Method for producing semi-curing piece and device thereof

A technology of prepreg and production method, which is applied to flat products, other household appliances, household appliances, etc., can solve the problems of reducing vehicle speed, high price, and reducing the efficiency of finished products, so as to reduce the probability of white streaks, expand the scope of application, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

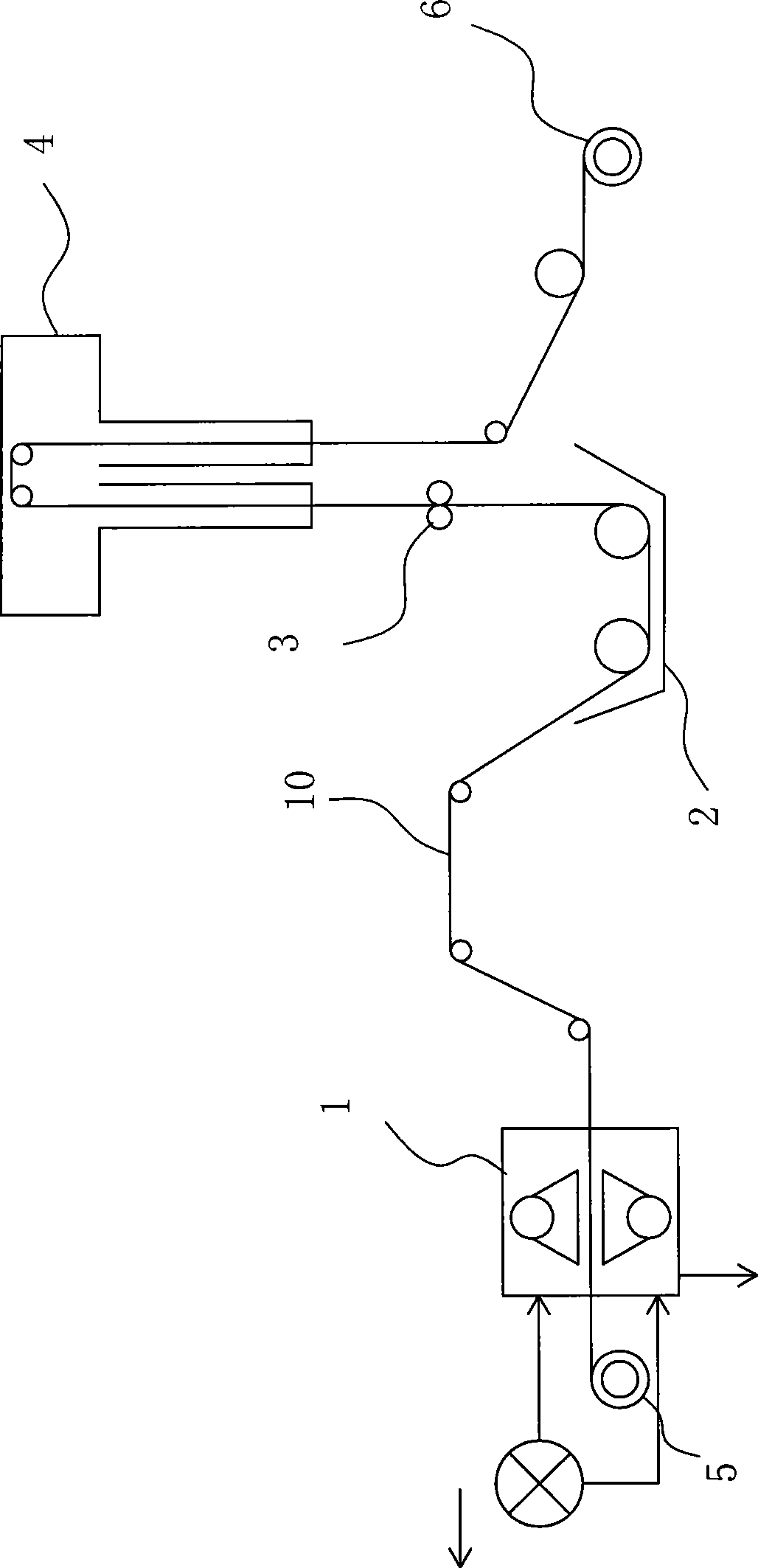

[0027] Embodiment one: see figure 1 , 2 As shown, a method for making a prepreg, the process steps include: performing a high-pressure spray coating process on the unrolled glass fiber cloth base material 10, the glue is sprayed on the glass fiber cloth base material 10 through a high-pressure nozzle, and the spraying The pressure is 1~10km / cm 2 , and then put it into the glue tank to impregnate the glue solution, control the glue solution content through the metering roller, and obtain it after being heated and dried in an oven; the production device is as follows: figure 1 As shown, there are uncoiling device 5, spray chamber 1, main dipping device 2, metering roller 3, heating and drying device 4 and winding device 6 in sequence.

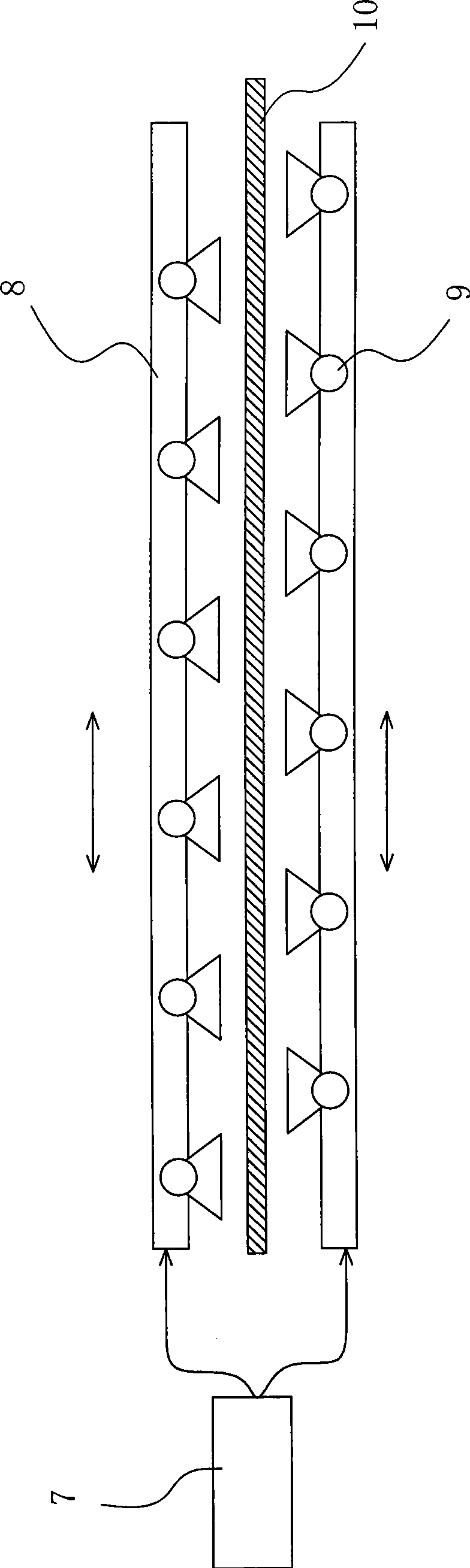

[0028] Such as figure 2 As shown, the spray chamber 1 is provided with a high-pressure pump 7, a horizontal movement mechanism (not shown), two upper and lower spray rods 8 arranged in parallel, and a plurality of spray rods evenly distribute...

Embodiment 2

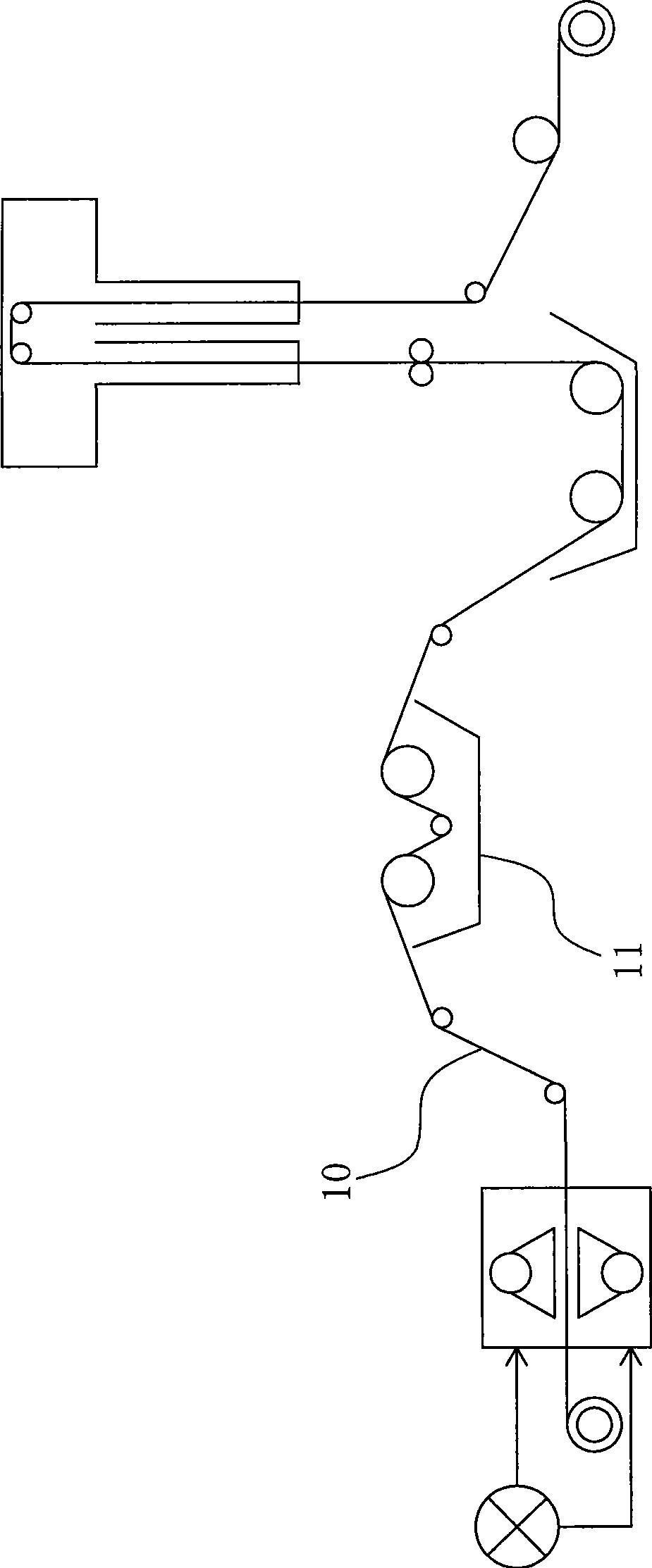

[0037] Embodiment two: if image 3 As shown, the present embodiment is basically similar to the first embodiment, the difference is that a prepreg process is set between the spray glue process and the dipping glue in the glue tank, which is realized by the prepreg device 11, and this embodiment is applicable In the production and processing of the thick fiberglass cloth base material 10 , a prepreg process is added to improve the glue wettability of the thick base material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com