Organically-polluted soil remediation method

An organic pollution and soil remediation technology, applied in the field of organic contaminated soil remediation, can solve the problems of small application range, unsatisfactory separation effect and limited application range of organic contaminated soil, achieve high soil remediation efficiency, avoid pollutant leakage, equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

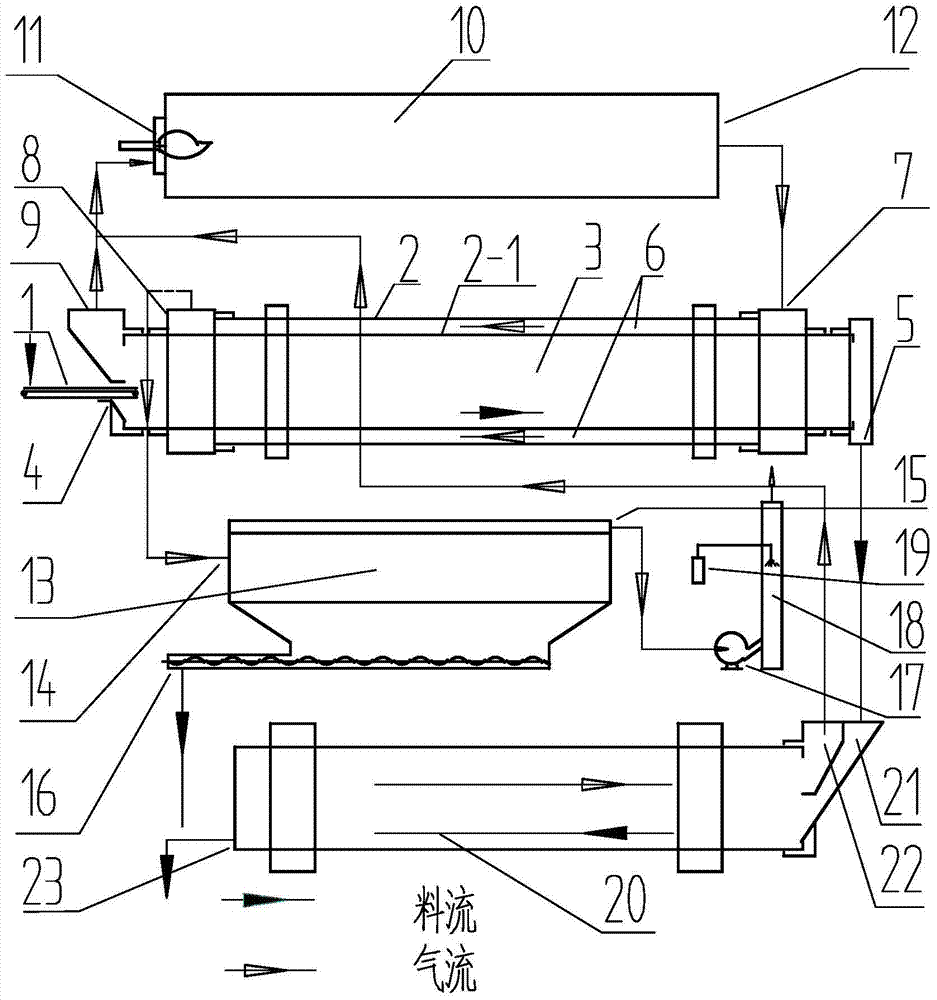

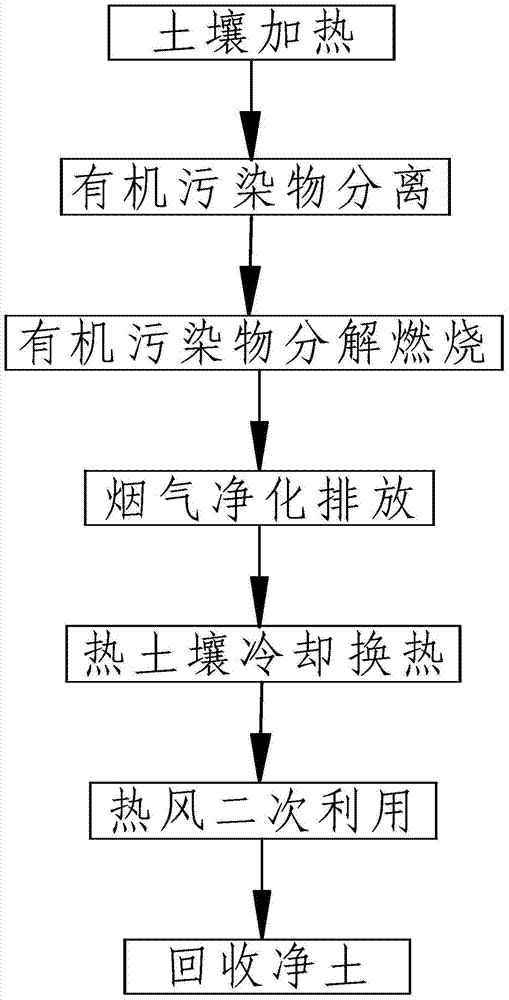

[0026] The organic polluted soil is sent into the roasting chamber 3, and the hot gas generated by the combustion furnace 10 enters the heating channel 6 to heat and restore the organic polluted soil in the roasting chamber 3, and the organic pollutants and moisture separated from the organic polluted soil enter the combustion furnace 10 to be burned. Complete decomposition and combustion, the flue gas produced after combustion passes through the heating channel 6, bag filter 13, exhaust fan 17, chimney 18, acid removal device 19, and finally discharged; the repaired soil enters the cooling machine 20 to exchange heat with cold air, generating The hot blast enters in the combustion furnace 10 and is used as secondary hot blast, and the soil after repairing and cooling is recycled.

Embodiment 2

[0028] The organic polluted soil enters the roasting chamber 3 from the conveying device 1 through the material inlet 4, and the material inlet 4 is closed; the clean fuel burns in the combustion furnace 10 to generate hot gas, the temperature of the hot gas is 600-750°C, and the hot gas comes out of the heat outlet of the combustion furnace After 12 is discharged, it enters the heating channel 6 through the heat inlet 7 of the heating channel, and the rotation of the rotary kiln 2 drives the rotation of the roasting furnace wall 2-1. Through indirect heating, the temperature of the organic polluted soil in the roasting chamber 3 reaches above 550°C, and the heating is continued for 6 -9 minutes, the organic pollutants in the soil are evaporated and separated.

Embodiment 3

[0030] During the heating process, the separated organic pollutants and moisture are discharged from the polluted gas outlet 9, enter the combustion furnace 10 through the gas inlet 11 of the combustion furnace, and are completely decomposed and burned, and the flue gas and hot gas generated after combustion are discharged from the heat outlet 12 of the combustion furnace , enter the heating channel 6 through the heat inlet 7 of the heating channel, after the flue gas and hot gas indirectly heat the organic contaminated soil, they are discharged from the heat outlet 8 of the heating channel, and enter the bag filter 13 through the air inlet 14 of the bag filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com