Thermal isolation structure of infrared detector and preparation method thereof

An infrared detector and thermal insulation technology, applied in the field of infrared detection, can solve the problems of detector surface warpage, stress mismatch, shedding, etc., achieve good stability and support effect, and overcome the problem of detector surface warpage and shedding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and functions adopted by the present invention to achieve the predetermined purpose, the thermal insulation structure of the infrared detector proposed by the present invention and its preparation method are described in detail below in conjunction with the accompanying drawings and examples.

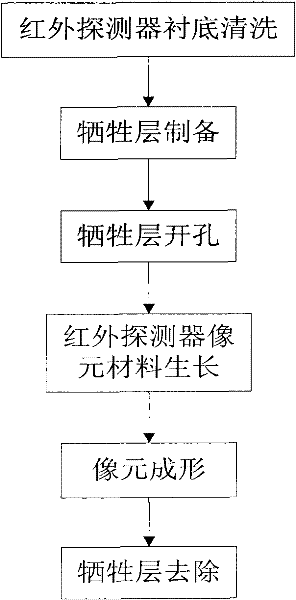

[0034] The first embodiment of the present invention is such as figure 1 As shown, a method for preparing an infrared detector thermal insulation structure specifically includes the following steps: the specific process for preparing a four-pillar-supported suspended microstructure is as follows:

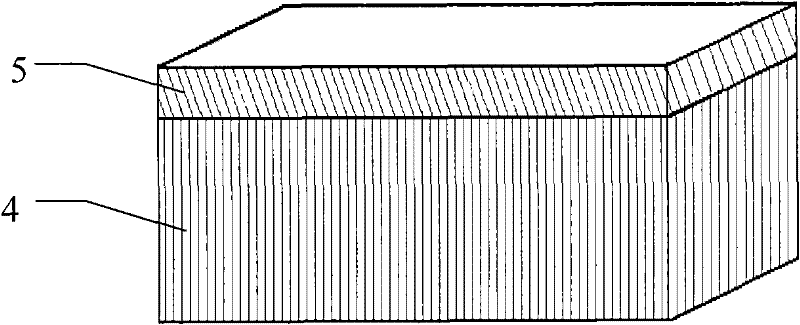

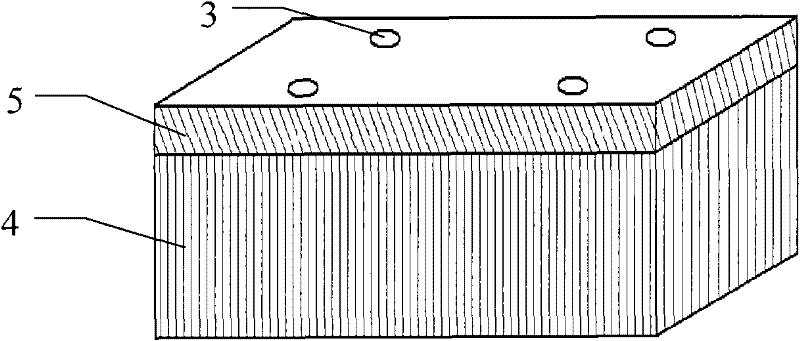

[0035] Step 1. Cleaning of the infrared detector substrate: After cleaning the infrared detector substrate 4 with petroleum ether, acetone, and ethanol in sequence, blow it dry with a nitrogen gun.

[0036] Step 2. Preparation of the sacrificial layer: the infrared detector substrate 4 is loaded into the magnetron sputtering equipment, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com