Filler special for glue mixing of plywood and preparation process of filler

A preparation process and plywood technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as high prices, affect the economic benefits of enterprises, waste food, etc., and achieve equipment investment Less, obvious social and economic benefits, and the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

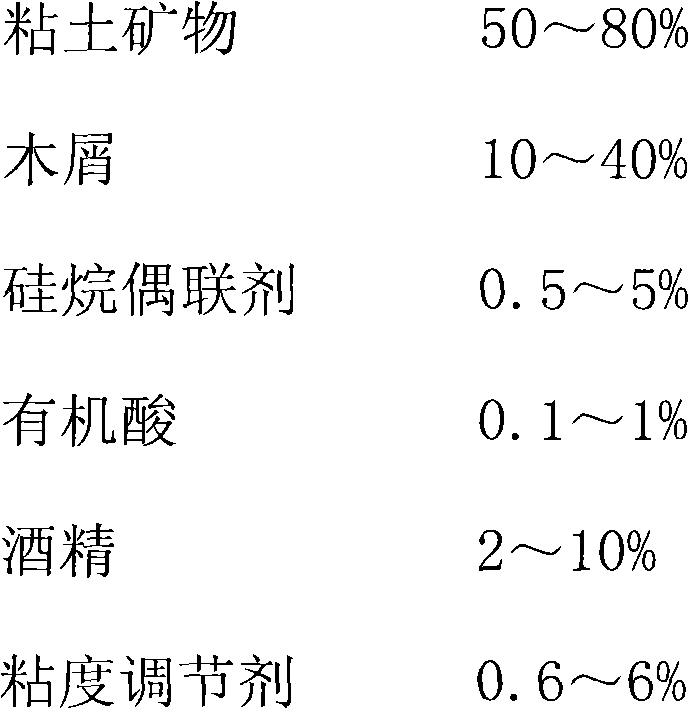

[0022] A special filler for plywood adjustment, comprising the following components (by weight percentage):

[0023]

[0024]

[0025] The beneficial effects of this embodiment are:

[0026] Increase the solid content, viscosity and initial viscosity of the adhesive stock solution, prolong the pot life, reduce the release of free formaldehyde, reduce the internal stress of the glue solution due to volume shrinkage during curing, improve the aging resistance of the adhesive layer, and effectively Overcome defects such as glue penetration, glue shortage, warping, and bubbling of plywood, and improve the production efficiency and quality of plywood.

Embodiment 2

[0028] A special filler for plywood adjustment, comprising the following components (by weight percentage):

[0029]

[0030] The beneficial effects of this embodiment are:

[0031] Increase the solid content, viscosity and initial viscosity of the adhesive stock solution, prolong the pot life, reduce the release of free formaldehyde, reduce the internal stress of the glue solution due to volume shrinkage during curing, improve the aging resistance of the adhesive layer, and effectively Overcome defects such as glue penetration, glue shortage, warping, and bubbling of plywood, and improve the production efficiency and quality of plywood.

Embodiment 3

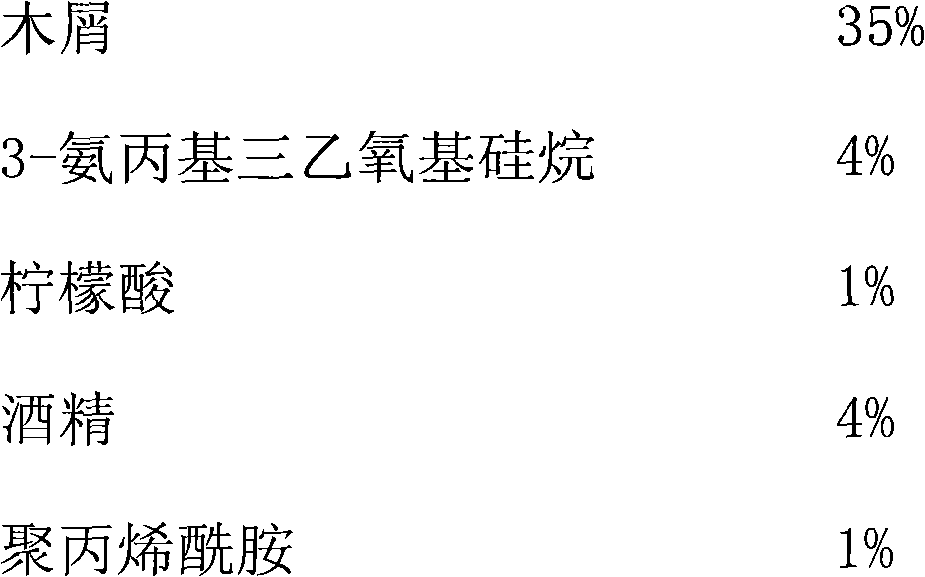

[0033] A special filler for plywood adjustment, comprising the following components (by weight percentage):

[0034]

[0035] The beneficial effects of this embodiment are:

[0036] Increase the solid content, viscosity and initial viscosity of the adhesive stock solution, prolong the pot life, reduce the release of free formaldehyde, reduce the internal stress of the glue solution due to volume shrinkage during curing, improve the aging resistance of the adhesive layer, and effectively Overcome defects such as glue penetration, glue shortage, warping, and bubbling of plywood, and improve the production efficiency and quality of plywood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com