Free disassembly type vacuum handle puller for automobile sheet metal repair

A technology that avoids disassembly and sheet metal. It is applied in the field of automotive sheet metal repair tools. It can solve the problems of inability to achieve sheet metal repair efficiently and conveniently, inconvenient access, and heavy workload. It achieves efficient and convenient sheet metal repair, improves efficiency, and The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

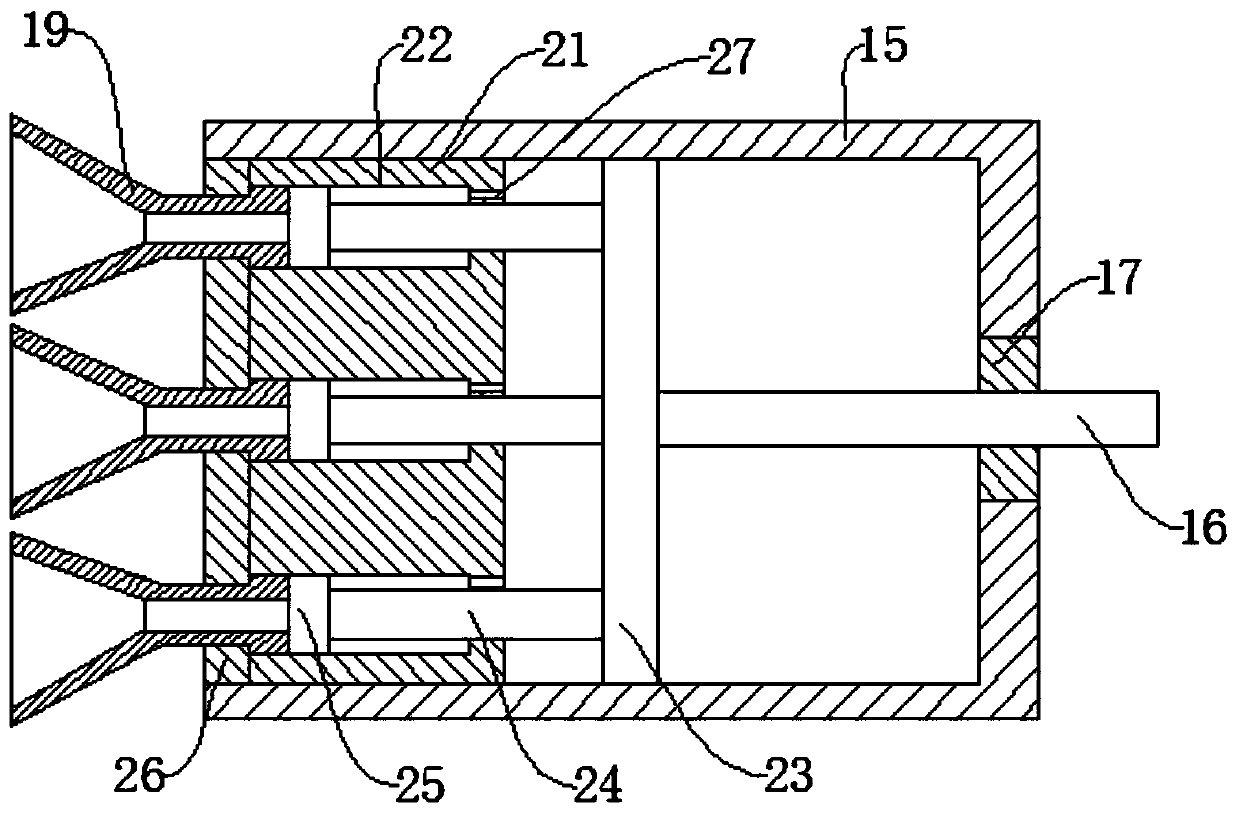

[0036] Such as Figure 1-Figure 3As shown, a disassembly-free vacuum handle for automobile sheet metal repair includes a support base 1, a lead screw 16, a nut 17 and a sheet metal box 15, and the four corners below the support base 1 are connected with universal joints by bolts. Wheel 2, a cabinet body 3 is provided on the upper side of the support base 1, a handle 4 is provided above the cabinet body 3, a bottom support 5 is connected to one side of the cabinet body 3 by bolts, and the bottom support 5 The upper middle part is provided with a vertical rod 6, and the vertical rod 6 is slidably connected with a height adjustment slide seat 7, and the side wall of the height adjustment slide seat 7 is provided with a fixing screw 8, and a top of the height adjustment slide seat 7 The side is provided with fixing screw 2 9, the other side wall of the height adjustment slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com