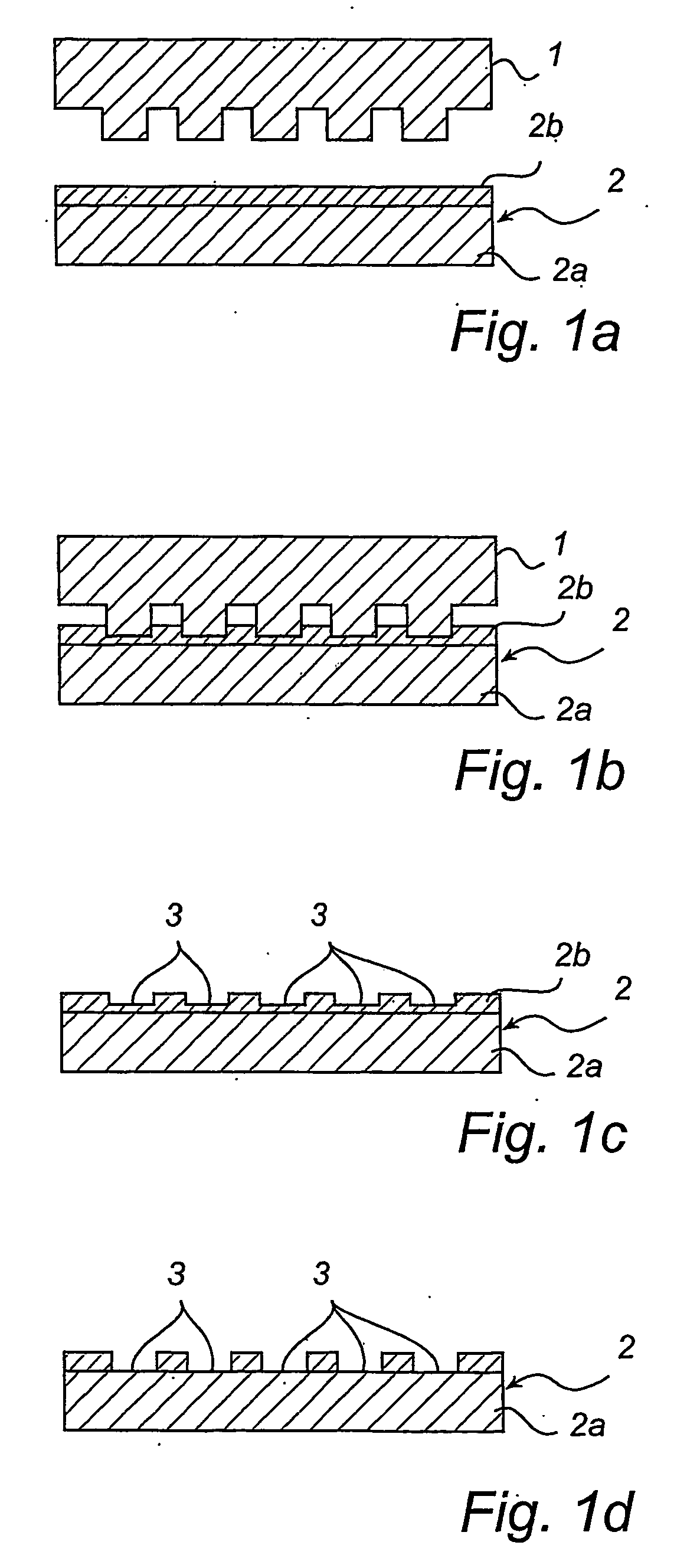

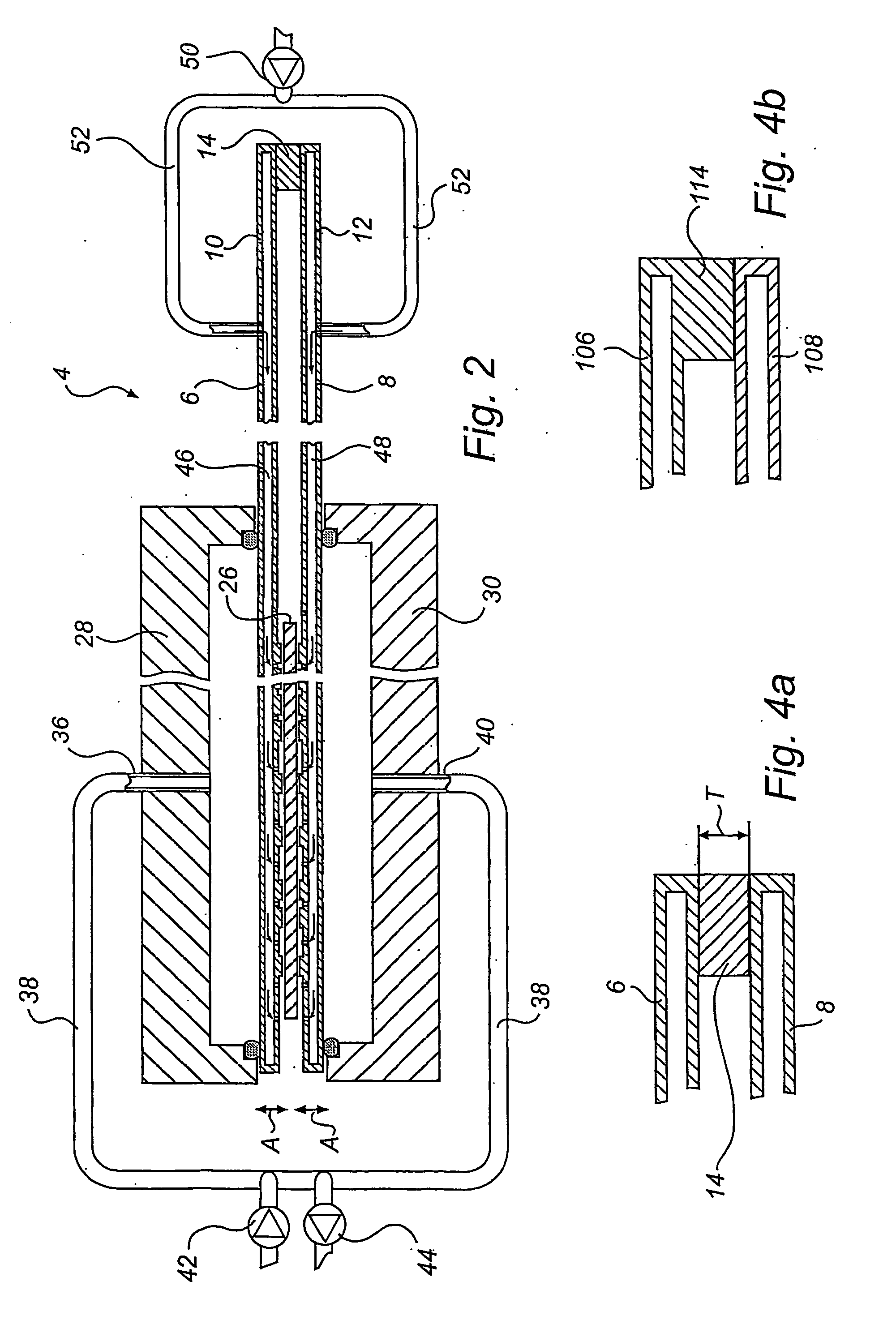

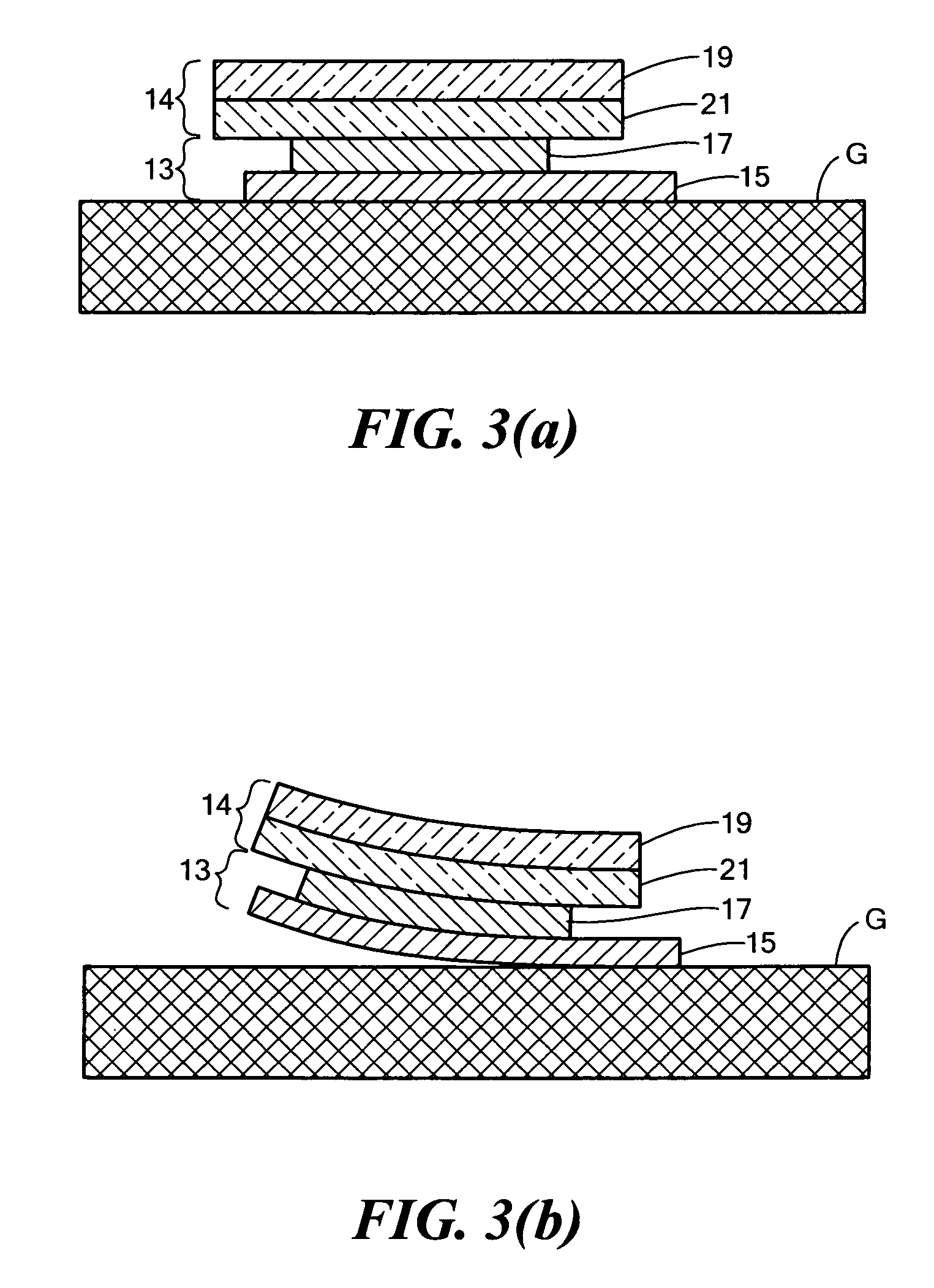

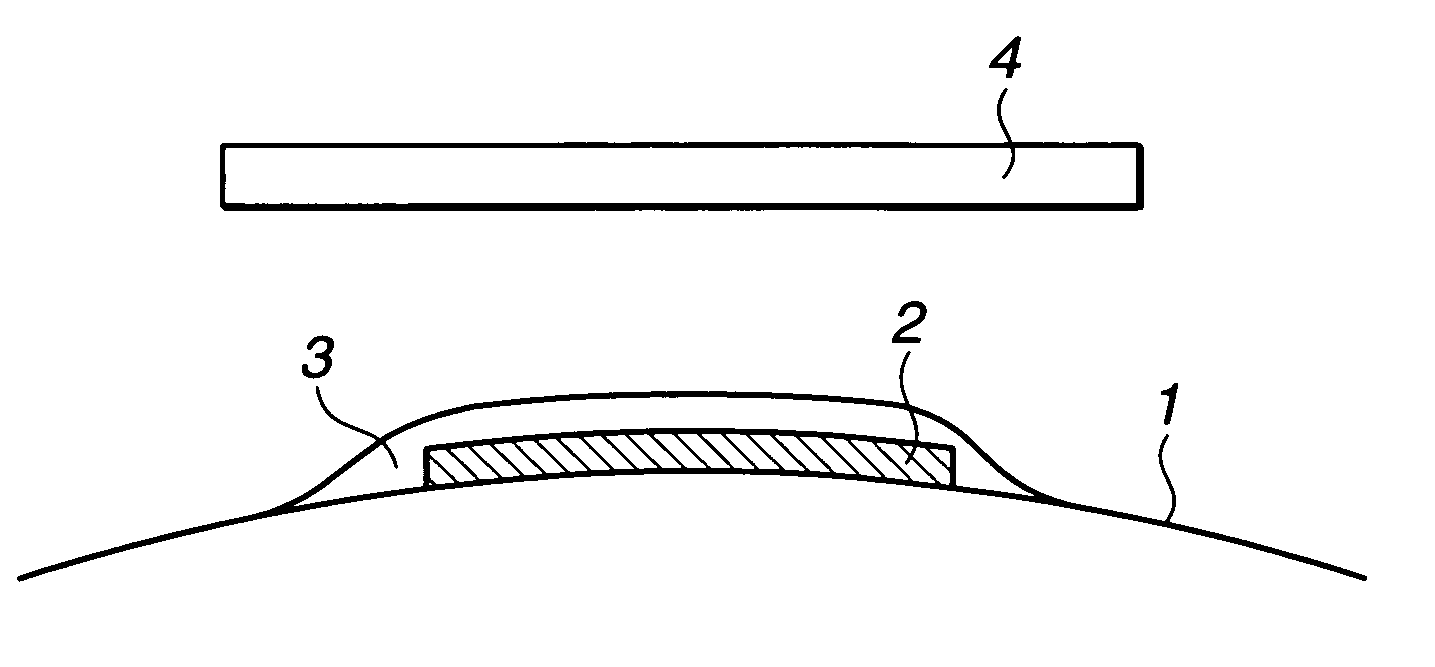

Device and method for transferring a pattern to a substrate

InactiveUS20050172848A1Efficiently patternAddressographsDecorative surface effectsEngineeringNanostructure

A device (4) for transferring patterns, especially micro- or nanostructures, to at least two faces of a substrate (26) comprises a first stamping plate (6) having a patterned area provided thereon for forming a first pattern on a first face of said substrate (26), a second stamping plate (8) having a patterned area provided thereon for forming a second pattern on a second face of said substrate (26), and a contacting means (28, 30) for contacting the respective patterned areas of the two stamping plates (6, 8) with the respective faces of said substrate (26). The first and the second stamping plates (6, 8) are aligned with each other and are secured to each other at respective holding areas (10, 12) of the stamping plates (6, 8) located at a distance from the patterned areas.

Owner:OBDUCAT AB SE

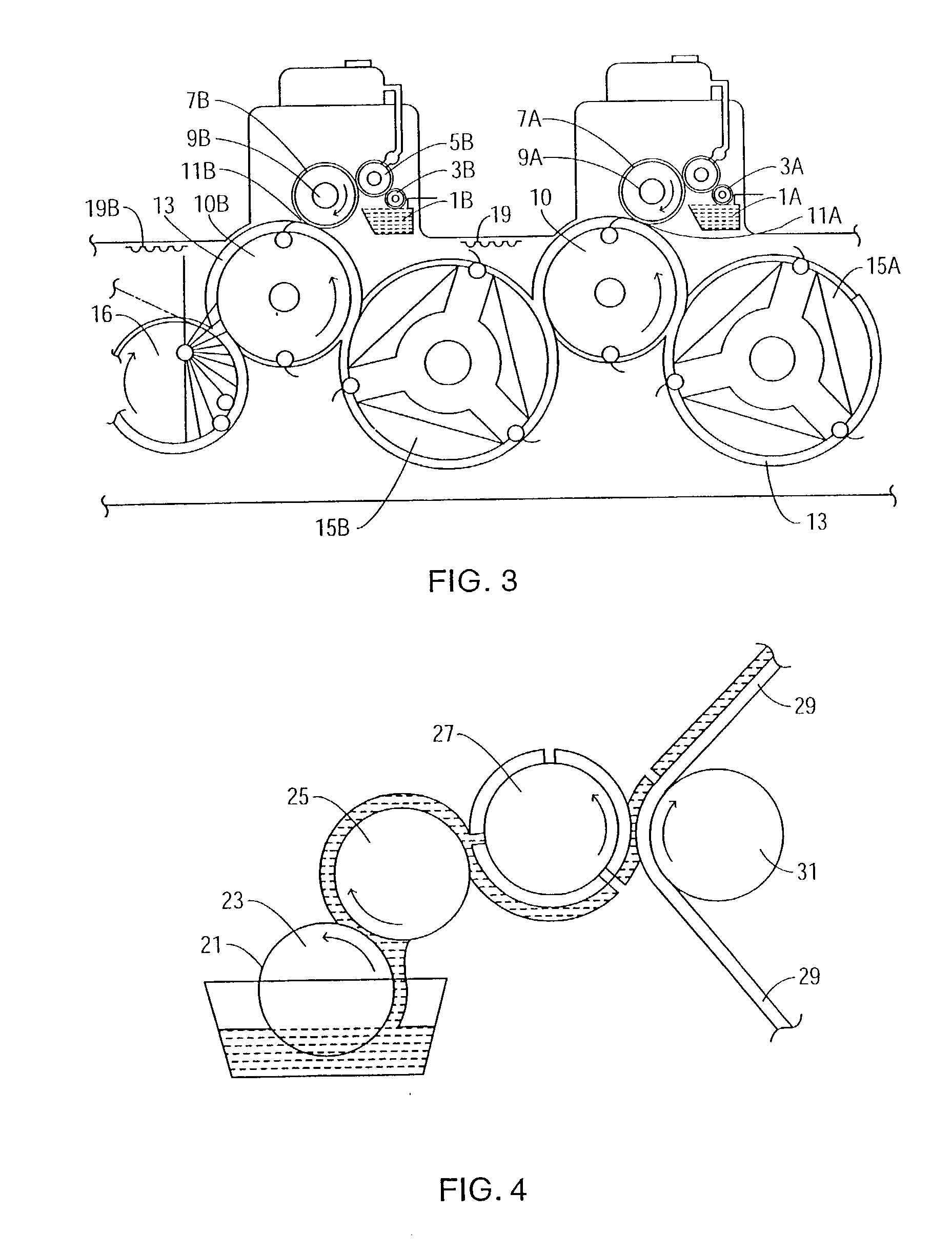

Method of producing a high gloss coating on a printed surface

InactiveUS20030113466A1High coatingLow production costCylinder pressesTransfer printingPresent methodPaper sheet

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH +1

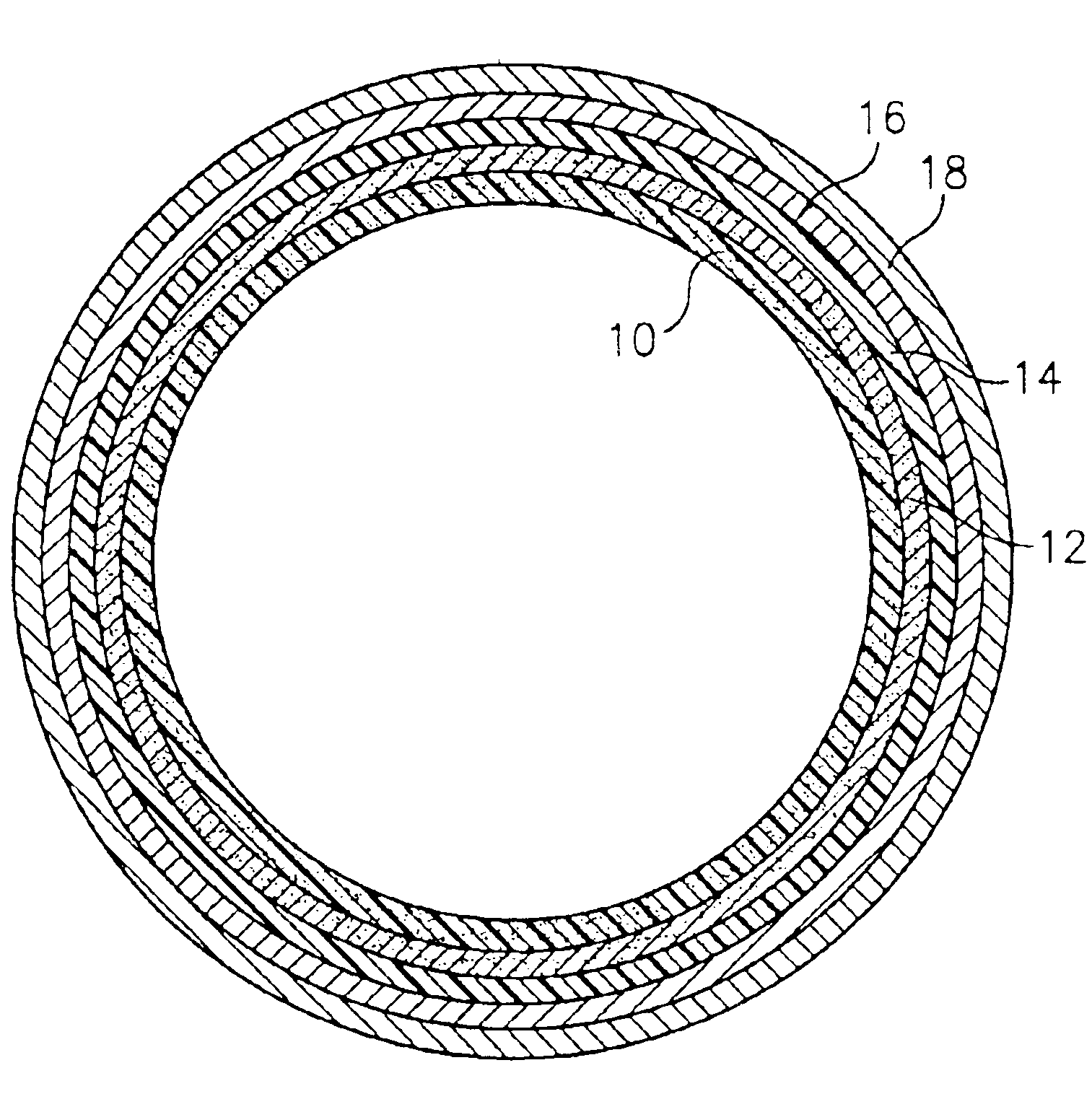

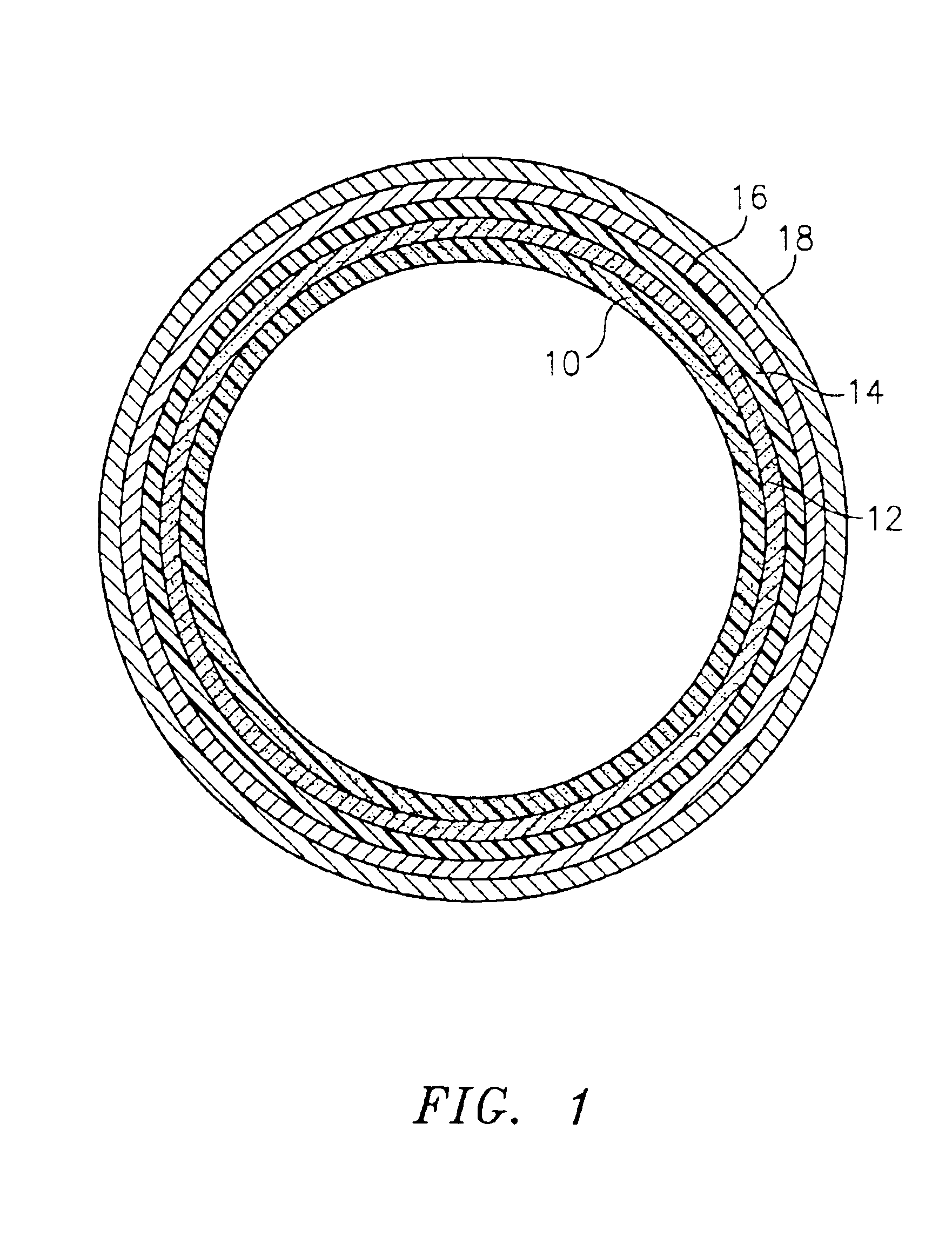

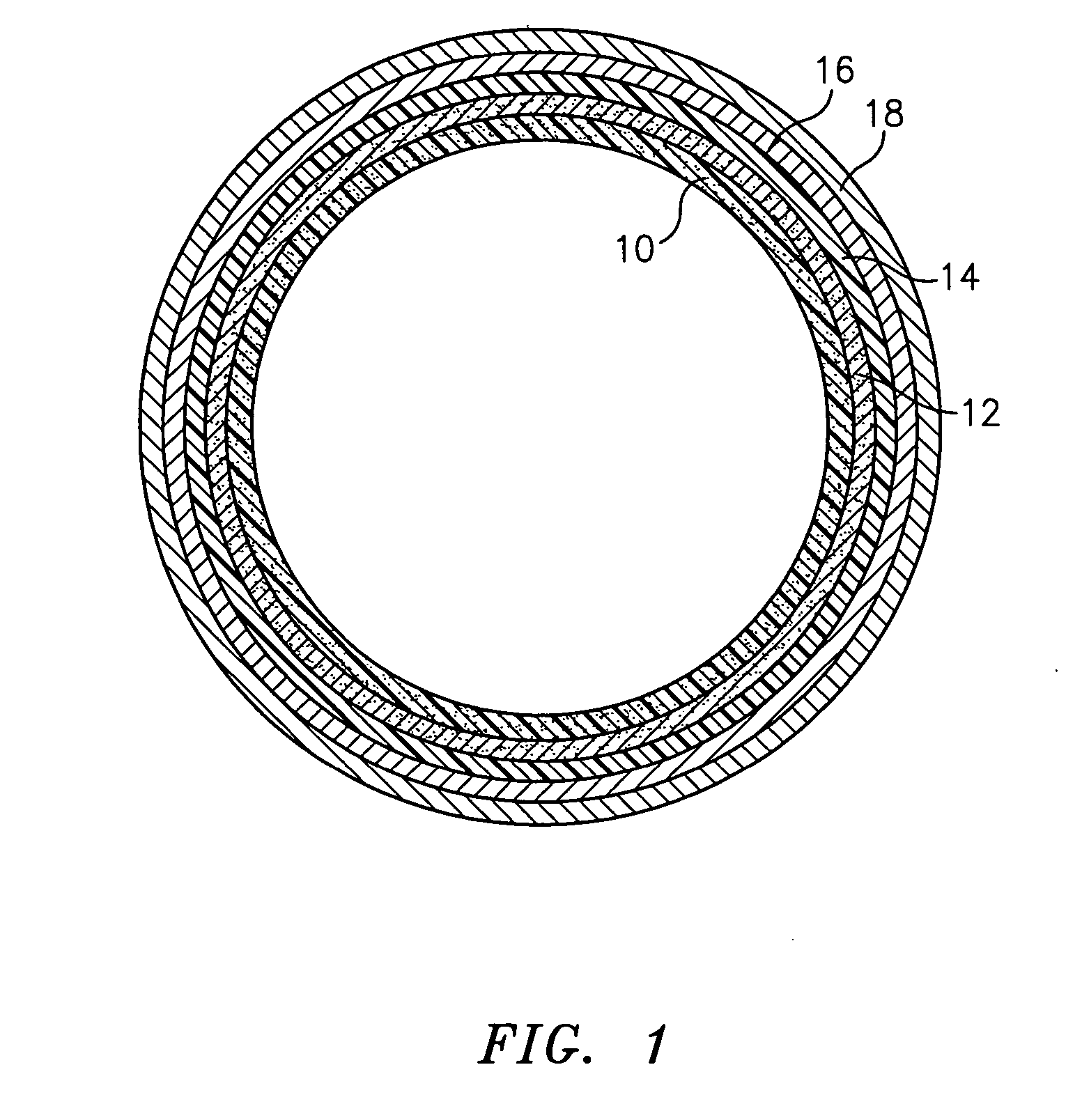

Printing sleeve with an integrated printing surface

ActiveUS6966259B2Improve adhesionQuality improvementElectric discharge tubesStereotype printingPhotopolymerEngineering

A seamless printing sleeve comprising a hollow cylindrical base and a seamless imageable surface as its outermost layer is described. The imageable surface acts as an integral flexographic printing surface. Preferably the printing sleeve comprises an intermediate photopolymer or resilient polymer layer between the outer surface of the base and the imageable surface. Also, preferably the base is uniformly transparent or translucent to actinic radiation.

Owner:MACDERMID PRINTING SOLUTIONS

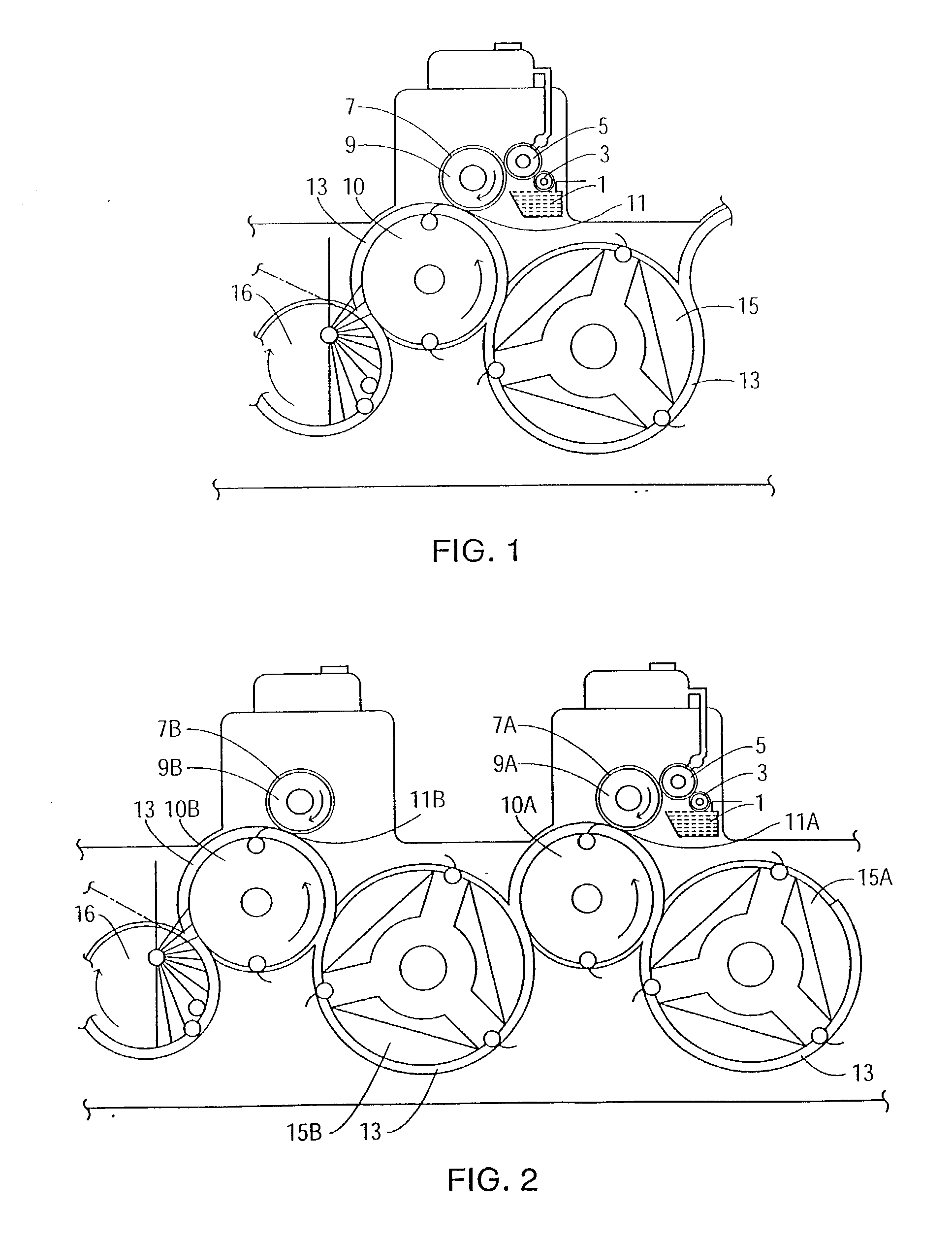

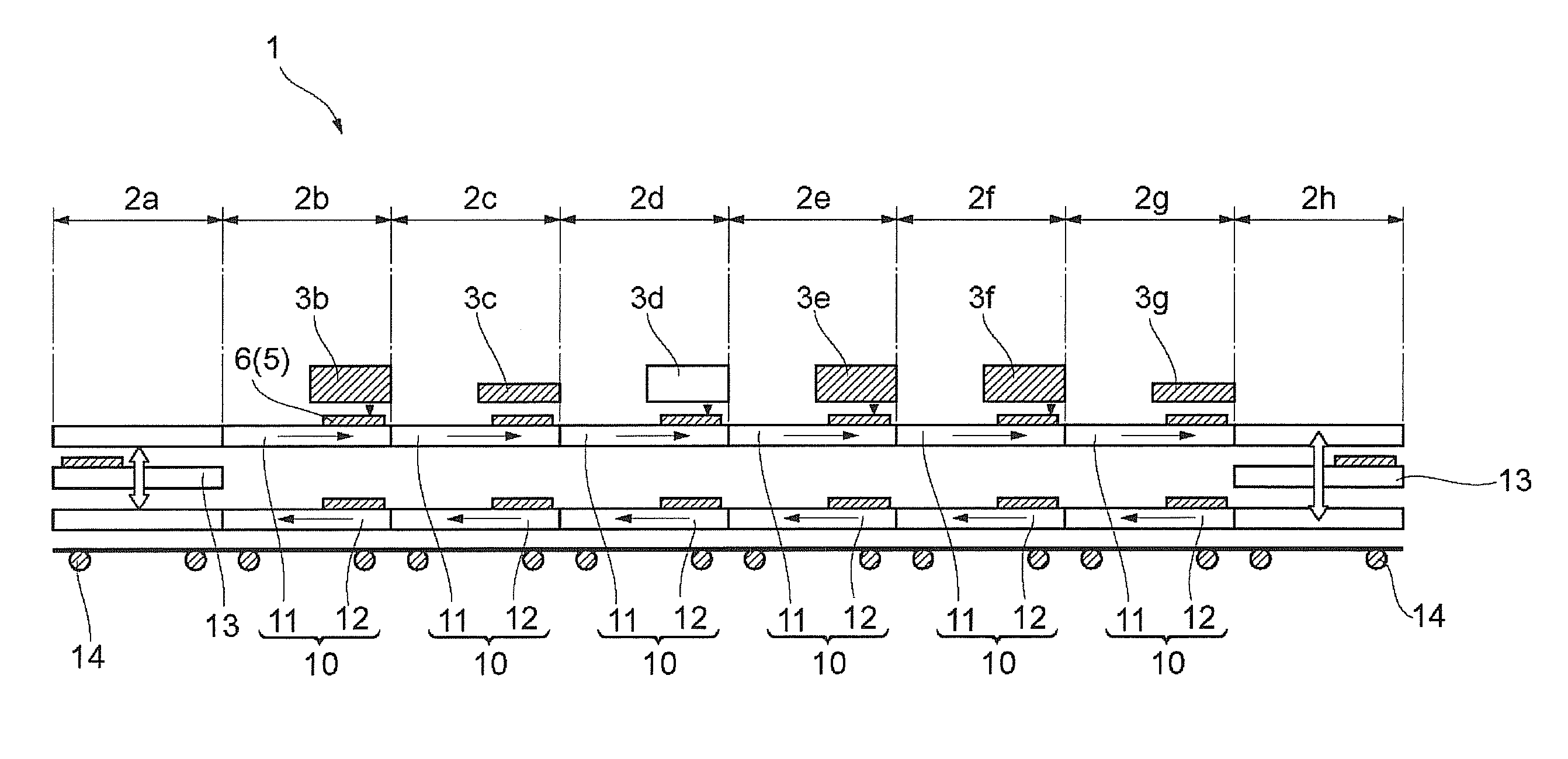

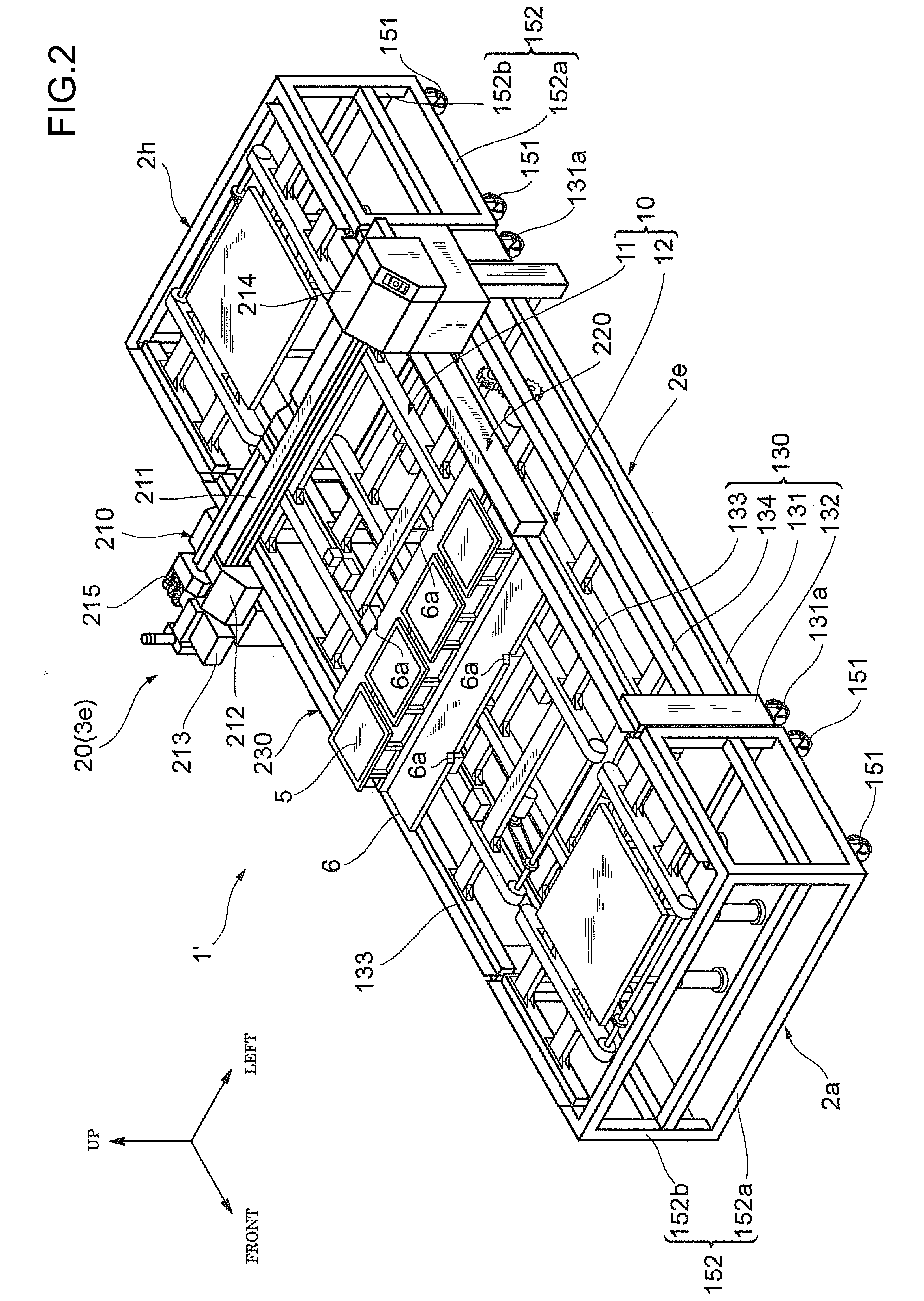

Printing apparatus

A printing apparatus for printing on a print substrate by sequentially conducting a plurality of processing operations. The printing apparatus includes a pallet configured to receive the print substrate, and work station units each comprising a conveyer mechanism configured to convey the pallet and a work mechanism configured to conduct a predetermined processing operation to the print substrate on the pallet. A plurality of the work station units are aligned adjacent to each other, and the work station units are configured to be replaceable or rearrangeable to change the sequence of the plurality of processing operations.

Owner:MIMAKI ENG +1

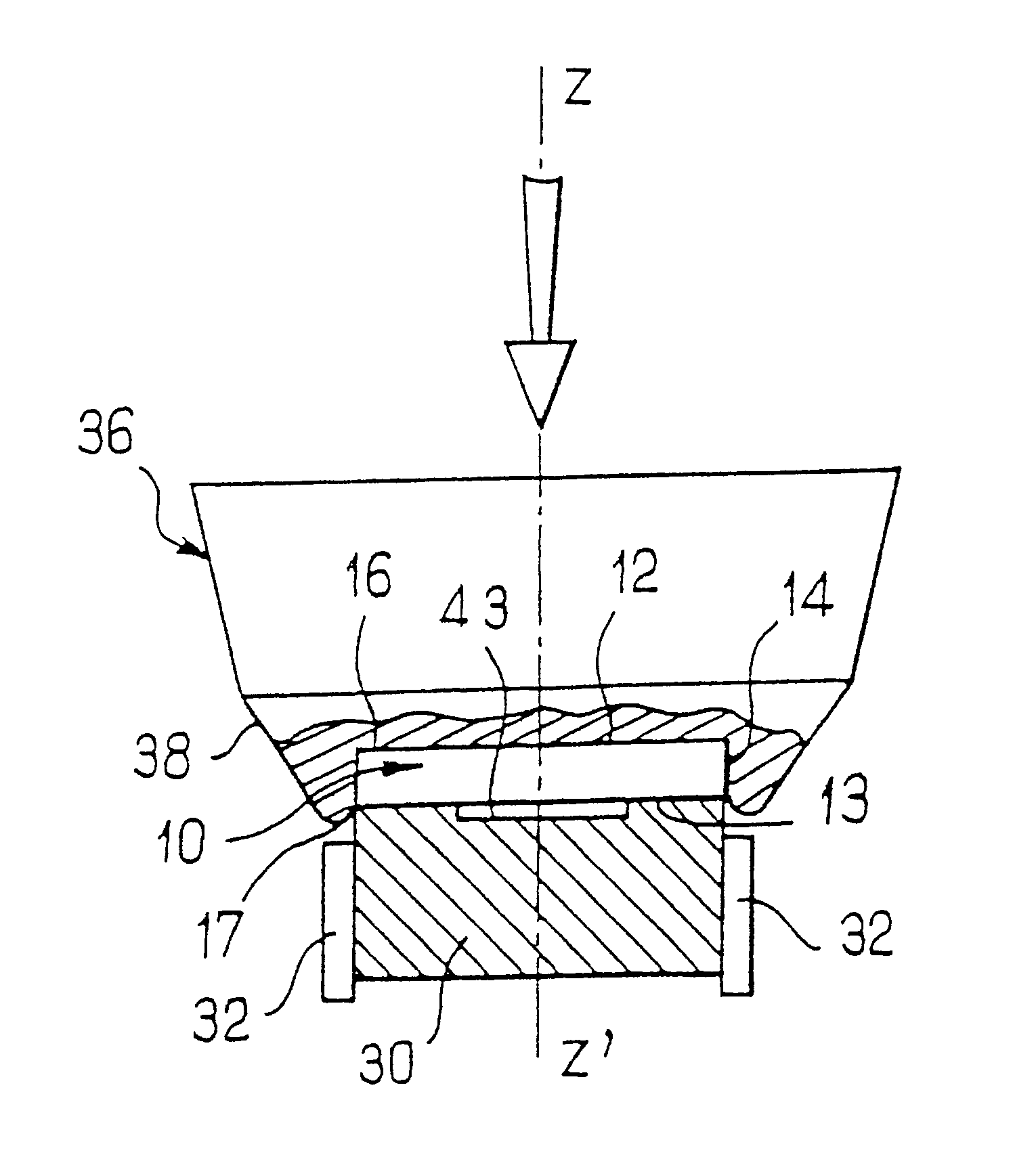

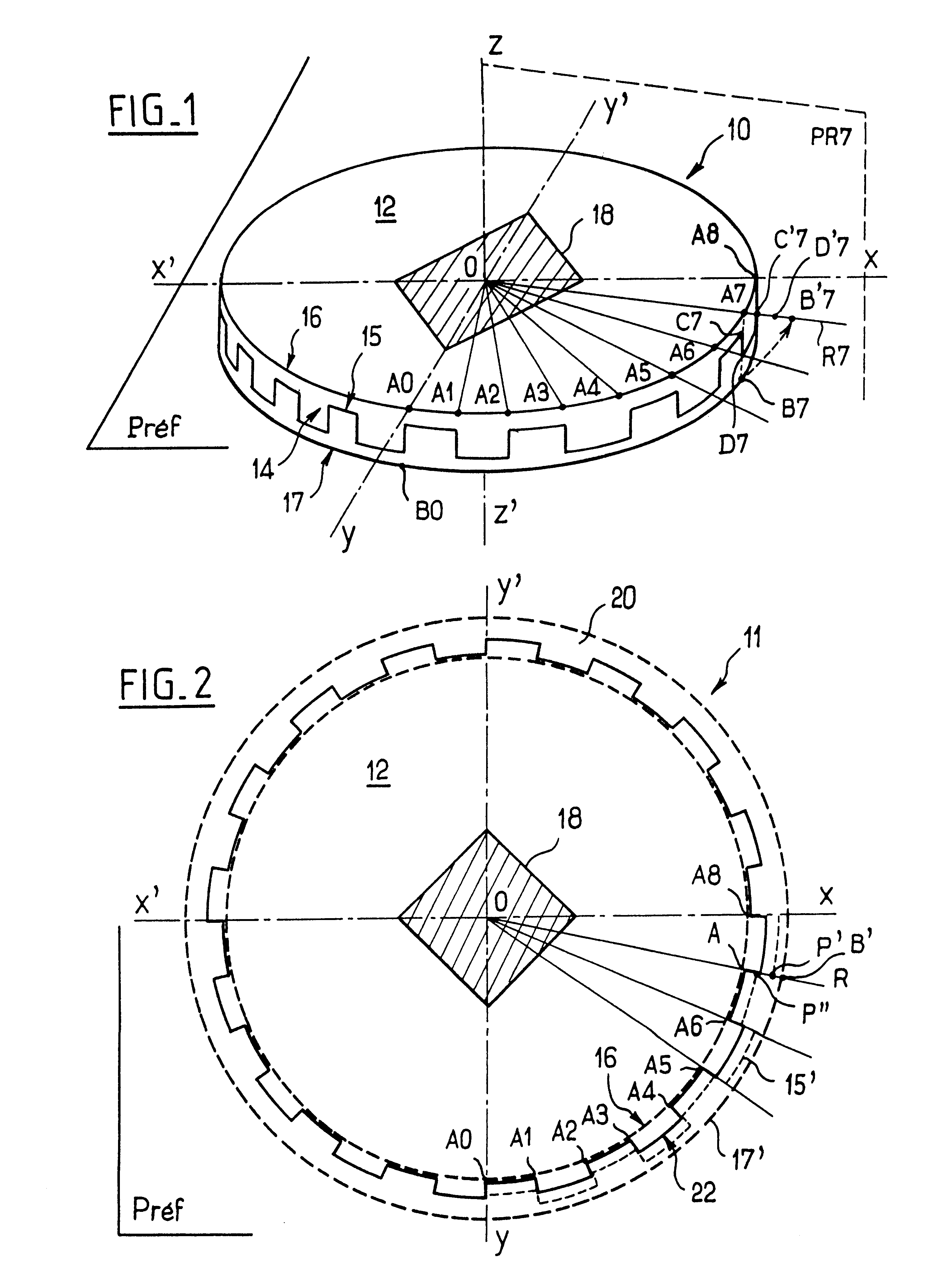

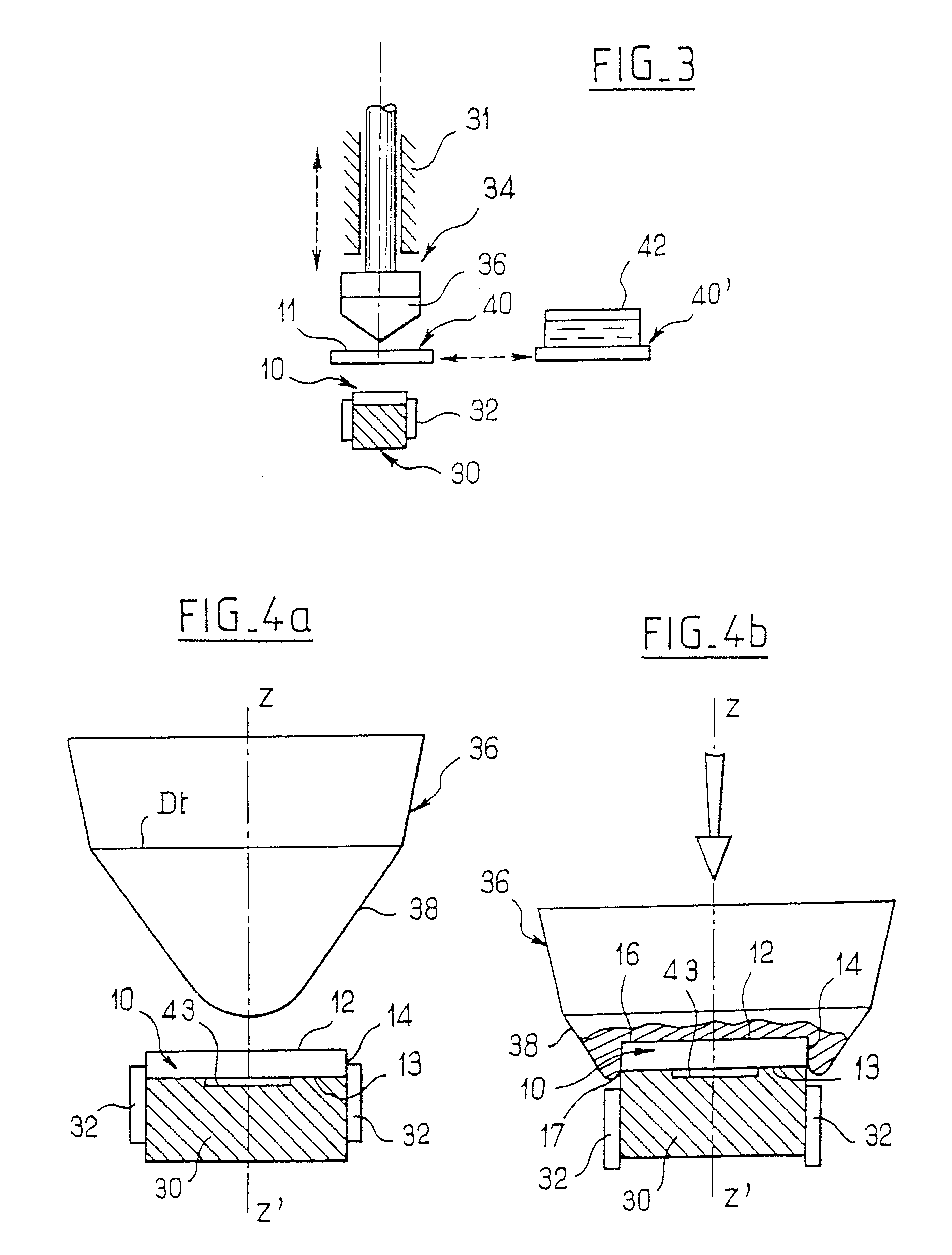

Method for marking a gaming disk by pad printing

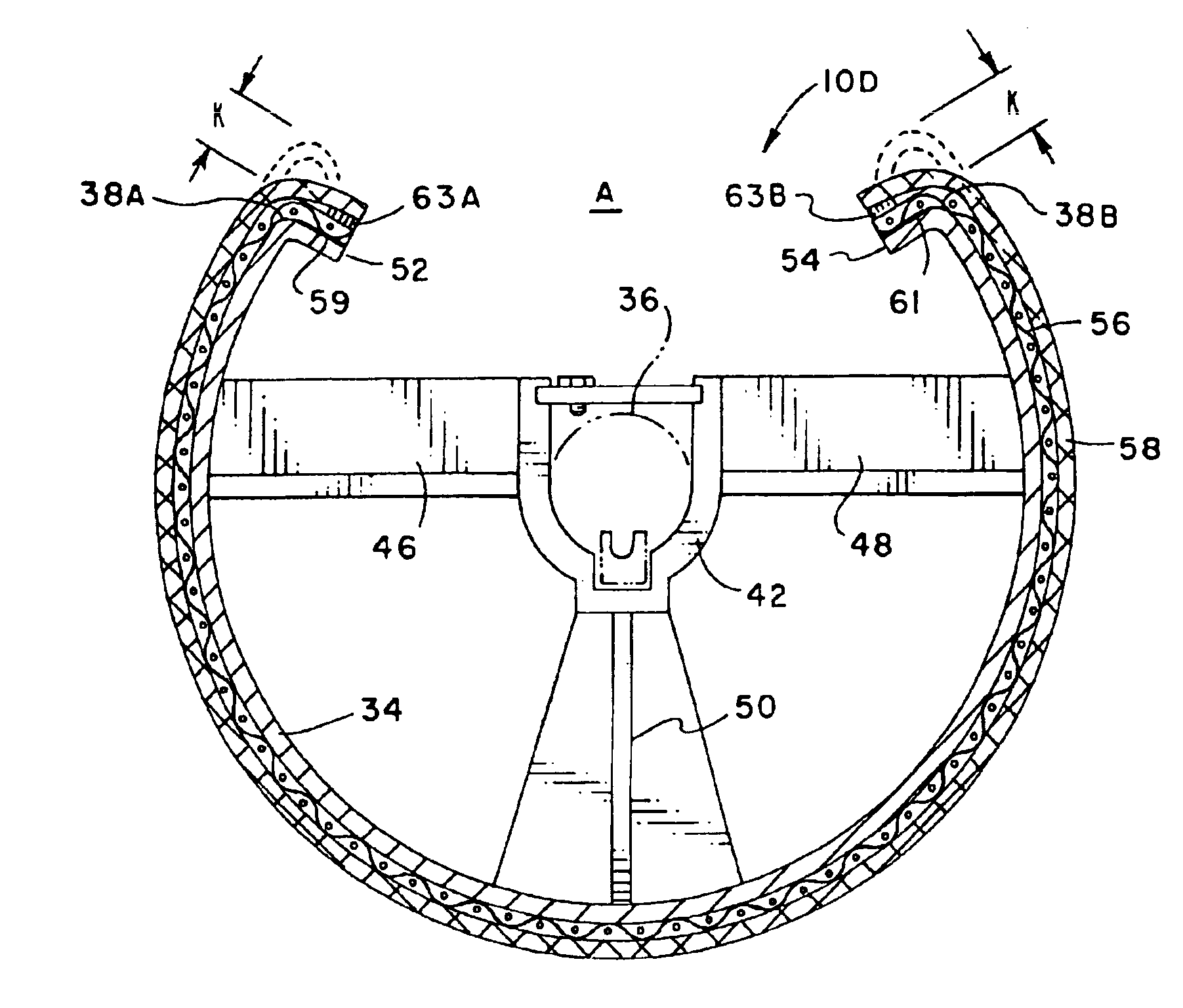

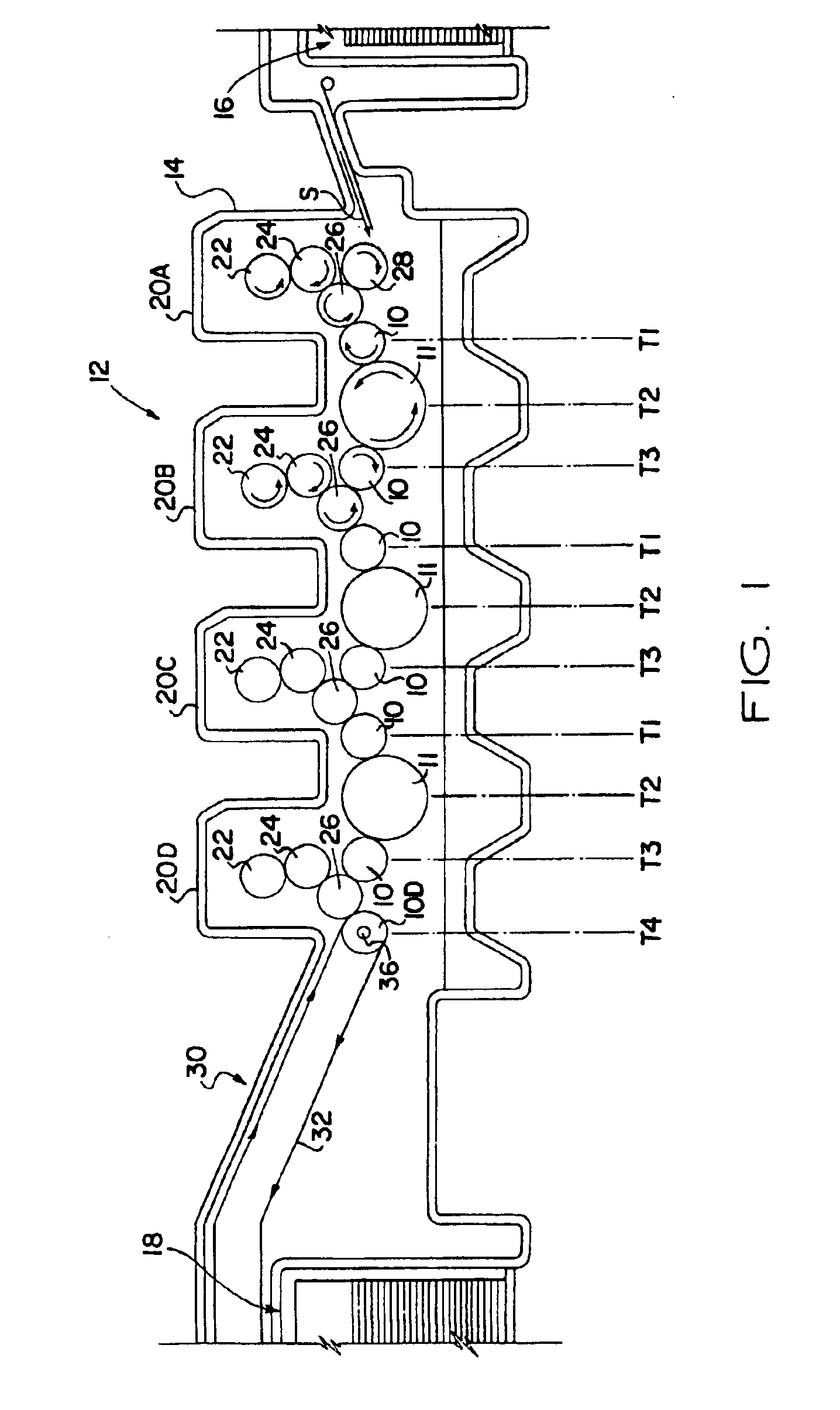

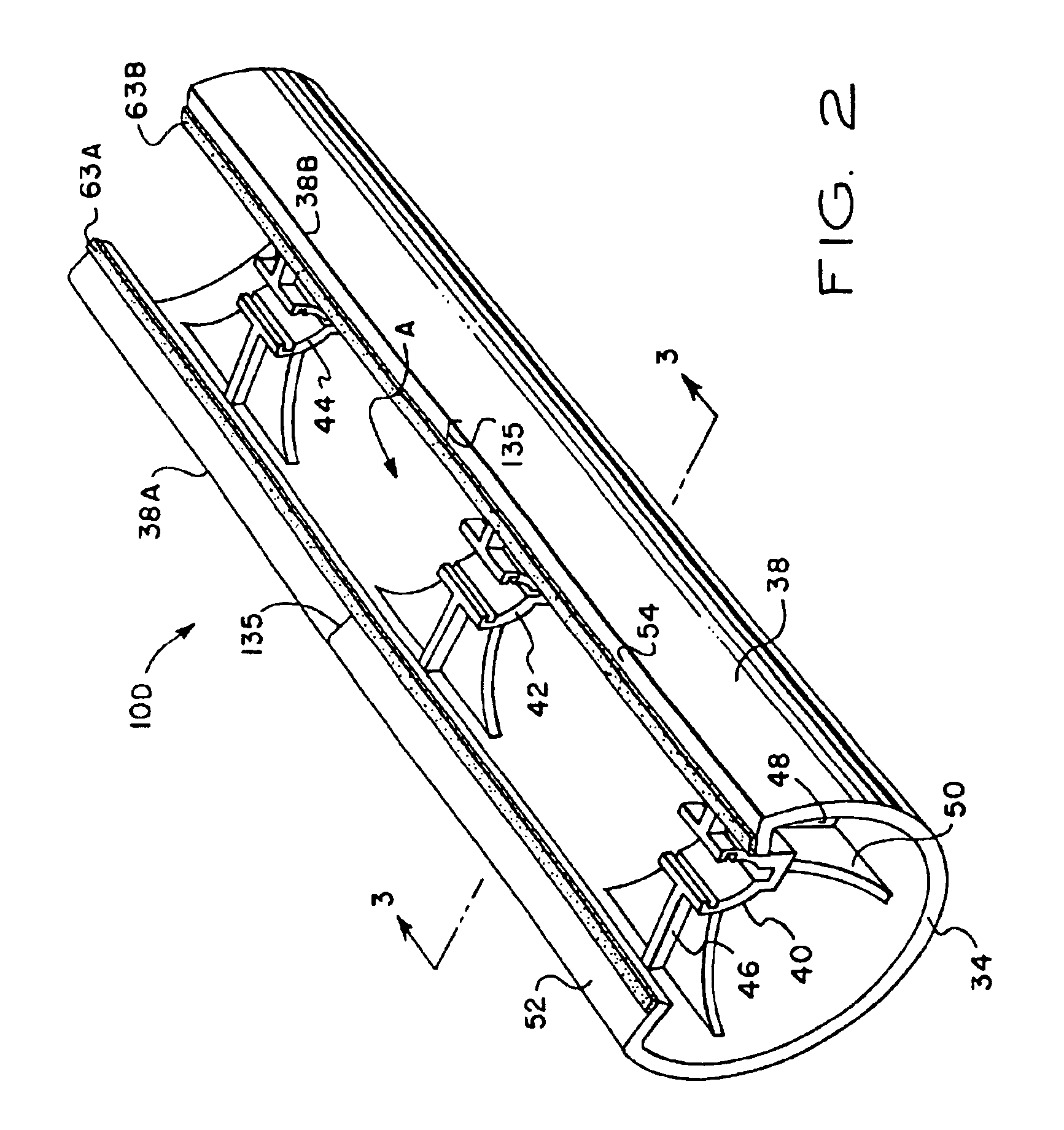

A method for marking a side of a straight-sided chip with a decoration by pad printing. The method comprises providing an ink plate with an image defined by radially deformed representation of the decoration of the straight side of the chip in a ring-shaped zone, moving a pad coaxially into contact with the ink plate such that the image transfers to the pad, and moving the pad coaxially into contact with the chip such that the image transfers to the side of the chip.

Owner:GAMING PARTNERS INTERNATIONAL CORPORATION +1

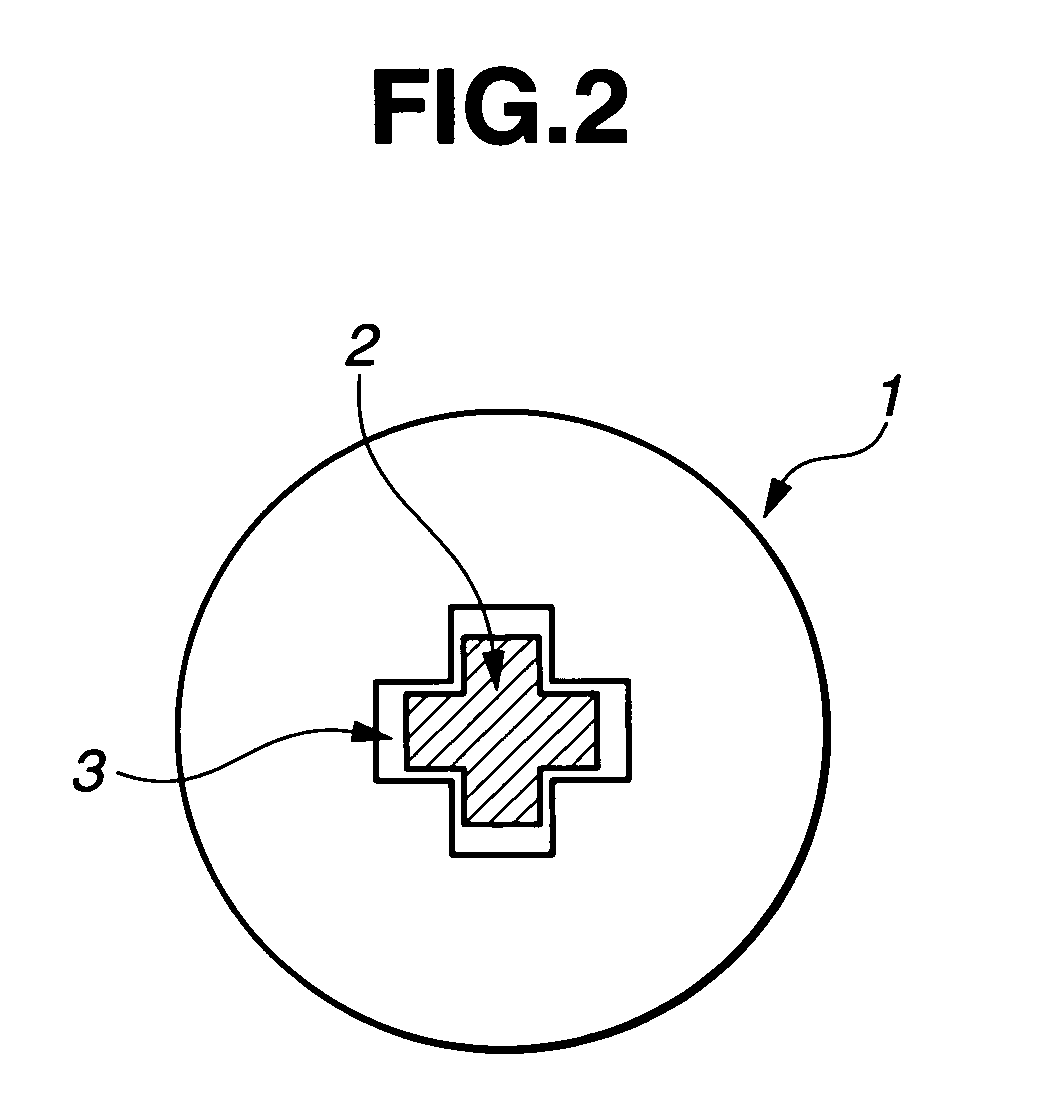

Intermediate transfer recording medium, print, and method for image formation thereby

InactiveUS6984281B2Transparency is deterioratedHigh opacityDecorative surface effectsStereotype printingImage formationEngineering

There is provided a print which has been produced by providing an intermediate transfer recording medium comprising a substrate film and a transfer portion, comprising at least a receptive layer, provided separably on the substrate film, forming a thermal transfer image onto the transfer portion, and retransferring the transfer portion onto an object while accurately and stably forming a non-transferred portion onto a part of the object and, in addition, does not increase a production cost for providing a final print. The intermediate transfer recording medium comprises a substrate film and a transfer portion comprising at least a receptive layer, the transfer portion being provided separably on the substrate film. The print has on its at least one side a transfer portion-non-retransferred portion.

Owner:DAI NIPPON PRINTING CO LTD

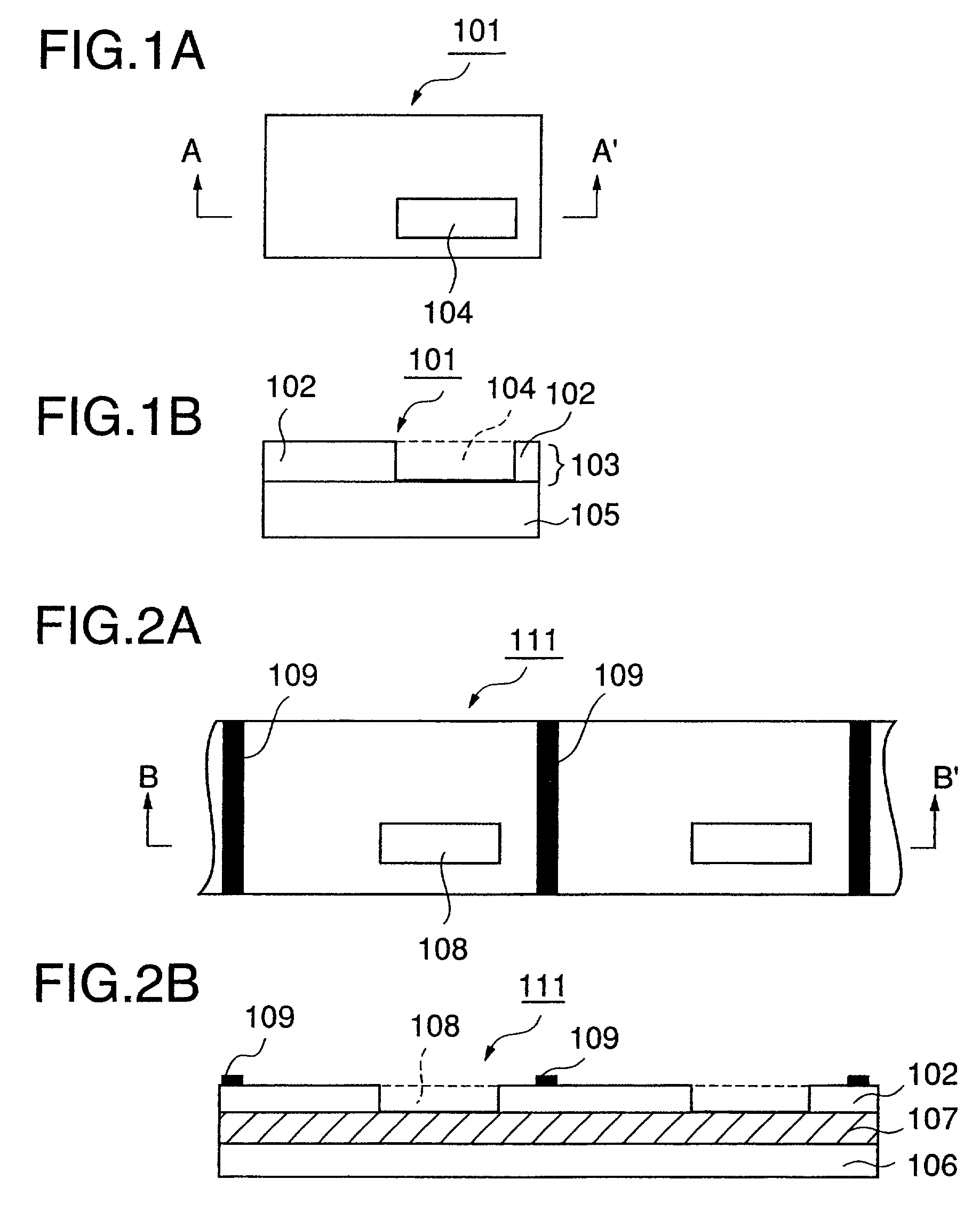

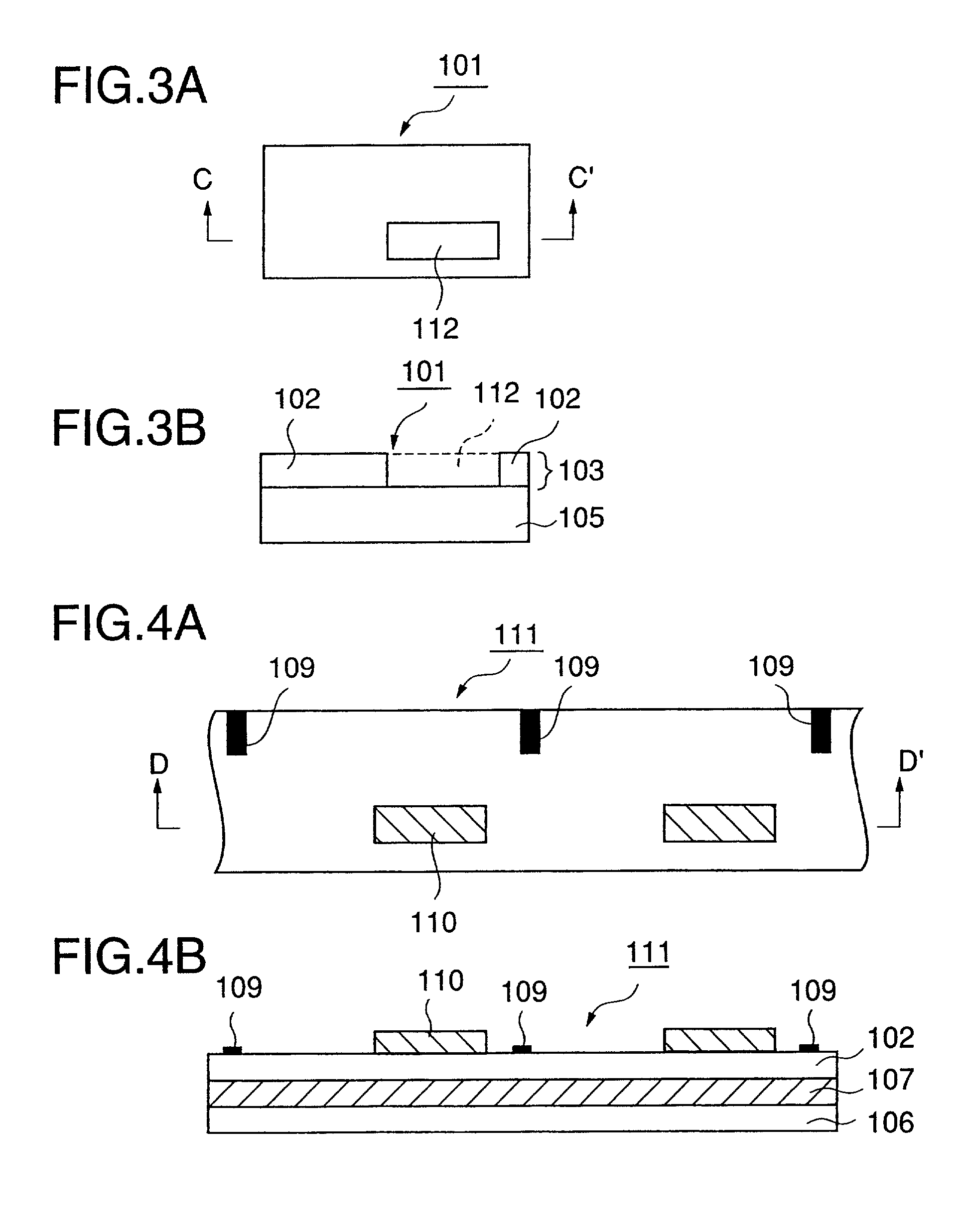

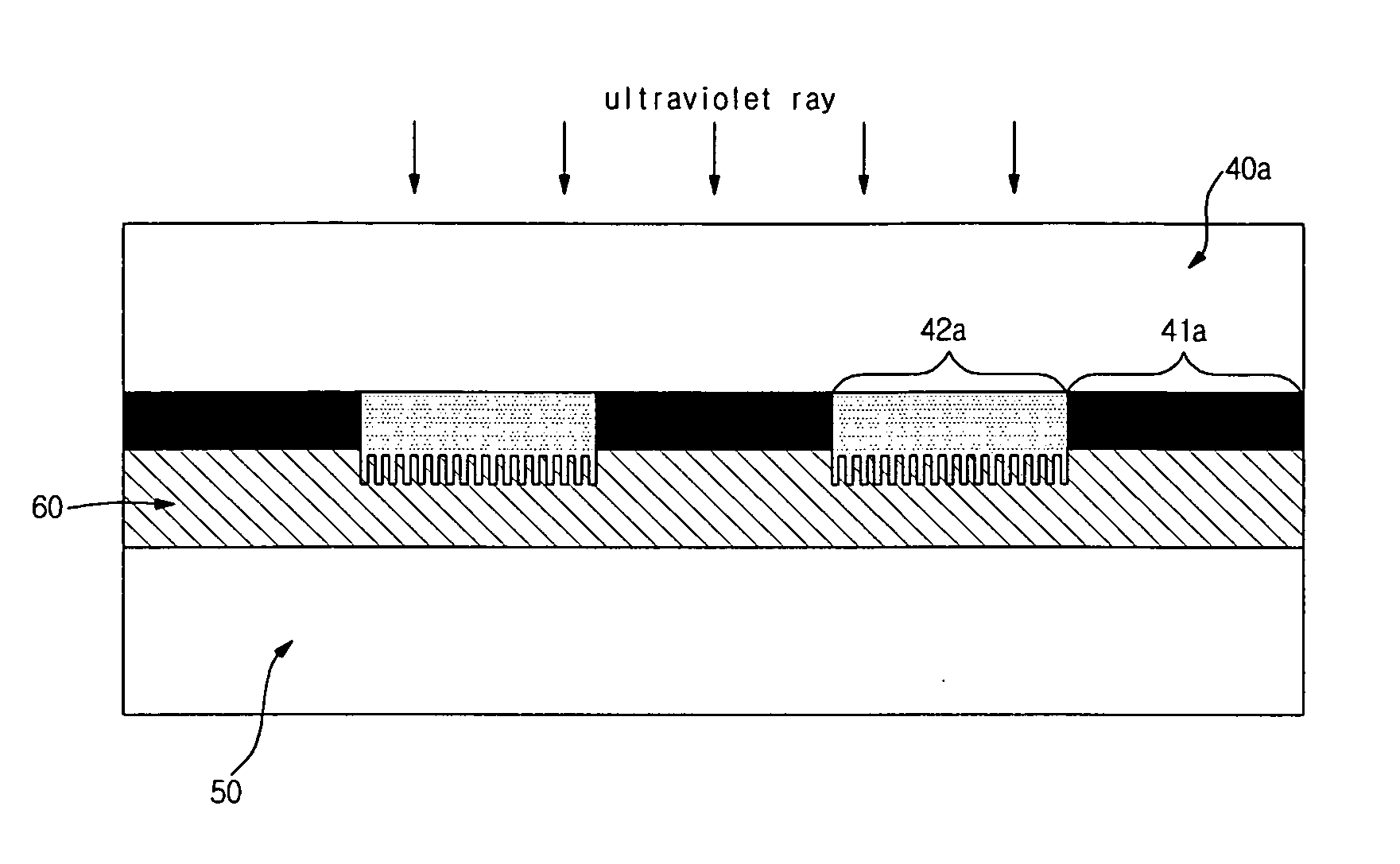

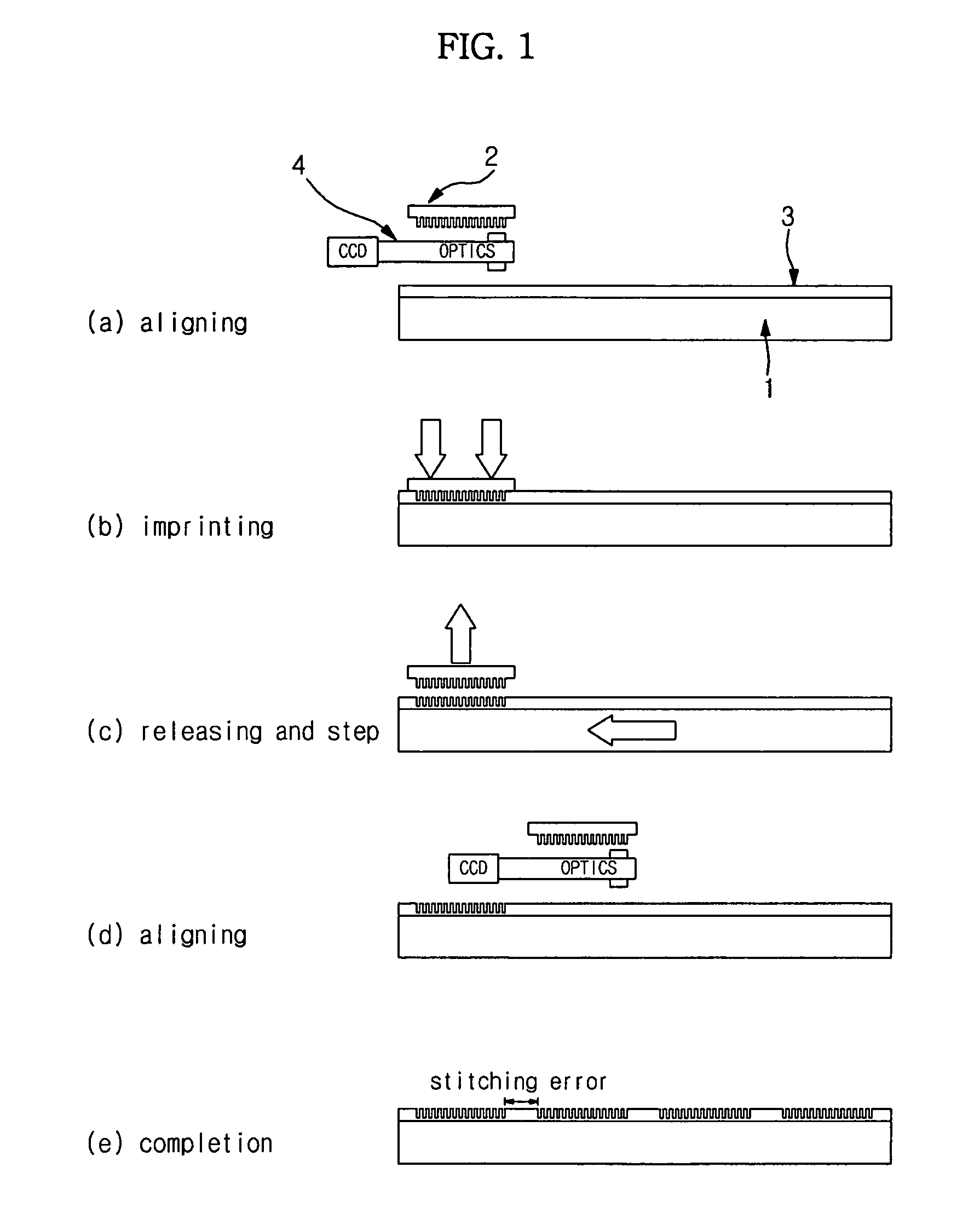

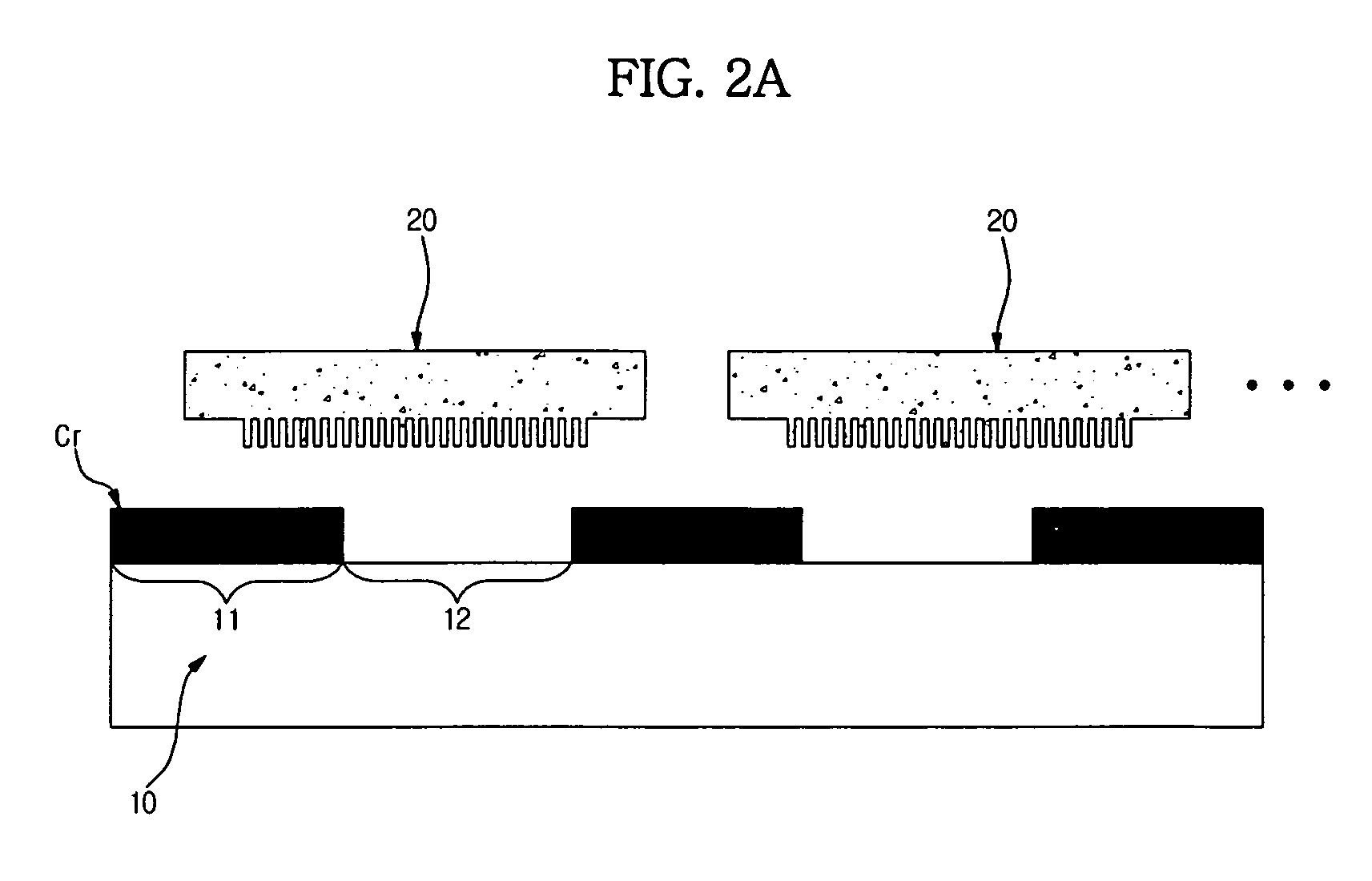

Mask mold, manufacturing method thereof, and method for forming large-sized micro pattern using mask mold

InactiveUS20080299467A1Low costStitching errorNanoinformaticsSemiconductor/solid-state device manufacturingResistMaterials science

Disclosed are a mask mold, a manufacturing method thereof, and a method for forming a large-sized micro pattern using the manufactured mask mold, in which the size of a nano-level micro pattern can be enlarged using a simple method with low cost and interference and stitching errors between cells forming a large area can be minimized. The method for manufacturing the mask mold includes the operations of coating resist on a mask or a plurality of small molds having an engraved micro pattern, pressing the small molds to imprint the micro pattern on the resist, curing the resist, and releasing the small molds from the resist.

Owner:SAMSUNG ELECTRONICS CO LTD

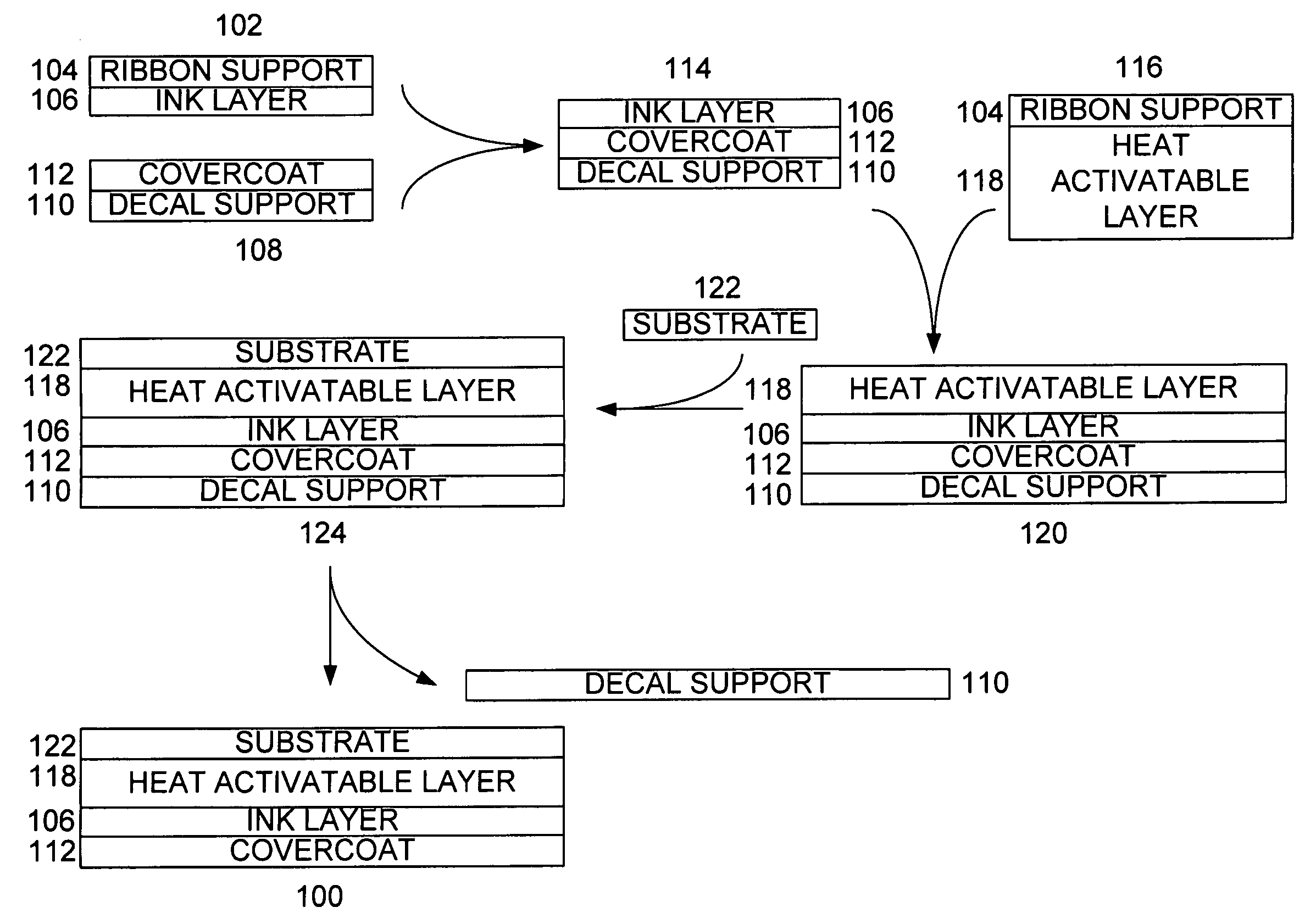

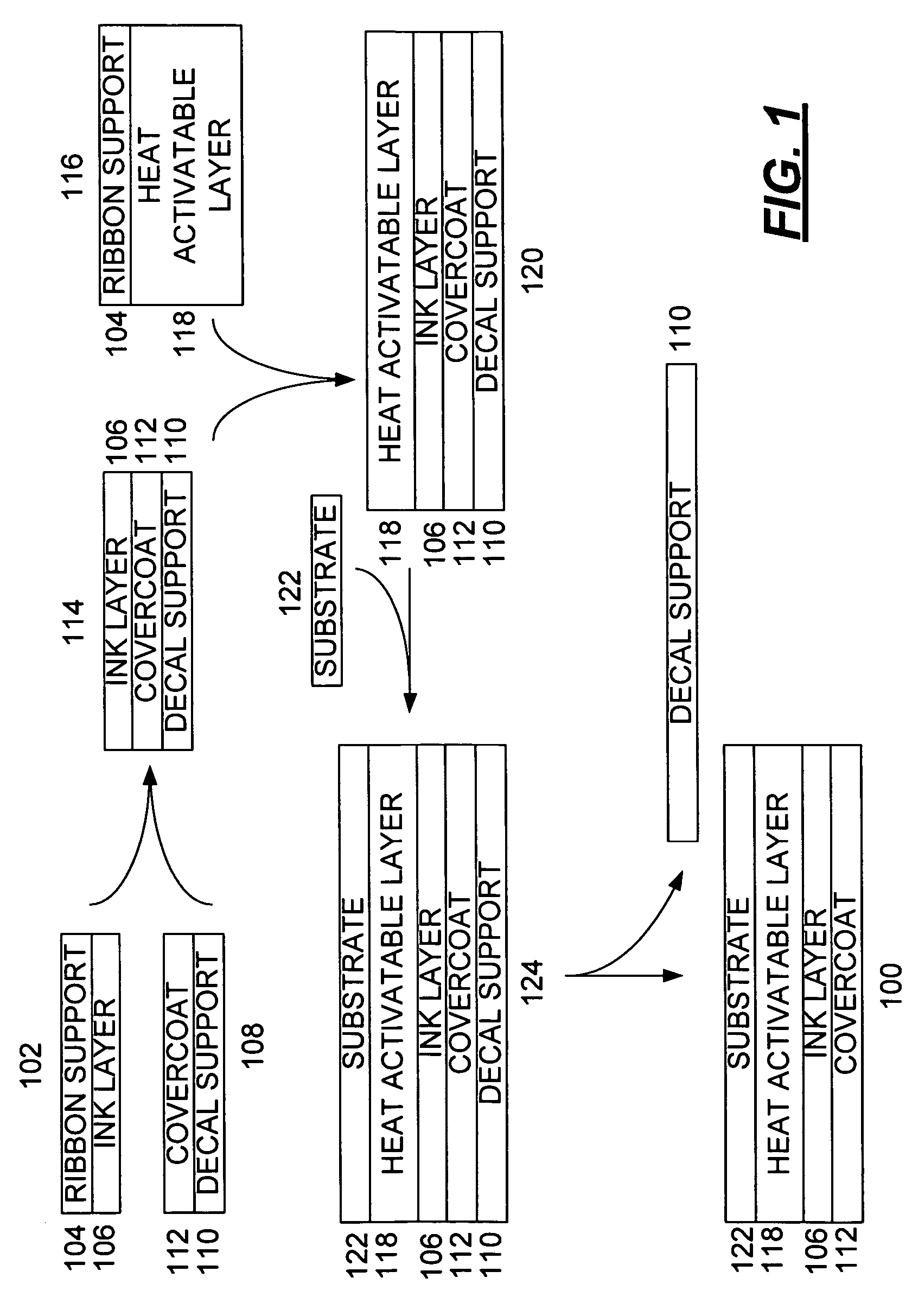

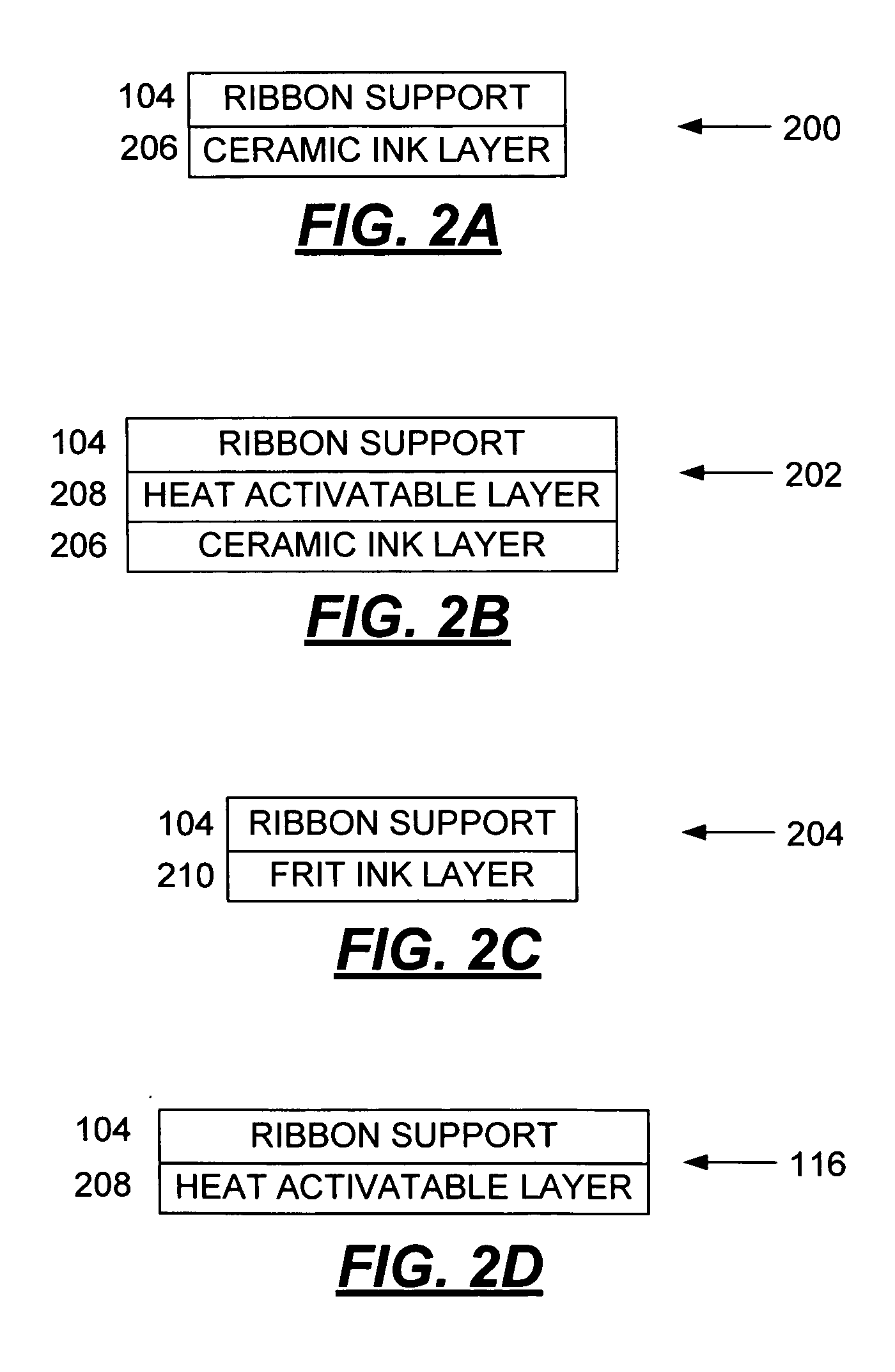

Digital decoration and marking of glass and ceramic substrates

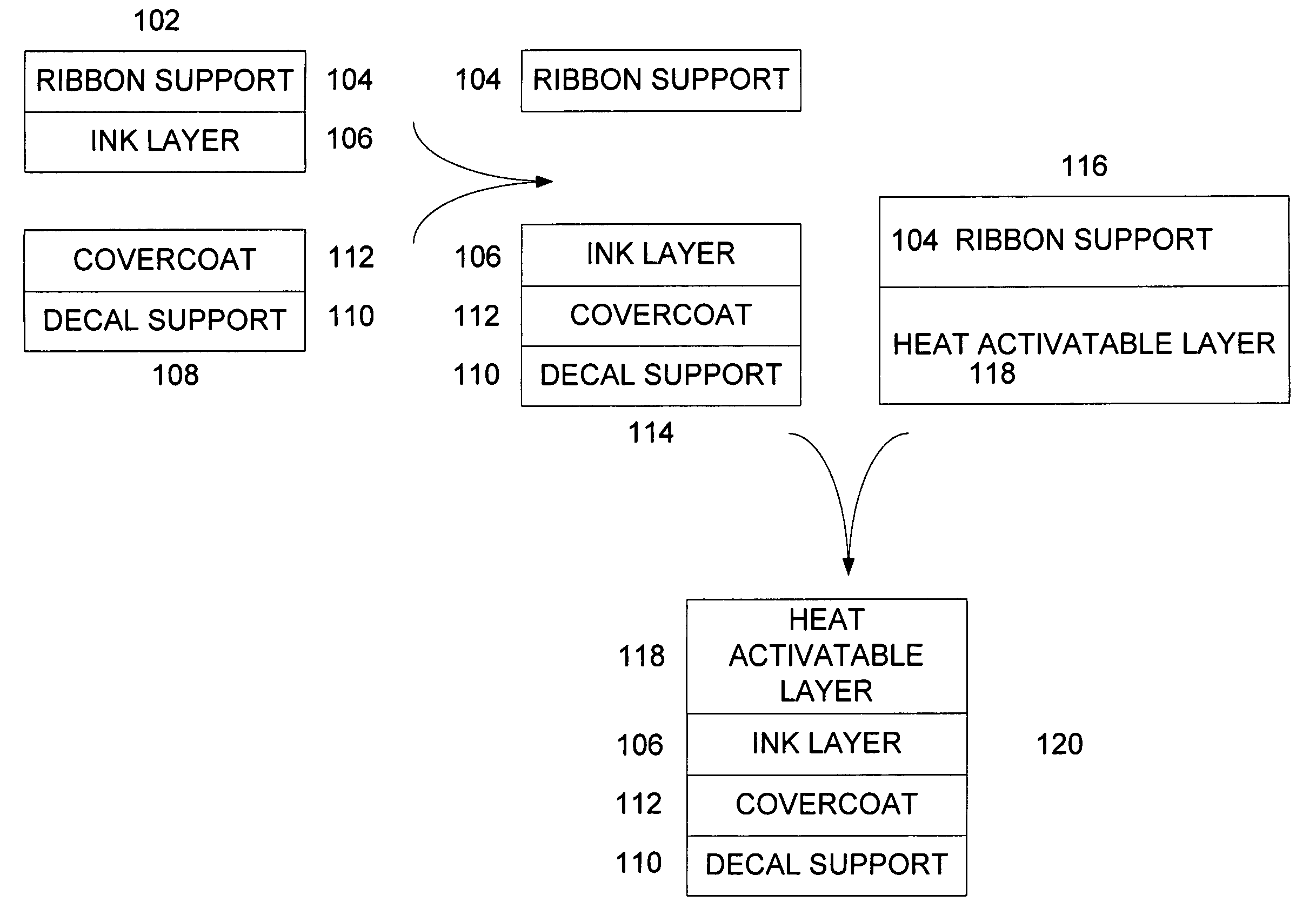

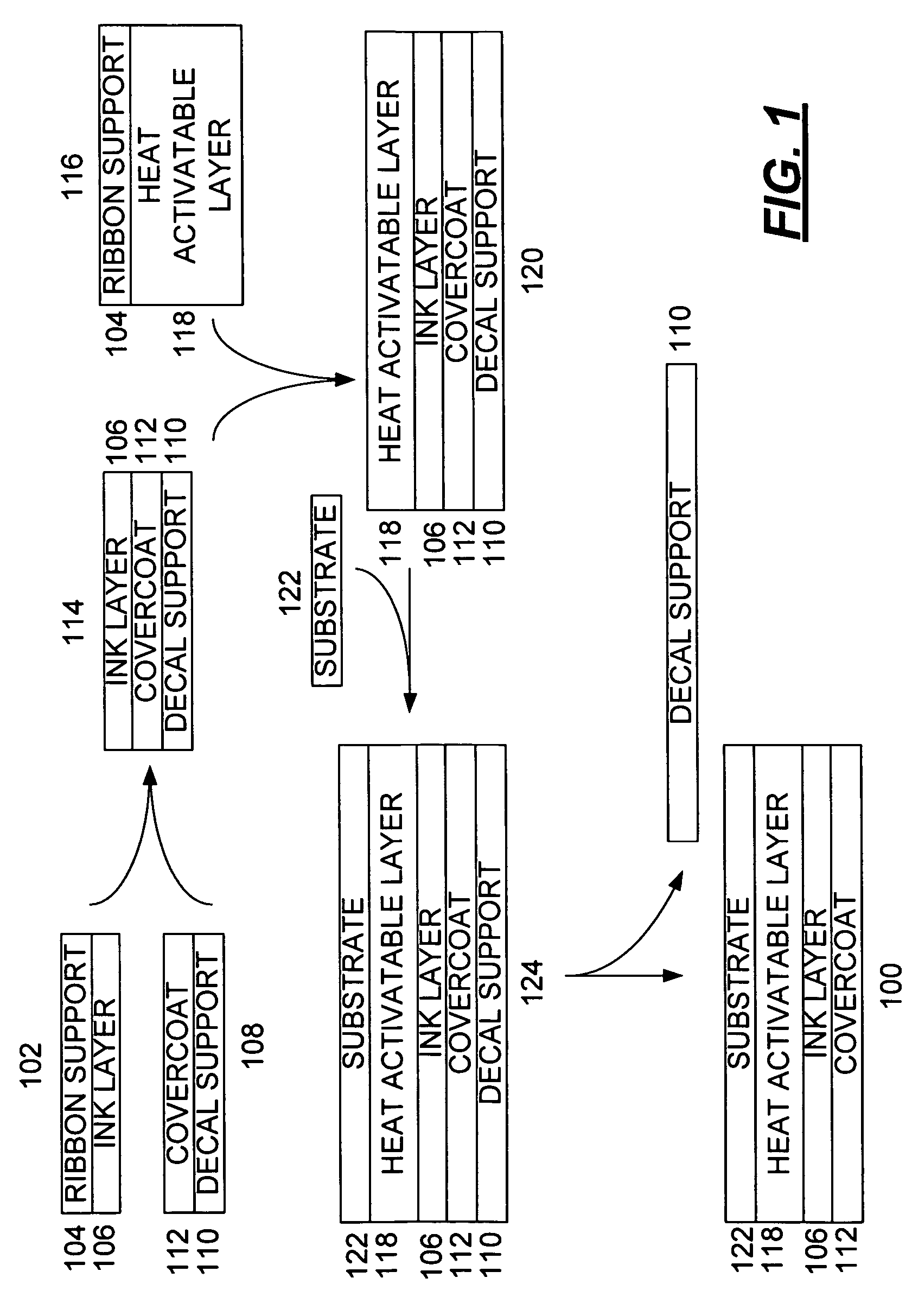

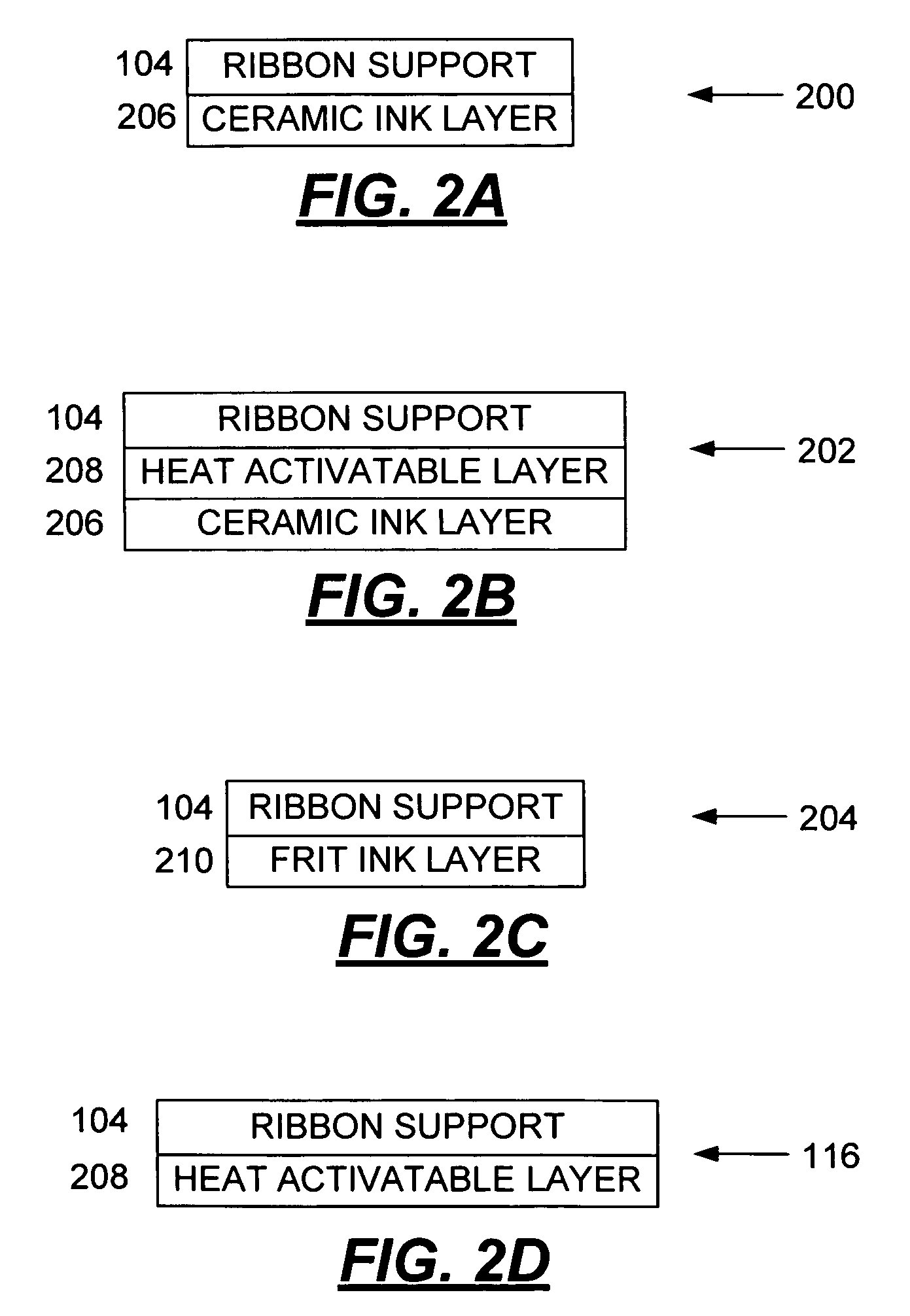

Disclosed in this specification is a decal assembly comprising a decal support, a releasable covercoat, a heat activatable layer, and an ink layer. The ink layer forms a digital image. The heat activatable layer has a high adhesion to a ceramic substrate at high temperatures and a low adhesion to the substrate at lower temperatures. Thus the adhesive properties of the decal are activated by heat. The resulting image has excellent adhesion to the substrate and resists the effects of washing.

Owner:INT IMAGING MATERIALS

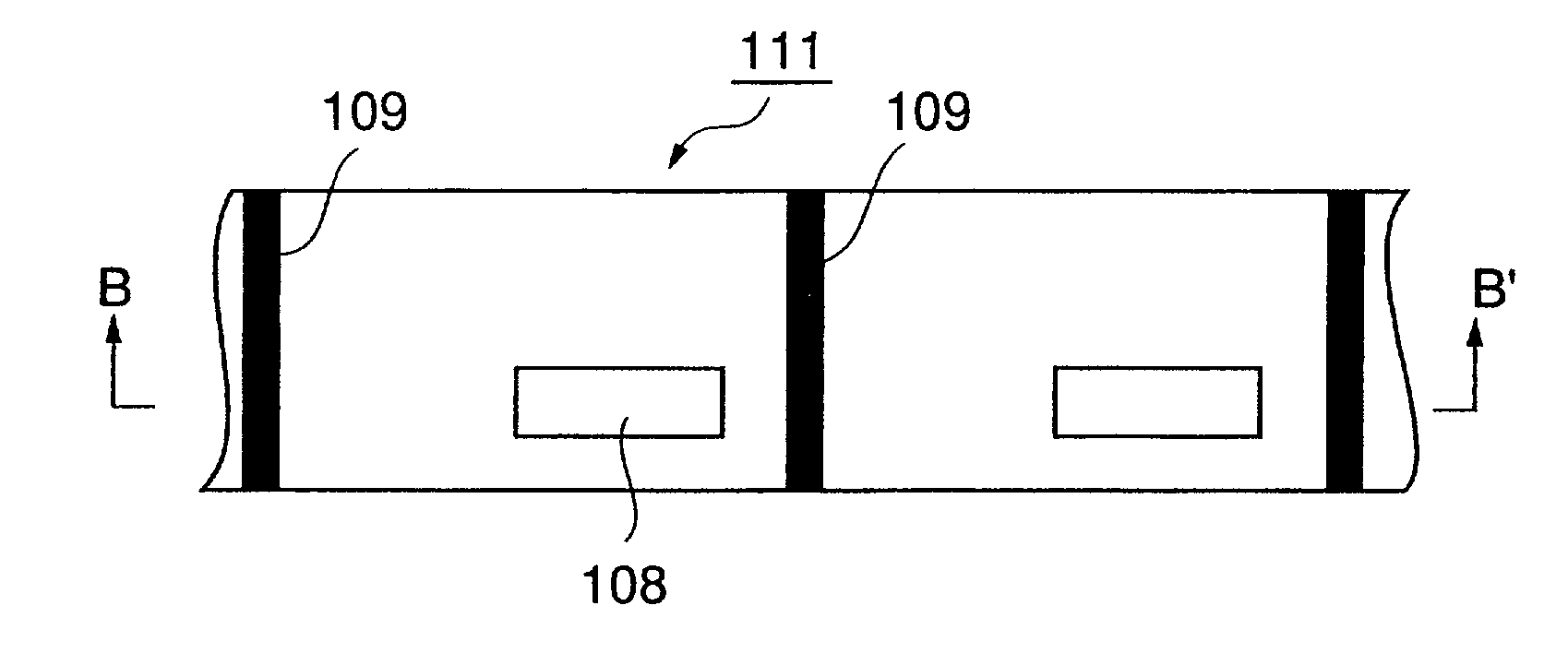

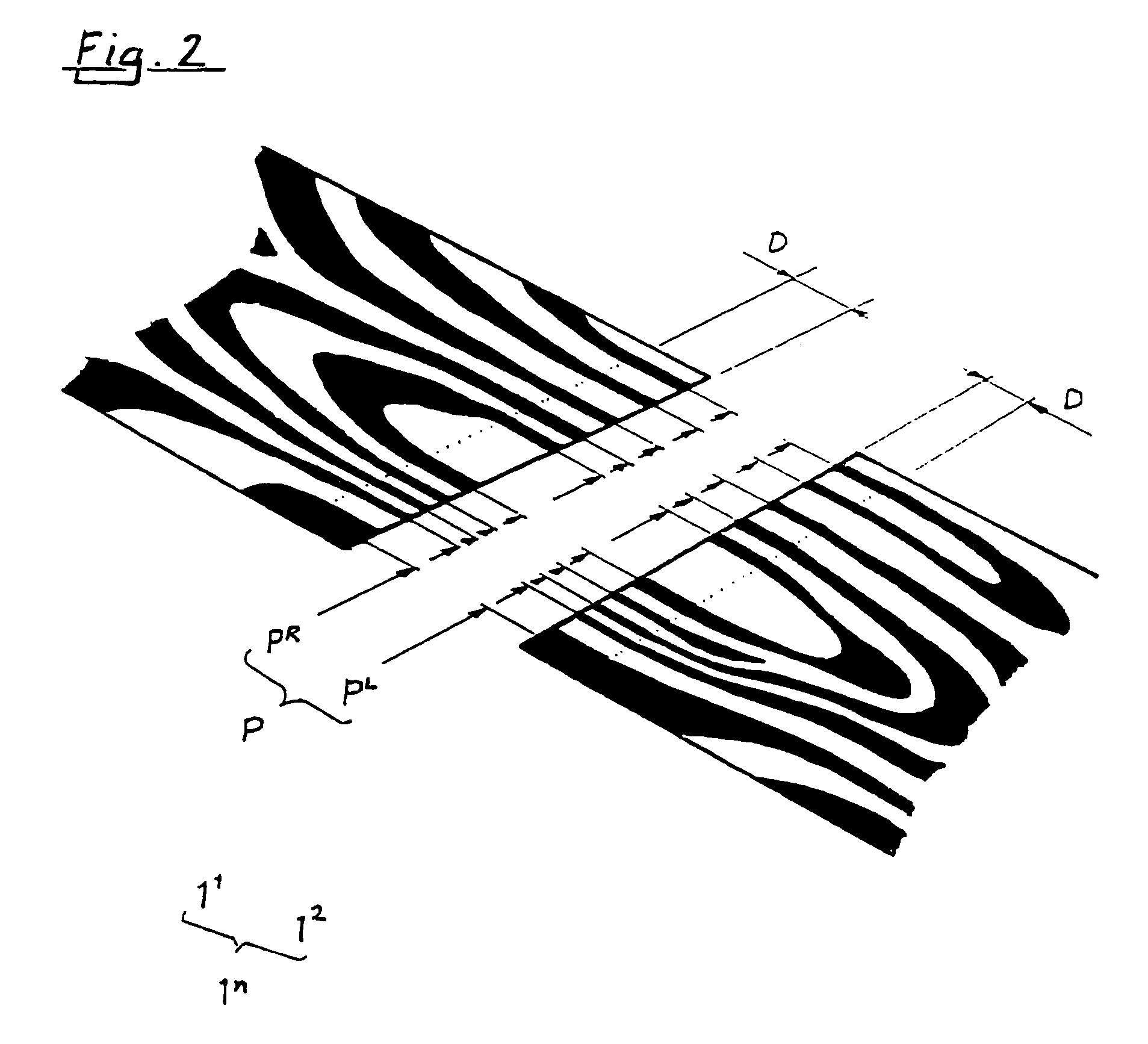

Anti-static, anti-smearing pre-stretched and pressed flat, precision-cut striped flexible coverings for transfer cylinders

InactiveUSRE39305E1Build-up of electrostatic charges on the movable, flexible jacket covering is preventedAvoid chargingCylinder pressesPlaten pressesFrictional coefficientConductive materials

Freshly printed sheets are transferred from one printing unit to another by transfer cylinders each having an ink repellent, electrically conductive, striped flexible jacket covering that is movable relative to the sheet support surface of the transfer cylinder. The jacket covering is made of a flexible fabric material that is pre-stretched, pressed flat, cut to size and treated with an ink repellent compound and is also treated with an anti-static ionic compound or is otherwise rendered electrically conductive by one or more conductive strands. Electrostatic charges carried by the freshly printed sheets are discharged through the ink repellent, electrically conductive, flexible jacket covering into the grounded transfer cylinder. A low friction, electrically conductive cylinder base covering that includes center alignment marks is secured to the transfer cylinder for engaging the flexible jacket covering. The ink repellent, electrically conductive flexible jacket covering is provided with alignment center marks and alignment stripes so that the flexible jacket covering can be precisely aligned with ease and secured over the gripper edge, tail edge and side edges of the transfer cylinder. The low frictional coefficient of the conductive cylinder base covering is further reduced by nodes and / or openings.

Owner:DEMOORE HOWARD WARREN +1

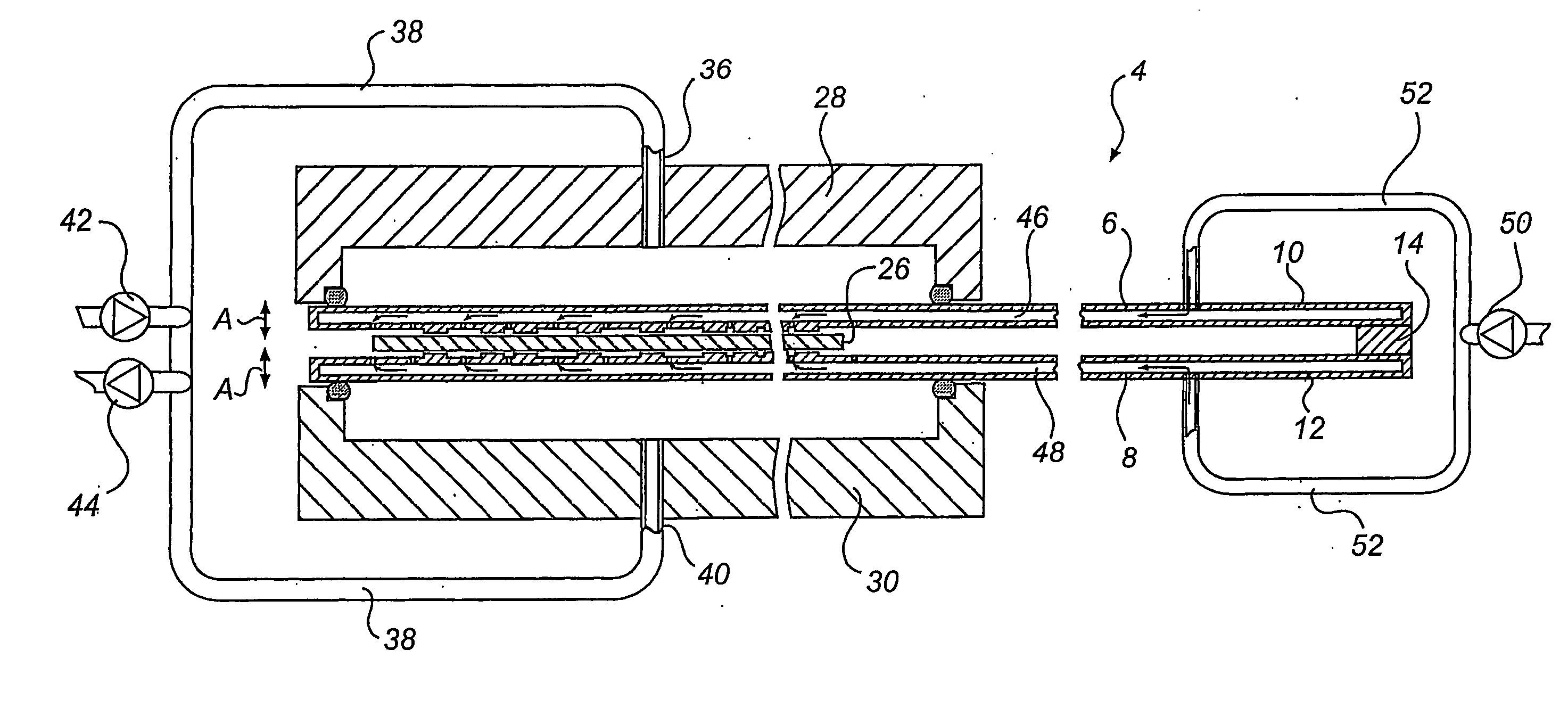

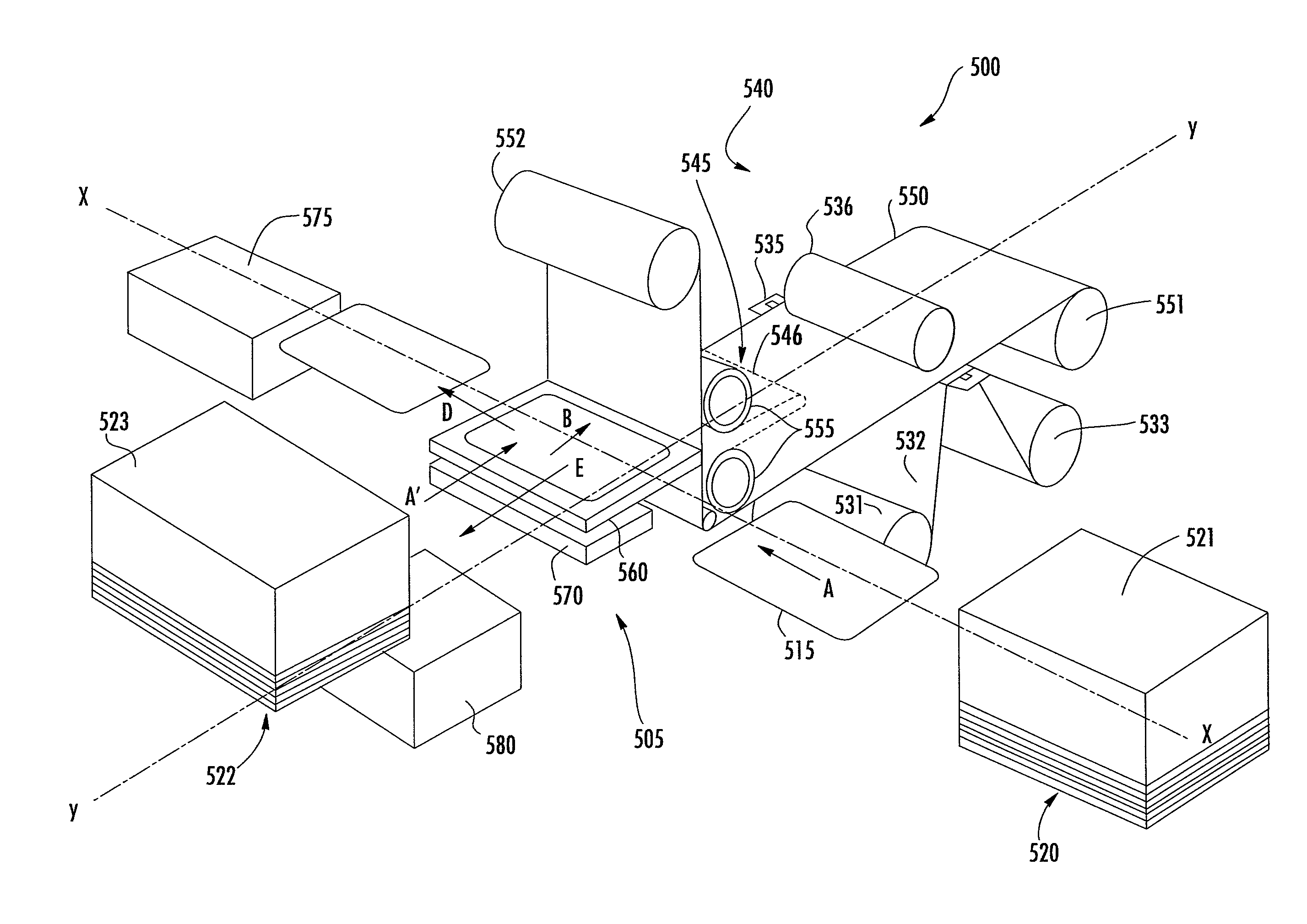

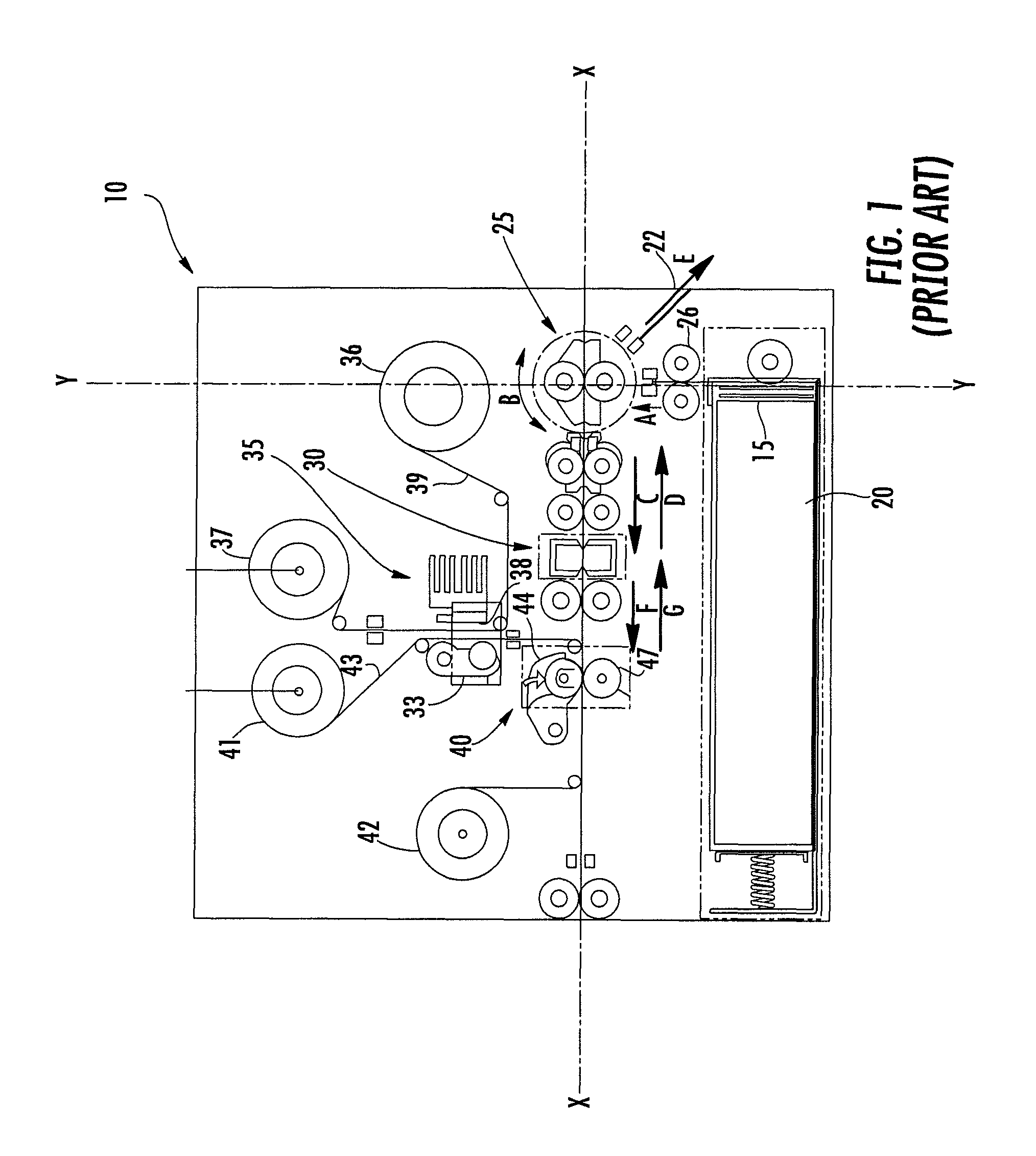

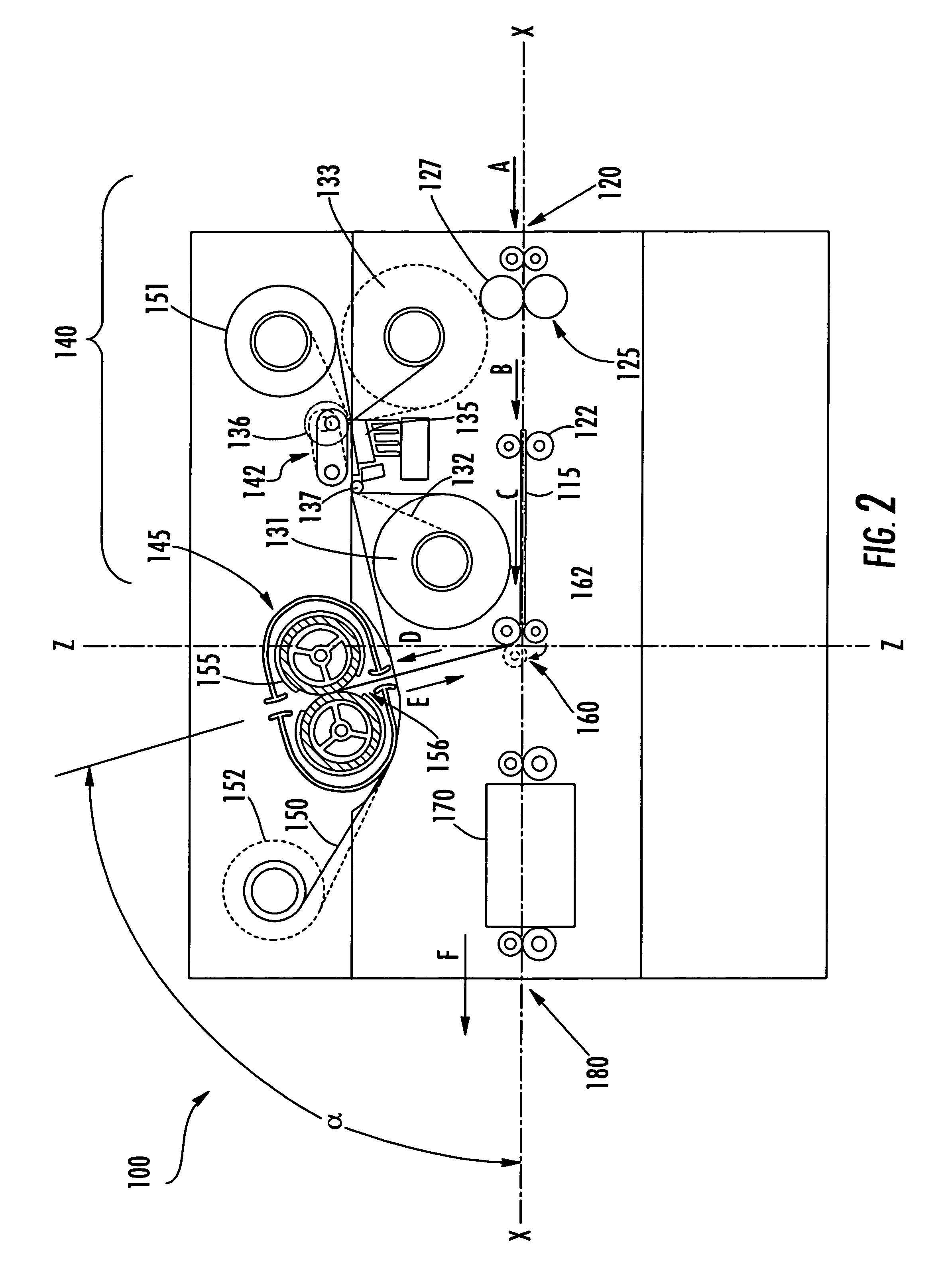

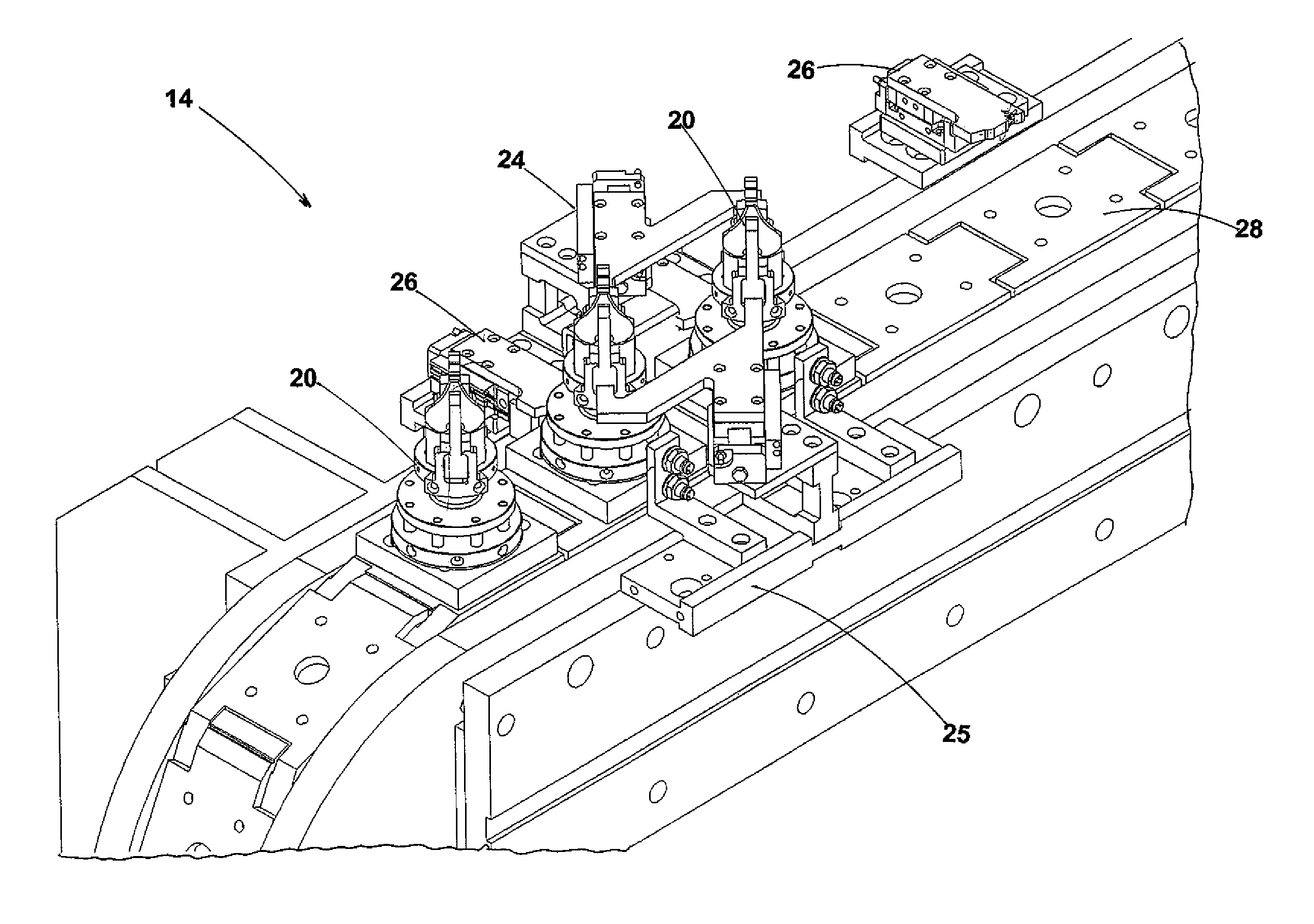

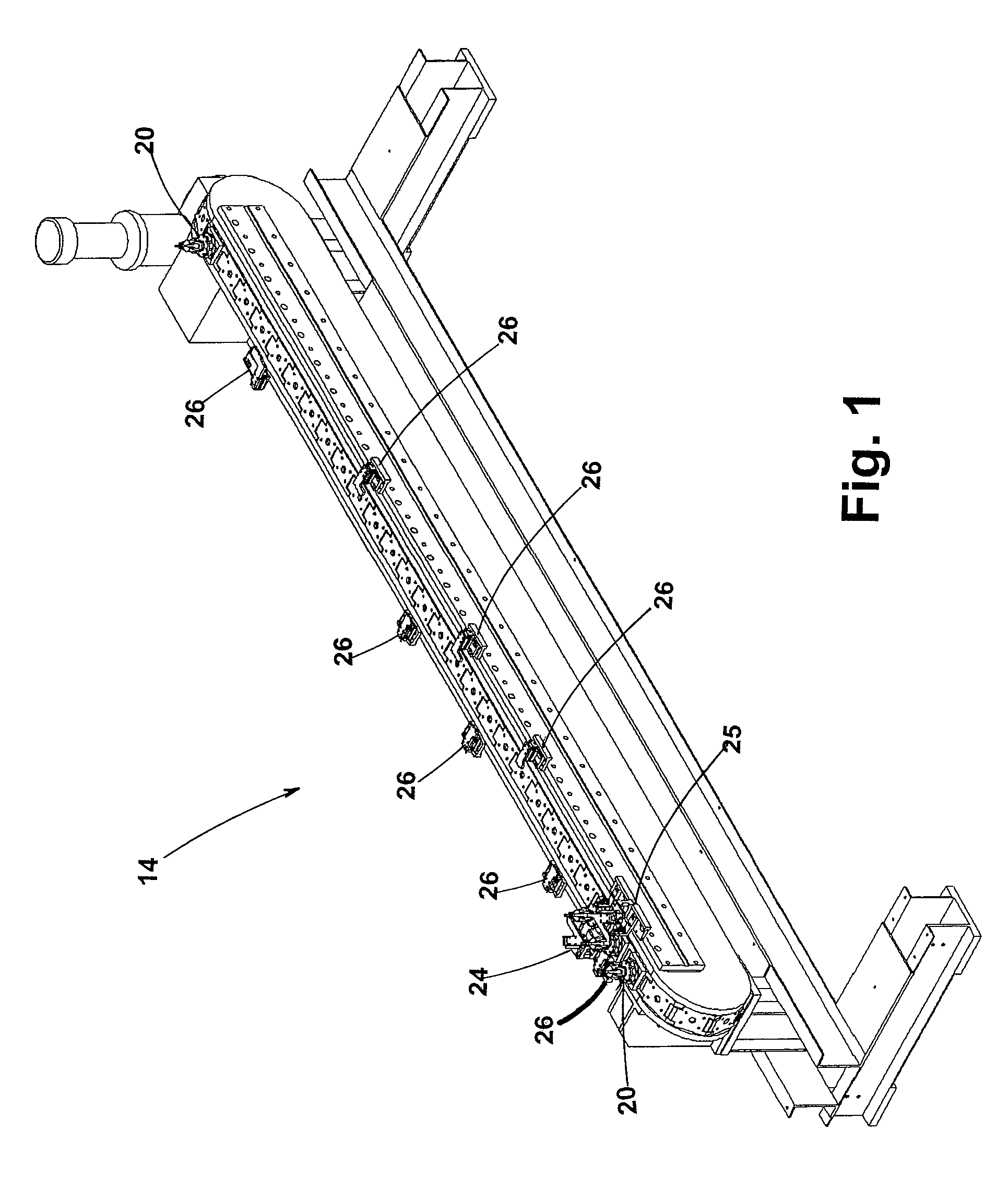

Single-pass double-sided image transfer process and system

ActiveUS7870824B2Improve precisionEasy to operateRecord carriersPlaten pressesImage transferProduct processing

The present disclosure is directed to a printing assembly incorporating an improved double-sided image transfer station. The present disclosure also describes a product processing apparatus including a cross feed processing architecture. The single-pass double-sided image transfer station and cross feed processing architectures described herein provide numerous advantages over prior art product processing devices. In particular, the single-pass double-sided image transfer station provides for reduced print times, less shuttling of the product during printing, and a less complex, therefore, more reliable printing operation overall. The cross feed architecture provides an efficient processing path for the product through the device and facilitates processing modularization.

Owner:ZEBRA TECH CORP

Label assembly and method of using the same to label articles durably yet removably

Owner:AVERY DENNISON CORP

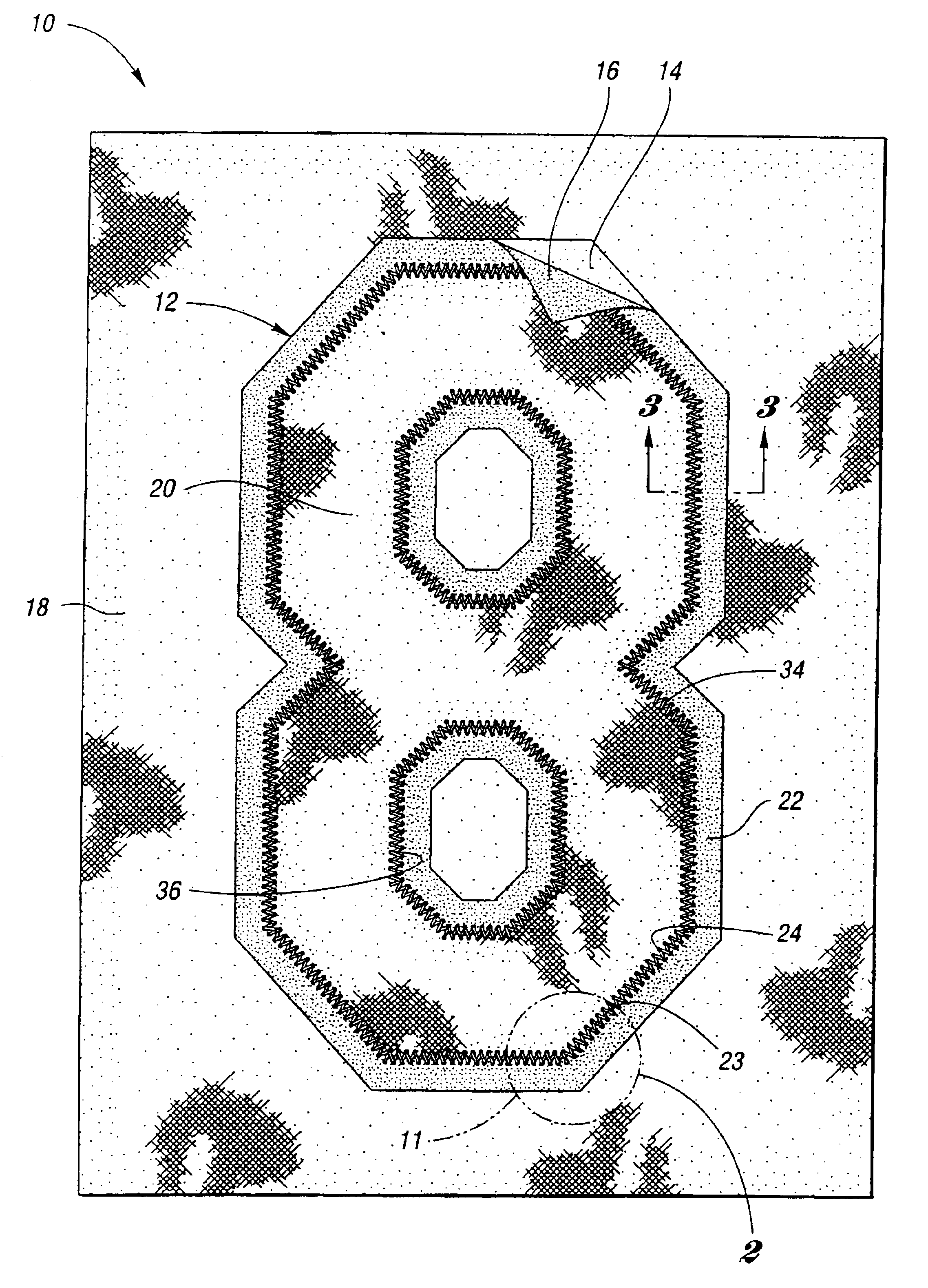

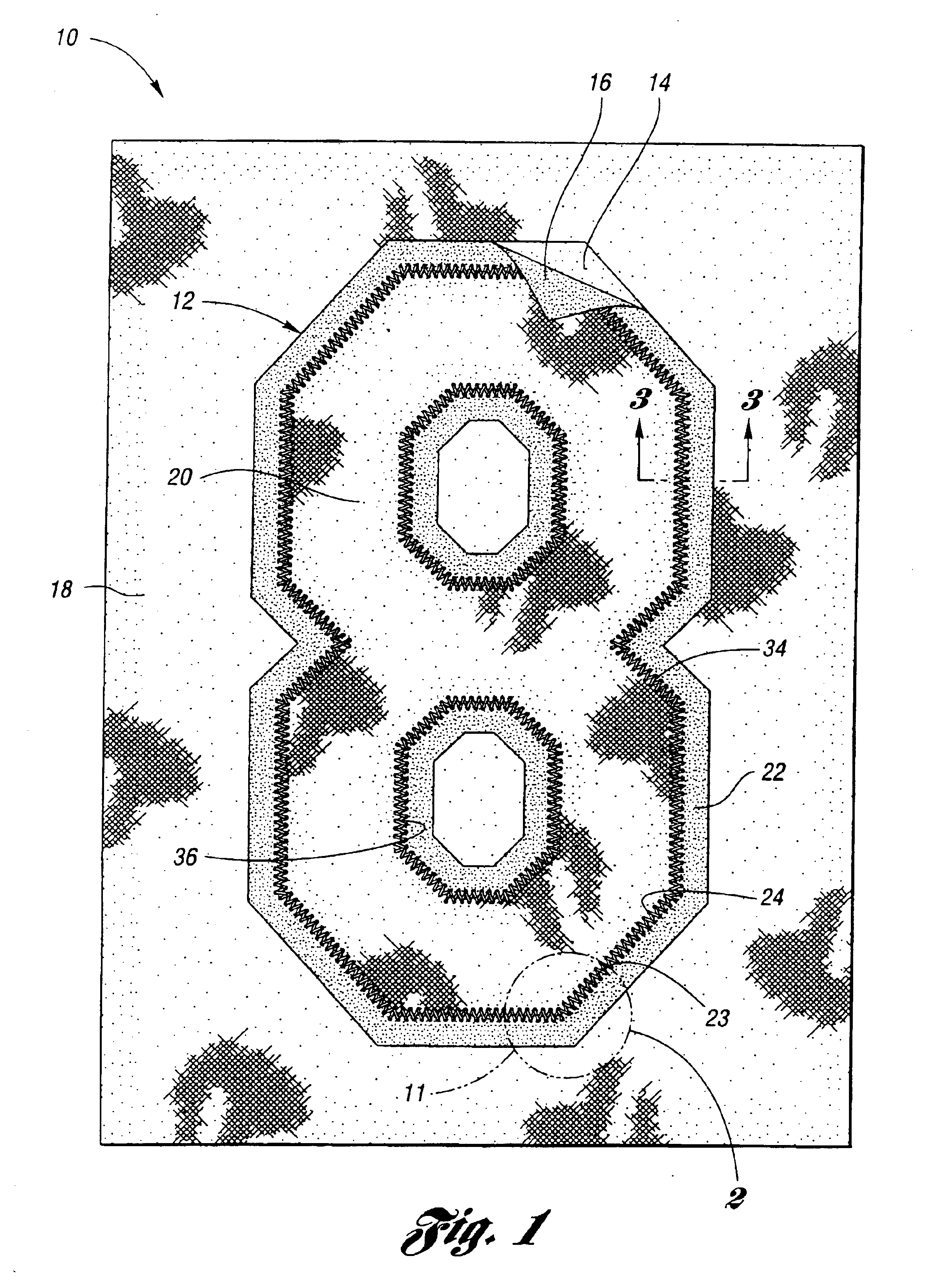

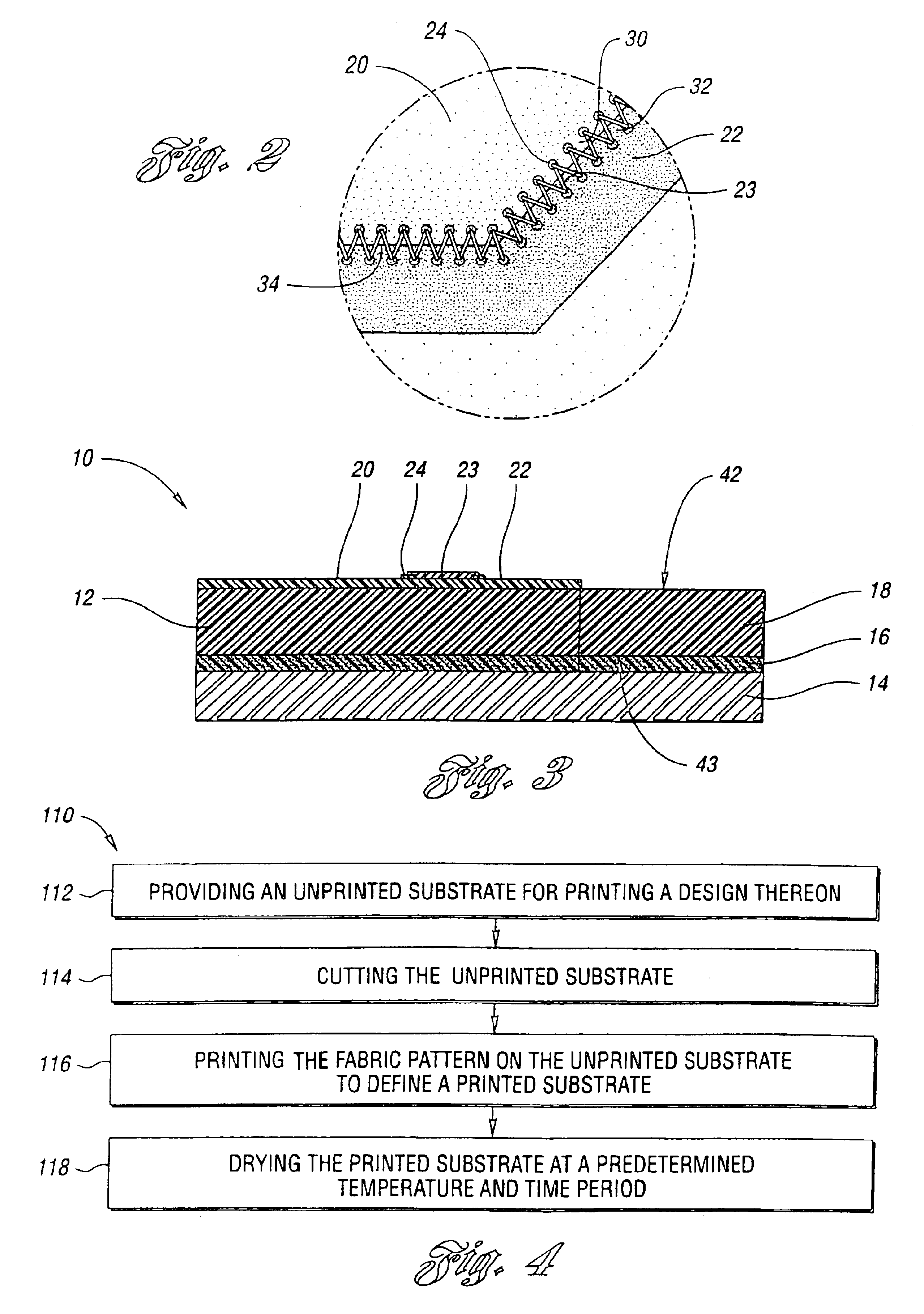

Screen printed fabric

InactiveUS6955124B2Without sacrificing aesthetic appearanceCost efficientPlaten pressesNatural patternsEngineering

Owner:STAHLS INC

Media having ink-receptive coatings for heat-transferring images to fabrics

An improved ink-jet printable heat-transfer medium comprising a base substrate having a surface coated with a hot-melt layer and an ink-receptive layer is provided. The ink-receptive layer comprises: i) non-polymeric organic particles that are a reaction product of a diamine and two molecules, each molecule having at least one carboxylic acid group and at least five carbon atoms, ii) thermoplastic polymer particles, and iii) a thermoplastic film-forming binder. The heat-transfer paper can produce printed images having improved color quality, hand, and wash-durability on a variety of fabric materials.

Owner:ARKWRIGHT ADVANCED COATING

Method of printing foil images upon textiles

A method of printing foil images upon textiles is provided. Advantageously, a digital inkjet printer can be utilized to apply an adhesive for affixing a foil embellishment. The method of printing foil images upon textiles includes applying a pretreatment solution upon a textile. After the pretreatment solution has dried, a white underbase in the form of a fanciful design is printed upon the textile using a digital inkjet printer. A heavy color layer of color ink is then digitally inkjet printed upon the white underbase. Thereafter, the textile is removed from the inkjet printer and positioned upon a heat press table. Foil transfer paper is positioned upon the textile so as to cover the white underbase and heavy color layer. The heat press is activated so as to adhere the foil, but only to those regions where the white underbase and color ink has been printed. Once cool to the touch, the foil is slowly peeled from the textile so as to leave a fanciful foil design.

Owner:R PATTERN INC

Printing sleeve with an intergrated printing surface

ActiveUS20050150406A1Improve adhesionQuality improvementElectric discharge tubesPhotomechanical coating apparatusPhotopolymerEngineering

A seamless printing sleeve comprising a hollow cylindrical base and a seamless imageable surface as its outermost layer is described. The imageable surface acts as an integral flexographic printing surface. Preferably the printing sleeve comprises an intermediate photopolymer or resilient polymer layer between the outer surface of the base and the imageable surface. Also, preferably the base is uniformly transparent or translucent to actinic radiation.

Owner:MACDERMID PRINTING SOLUTIONS

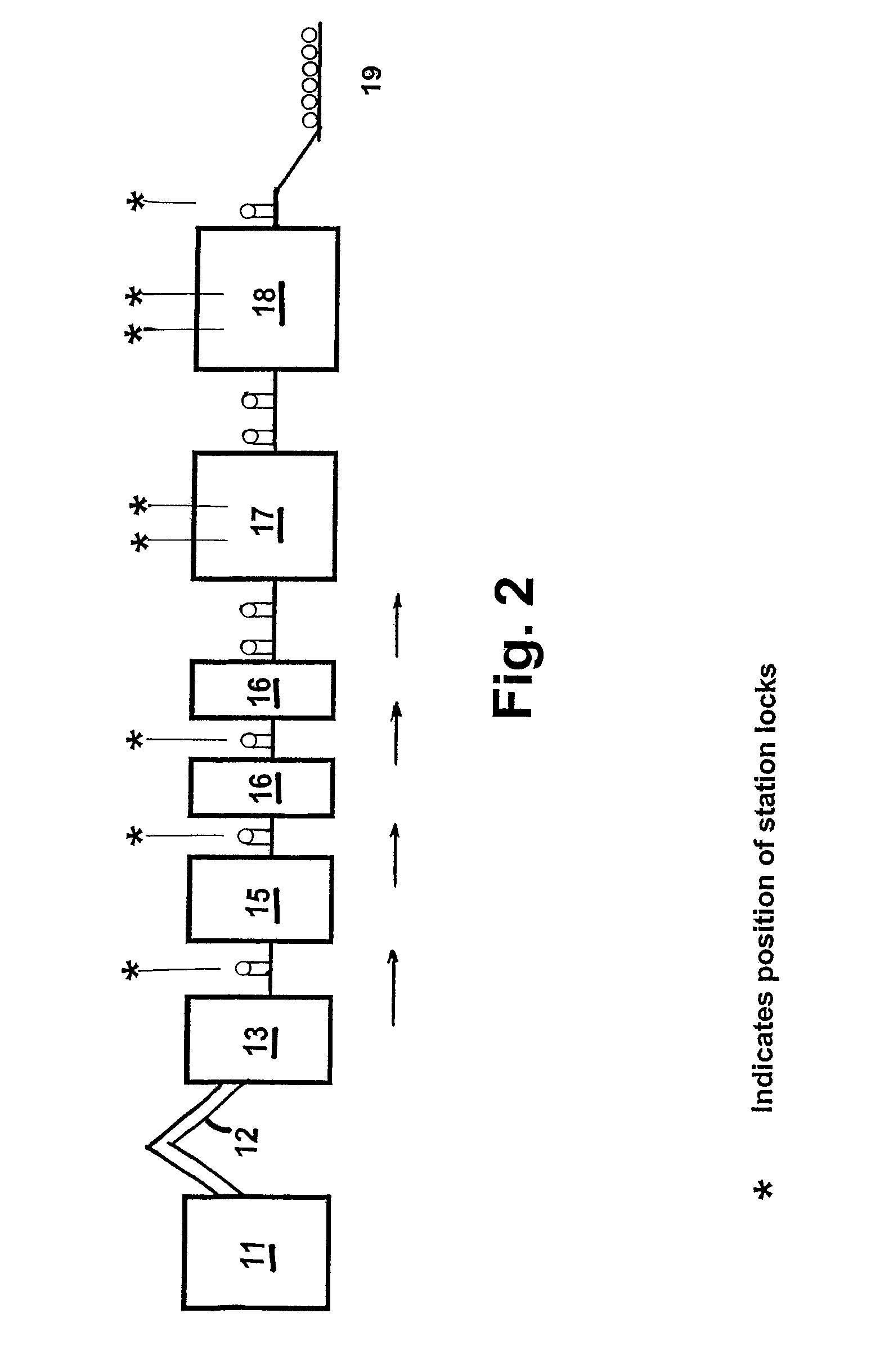

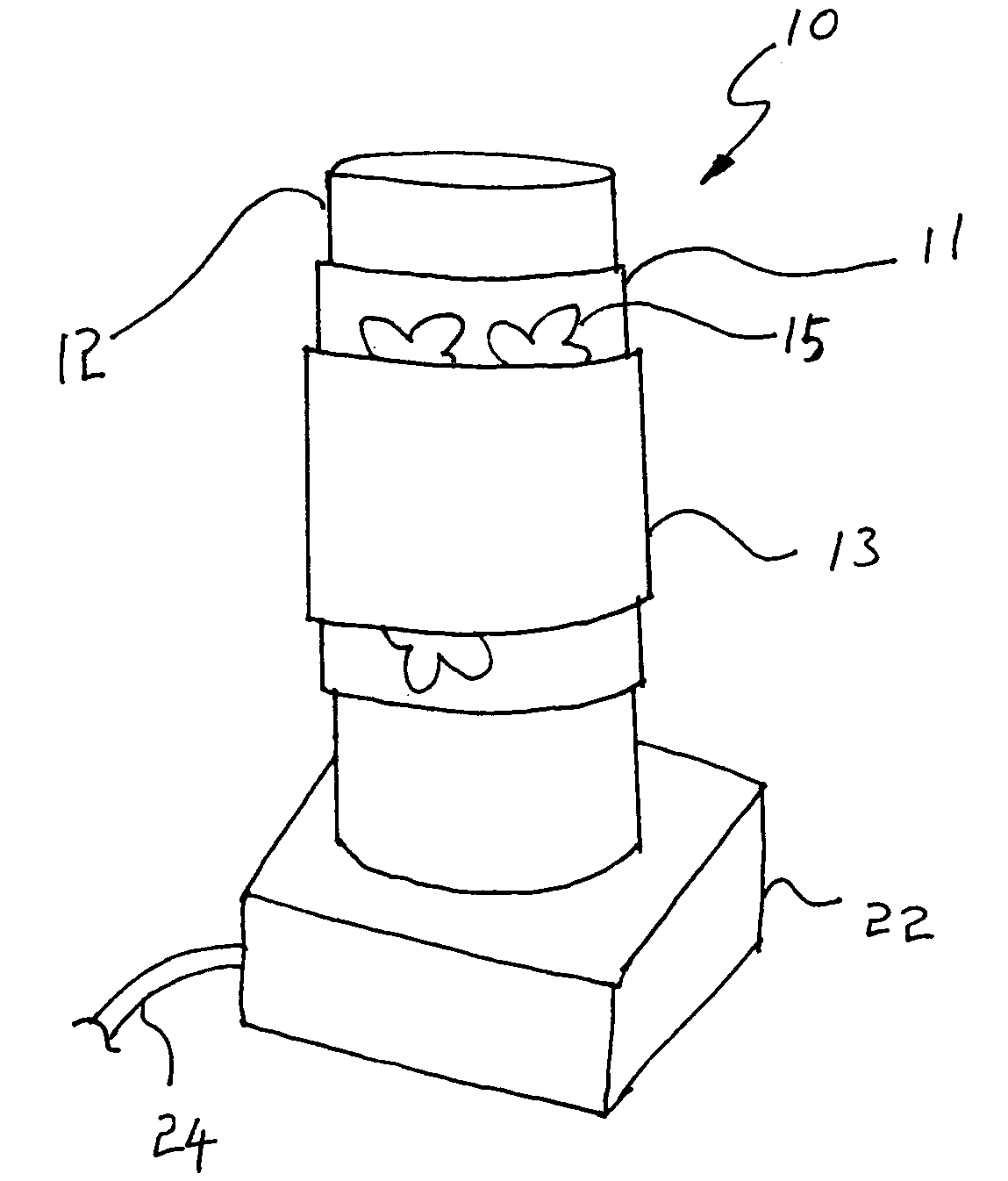

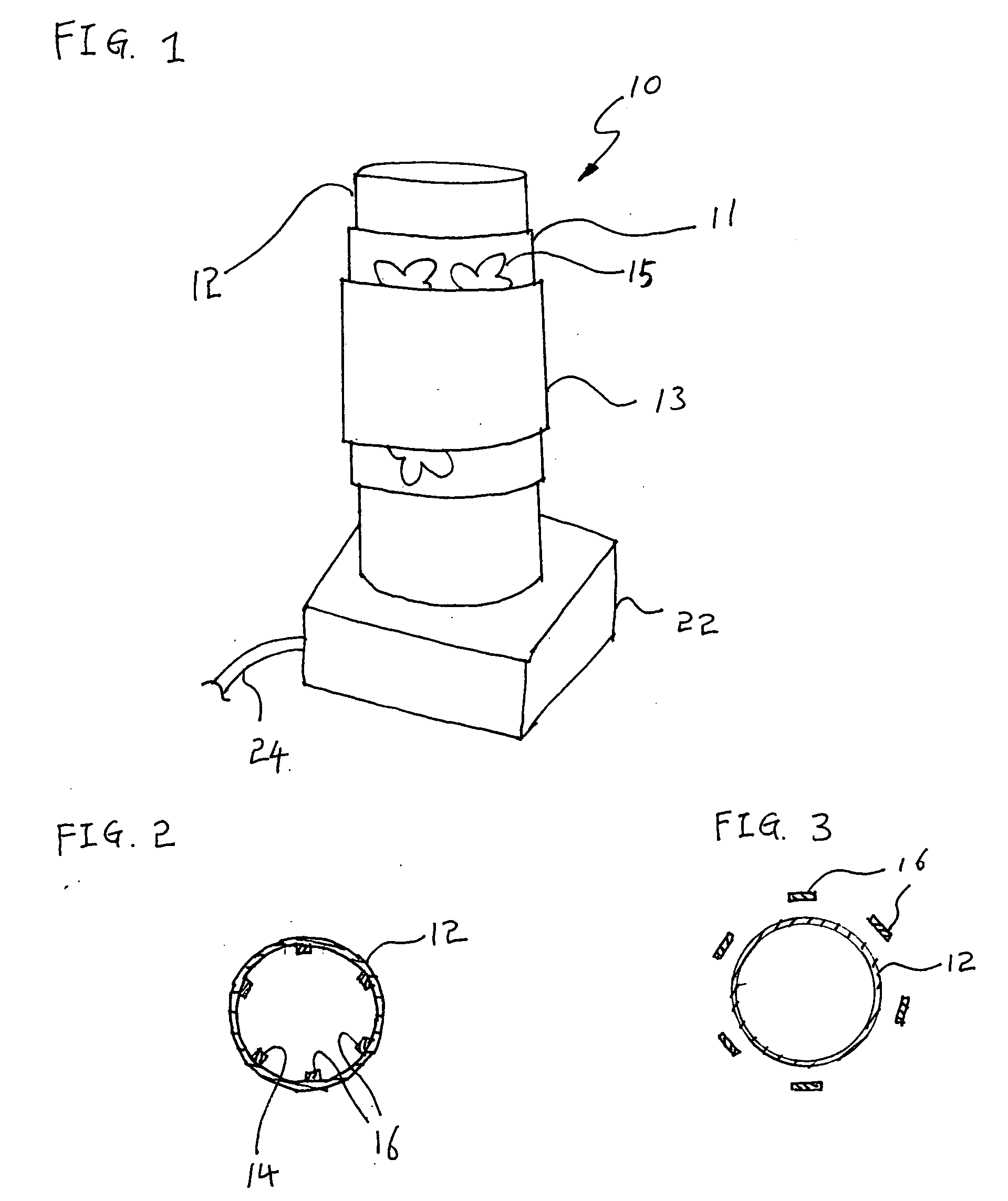

Method and apparatus for automatic indexing of a golf ball

ActiveUS7387070B1Reduce and eliminate wearReduce and eliminate and tearCylinder pressesPlaten pressesPad printingAutomatic indexing

A method and apparatus for applying printing of indicia and logo to golf balls held and indexed by magnetic indexing devices connected to a conveyor. The device includes a stationary base portion and a rotating cup portion which are magnetically coupled to each other. Each portion has recesses for housing magnets to create a magnetic field of attraction which firmly locks the two portions together. When rotation of the cup portion to the base portion is required, the rotation is substantially friction-free because of a thrust bearing ring set in the base portion. The cup portion is caused to rotate 45° or 90° upon being biasly urged by station locks located on the conveyor. The cup portion has an open bridge section wherein cam surfaces of the station locks can engage and cause the cup portion to rotate, which is necessary for each new procedure, whether it be inspection of the ball, pad printing of indicia and logo, or curing the printed ink with ultraviolet light.

Owner:ACUSHNET CO

Intermediate transfer members for use with indirect printing systems and protonatable intermediate transfer members for use with indirect printing systems

ActiveUS10642198B2Increase resistanceHigh strengthStereotype printingElectrographic process apparatusElastomerPolymer science

Disclosed are curable polymer compositions, elastomers thereof and release layers useful in the art of printing made of the disclosed elastomers. Disclosed are also intermediate transfer members having a release layer useful in the art of printing. Disclosed are anisotropic intermediate transfer members. Disclosed are curable adhesive compositions, that in some embodiments are useful in preparing intermediate transfer members useful in printing. Also disclosed are intermediate transfer members useful in the art of printing having a release layer with an image transfer surface having protonatable functional groups apparent thereupon. Also disclosed are methods of making such intermediate transfer members.

Owner:LANDA

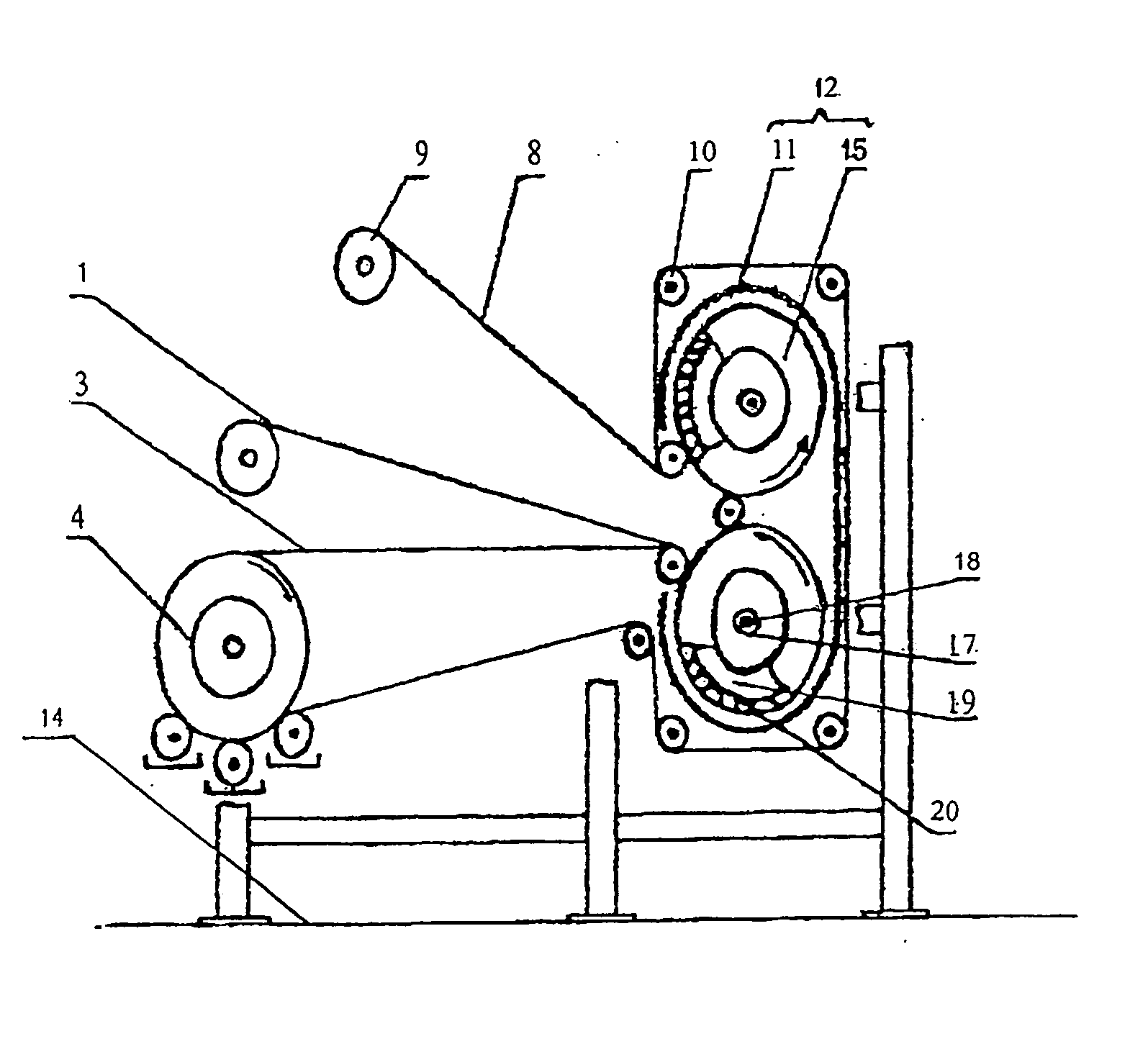

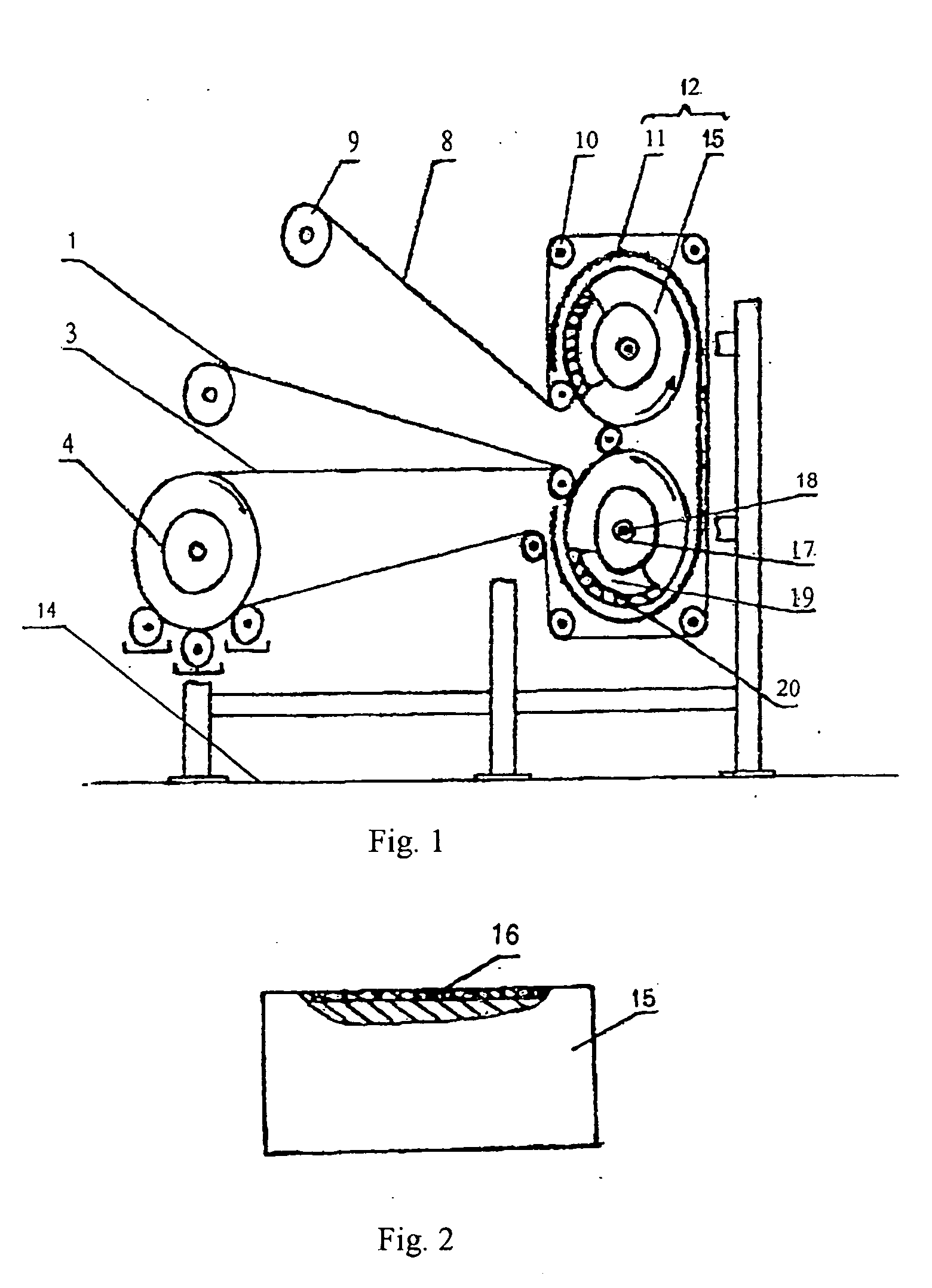

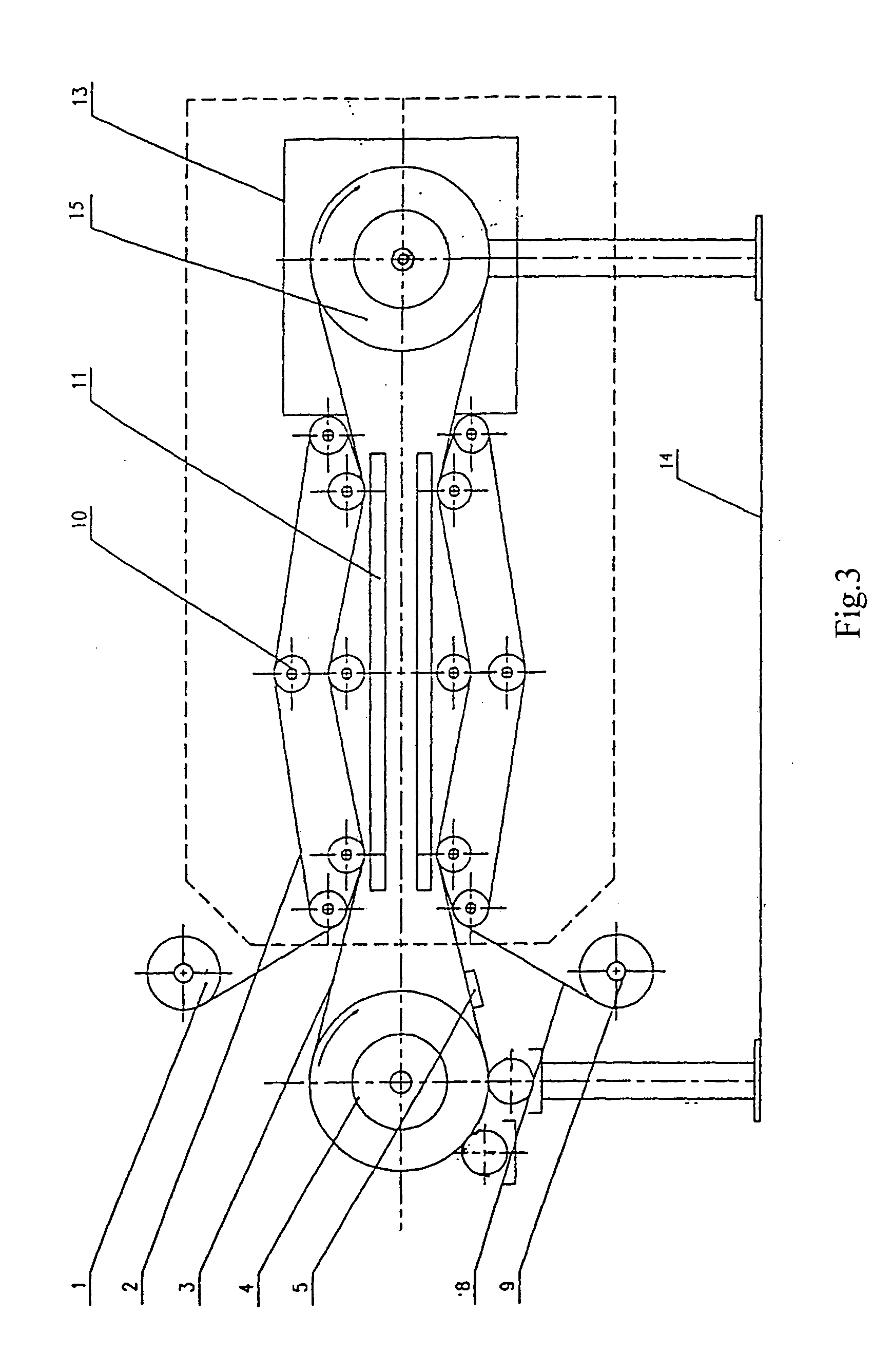

Apparatus for paperless transfer printing and the process thereof

InactiveUS20050139096A1Strong absorption capabilityReduce tensionRecording apparatusTransfer printingMetal foilClose contact

The present invention is related to an apparatus for paperless transfer printing, which includes a printer and a heat transfer printing machine, the printer is connected and assembled with the heat transfer printing machine by an endless metal foil belt, the heat transfer printing machine includes at least a heating transfer printing roller, or a weight bearing crawler belt, or a weight bearing plate the heating transfer printing roller can absorb the belt of metal foil by negative pressure of vacuum or by magnetic means, which result in the close fitting of the belt to the surface of the heating transfer printing roller. The paperless heating transfer printing apparatus also includes a heating device to heat the belt of the metal foil. A set process of printing is also proposed in this invention, which used said apparatus. By using this kind of apparatus and the process, the problem, that the metal foil easier wrinkles than paper does is overcome, and the substrate can close contact with the surface of the roller, the heat can be transferred more uniformly. The patterns the apparatus made are lucidity and less color difference or un-sharpness, the pulling force acting on the foil is also reduced.

Owner:XIANGYANG LU +1

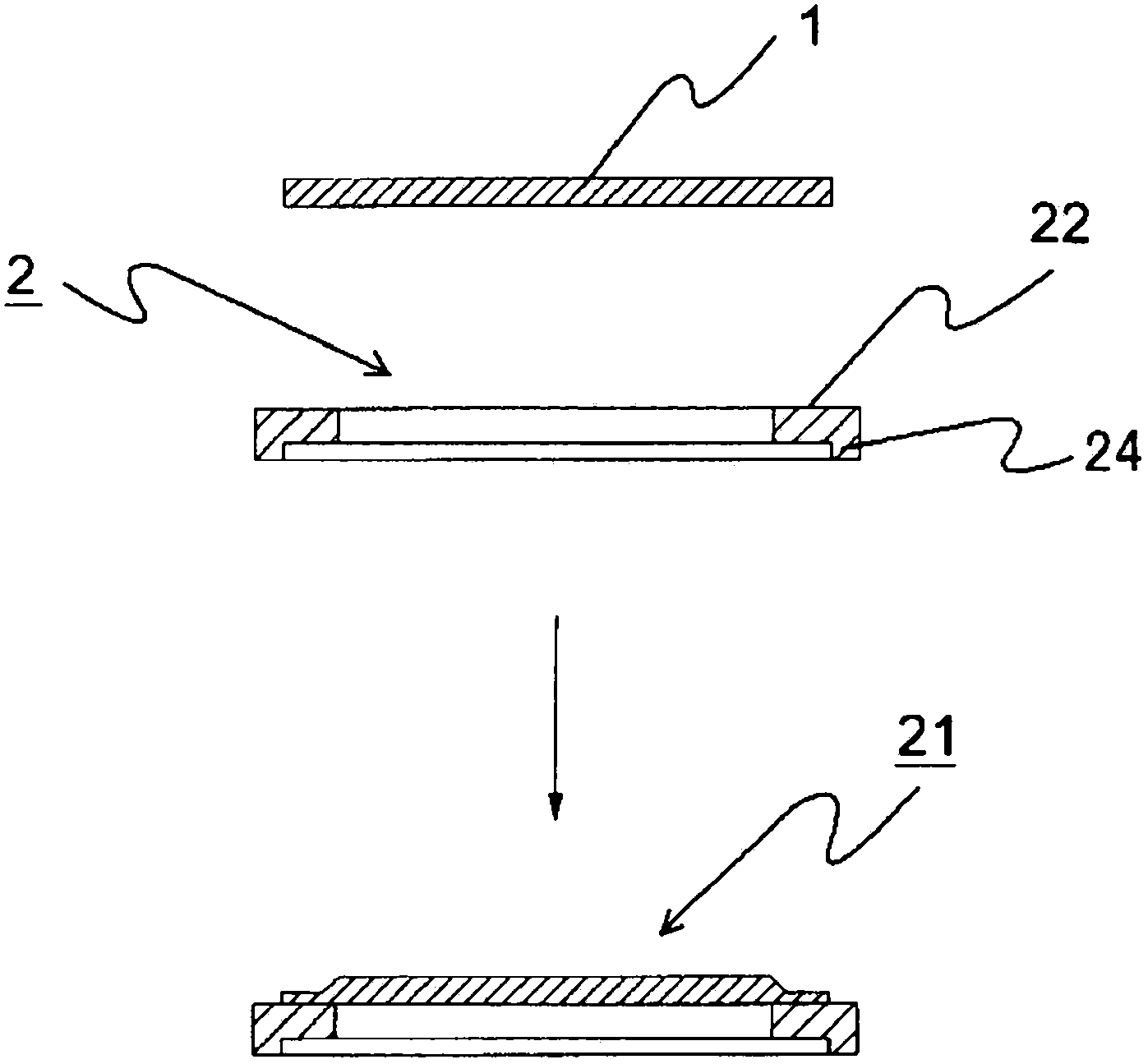

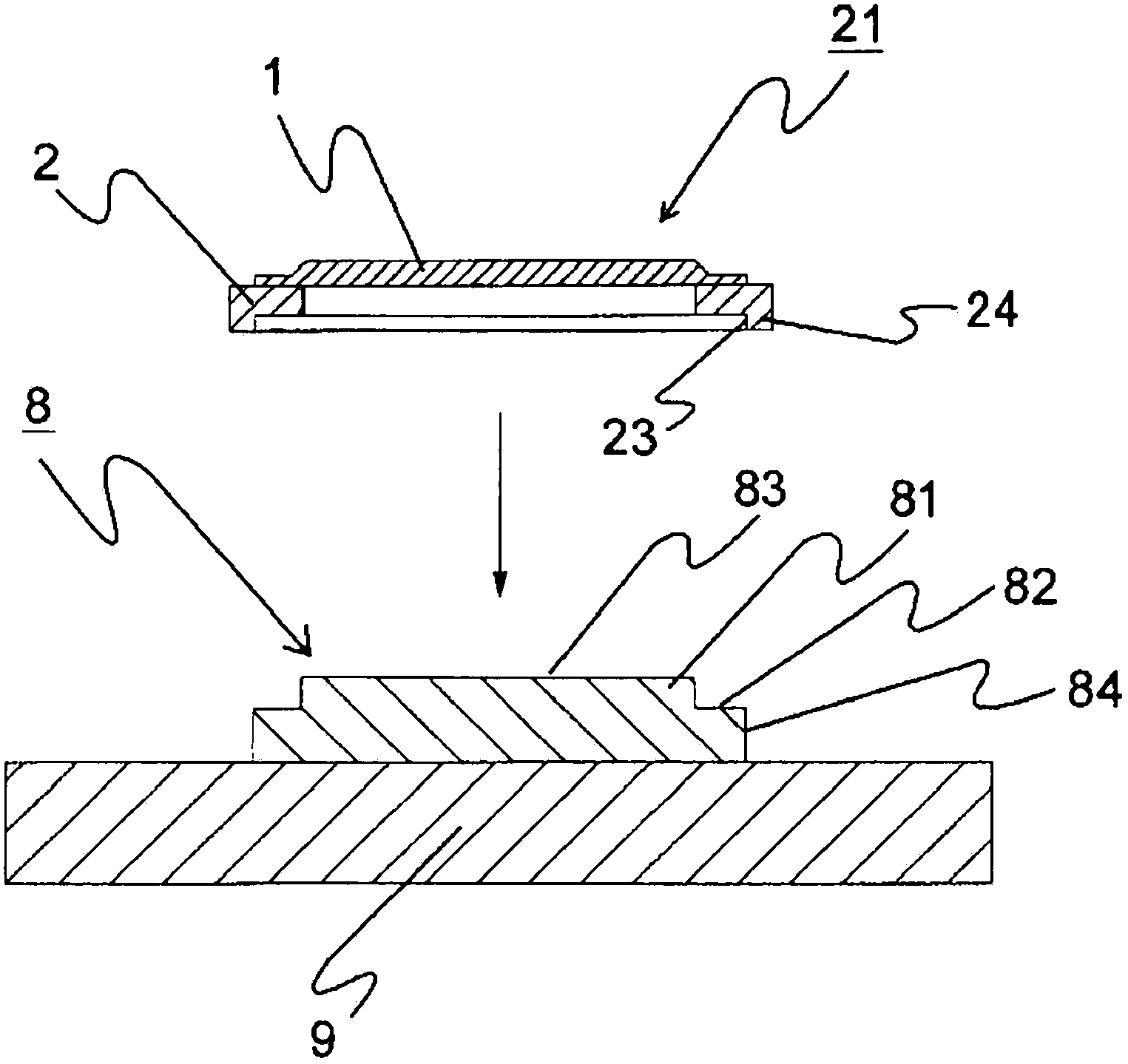

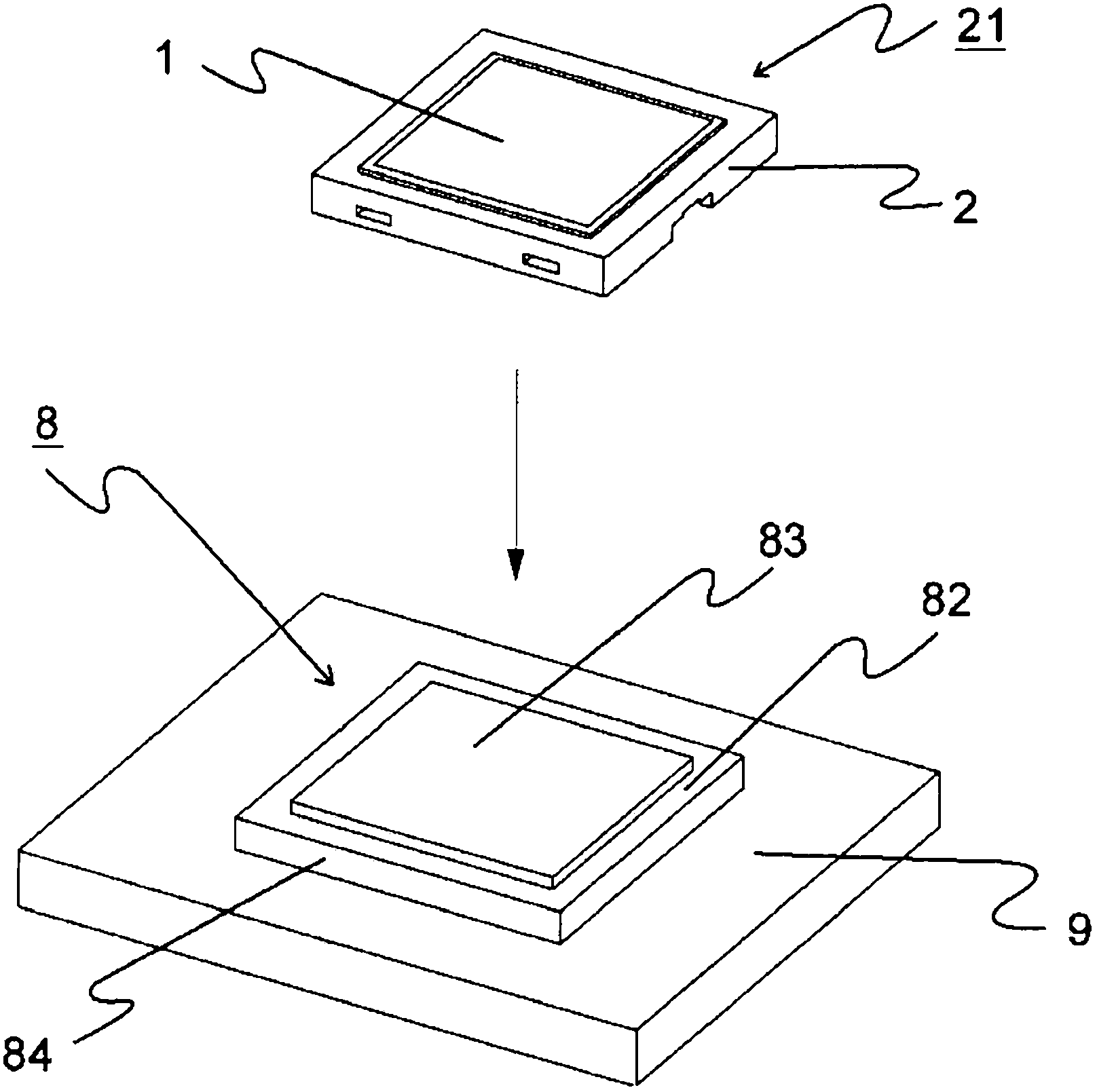

Porous stamp assembly, and manufacturing method and apparatus of the same

The present invention relates to a porous stamp assembly. The manufacturing method of the assembly comprises a first step of hermetically adhering a porous impression die member of thermoplastic resin to a front end face of a frame; a second step of fixing the die member embedded frame onto a mount that is to be in face-to-face relation with a thermal head attached to a seal carving device; a third step of putting the thermal head in contact with an upper major surface of the porous impression die member, with a resin film interposed therebetween, and moving the thermal head and the porous impression die member relative to each other; and a fourth step of removing the die member embedded frame from the mount.

Owner:SHACHIHATA IND

Flexo Cushion

InactiveUS20090211480A1Reduces smutting during printingConvenient registrationPrinting platesStereotype printingEngineeringCushion

A method of improving performance of a relief image printing plate on a printing cylinder which includes mounting a compressible cushion element on a surface of the printing cylinder. The surface of the cushion element that is contactable with the relief image printing plate is a low friction surface that allows a relief image printing plate to slide freely across its surface and settle into position on the printing cylinder. The use of a cushion element having a low friction surface reduces smut and improves registration of the printing plate on the printing cylinder.

Owner:NAPP SYSTEMS (USA) INC

Preparation technique of silica-gel plate

The invention relates to a preparation technology of a silica gel plate. At first, a corresponding cover die is engraved according to a three-dimensional diagram for design and processing of the die assembly. The cover die comprises a cavity die and an upper die. The upper die is cleaned with mixed liquid of vinyl triethoxy silane, absolute ethyl alcohol, de-ionized water and hydrochloric acid. The silicone oil parting compound is coated on the surface of the cavity die and heated until the cavity die is completely moistened by the parting compound. After R401 / 70S or mixture of R401 / 70S and R401 / 40S is mixed and then sulphurated and the dies are matched and cut, the post cure is performed. The finished product is baked in an air-blast oven. As the solid cover die and the processing technology thereof are adopted, the preparation technology of the invention can be used in the hot stamping surface with different radian measures or the irregular hot stamping surface and has the advantages that the hot stamping graphic context is full, clear, and high in surface smoothness. The gold stamping with good effect adopts the solid silica gel module as the production technology.

Owner:郑汉平

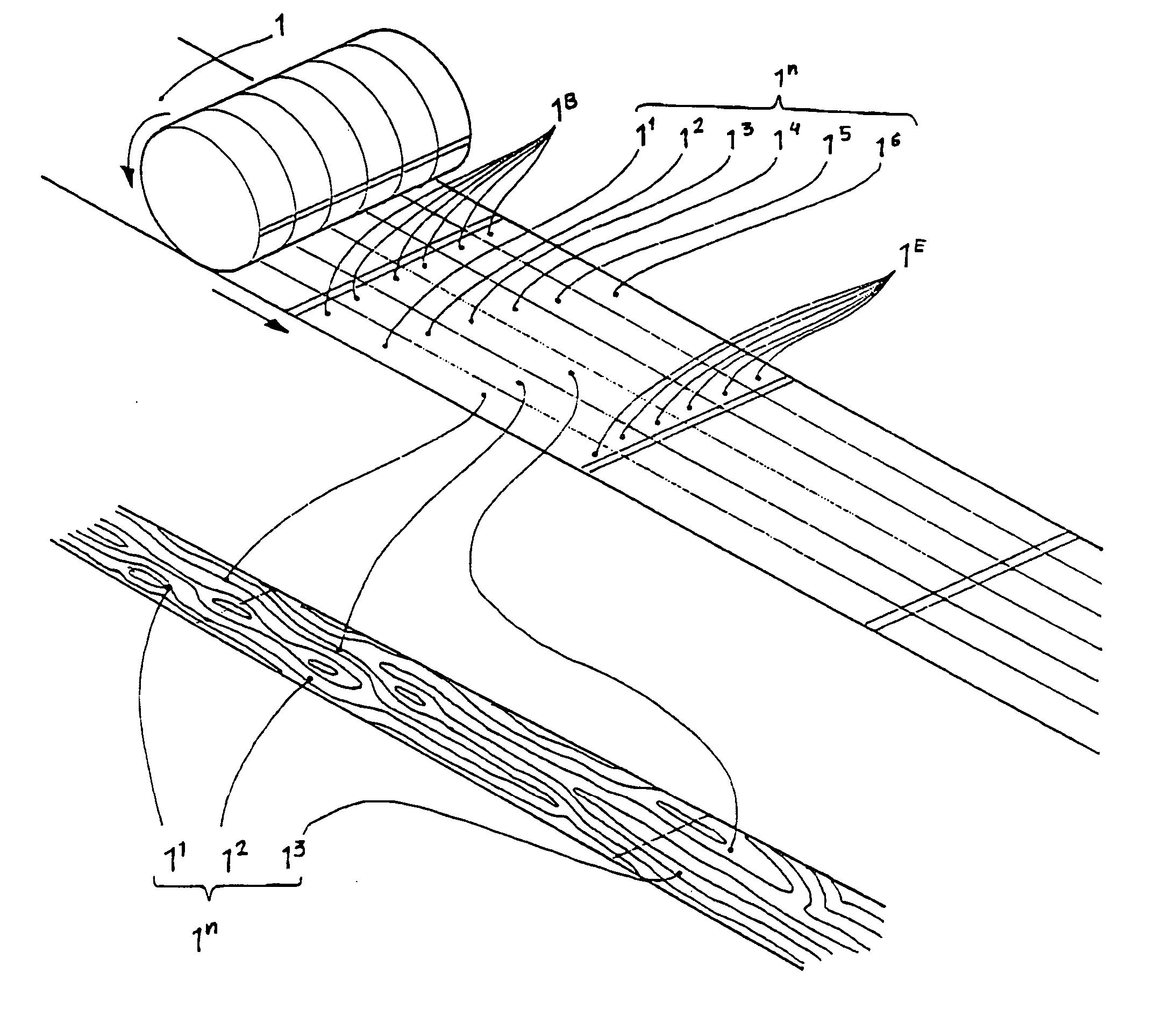

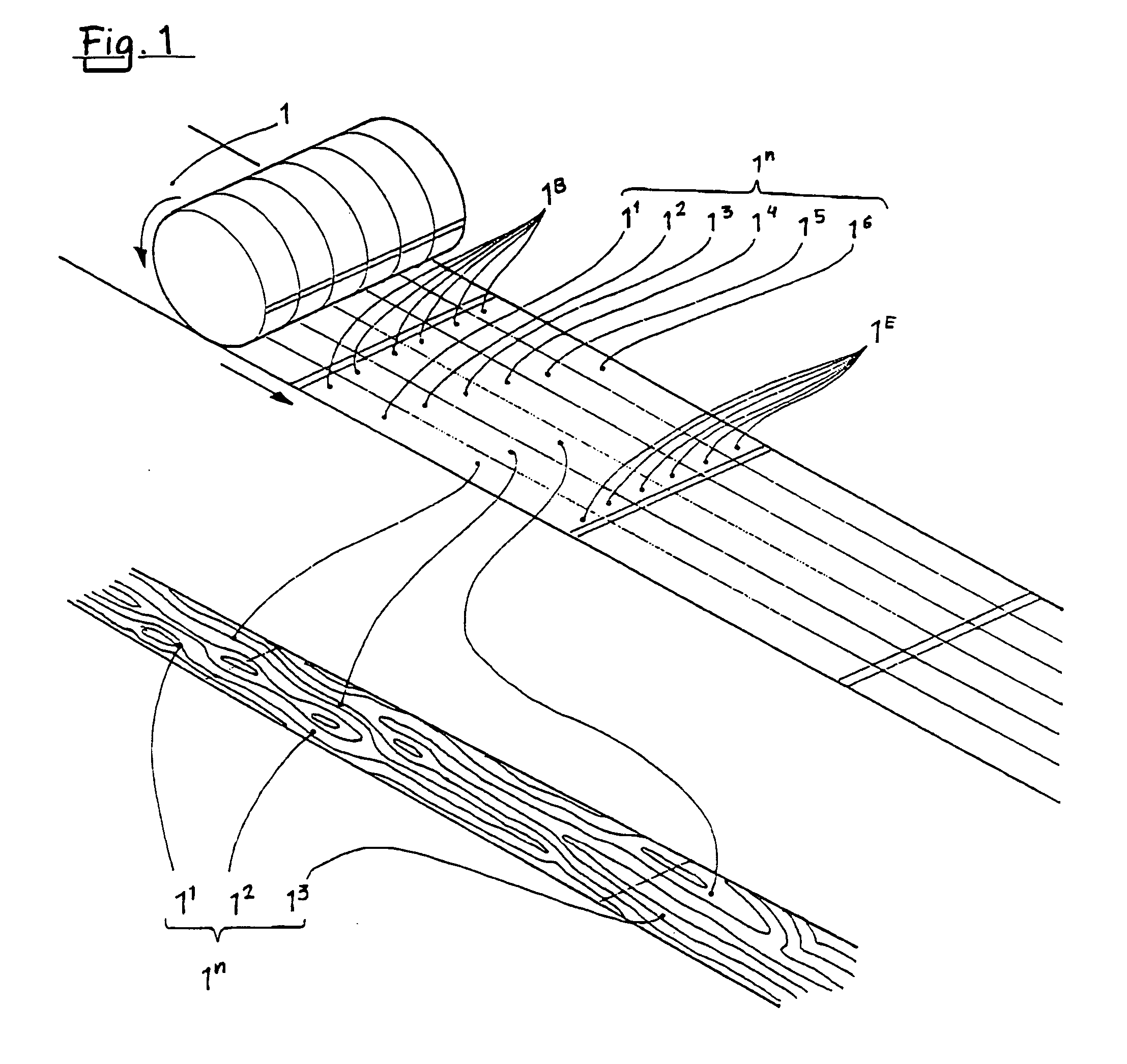

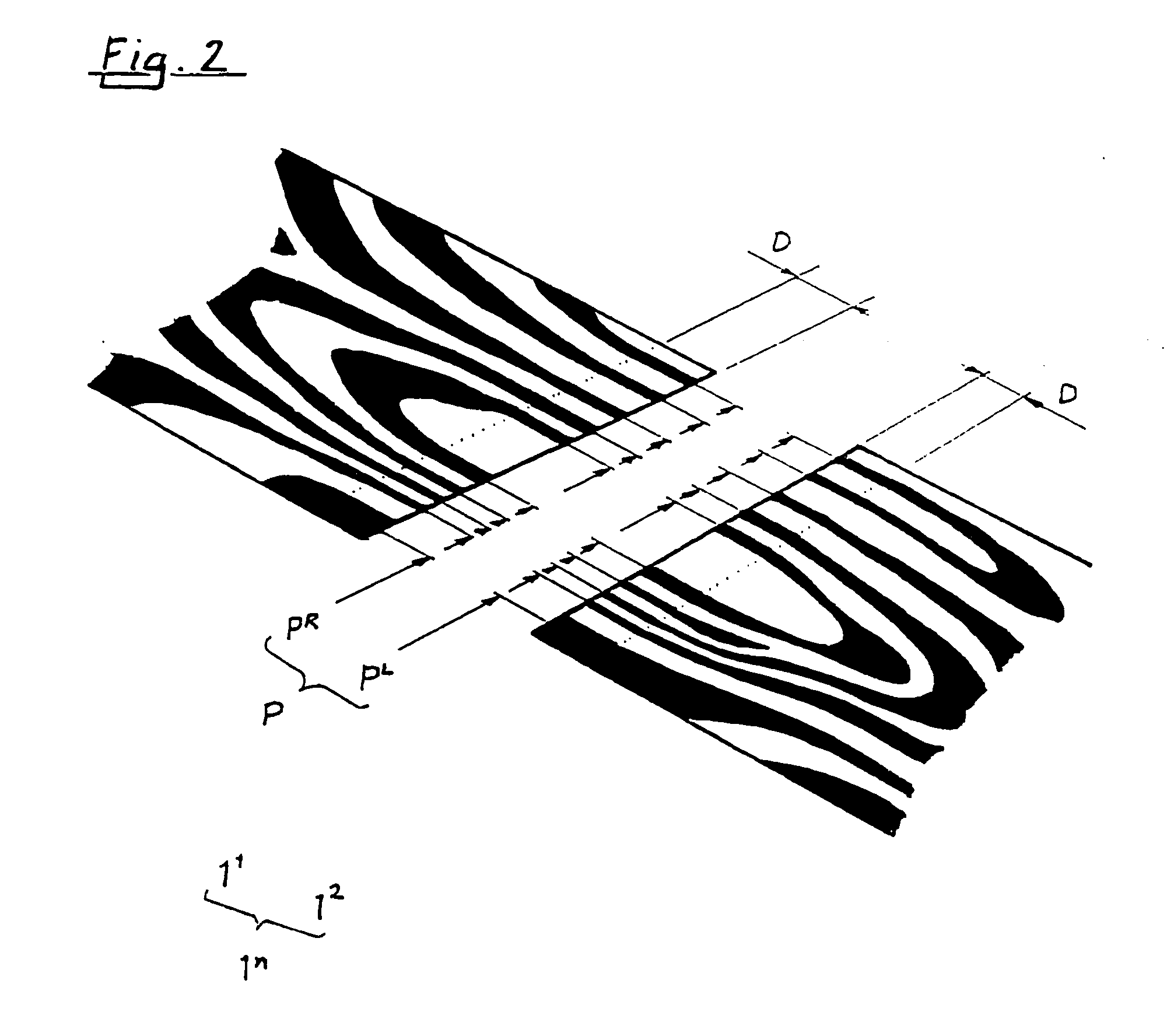

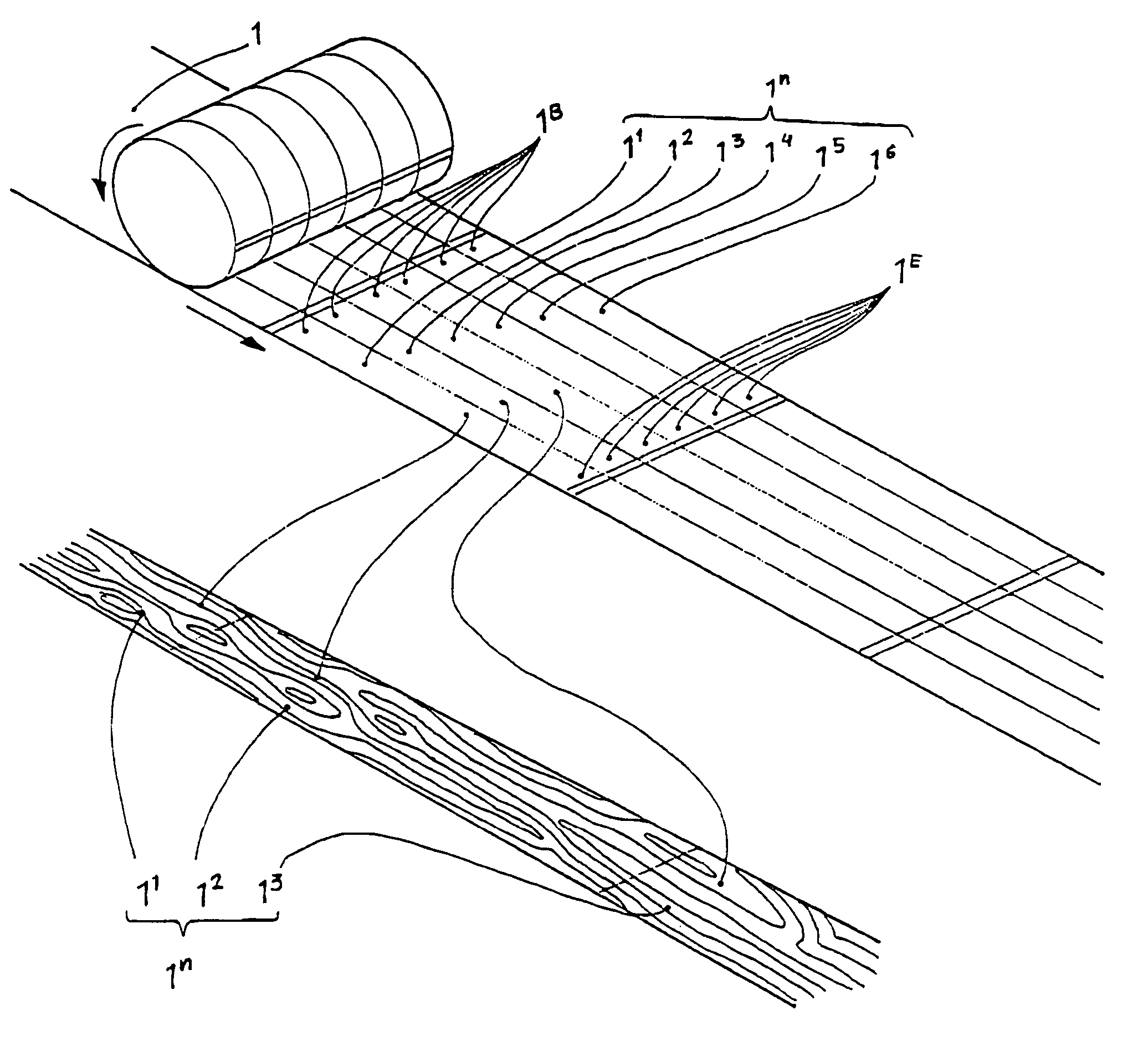

Process for the manufacturing of panels having a decorative surface

InactiveUS20050144898A1Convenient ArrangementLiquid surface applicatorsPlaten pressesEngineeringMechanical engineering

Owner:PERGO

Process for the manufacturing of panels having a decorative surface

InactiveUS7255040B2Convenient ArrangementLiquid surface applicatorsPlaten pressesMechanical engineeringEngineering

Owner:PERGO

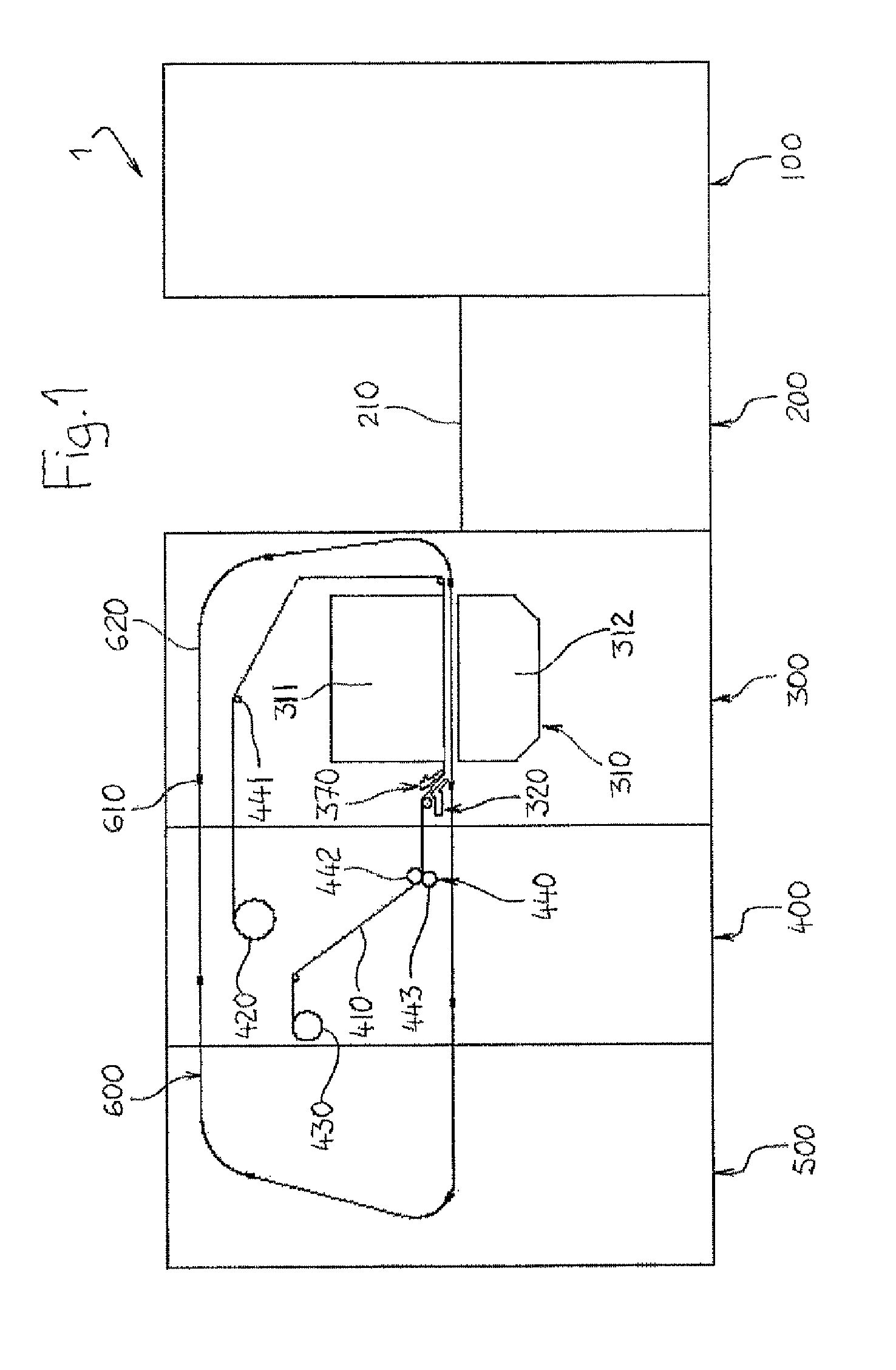

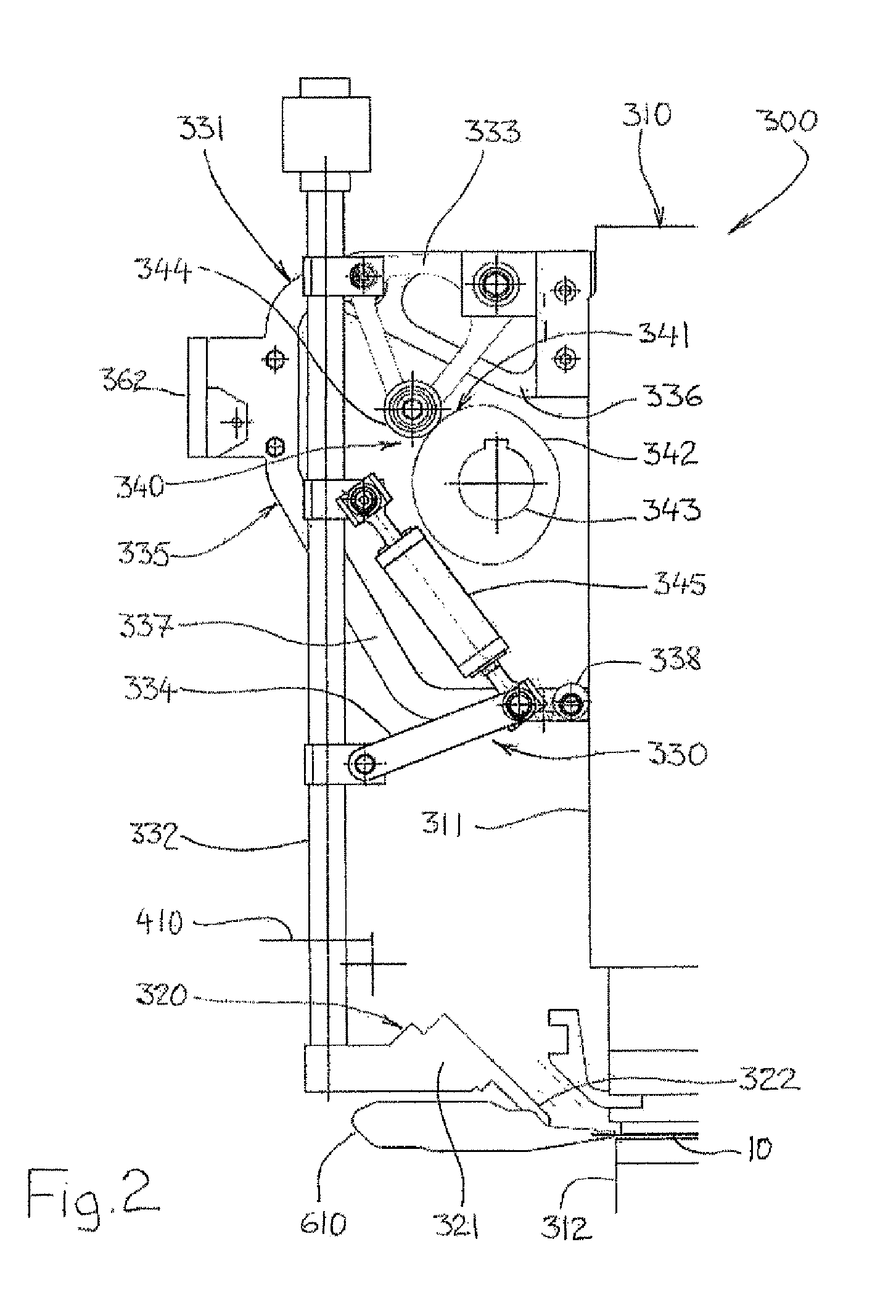

Printing device using stamping

ActiveUS8881649B2Avoid problemsReduce riskTransfer printingMechanical working/deformationEngineeringSheet material

A printing device for printing elements in sheet fond: a platen press 310 for depositing onto each sheet 10, by stamping, colored or metalized film from at least one stamping foil; a conveyor using a succession of gripper bars for moving each sheet 10 individually through the platen press 310; a blower member separates each stamping foil from each sheet as it leaves the platen press, the blower member being movable between a work position, in which it is able to operate from the transfer region in which the gripper bars 610 run to the exit of the platen press 310, and a withdrawn position, in which it keeps away from said transfer region.

Owner:BOBST MEX SA

Method for marking golf ball and golf ball

ActiveUS7018307B2Improved in sharpness and reproducibilityStereotype printingGolf ballsDark colorEngineering

The invention provides a golf ball marking method of marking the surface of a golf ball with a character, pattern or the like by a direct or indirect printing technique, comprising applying a marking layer onto the ball surface for marking, the marking layer being of a two-layer structure consisting of a lower layer of a composition containing a color pigment in a lower layer ink medium and an upper layer which is formed on the lower layer from a composition containing a metal powder in an upper layer ink medium and which is transparent or translucent and has brilliance, and adjusting the content of the metal powder and the thickness of the upper layer such that the relation of the content (wt %) of the metal powder relative to the upper layer ink medium solids to the thickness (μm) of the upper layer may satisfy the inequality: 1≦[metal powder content (wt %)]×[upper layer thickness (μm)]≦10. When it is desired to impart brilliance in a dark color such as black, the dark color is improved in sharpness and reproducibility.

Owner:BRIDGESTONE SPORTS

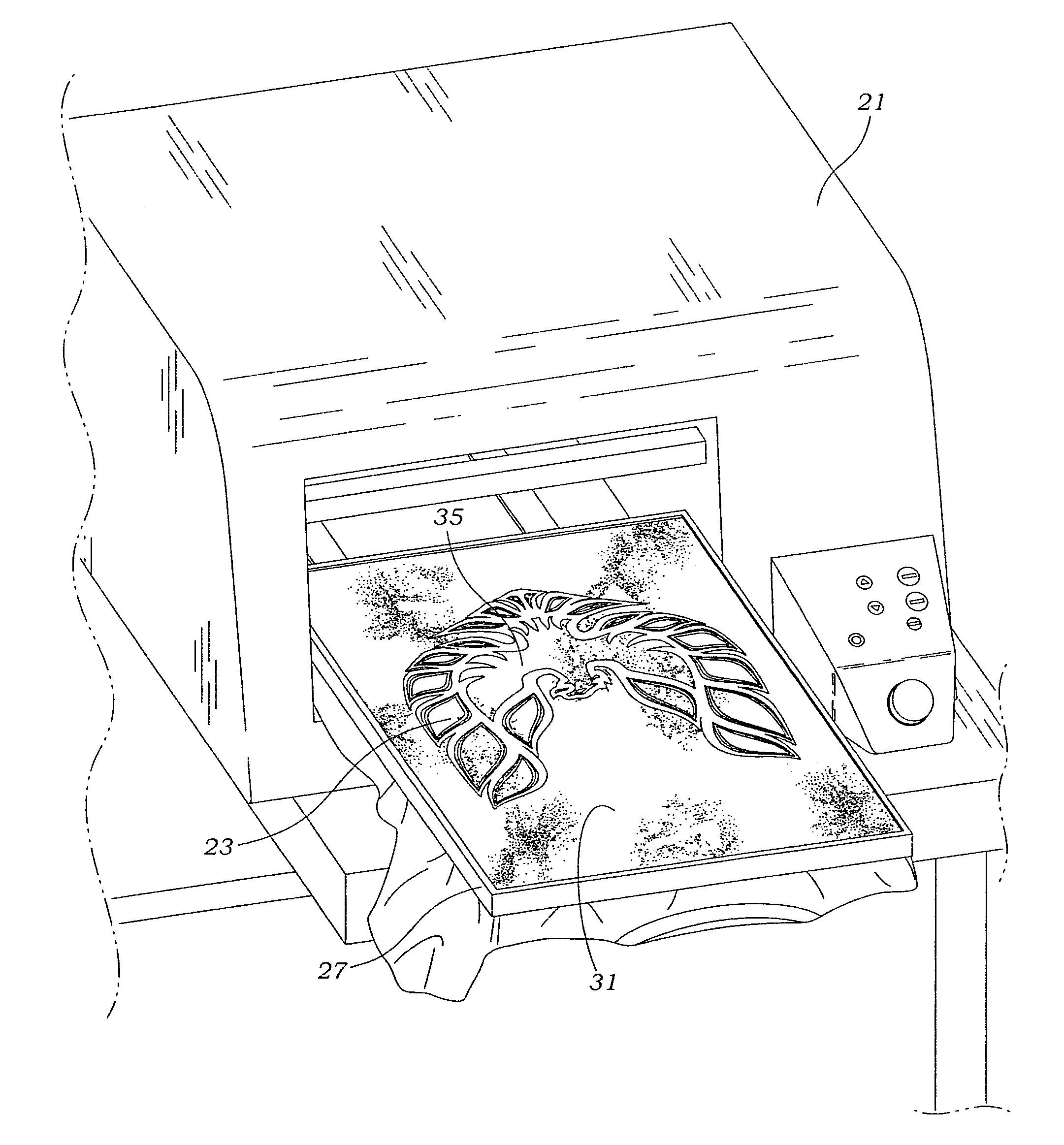

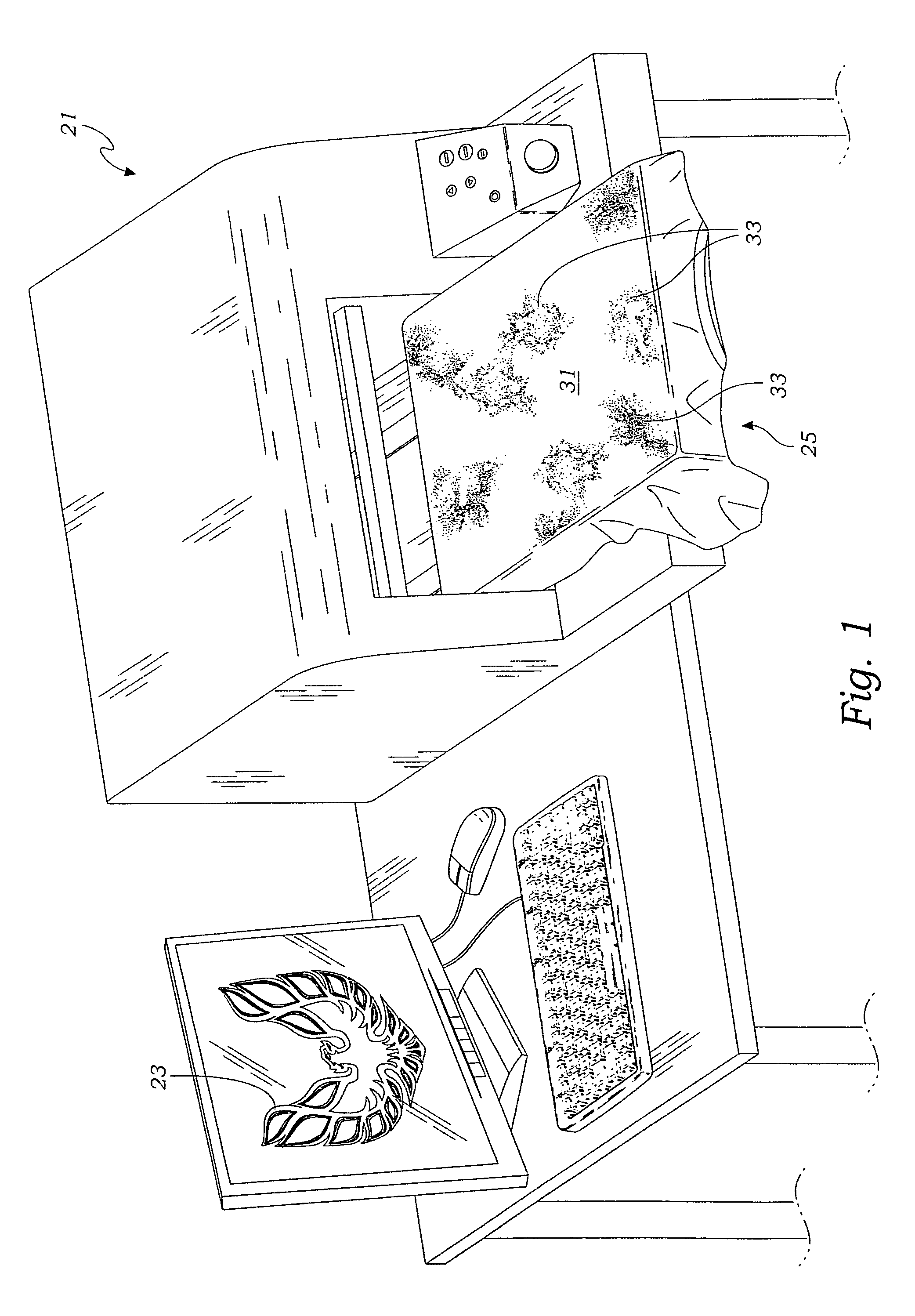

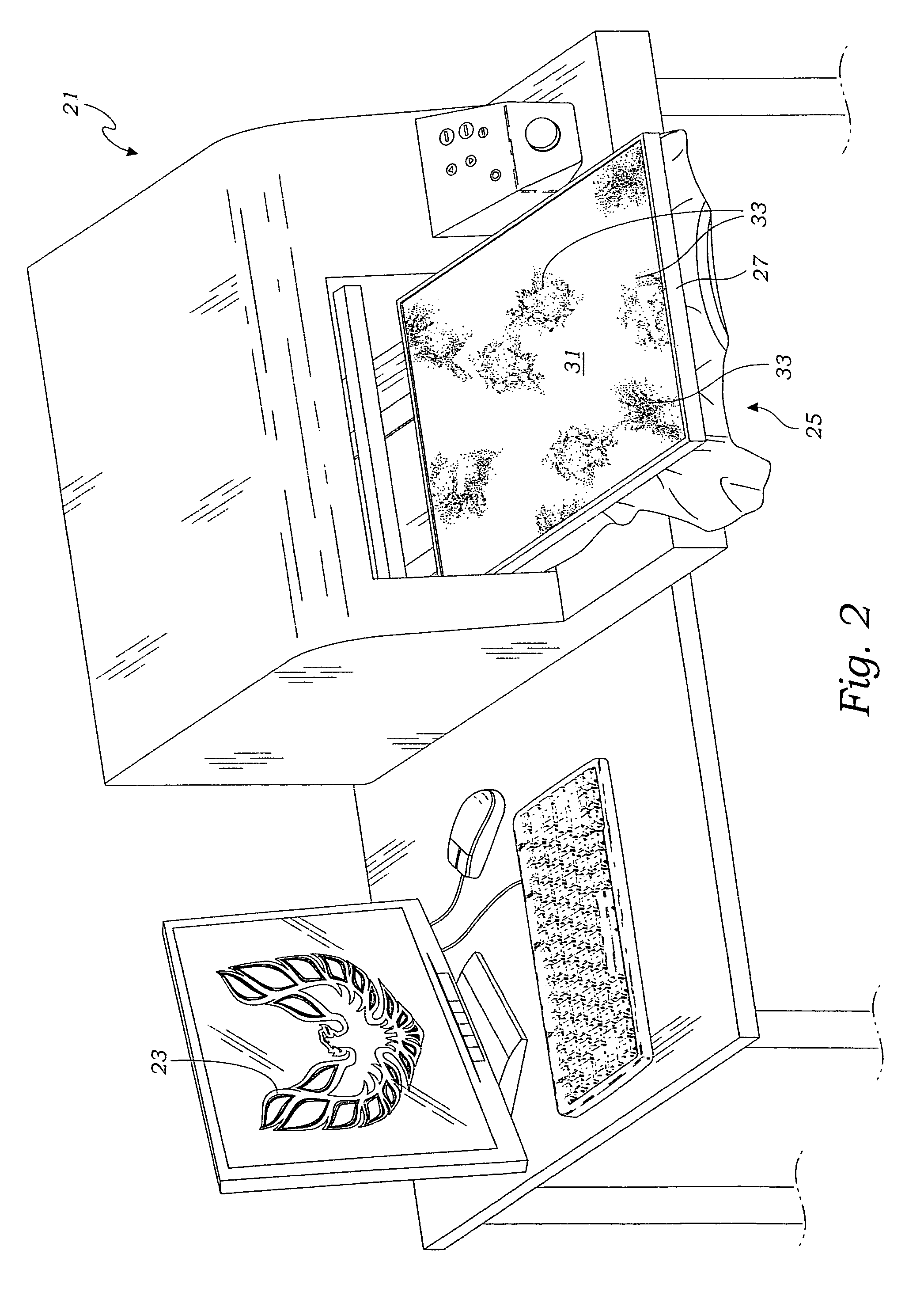

Method of seamless printing on clothing and articles made therefrom

InactiveUS20050252392A1Maximizes decorative effectHeating evenlyTransfer printingStereotype printingMechanical engineeringTextile

Owner:KIM ROBERT H +1

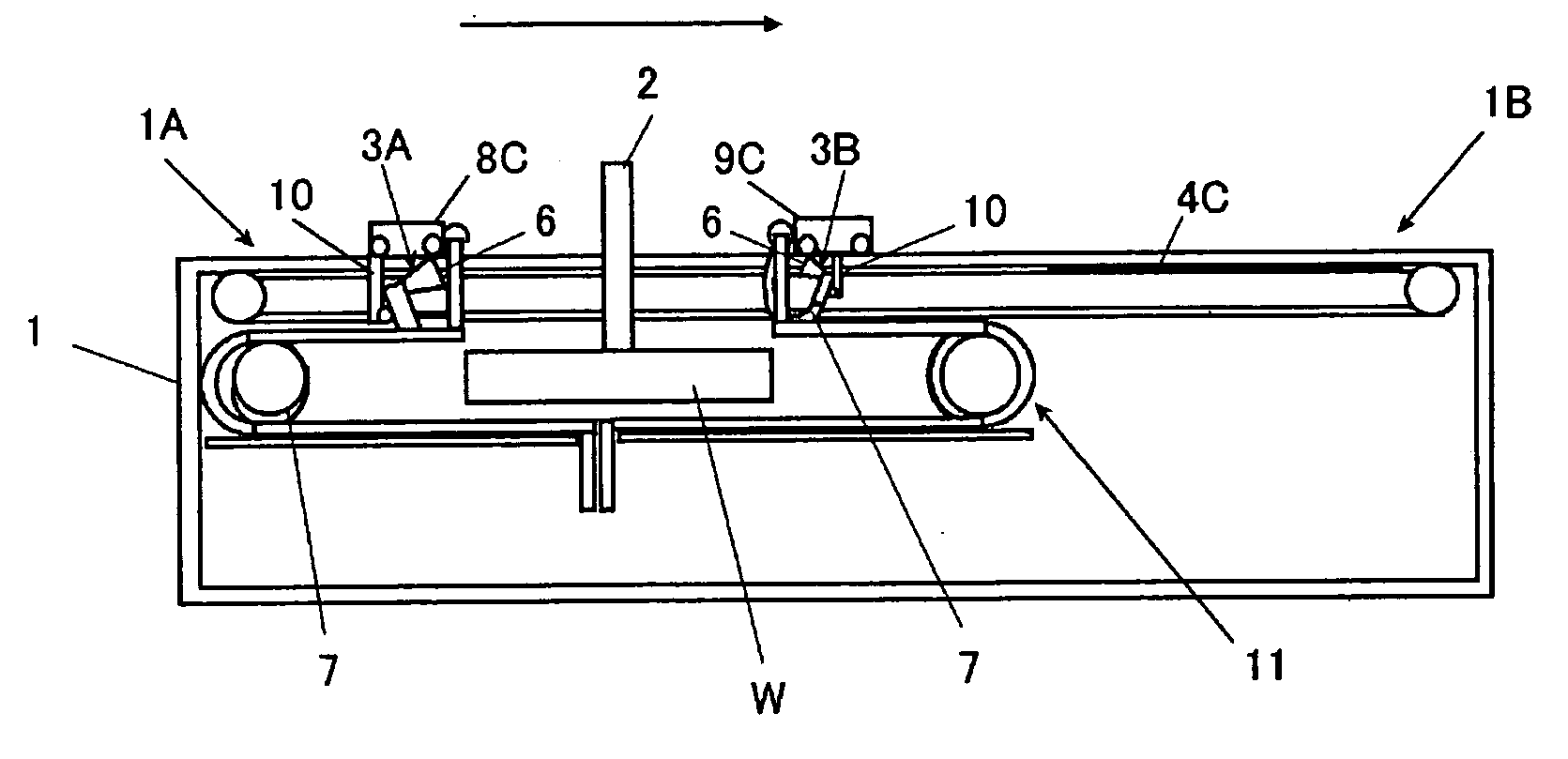

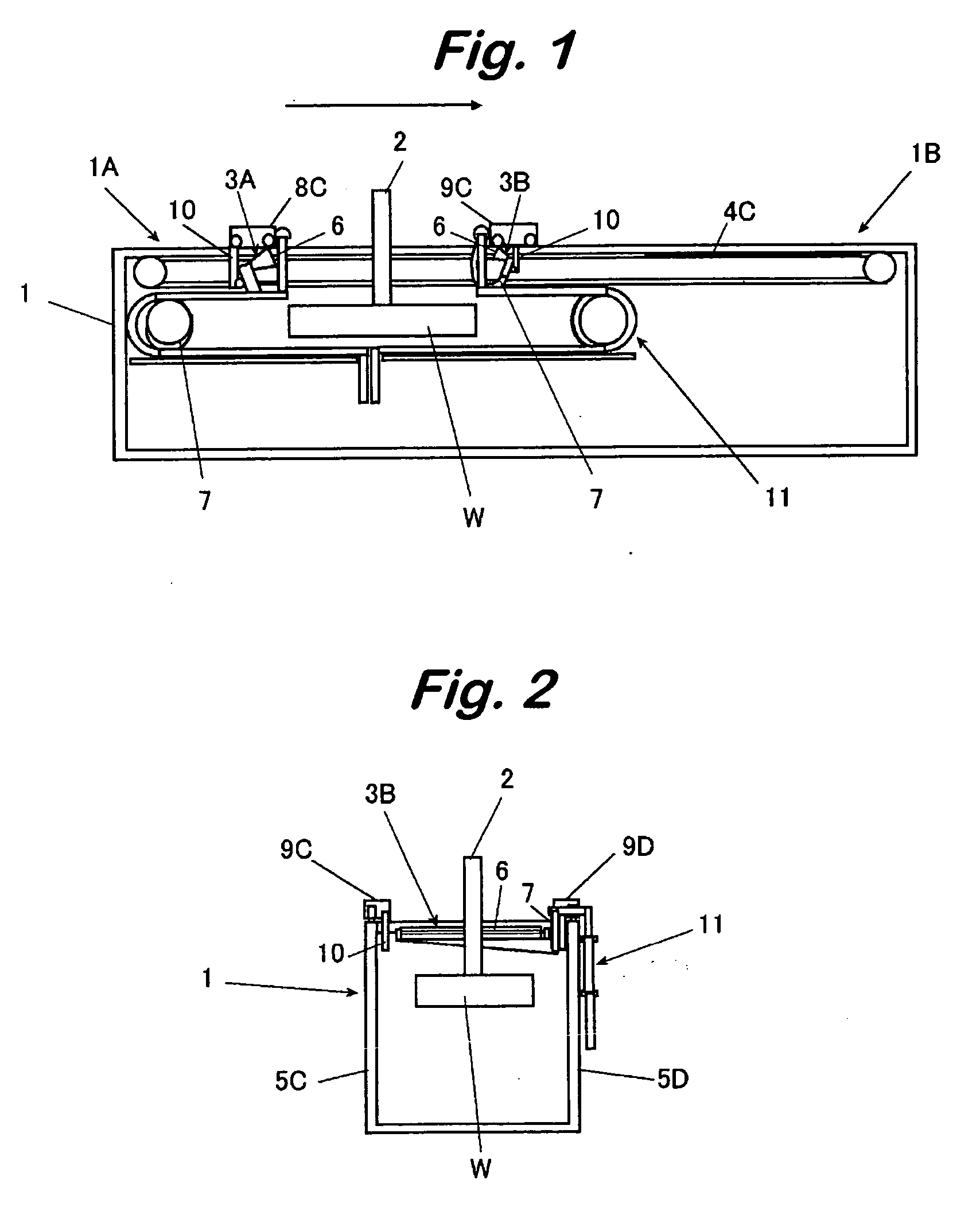

Liquid pressure transfer printing apparatus

InactiveUS20060162583A1Avoid depositionSimple compositionTransfer printingDecorative surface effectsAdemetionineExit side

A liquid pressure transfer printing apparatus in which a work to be applied with transfer printing is urged onto a film for applying liquid pressure transfer printing supplied to the surface of a liquid in a tank for liquid pressure transfer printing to submerge the film into the liquid comprises a pair of gates each having a suction mechanism for sucking residues not transferred to the submerged work but remained on the surface of the liquid in the tank from the inlet side and the exit side of the tank while the work W is submerged in the liquid, thereby capable of preventing the residues of the film remained on the surface of the liquid in the tank not transferred to the surface of the work from depositing to the surface of the work and forming seeds.

Owner:TRINITY IND CORP

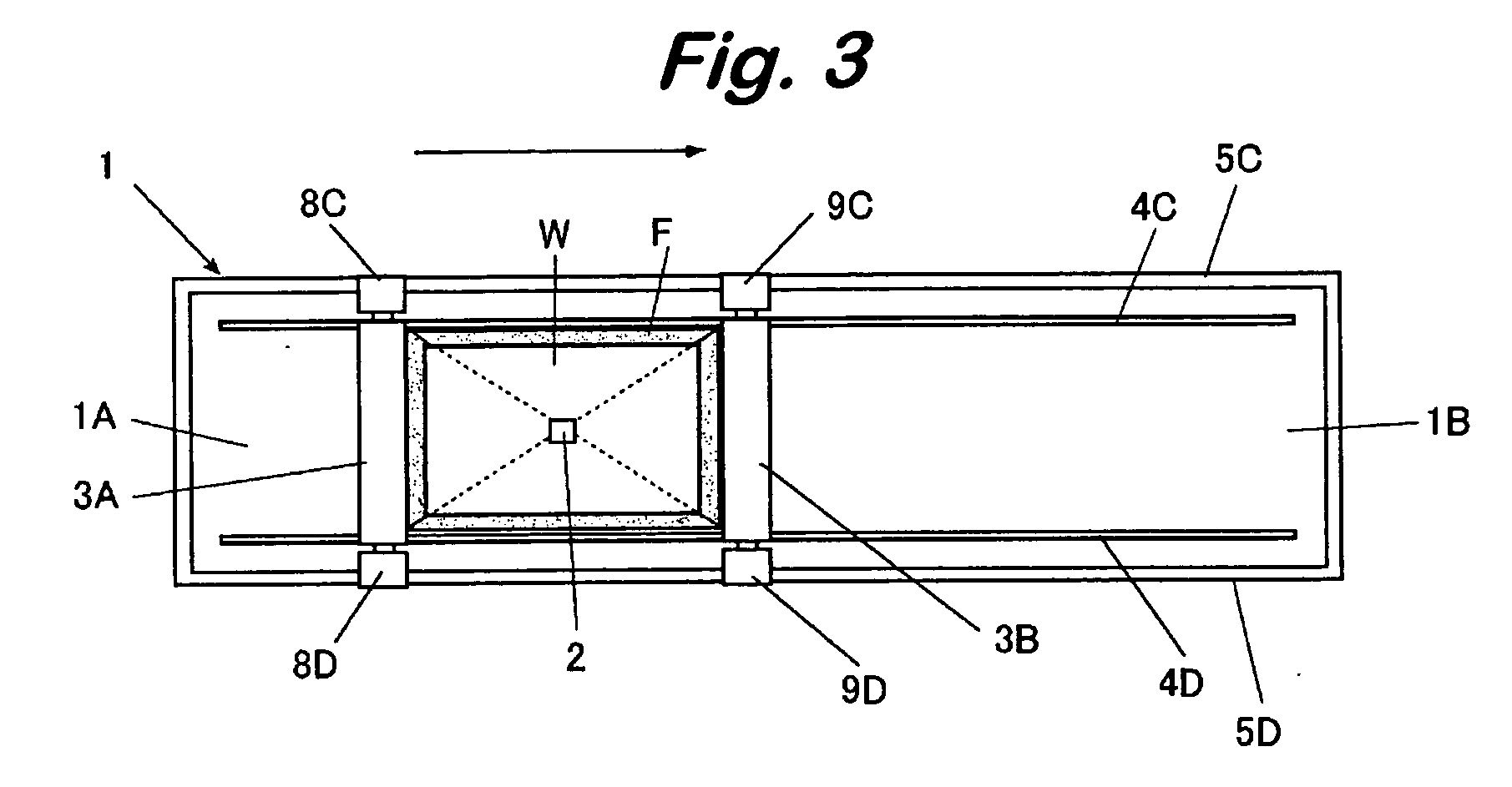

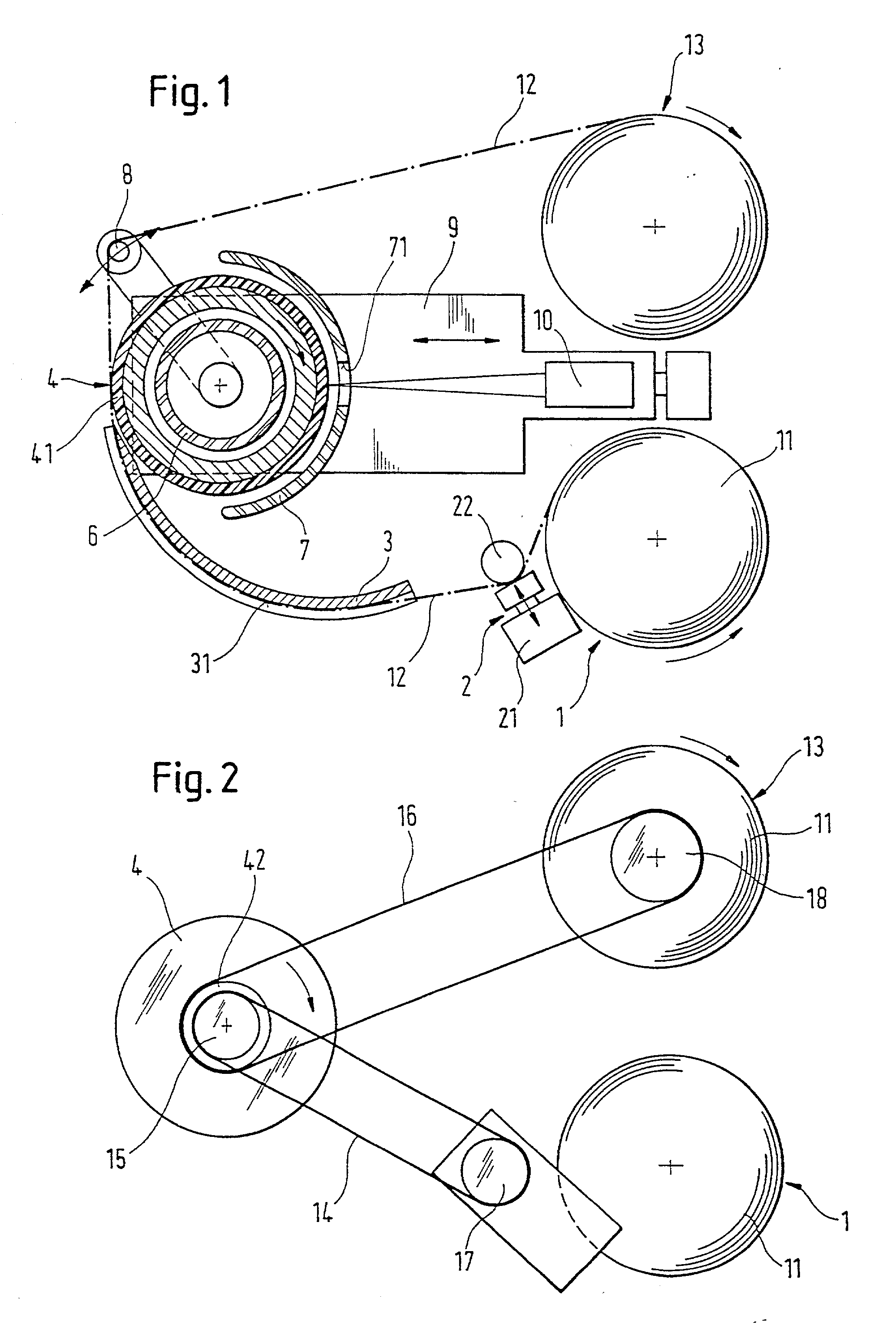

Processing center comprising a hot-stamping machine, hot-stamping machine and processing center comprising a special storage magazine for such a hot-stamping machine

A processing center is disclosed that comprises at least one support capable of displacement in the X and Y axes, and preferably also in the Z axis, and at least one hot-stamping machine for applying a paint layer or a transfer layer, which is located on a support film, onto the surface of a workpiece and mainly onto the curved outline of a plate-shaped workpiece. The hot-stamping machine comprises an unwinding unit for unwinding the support film supporting the paint or transfer layer, a take-up unit for taking up the support film used, and at least one stamping cylinder which is rotationally mounted between the unwinding unit and the take-up unit and which can be applied onto the workpiece. The stamping cylinder is used for transferring the paint or transfer layer from the support film onto the workpiece.

Owner:HOMAG MASCHBAUU

Digital decoration and marking of glass and ceramic substrates

Disclosed in this specification is a decal assembly comprising a decal support, a releasable covercoat, a heat activatable layer, and an ink layer. The ink layer forms a digital image. The heat activatable layer has a high adhesion to a ceramic substrate at high temperatures and a low adhesion to the substrate at lower temperatures. Thus the adhesive properties of the decal are activated by heat. The resulting image has excellent adhesion to the substrate and resists the effects of washing.

Owner:INT IMAGING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com