A kind of preparation method of dual-phase hot forming steel

A hot-forming steel and hot-forming technology, applied in the field of high-strength automotive steel, can solve the problems of increased difficulty in surface treatment process, surface oxidation, damage to the surface quality of steel plates, etc., to improve plasticity, low heating temperature, and reduce surface oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

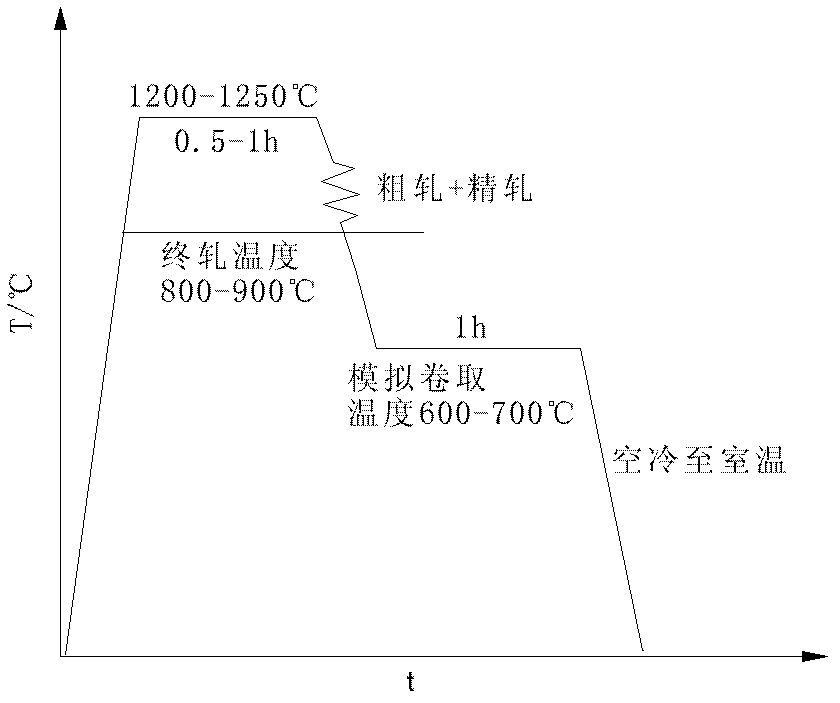

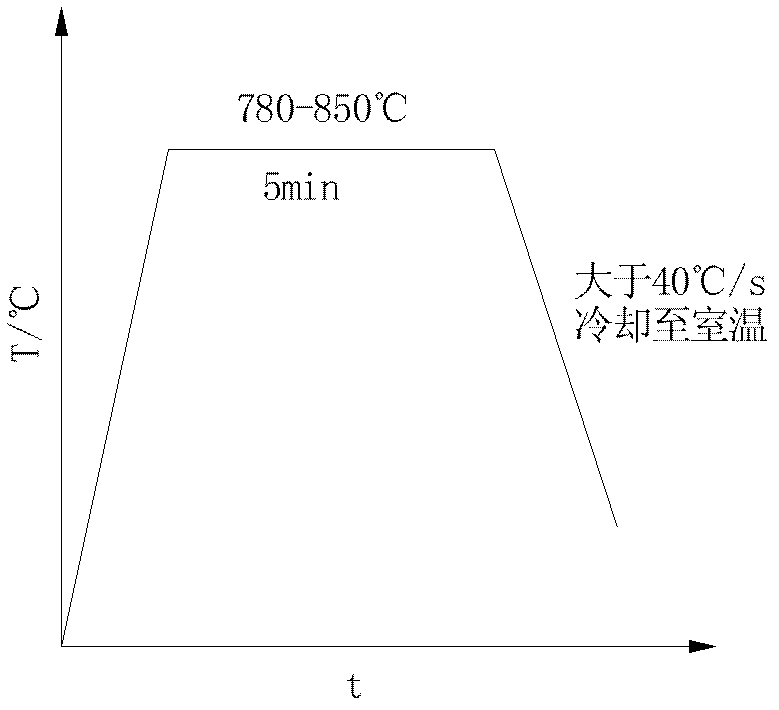

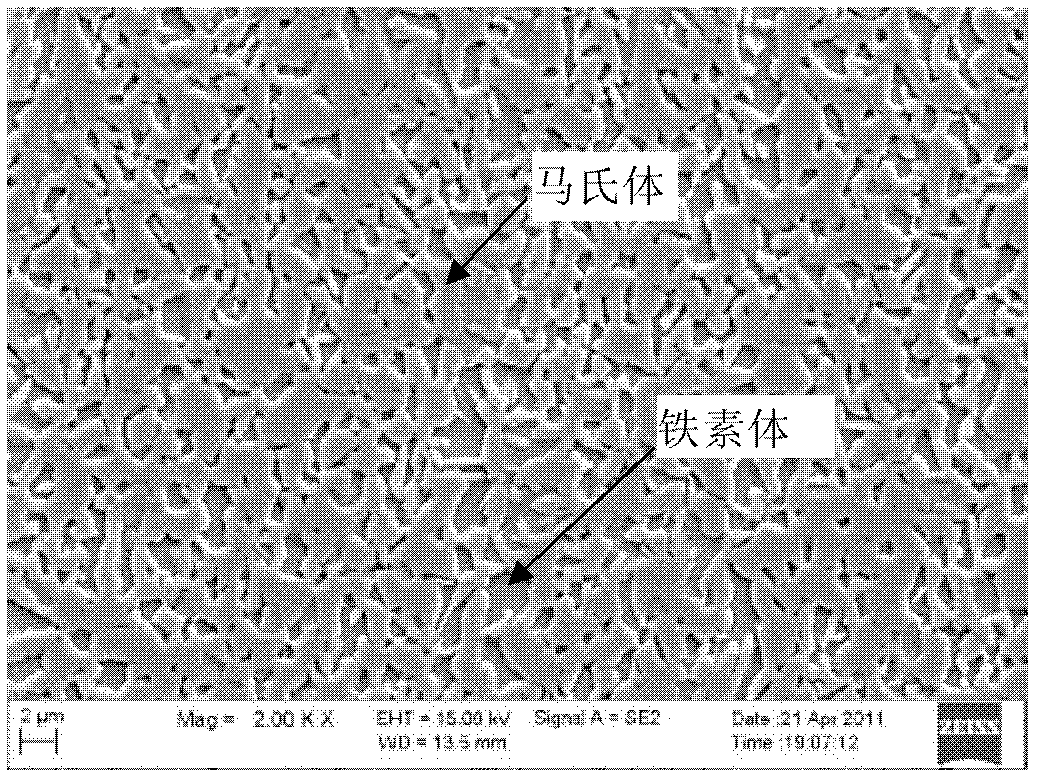

[0027] Heat the hot-rolled steel plate to 800°C, keep it warm for 5 minutes, and cool it to room temperature at a rate greater than 40°C / s, as shown in Figure 1(b). The microstructure and mechanical properties of the steel plate after hot forming simulation are as follows: figure 2 And as shown in Table 2. The microstructure of the steel plate after hot forming is ferrite + martensite dual phase microstructure.

Embodiment 2

[0029] Heat the hot-rolled steel plate to 820°C, keep it warm for 5 minutes, and cool it to room temperature at a rate greater than 40°C / s, as shown in Figure 1(b). The mechanical properties of the steel plate after hot forming simulation are shown in Table 2, and the microstructure is the same as that of Example 1. The microstructure of the steel plate after hot forming is ferrite + martensite dual phase microstructure.

Embodiment 3

[0031] Heat the hot-rolled steel plate to 850°C, keep it warm for 5 minutes, and cool to room temperature at a rate greater than 40°C / s, as shown in Figure 1(b). The mechanical properties of the steel plate after hot forming simulation are shown in Table 2, and the microstructure is the same as that of Example 1. The microstructure of the steel plate after hot forming is ferrite + martensite dual phase microstructure.

[0032] The chemical composition of table 1 embodiment (mass fraction / %)

[0033]

[0034] The mechanical property of table 2 embodiment

[0035] Numbering Thermoforming heating temperature / ℃ R p0.2 / MPa R m / MPa Embodiment one 800 720 1155 Embodiment two 820 770 1260 Embodiment three 850 780 1330

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com