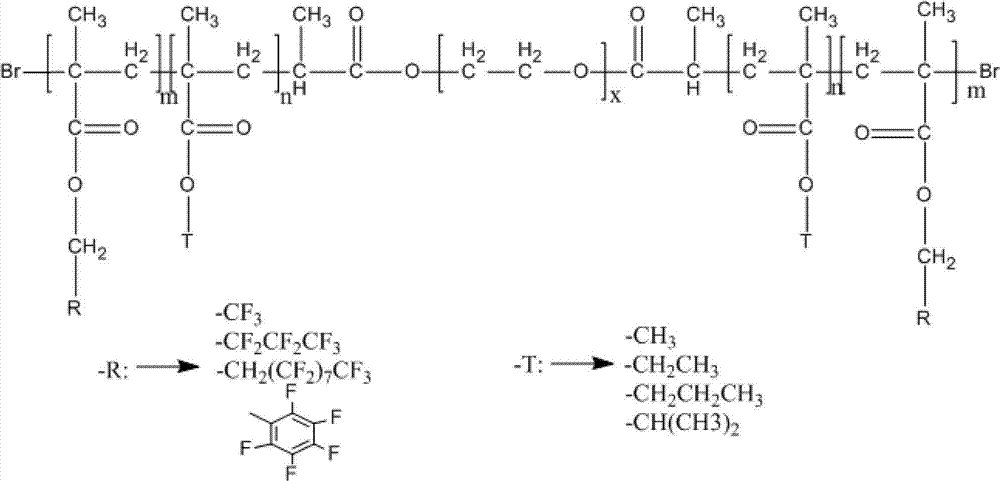

Amphiphilic fluorinated acrylate penta-block copolymer and preparation method thereof

A technology of acrylate and methacrylate, which is applied in the field of amphiphilic fluorine-containing acrylate pentablock copolymer and its preparation, can solve the problems of difficult separation process, low synthesis efficiency, and many separation steps, and achieve product yield high yield, increased yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Under the protection of nitrogen atmosphere (purity is more than 99.99% by mass ratio), 1 part of polyethylene glycol (molecular weight is 4000), 4 parts of 2-bromopropionyl bromide, 4 parts of three Ethylamine was reacted with 0.25 parts of 4-dimethylaminopyridine in an ice-water bath. After the addition is complete, react at 30°C for 24 hours, filter after the reaction, then evaporate half of the solvent, precipitate with n-hexane, dissolve the precipitate with methylene chloride, and then precipitate with n-hexane, repeat precipitation-dissolution-precipitation 3 times, The product is dried in a vacuum drying oven to constant weight to obtain an active bromine-terminated macromolecular initiator of polyethylene glycol.

[0027] 2) Under the protection of nitrogen (purity exceeds 99.99% by mass ratio) atmosphere (the reaction system must be strictly deoxygenated), in molar parts, 1 part of active bromine-terminated polyethylene glycol is used as the initiator, 1.5 ...

Embodiment 2

[0030] 1) Except that polyethylene glycol (molecular weight is 2000) is one part, the others are the same as step 1 in Example 1);

[0031] 2) Except for 150 parts of methacrylate, 150 parts of fluorine-containing acrylate, and a reaction temperature of 80°C, the same as step 2 in Example 1);

[0032] An amphiphilic fluorine-containing acrylate pentablock copolymer was prepared.

Embodiment 3

[0034] 1) Except for 3 parts of 2-bromopropionyl bromide and 3 parts of triethylamine, the others are the same as step 1 in Example 1);

[0035] 2) Except for 200 parts of fluorine-containing acrylate and a reaction time of 10 hours, the others are the same as step 2 in Example 1);

[0036] An amphiphilic fluorine-containing acrylate pentablock copolymer was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com